AM ucho [M8] - magnetic accessories

magnetic accessories

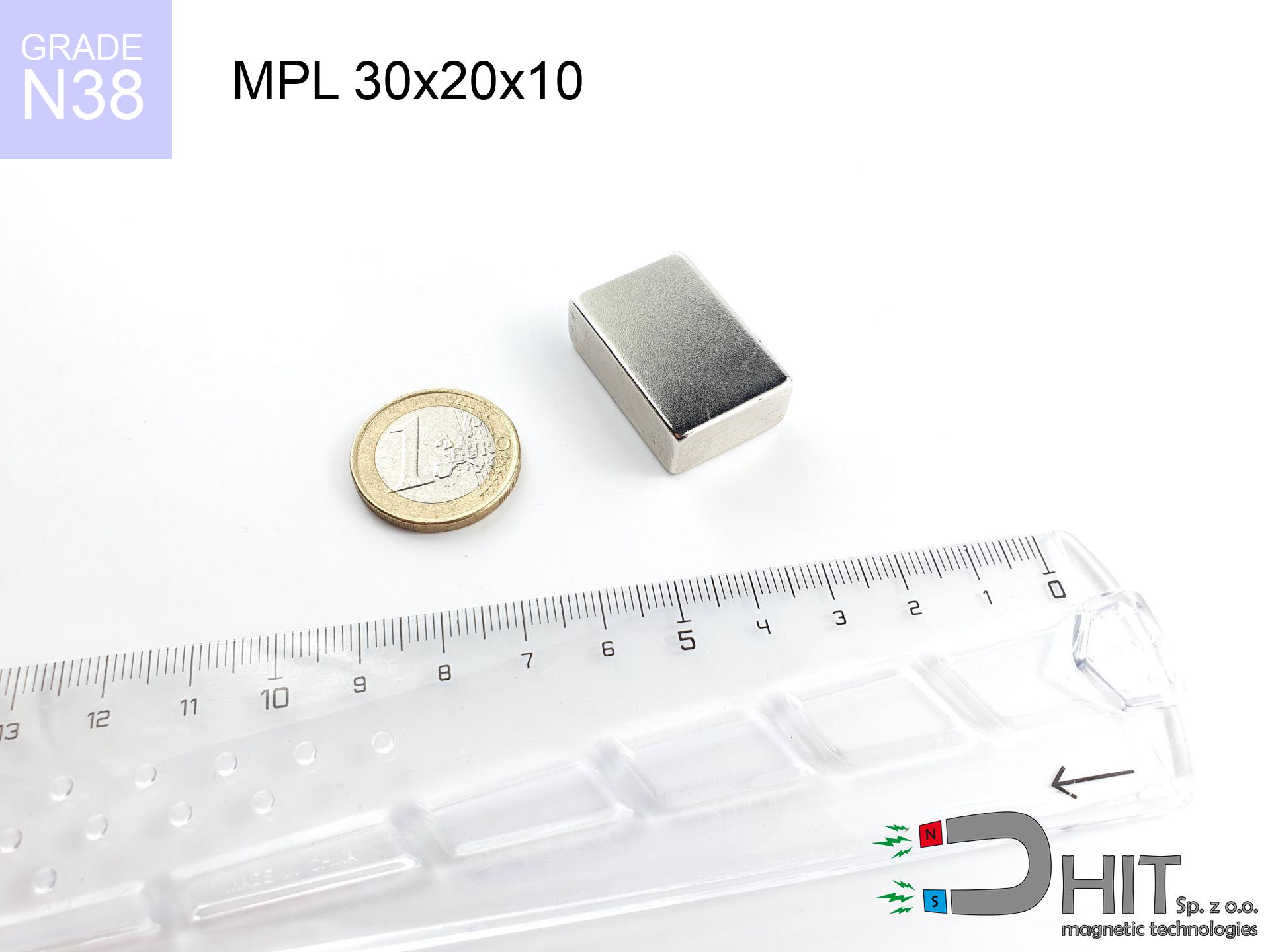

Catalog no 080268

GTIN/EAN: 5906301812470

Weight

53 g

Load capacity

240.00 kg / 2353.60 N

4.92 ZŁ with VAT / pcs + price for transport

4.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

otherwise let us know via

our online form

the contact form page.

Lifting power as well as form of magnetic components can be reviewed with our

magnetic mass calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical of the product - AM ucho [M8] - magnetic accessories

Specification / characteristics - AM ucho [M8] - magnetic accessories

| properties | values |

|---|---|

| Cat. no. | 080268 |

| GTIN/EAN | 5906301812470 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Weight | 53 g |

| Load capacity ~ ? | 240.00 kg / 2353.60 N |

| Manufacturing Tolerance | ±1 mm |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Strengths and weaknesses of neodymium magnets.

Pros

- They have unchanged lifting capacity, and over around 10 years their attraction force decreases symbolically – ~1% (in testing),

- They possess excellent resistance to magnetic field loss when exposed to external magnetic sources,

- Thanks to the smooth finish, the plating of Ni-Cu-Ni, gold-plated, or silver-plated gives an aesthetic appearance,

- They feature high magnetic induction at the operating surface, which improves attraction properties,

- Thanks to resistance to high temperature, they are capable of working (depending on the form) even at temperatures up to 230°C and higher...

- Possibility of detailed shaping and adapting to individual conditions,

- Significant place in modern industrial fields – they find application in hard drives, brushless drives, precision medical tools, as well as industrial machines.

- Thanks to concentrated force, small magnets offer high operating force, occupying minimum space,

Weaknesses

- To avoid cracks upon strong impacts, we recommend using special steel holders. Such a solution protects the magnet and simultaneously increases its durability.

- When exposed to high temperature, neodymium magnets experience a drop in power. Often, when the temperature exceeds 80°C, their power decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material immune to moisture, when using outdoors

- Limited possibility of producing nuts in the magnet and complicated forms - recommended is a housing - magnetic holder.

- Potential hazard resulting from small fragments of magnets are risky, when accidentally swallowed, which gains importance in the context of child health protection. Furthermore, tiny parts of these devices are able to be problematic in diagnostics medical in case of swallowing.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Holding force characteristics

Breakaway strength of the magnet in ideal conditions – what affects it?

- with the application of a sheet made of special test steel, ensuring maximum field concentration

- with a cross-section of at least 10 mm

- characterized by smoothness

- with direct contact (no impurities)

- under perpendicular force direction (90-degree angle)

- in temp. approx. 20°C

Lifting capacity in practice – influencing factors

- Air gap (between the magnet and the metal), because even a microscopic clearance (e.g. 0.5 mm) can cause a decrease in force by up to 50% (this also applies to varnish, corrosion or debris).

- Force direction – catalog parameter refers to pulling vertically. When attempting to slide, the magnet holds much less (often approx. 20-30% of maximum force).

- Plate thickness – too thin steel causes magnetic saturation, causing part of the power to be lost into the air.

- Material composition – different alloys attracts identically. Alloy additives weaken the attraction effect.

- Surface finish – full contact is obtained only on polished steel. Rough texture create air cushions, reducing force.

- Thermal environment – temperature increase results in weakening of force. Check the thermal limit for a given model.

Lifting capacity was assessed by applying a steel plate with a smooth surface of optimal thickness (min. 20 mm), under perpendicular pulling force, whereas under parallel forces the holding force is lower. In addition, even a slight gap between the magnet and the plate lowers the holding force.

Safe handling of neodymium magnets

Heat warning

Avoid heat. NdFeB magnets are sensitive to heat. If you require resistance above 80°C, ask us about HT versions (H, SH, UH).

Pinching danger

Protect your hands. Two large magnets will snap together immediately with a force of massive weight, crushing anything in their path. Be careful!

Eye protection

Beware of splinters. Magnets can explode upon violent connection, ejecting sharp fragments into the air. Eye protection is mandatory.

Data carriers

Do not bring magnets near a wallet, computer, or TV. The magnetic field can destroy these devices and erase data from cards.

Choking Hazard

Strictly keep magnets out of reach of children. Risk of swallowing is high, and the effects of magnets connecting inside the body are fatal.

Immense force

Before use, read the rules. Uncontrolled attraction can destroy the magnet or injure your hand. Be predictive.

Nickel coating and allergies

It is widely known that the nickel plating (the usual finish) is a potent allergen. If your skin reacts to metals, prevent direct skin contact or select coated magnets.

Medical implants

For implant holders: Strong magnetic fields affect electronics. Maintain at least 30 cm distance or ask another person to work with the magnets.

Fire risk

Drilling and cutting of neodymium magnets poses a fire hazard. Magnetic powder oxidizes rapidly with oxygen and is hard to extinguish.

Threat to navigation

GPS units and mobile phones are highly susceptible to magnetic fields. Direct contact with a powerful NdFeB magnet can permanently damage the internal compass in your phone.

![Equipment for magnets AM ucho [M8] Equipment for magnets AM ucho [M8]](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![AM ucho [M8] - magnetic accessories](https://cdn3.dhit.pl/graphics/products/am-ucho-m8-lib.jpg)

![UMGGZ 88x8.5 [M8] GZ / N38 - rubber magnetic holder external thread UMGGZ 88x8.5 [M8] GZ / N38 - rubber magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umg-88x8.5-m8-gz-waf.jpg)

![UMGZ 20x15x7 [M4] GZ / N38 - magnetic holder external thread UMGZ 20x15x7 [M4] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/um-20x15x7-m4-gz-vaf.jpg)

![UMP 107x40 [M8+M10] GW F400 Lina / N38 - search holder UMP 107x40 [M8+M10] GW F400 Lina / N38 - search holder](https://cdn3.dhit.pl/graphics/products/ump-107x40-m8+m10-gw-f400-+lina-bel.jpg)