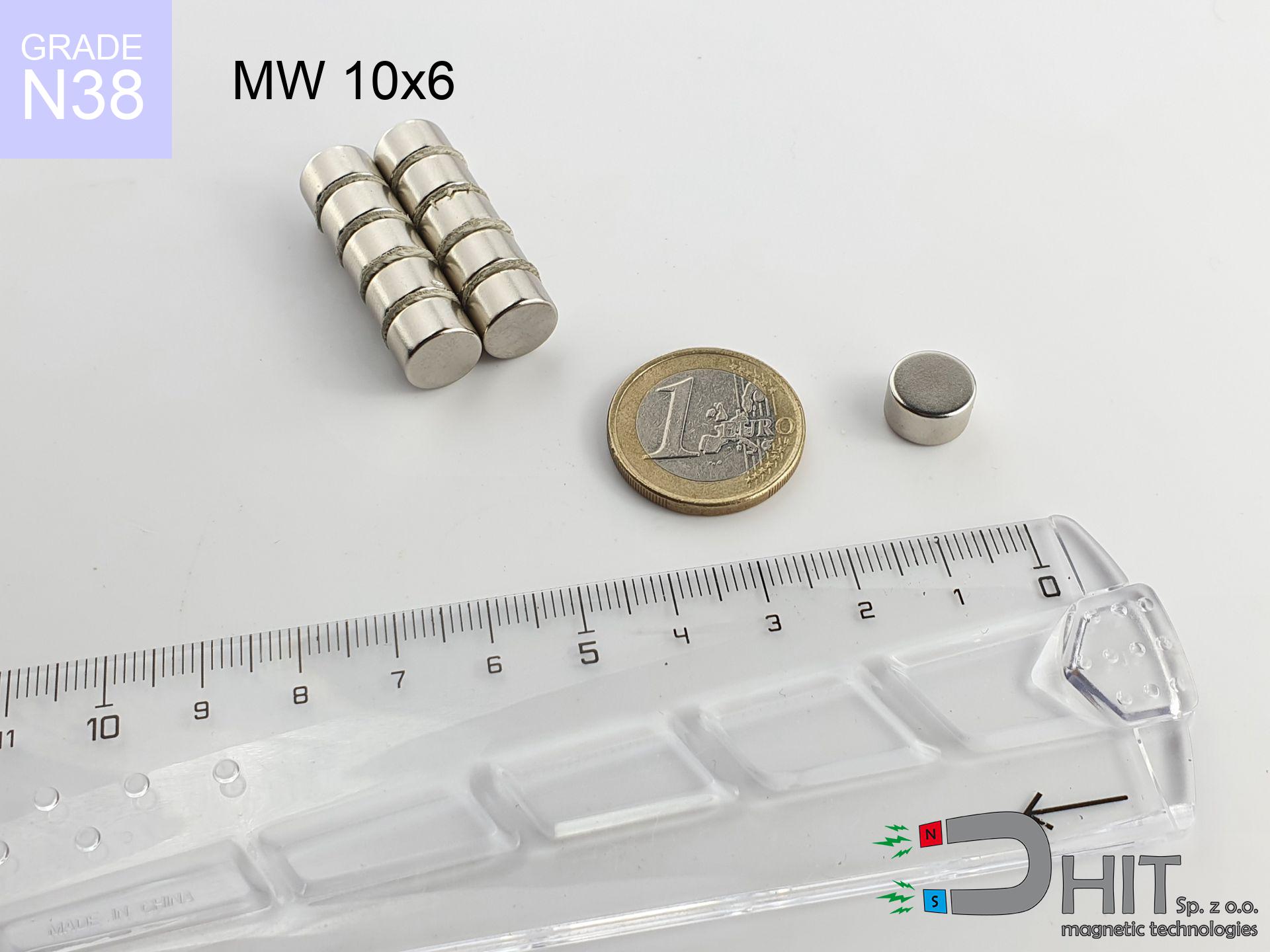

MW 10x6 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010012

GTIN/EAN: 5906301810117

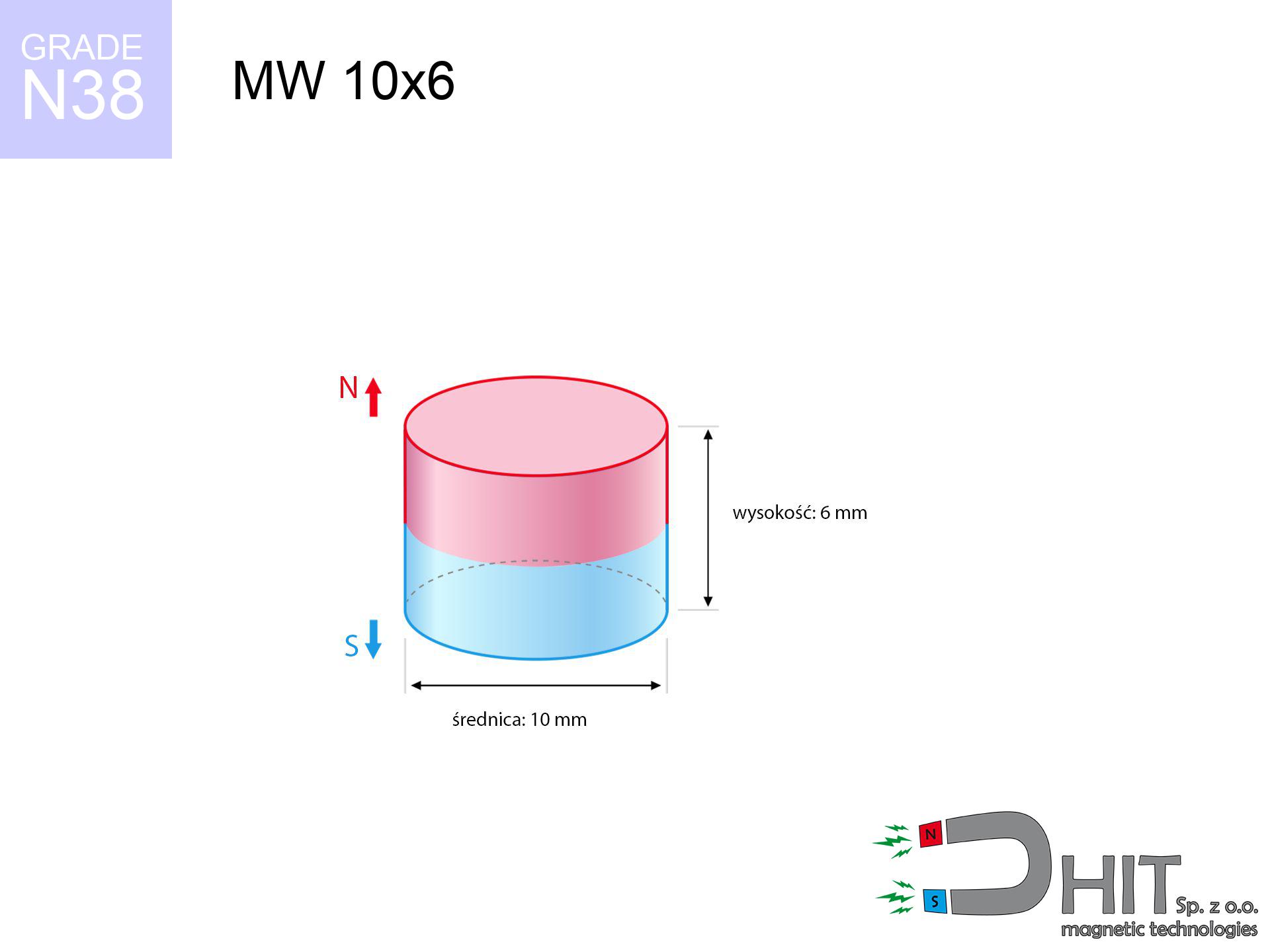

Diameter Ø

10 mm [±0,1 mm]

Height

6 mm [±0,1 mm]

Weight

3.53 g

Magnetization Direction

↑ axial

Load capacity

3.38 kg / 33.12 N

Magnetic Induction

475.73 mT / 4757 Gs

Coating

[NiCuNi] Nickel

1.045 ZŁ with VAT / pcs + price for transport

0.850 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

if you prefer get in touch by means of

request form

the contact form page.

Strength as well as structure of a neodymium magnet can be tested using our

power calculator.

Order by 14:00 and we’ll ship today!

Technical specification of the product - MW 10x6 / N38 - cylindrical magnet

Specification / characteristics - MW 10x6 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010012 |

| GTIN/EAN | 5906301810117 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 10 mm [±0,1 mm] |

| Height | 6 mm [±0,1 mm] |

| Weight | 3.53 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 3.38 kg / 33.12 N |

| Magnetic Induction ~ ? | 475.73 mT / 4757 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the assembly - data

The following data are the outcome of a physical simulation. Values rely on algorithms for the material Nd2Fe14B. Real-world performance may differ. Treat these calculations as a supplementary guide when designing systems.

Table 1: Static pull force (force vs gap) - power drop

MW 10x6 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4754 Gs

475.4 mT

|

3.38 kg / 7.45 LBS

3380.0 g / 33.2 N

|

strong |

| 1 mm |

3829 Gs

382.9 mT

|

2.19 kg / 4.83 LBS

2193.1 g / 21.5 N

|

strong |

| 2 mm |

2955 Gs

295.5 mT

|

1.31 kg / 2.88 LBS

1306.0 g / 12.8 N

|

low risk |

| 3 mm |

2230 Gs

223.0 mT

|

0.74 kg / 1.64 LBS

743.7 g / 7.3 N

|

low risk |

| 5 mm |

1260 Gs

126.0 mT

|

0.24 kg / 0.52 LBS

237.5 g / 2.3 N

|

low risk |

| 10 mm |

372 Gs

37.2 mT

|

0.02 kg / 0.05 LBS

20.7 g / 0.2 N

|

low risk |

| 15 mm |

150 Gs

15.0 mT

|

0.00 kg / 0.01 LBS

3.3 g / 0.0 N

|

low risk |

| 20 mm |

74 Gs

7.4 mT

|

0.00 kg / 0.00 LBS

0.8 g / 0.0 N

|

low risk |

| 30 mm |

25 Gs

2.5 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

low risk |

| 50 mm |

6 Gs

0.6 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

Table 2: Slippage force (vertical surface)

MW 10x6 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.68 kg / 1.49 LBS

676.0 g / 6.6 N

|

| 1 mm | Stal (~0.2) |

0.44 kg / 0.97 LBS

438.0 g / 4.3 N

|

| 2 mm | Stal (~0.2) |

0.26 kg / 0.58 LBS

262.0 g / 2.6 N

|

| 3 mm | Stal (~0.2) |

0.15 kg / 0.33 LBS

148.0 g / 1.5 N

|

| 5 mm | Stal (~0.2) |

0.05 kg / 0.11 LBS

48.0 g / 0.5 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MW 10x6 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.01 kg / 2.24 LBS

1014.0 g / 9.9 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.68 kg / 1.49 LBS

676.0 g / 6.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.34 kg / 0.75 LBS

338.0 g / 3.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.69 kg / 3.73 LBS

1690.0 g / 16.6 N

|

Table 4: Material efficiency (saturation) - power losses

MW 10x6 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.34 kg / 0.75 LBS

338.0 g / 3.3 N

|

| 1 mm |

|

0.85 kg / 1.86 LBS

845.0 g / 8.3 N

|

| 2 mm |

|

1.69 kg / 3.73 LBS

1690.0 g / 16.6 N

|

| 3 mm |

|

2.54 kg / 5.59 LBS

2535.0 g / 24.9 N

|

| 5 mm |

|

3.38 kg / 7.45 LBS

3380.0 g / 33.2 N

|

| 10 mm |

|

3.38 kg / 7.45 LBS

3380.0 g / 33.2 N

|

| 11 mm |

|

3.38 kg / 7.45 LBS

3380.0 g / 33.2 N

|

| 12 mm |

|

3.38 kg / 7.45 LBS

3380.0 g / 33.2 N

|

Table 5: Thermal resistance (material behavior) - resistance threshold

MW 10x6 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

3.38 kg / 7.45 LBS

3380.0 g / 33.2 N

|

OK |

| 40 °C | -2.2% |

3.31 kg / 7.29 LBS

3305.6 g / 32.4 N

|

OK |

| 60 °C | -4.4% |

3.23 kg / 7.12 LBS

3231.3 g / 31.7 N

|

OK |

| 80 °C | -6.6% |

3.16 kg / 6.96 LBS

3156.9 g / 31.0 N

|

|

| 100 °C | -28.8% |

2.41 kg / 5.31 LBS

2406.6 g / 23.6 N

|

Table 6: Magnet-Magnet interaction (attraction) - forces in the system

MW 10x6 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

10.94 kg / 24.12 LBS

5 711 Gs

|

1.64 kg / 3.62 LBS

1641 g / 16.1 N

|

N/A |

| 1 mm |

8.94 kg / 19.71 LBS

8 595 Gs

|

1.34 kg / 2.96 LBS

1341 g / 13.2 N

|

8.05 kg / 17.74 LBS

~0 Gs

|

| 2 mm |

7.10 kg / 15.65 LBS

7 658 Gs

|

1.06 kg / 2.35 LBS

1065 g / 10.4 N

|

6.39 kg / 14.09 LBS

~0 Gs

|

| 3 mm |

5.52 kg / 12.17 LBS

6 754 Gs

|

0.83 kg / 1.83 LBS

828 g / 8.1 N

|

4.97 kg / 10.96 LBS

~0 Gs

|

| 5 mm |

3.20 kg / 7.06 LBS

5 143 Gs

|

0.48 kg / 1.06 LBS

480 g / 4.7 N

|

2.88 kg / 6.35 LBS

~0 Gs

|

| 10 mm |

0.77 kg / 1.70 LBS

2 520 Gs

|

0.12 kg / 0.25 LBS

115 g / 1.1 N

|

0.69 kg / 1.53 LBS

~0 Gs

|

| 20 mm |

0.07 kg / 0.15 LBS

745 Gs

|

0.01 kg / 0.02 LBS

10 g / 0.1 N

|

0.06 kg / 0.13 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

83 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

51 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

33 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

23 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

17 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

12 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Hazards (implants) - warnings

MW 10x6 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 3.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 3.0 cm |

| Car key | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (cracking risk) - collision effects

MW 10x6 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

31.33 km/h

(8.70 m/s)

|

0.13 J | |

| 30 mm |

54.05 km/h

(15.01 m/s)

|

0.40 J | |

| 50 mm |

69.78 km/h

(19.38 m/s)

|

0.66 J | |

| 100 mm |

98.69 km/h

(27.41 m/s)

|

1.33 J |

Table 9: Corrosion resistance

MW 10x6 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 10x6 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 767 Mx | 37.7 µWb |

| Pc Coefficient | 0.66 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MW 10x6 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 3.38 kg | Standard |

| Water (riverbed) |

3.87 kg

(+0.49 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical surface, the magnet holds only approx. 20-30% of its perpendicular strength.

2. Steel thickness impact

*Thin steel (e.g. 0.5mm PC case) drastically weakens the holding force.

3. Thermal stability

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.66

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also products

Pros and cons of Nd2Fe14B magnets.

Strengths

- They virtually do not lose strength, because even after 10 years the decline in efficiency is only ~1% (according to literature),

- Neodymium magnets remain extremely resistant to magnetic field loss caused by external interference,

- By using a smooth layer of gold, the element presents an nice look,

- They are known for high magnetic induction at the operating surface, which affects their effectiveness,

- Through (adequate) combination of ingredients, they can achieve high thermal strength, allowing for operation at temperatures approaching 230°C and above...

- Thanks to versatility in designing and the ability to adapt to specific needs,

- Huge importance in innovative solutions – they are utilized in hard drives, electric drive systems, advanced medical instruments, also other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer high power in tiny dimensions, which allows their use in small systems

Disadvantages

- To avoid cracks upon strong impacts, we suggest using special steel housings. Such a solution secures the magnet and simultaneously improves its durability.

- When exposed to high temperature, neodymium magnets suffer a drop in power. Often, when the temperature exceeds 80°C, their power decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can rust. Therefore when using outdoors, we recommend using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- Due to limitations in realizing nuts and complicated shapes in magnets, we propose using a housing - magnetic mount.

- Potential hazard resulting from small fragments of magnets pose a threat, in case of ingestion, which gains importance in the context of child health protection. It is also worth noting that small elements of these magnets can disrupt the diagnostic process medical when they are in the body.

- Due to neodymium price, their price is higher than average,

Pull force analysis

Optimal lifting capacity of a neodymium magnet – what it depends on?

- on a plate made of mild steel, optimally conducting the magnetic flux

- with a thickness of at least 10 mm

- with a plane cleaned and smooth

- with total lack of distance (no paint)

- for force acting at a right angle (pull-off, not shear)

- at conditions approx. 20°C

Practical aspects of lifting capacity – factors

- Distance (between the magnet and the metal), as even a microscopic clearance (e.g. 0.5 mm) can cause a decrease in force by up to 50% (this also applies to paint, rust or debris).

- Angle of force application – highest force is reached only during perpendicular pulling. The force required to slide of the magnet along the plate is usually several times smaller (approx. 1/5 of the lifting capacity).

- Metal thickness – the thinner the sheet, the weaker the hold. Magnetic flux penetrates through instead of generating force.

- Material type – ideal substrate is pure iron steel. Hardened steels may generate lower lifting capacity.

- Surface finish – ideal contact is obtained only on polished steel. Any scratches and bumps create air cushions, reducing force.

- Thermal factor – high temperature weakens magnetic field. Exceeding the limit temperature can permanently damage the magnet.

Holding force was measured on the plate surface of 20 mm thickness, when a perpendicular force was applied, in contrast under shearing force the load capacity is reduced by as much as fivefold. Moreover, even a minimal clearance between the magnet and the plate decreases the load capacity.

Safety rules for work with NdFeB magnets

Do not overheat magnets

Watch the temperature. Heating the magnet to high heat will permanently weaken its properties and strength.

Bodily injuries

Pinching hazard: The attraction force is so great that it can cause hematomas, crushing, and broken bones. Protective gloves are recommended.

This is not a toy

Absolutely store magnets out of reach of children. Ingestion danger is significant, and the consequences of magnets connecting inside the body are very dangerous.

Machining danger

Powder produced during grinding of magnets is flammable. Avoid drilling into magnets unless you are an expert.

ICD Warning

For implant holders: Strong magnetic fields affect electronics. Keep minimum 30 cm distance or request help to work with the magnets.

Immense force

Handle with care. Neodymium magnets attract from a distance and connect with huge force, often faster than you can react.

Skin irritation risks

Allergy Notice: The nickel-copper-nickel coating contains nickel. If an allergic reaction appears, cease handling magnets and use protective gear.

Risk of cracking

Despite metallic appearance, the material is delicate and cannot withstand shocks. Avoid impacts, as the magnet may shatter into hazardous fragments.

Precision electronics

An intense magnetic field negatively affects the functioning of compasses in smartphones and GPS navigation. Maintain magnets near a device to prevent damaging the sensors.

Data carriers

Powerful magnetic fields can erase data on payment cards, HDDs, and storage devices. Keep a distance of at least 10 cm.

![SM 32x250 [2xM8] / N42 - magnetic separator SM 32x250 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x250-2xm8-kex.jpg)

![UMGGZ 66x8.5 [M8] GZ / N38 - rubber magnetic holder external thread UMGGZ 66x8.5 [M8] GZ / N38 - rubber magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umggz-66x8.5-m6-gz-gas.jpg)

![UMGGZ 34x6 [M4] GZ / N38 - rubber magnetic holder external thread UMGGZ 34x6 [M4] GZ / N38 - rubber magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umg-34x6-m4-gz-rad.jpg)