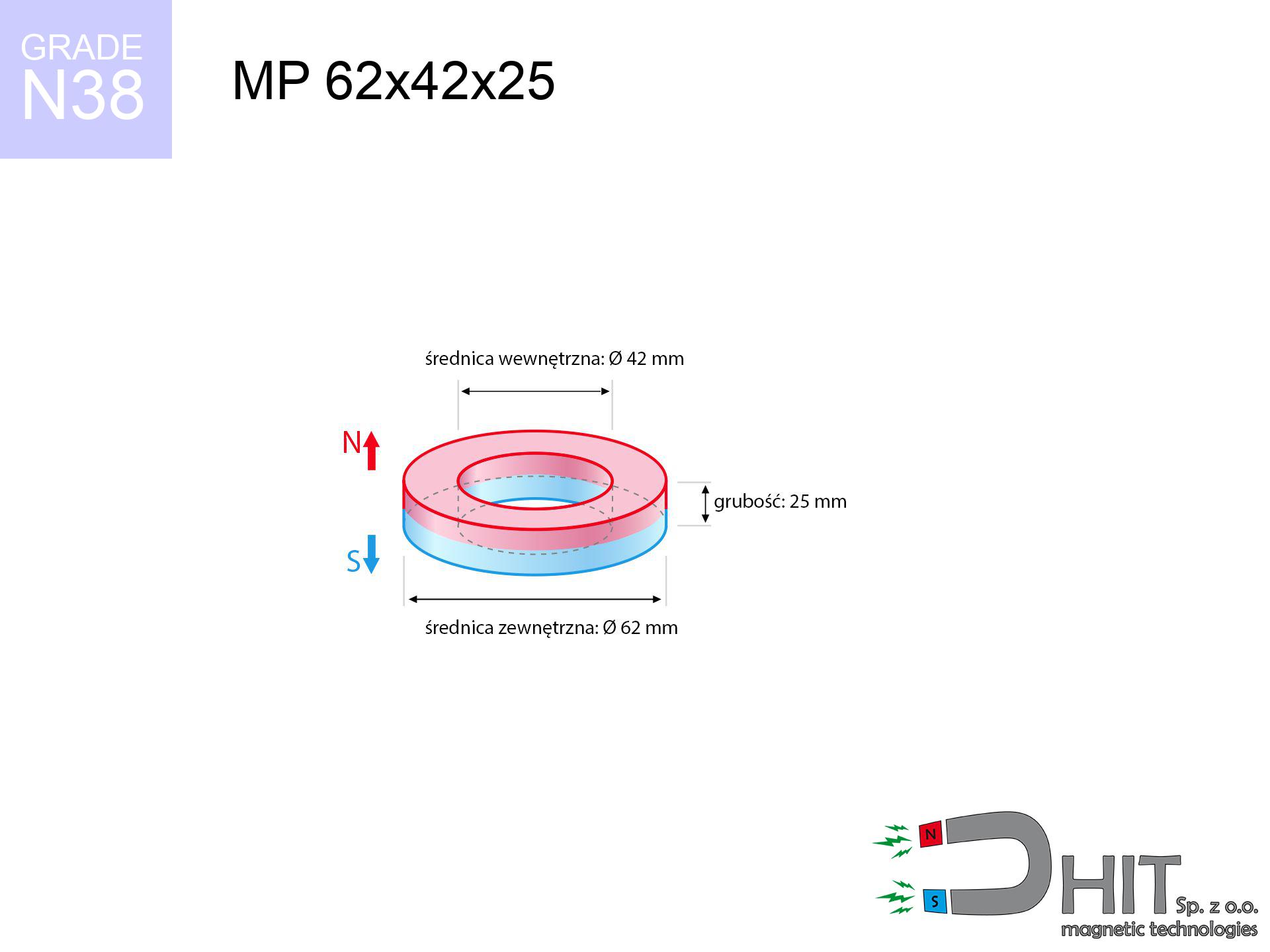

MP 62x42x25 / N38 - ring magnet

ring magnet

Catalog no 030205

GTIN/EAN: 5906301812227

Diameter

62 mm [±0,1 mm]

internal diameter Ø

42 mm [±0,1 mm]

Height

25 mm [±0,1 mm]

Weight

306.31 g

Magnetization Direction

↑ axial

Load capacity

58.67 kg / 575.60 N

Magnetic Induction

389.14 mT / 3891 Gs

Coating

[NiCuNi] Nickel

165.00 ZŁ with VAT / pcs + price for transport

134.15 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

otherwise let us know through

our online form

through our site.

Specifications and form of neodymium magnets can be tested with our

magnetic mass calculator.

Same-day shipping for orders placed before 14:00.

Technical specification of the product - MP 62x42x25 / N38 - ring magnet

Specification / characteristics - MP 62x42x25 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030205 |

| GTIN/EAN | 5906301812227 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 62 mm [±0,1 mm] |

| internal diameter Ø | 42 mm [±0,1 mm] |

| Height | 25 mm [±0,1 mm] |

| Weight | 306.31 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 58.67 kg / 575.60 N |

| Magnetic Induction ~ ? | 389.14 mT / 3891 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the assembly - report

These values represent the direct effect of a mathematical analysis. Values were calculated on models for the material Nd2Fe14B. Real-world conditions may deviate from the simulation results. Treat these calculations as a reference point for designers.

Table 1: Static pull force (pull vs gap) - power drop

MP 62x42x25 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4472 Gs

447.2 mT

|

58.67 kg / 129.35 lbs

58670.0 g / 575.6 N

|

dangerous! |

| 1 mm |

4338 Gs

433.8 mT

|

55.21 kg / 121.72 lbs

55213.2 g / 541.6 N

|

dangerous! |

| 2 mm |

4201 Gs

420.1 mT

|

51.77 kg / 114.13 lbs

51768.5 g / 507.8 N

|

dangerous! |

| 3 mm |

4061 Gs

406.1 mT

|

48.39 kg / 106.69 lbs

48394.9 g / 474.8 N

|

dangerous! |

| 5 mm |

3781 Gs

378.1 mT

|

41.94 kg / 92.47 lbs

41942.4 g / 411.5 N

|

dangerous! |

| 10 mm |

3097 Gs

309.7 mT

|

28.15 kg / 62.06 lbs

28148.0 g / 276.1 N

|

dangerous! |

| 15 mm |

2485 Gs

248.5 mT

|

18.12 kg / 39.94 lbs

18118.5 g / 177.7 N

|

dangerous! |

| 20 mm |

1972 Gs

197.2 mT

|

11.41 kg / 25.16 lbs

11412.7 g / 112.0 N

|

dangerous! |

| 30 mm |

1239 Gs

123.9 mT

|

4.51 kg / 9.93 lbs

4505.2 g / 44.2 N

|

strong |

| 50 mm |

533 Gs

53.3 mT

|

0.83 kg / 1.84 lbs

832.4 g / 8.2 N

|

low risk |

Table 2: Sliding load (vertical surface)

MP 62x42x25 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

11.73 kg / 25.87 lbs

11734.0 g / 115.1 N

|

| 1 mm | Stal (~0.2) |

11.04 kg / 24.34 lbs

11042.0 g / 108.3 N

|

| 2 mm | Stal (~0.2) |

10.35 kg / 22.83 lbs

10354.0 g / 101.6 N

|

| 3 mm | Stal (~0.2) |

9.68 kg / 21.34 lbs

9678.0 g / 94.9 N

|

| 5 mm | Stal (~0.2) |

8.39 kg / 18.49 lbs

8388.0 g / 82.3 N

|

| 10 mm | Stal (~0.2) |

5.63 kg / 12.41 lbs

5630.0 g / 55.2 N

|

| 15 mm | Stal (~0.2) |

3.62 kg / 7.99 lbs

3624.0 g / 35.6 N

|

| 20 mm | Stal (~0.2) |

2.28 kg / 5.03 lbs

2282.0 g / 22.4 N

|

| 30 mm | Stal (~0.2) |

0.90 kg / 1.99 lbs

902.0 g / 8.8 N

|

| 50 mm | Stal (~0.2) |

0.17 kg / 0.37 lbs

166.0 g / 1.6 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MP 62x42x25 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

17.60 kg / 38.80 lbs

17601.0 g / 172.7 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

11.73 kg / 25.87 lbs

11734.0 g / 115.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

5.87 kg / 12.93 lbs

5867.0 g / 57.6 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

29.34 kg / 64.67 lbs

29335.0 g / 287.8 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MP 62x42x25 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.96 kg / 4.31 lbs

1955.7 g / 19.2 N

|

| 1 mm |

|

4.89 kg / 10.78 lbs

4889.2 g / 48.0 N

|

| 2 mm |

|

9.78 kg / 21.56 lbs

9778.3 g / 95.9 N

|

| 3 mm |

|

14.67 kg / 32.34 lbs

14667.5 g / 143.9 N

|

| 5 mm |

|

24.45 kg / 53.89 lbs

24445.8 g / 239.8 N

|

| 10 mm |

|

48.89 kg / 107.79 lbs

48891.7 g / 479.6 N

|

| 11 mm |

|

53.78 kg / 118.57 lbs

53780.8 g / 527.6 N

|

| 12 mm |

|

58.67 kg / 129.35 lbs

58670.0 g / 575.6 N

|

Table 5: Working in heat (stability) - power drop

MP 62x42x25 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

58.67 kg / 129.35 lbs

58670.0 g / 575.6 N

|

OK |

| 40 °C | -2.2% |

57.38 kg / 126.50 lbs

57379.3 g / 562.9 N

|

OK |

| 60 °C | -4.4% |

56.09 kg / 123.65 lbs

56088.5 g / 550.2 N

|

OK |

| 80 °C | -6.6% |

54.80 kg / 120.81 lbs

54797.8 g / 537.6 N

|

|

| 100 °C | -28.8% |

41.77 kg / 92.09 lbs

41773.0 g / 409.8 N

|

Table 6: Two magnets (repulsion) - field range

MP 62x42x25 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

264.93 kg / 584.07 lbs

5 588 Gs

|

39.74 kg / 87.61 lbs

39740 g / 389.8 N

|

N/A |

| 1 mm |

257.19 kg / 567.00 lbs

8 812 Gs

|

38.58 kg / 85.05 lbs

38578 g / 378.4 N

|

231.47 kg / 510.30 lbs

~0 Gs

|

| 2 mm |

249.32 kg / 549.66 lbs

8 676 Gs

|

37.40 kg / 82.45 lbs

37398 g / 366.9 N

|

224.39 kg / 494.69 lbs

~0 Gs

|

| 3 mm |

241.51 kg / 532.44 lbs

8 539 Gs

|

36.23 kg / 79.87 lbs

36227 g / 355.4 N

|

217.36 kg / 479.19 lbs

~0 Gs

|

| 5 mm |

226.10 kg / 498.47 lbs

8 262 Gs

|

33.92 kg / 74.77 lbs

33915 g / 332.7 N

|

203.49 kg / 448.62 lbs

~0 Gs

|

| 10 mm |

189.40 kg / 417.55 lbs

7 562 Gs

|

28.41 kg / 62.63 lbs

28409 g / 278.7 N

|

170.46 kg / 375.79 lbs

~0 Gs

|

| 20 mm |

127.11 kg / 280.22 lbs

6 195 Gs

|

19.07 kg / 42.03 lbs

19066 g / 187.0 N

|

114.40 kg / 252.20 lbs

~0 Gs

|

| 50 mm |

32.28 kg / 71.17 lbs

3 122 Gs

|

4.84 kg / 10.68 lbs

4843 g / 47.5 N

|

29.06 kg / 64.06 lbs

~0 Gs

|

| 60 mm |

20.34 kg / 44.85 lbs

2 478 Gs

|

3.05 kg / 6.73 lbs

3052 g / 29.9 N

|

18.31 kg / 40.36 lbs

~0 Gs

|

| 70 mm |

12.99 kg / 28.63 lbs

1 980 Gs

|

1.95 kg / 4.29 lbs

1948 g / 19.1 N

|

11.69 kg / 25.77 lbs

~0 Gs

|

| 80 mm |

8.43 kg / 18.59 lbs

1 595 Gs

|

1.26 kg / 2.79 lbs

1265 g / 12.4 N

|

7.59 kg / 16.73 lbs

~0 Gs

|

| 90 mm |

5.58 kg / 12.29 lbs

1 298 Gs

|

0.84 kg / 1.84 lbs

836 g / 8.2 N

|

5.02 kg / 11.06 lbs

~0 Gs

|

| 100 mm |

3.76 kg / 8.29 lbs

1 065 Gs

|

0.56 kg / 1.24 lbs

564 g / 5.5 N

|

3.38 kg / 7.46 lbs

~0 Gs

|

Table 7: Hazards (electronics) - warnings

MP 62x42x25 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 32.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 25.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 20.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 15.5 cm |

| Car key | 50 Gs (5.0 mT) | 14.0 cm |

| Payment card | 400 Gs (40.0 mT) | 6.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 5.0 cm |

Table 8: Dynamics (kinetic energy) - warning

MP 62x42x25 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

17.65 km/h

(4.90 m/s)

|

3.68 J | |

| 30 mm |

25.31 km/h

(7.03 m/s)

|

7.57 J | |

| 50 mm |

31.49 km/h

(8.75 m/s)

|

11.72 J | |

| 100 mm |

44.16 km/h

(12.27 m/s)

|

23.04 J |

Table 9: Corrosion resistance

MP 62x42x25 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MP 62x42x25 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 100 906 Mx | 1009.1 µWb |

| Pc Coefficient | 0.64 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MP 62x42x25 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 58.67 kg | Standard |

| Water (riverbed) |

67.18 kg

(+8.51 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical wall, the magnet holds just ~20% of its perpendicular strength.

2. Steel thickness impact

*Thin steel (e.g. computer case) severely limits the holding force.

3. Thermal stability

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.64

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Pros and cons of neodymium magnets.

Advantages

- Their magnetic field remains stable, and after approximately ten years it drops only by ~1% (according to research),

- Neodymium magnets prove to be exceptionally resistant to demagnetization caused by external interference,

- The use of an shiny finish of noble metals (nickel, gold, silver) causes the element to present itself better,

- Neodymium magnets generate maximum magnetic induction on a contact point, which ensures high operational effectiveness,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- In view of the possibility of accurate molding and customization to specialized projects, NdFeB magnets can be produced in a broad palette of geometric configurations, which amplifies use scope,

- Significant place in future technologies – they find application in hard drives, electric drive systems, medical equipment, and technologically advanced constructions.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Disadvantages

- At strong impacts they can break, therefore we advise placing them in special holders. A metal housing provides additional protection against damage and increases the magnet's durability.

- Neodymium magnets lose their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore during using outdoors, we suggest using water-impermeable magnets made of rubber, plastic or other material resistant to moisture

- Limited possibility of creating nuts in the magnet and complex forms - preferred is casing - magnet mounting.

- Health risk resulting from small fragments of magnets can be dangerous, in case of ingestion, which gains importance in the aspect of protecting the youngest. It is also worth noting that small components of these magnets are able to disrupt the diagnostic process medical in case of swallowing.

- Due to expensive raw materials, their price is higher than average,

Holding force characteristics

Maximum holding power of the magnet – what affects it?

- on a block made of structural steel, perfectly concentrating the magnetic flux

- whose thickness equals approx. 10 mm

- with a surface cleaned and smooth

- without the slightest clearance between the magnet and steel

- for force acting at a right angle (pull-off, not shear)

- at temperature approx. 20 degrees Celsius

Lifting capacity in practice – influencing factors

- Clearance – existence of foreign body (rust, dirt, gap) acts as an insulator, which lowers power rapidly (even by 50% at 0.5 mm).

- Load vector – maximum parameter is reached only during pulling at a 90° angle. The shear force of the magnet along the plate is standardly several times smaller (approx. 1/5 of the lifting capacity).

- Element thickness – to utilize 100% power, the steel must be sufficiently thick. Thin sheet limits the lifting capacity (the magnet "punches through" it).

- Metal type – not every steel attracts identically. Alloy additives worsen the interaction with the magnet.

- Plate texture – smooth surfaces ensure maximum contact, which increases force. Rough surfaces weaken the grip.

- Thermal conditions – neodymium magnets have a sensitivity to temperature. At higher temperatures they lose power, and in frost gain strength (up to a certain limit).

Lifting capacity was assessed by applying a steel plate with a smooth surface of suitable thickness (min. 20 mm), under perpendicular detachment force, in contrast under attempts to slide the magnet the load capacity is reduced by as much as 5 times. Additionally, even a minimal clearance between the magnet’s surface and the plate decreases the holding force.

Safety rules for work with neodymium magnets

Precision electronics

Note: neodymium magnets generate a field that disrupts sensitive sensors. Maintain a separation from your phone, tablet, and navigation systems.

Choking Hazard

Absolutely keep magnets out of reach of children. Risk of swallowing is significant, and the consequences of magnets clamping inside the body are life-threatening.

Warning for heart patients

Patients with a ICD have to maintain an absolute distance from magnets. The magnetism can stop the functioning of the life-saving device.

Protect data

Equipment safety: Neodymium magnets can damage payment cards and sensitive devices (pacemakers, medical aids, mechanical watches).

Nickel allergy

Allergy Notice: The nickel-copper-nickel coating contains nickel. If redness happens, cease handling magnets and wear gloves.

Fire warning

Drilling and cutting of NdFeB material poses a fire risk. Magnetic powder reacts violently with oxygen and is difficult to extinguish.

Magnets are brittle

Neodymium magnets are ceramic materials, meaning they are very brittle. Collision of two magnets will cause them cracking into small pieces.

Demagnetization risk

Avoid heat. NdFeB magnets are sensitive to heat. If you require resistance above 80°C, ask us about HT versions (H, SH, UH).

Handling guide

Handle magnets with awareness. Their huge power can shock even professionals. Plan your moves and do not underestimate their force.

Crushing force

Mind your fingers. Two large magnets will snap together instantly with a force of several hundred kilograms, crushing anything in their path. Exercise extreme caution!

![HH 25x7.7 [M5] / N38 - through hole magnetic holder HH 25x7.7 [M5] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-25x7.7-m5-pov.jpg)