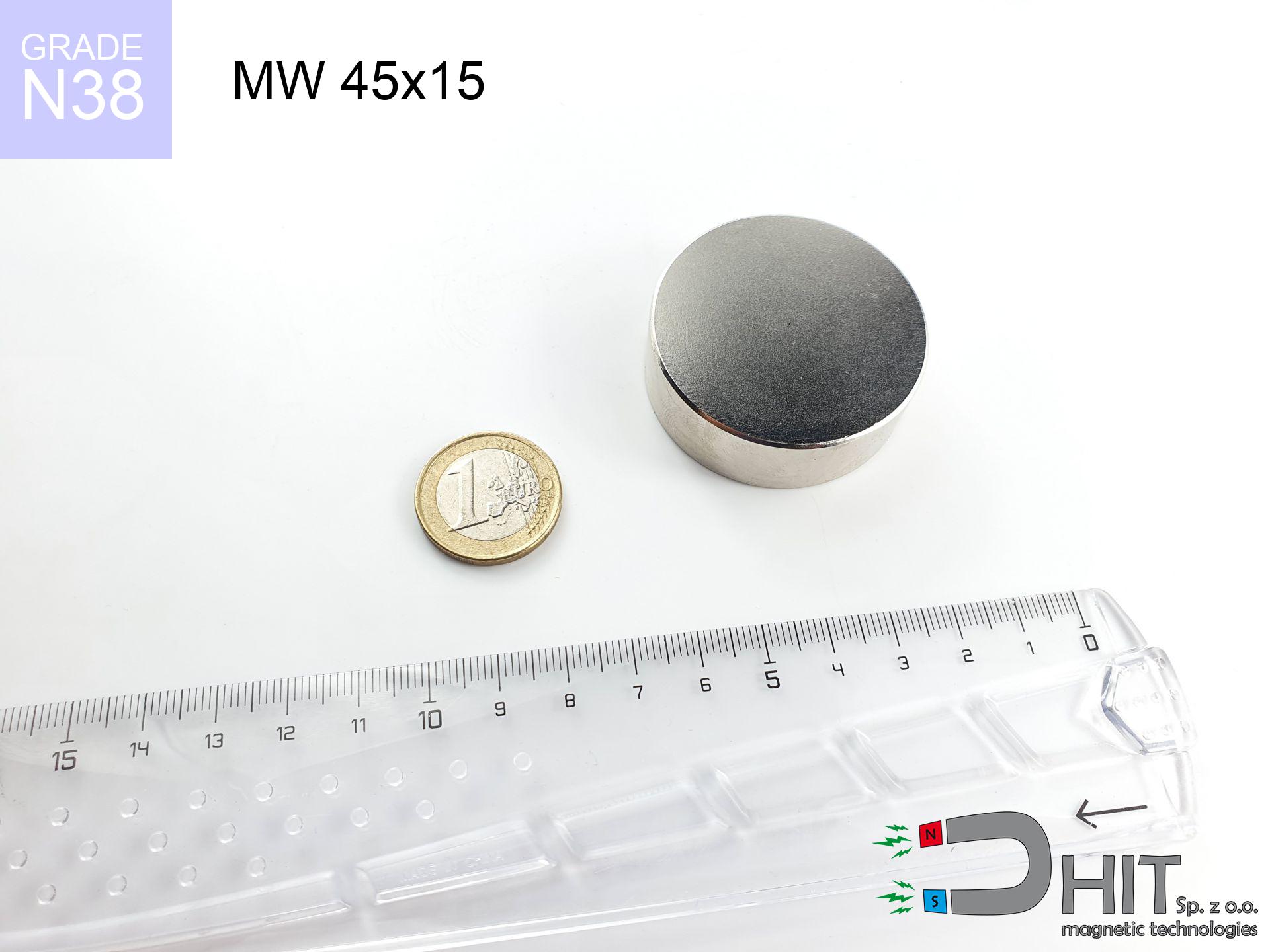

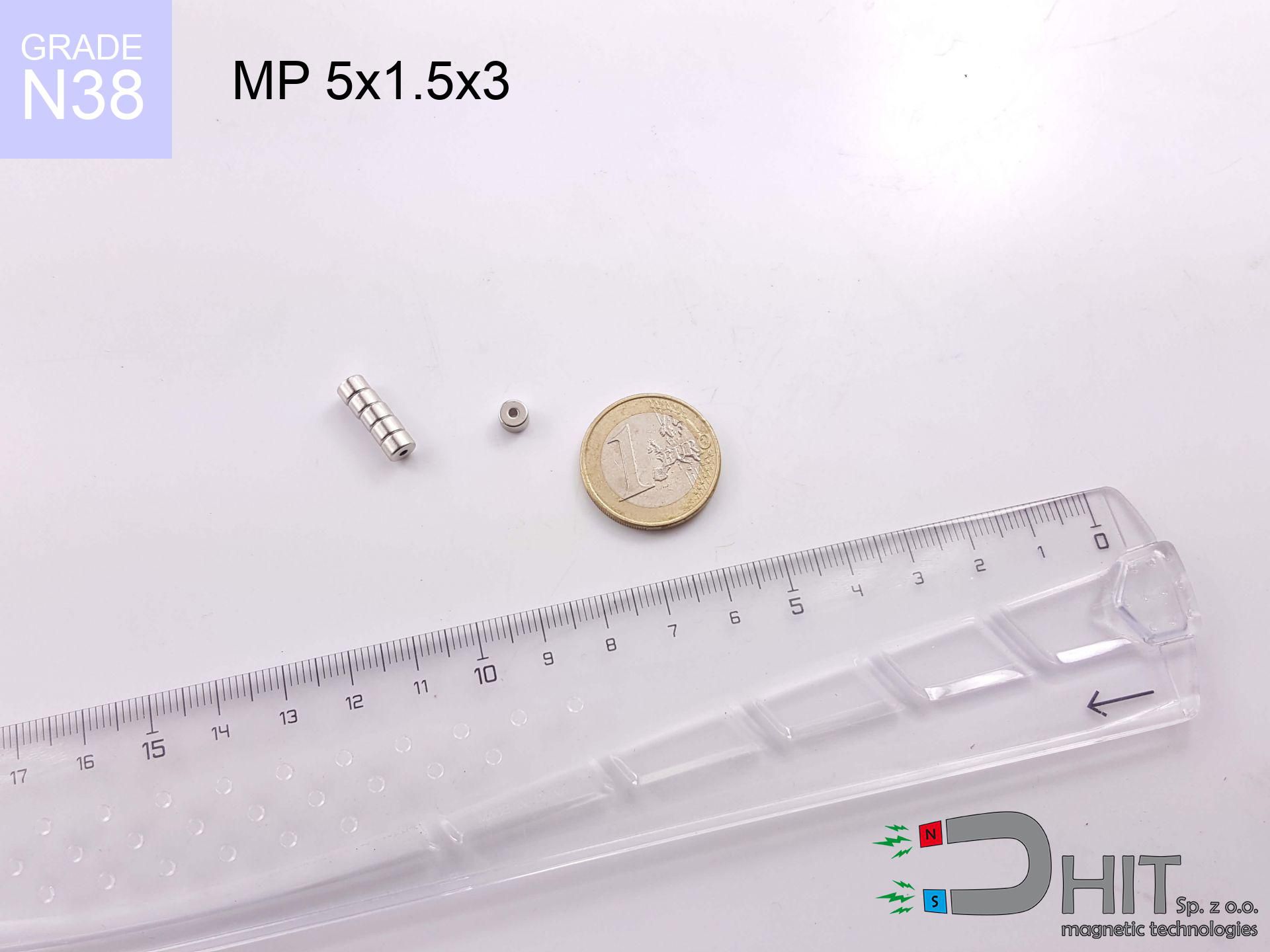

MP 5x1.5x3 / N38 - ring magnet

ring magnet

Catalog no 030451

GTIN/EAN: 5906301812357

Diameter

5 mm [±0,1 mm]

internal diameter Ø

1.5 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

0.4 g

Magnetization Direction

↑ axial

Load capacity

0.77 kg / 7.50 N

Magnetic Induction

475.16 mT / 4752 Gs

Coating

[NiCuNi] Nickel

0.344 ZŁ with VAT / pcs + price for transport

0.280 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

if you prefer get in touch by means of

inquiry form

the contact section.

Parameters along with form of a magnet can be estimated on our

magnetic calculator.

Same-day shipping for orders placed before 14:00.

Physical properties - MP 5x1.5x3 / N38 - ring magnet

Specification / characteristics - MP 5x1.5x3 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030451 |

| GTIN/EAN | 5906301812357 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 5 mm [±0,1 mm] |

| internal diameter Ø | 1.5 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 0.4 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.77 kg / 7.50 N |

| Magnetic Induction ~ ? | 475.16 mT / 4752 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the product - data

The following information are the outcome of a engineering calculation. Values were calculated on algorithms for the class Nd2Fe14B. Operational performance might slightly differ. Please consider these data as a reference point for designers.

Table 1: Static force (force vs distance) - interaction chart

MP 5x1.5x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

6157 Gs

615.7 mT

|

0.77 kg / 1.70 pounds

770.0 g / 7.6 N

|

weak grip |

| 1 mm |

3880 Gs

388.0 mT

|

0.31 kg / 0.67 pounds

305.8 g / 3.0 N

|

weak grip |

| 2 mm |

2310 Gs

231.0 mT

|

0.11 kg / 0.24 pounds

108.4 g / 1.1 N

|

weak grip |

| 3 mm |

1422 Gs

142.2 mT

|

0.04 kg / 0.09 pounds

41.0 g / 0.4 N

|

weak grip |

| 5 mm |

641 Gs

64.1 mT

|

0.01 kg / 0.02 pounds

8.3 g / 0.1 N

|

weak grip |

| 10 mm |

174 Gs

17.4 mT

|

0.00 kg / 0.00 pounds

0.6 g / 0.0 N

|

weak grip |

| 15 mm |

76 Gs

7.6 mT

|

0.00 kg / 0.00 pounds

0.1 g / 0.0 N

|

weak grip |

| 20 mm |

41 Gs

4.1 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

weak grip |

| 30 mm |

16 Gs

1.6 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

weak grip |

| 50 mm |

5 Gs

0.5 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

weak grip |

Table 2: Sliding force (wall)

MP 5x1.5x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.15 kg / 0.34 pounds

154.0 g / 1.5 N

|

| 1 mm | Stal (~0.2) |

0.06 kg / 0.14 pounds

62.0 g / 0.6 N

|

| 2 mm | Stal (~0.2) |

0.02 kg / 0.05 pounds

22.0 g / 0.2 N

|

| 3 mm | Stal (~0.2) |

0.01 kg / 0.02 pounds

8.0 g / 0.1 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MP 5x1.5x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.23 kg / 0.51 pounds

231.0 g / 2.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.15 kg / 0.34 pounds

154.0 g / 1.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.08 kg / 0.17 pounds

77.0 g / 0.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.39 kg / 0.85 pounds

385.0 g / 3.8 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MP 5x1.5x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.08 kg / 0.17 pounds

77.0 g / 0.8 N

|

| 1 mm |

|

0.19 kg / 0.42 pounds

192.5 g / 1.9 N

|

| 2 mm |

|

0.39 kg / 0.85 pounds

385.0 g / 3.8 N

|

| 3 mm |

|

0.58 kg / 1.27 pounds

577.5 g / 5.7 N

|

| 5 mm |

|

0.77 kg / 1.70 pounds

770.0 g / 7.6 N

|

| 10 mm |

|

0.77 kg / 1.70 pounds

770.0 g / 7.6 N

|

| 11 mm |

|

0.77 kg / 1.70 pounds

770.0 g / 7.6 N

|

| 12 mm |

|

0.77 kg / 1.70 pounds

770.0 g / 7.6 N

|

Table 5: Working in heat (material behavior) - thermal limit

MP 5x1.5x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.77 kg / 1.70 pounds

770.0 g / 7.6 N

|

OK |

| 40 °C | -2.2% |

0.75 kg / 1.66 pounds

753.1 g / 7.4 N

|

OK |

| 60 °C | -4.4% |

0.74 kg / 1.62 pounds

736.1 g / 7.2 N

|

OK |

| 80 °C | -6.6% |

0.72 kg / 1.59 pounds

719.2 g / 7.1 N

|

|

| 100 °C | -28.8% |

0.55 kg / 1.21 pounds

548.2 g / 5.4 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MP 5x1.5x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

2.50 kg / 5.50 pounds

6 171 Gs

|

0.37 kg / 0.83 pounds

374 g / 3.7 N

|

N/A |

| 1 mm |

1.62 kg / 3.58 pounds

9 932 Gs

|

0.24 kg / 0.54 pounds

244 g / 2.4 N

|

1.46 kg / 3.22 pounds

~0 Gs

|

| 2 mm |

0.99 kg / 2.19 pounds

7 760 Gs

|

0.15 kg / 0.33 pounds

149 g / 1.5 N

|

0.89 kg / 1.97 pounds

~0 Gs

|

| 3 mm |

0.59 kg / 1.30 pounds

5 986 Gs

|

0.09 kg / 0.20 pounds

88 g / 0.9 N

|

0.53 kg / 1.17 pounds

~0 Gs

|

| 5 mm |

0.21 kg / 0.47 pounds

3 600 Gs

|

0.03 kg / 0.07 pounds

32 g / 0.3 N

|

0.19 kg / 0.42 pounds

~0 Gs

|

| 10 mm |

0.03 kg / 0.06 pounds

1 281 Gs

|

0.00 kg / 0.01 pounds

4 g / 0.0 N

|

0.02 kg / 0.05 pounds

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 pounds

349 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

50 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

33 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

23 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

17 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

13 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

10 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Hazards (implants) - warnings

MP 5x1.5x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 3.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.5 cm |

| Car key | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (cracking risk) - collision effects

MP 5x1.5x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

44.27 km/h

(12.30 m/s)

|

0.03 J | |

| 30 mm |

76.64 km/h

(21.29 m/s)

|

0.09 J | |

| 50 mm |

98.94 km/h

(27.48 m/s)

|

0.15 J | |

| 100 mm |

139.93 km/h

(38.87 m/s)

|

0.30 J |

Table 9: Coating parameters (durability)

MP 5x1.5x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MP 5x1.5x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 811 Mx | 8.1 µWb |

| Pc Coefficient | 1.66 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MP 5x1.5x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.77 kg | Standard |

| Water (riverbed) |

0.88 kg

(+0.11 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical surface, the magnet retains just approx. 20-30% of its max power.

2. Plate thickness effect

*Thin steel (e.g. computer case) severely weakens the holding force.

3. Heat tolerance

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.66

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out more proposals

Advantages and disadvantages of rare earth magnets.

Strengths

- They retain attractive force for around ten years – the loss is just ~1% (based on simulations),

- They retain their magnetic properties even under strong external field,

- By using a smooth layer of silver, the element has an modern look,

- Magnets possess extremely high magnetic induction on the outer layer,

- Through (appropriate) combination of ingredients, they can achieve high thermal strength, allowing for action at temperatures reaching 230°C and above...

- Thanks to freedom in shaping and the capacity to modify to individual projects,

- Significant place in high-tech industry – they serve a role in data components, drive modules, advanced medical instruments, as well as technologically advanced constructions.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in compact dimensions, which makes them useful in small systems

Limitations

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can fracture. We advise keeping them in a special holder, which not only secures them against impacts but also increases their durability

- We warn that neodymium magnets can reduce their strength at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material stable to moisture, in case of application outdoors

- We suggest casing - magnetic mechanism, due to difficulties in producing threads inside the magnet and complex shapes.

- Health risk to health – tiny shards of magnets pose a threat, if swallowed, which becomes key in the context of child health protection. Furthermore, small elements of these magnets can disrupt the diagnostic process medical after entering the body.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Lifting parameters

Highest magnetic holding force – what contributes to it?

- using a sheet made of mild steel, functioning as a magnetic yoke

- possessing a massiveness of minimum 10 mm to avoid saturation

- with a plane perfectly flat

- with direct contact (no impurities)

- under vertical force vector (90-degree angle)

- in stable room temperature

Key elements affecting lifting force

- Gap (betwixt the magnet and the metal), because even a tiny clearance (e.g. 0.5 mm) can cause a decrease in force by up to 50% (this also applies to paint, corrosion or dirt).

- Load vector – maximum parameter is available only during perpendicular pulling. The shear force of the magnet along the surface is standardly many times smaller (approx. 1/5 of the lifting capacity).

- Substrate thickness – to utilize 100% power, the steel must be adequately massive. Paper-thin metal restricts the lifting capacity (the magnet "punches through" it).

- Steel grade – the best choice is high-permeability steel. Cast iron may generate lower lifting capacity.

- Surface finish – ideal contact is possible only on smooth steel. Rough texture reduce the real contact area, reducing force.

- Temperature – temperature increase results in weakening of induction. It is worth remembering the thermal limit for a given model.

Lifting capacity was determined using a polished steel plate of optimal thickness (min. 20 mm), under perpendicular pulling force, however under attempts to slide the magnet the load capacity is reduced by as much as 5 times. In addition, even a slight gap between the magnet and the plate decreases the holding force.

Warnings

Precision electronics

Be aware: neodymium magnets produce a field that confuses sensitive sensors. Maintain a separation from your mobile, tablet, and navigation systems.

Do not give to children

Always store magnets out of reach of children. Ingestion danger is high, and the consequences of magnets clamping inside the body are fatal.

Respect the power

Before use, check safety instructions. Uncontrolled attraction can break the magnet or hurt your hand. Think ahead.

Allergy Warning

Some people have a hypersensitivity to nickel, which is the standard coating for neodymium magnets. Frequent touching can result in a rash. We strongly advise use safety gloves.

Permanent damage

Keep cool. Neodymium magnets are sensitive to heat. If you require resistance above 80°C, inquire about special high-temperature series (H, SH, UH).

Magnet fragility

Despite the nickel coating, neodymium is brittle and cannot withstand shocks. Avoid impacts, as the magnet may shatter into sharp, dangerous pieces.

Dust is flammable

Fire warning: Rare earth powder is highly flammable. Avoid machining magnets without safety gear as this risks ignition.

Electronic hazard

Device Safety: Neodymium magnets can damage payment cards and sensitive devices (pacemakers, hearing aids, timepieces).

Serious injuries

Pinching hazard: The attraction force is so great that it can result in blood blisters, pinching, and broken bones. Use thick gloves.

Life threat

Life threat: Neodymium magnets can turn off heart devices and defibrillators. Stay away if you have medical devices.

![UMH 20x7x35 [M4] / N38 - magnetic holder with hook UMH 20x7x35 [M4] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-20x7x35-m4-hiz.jpg)