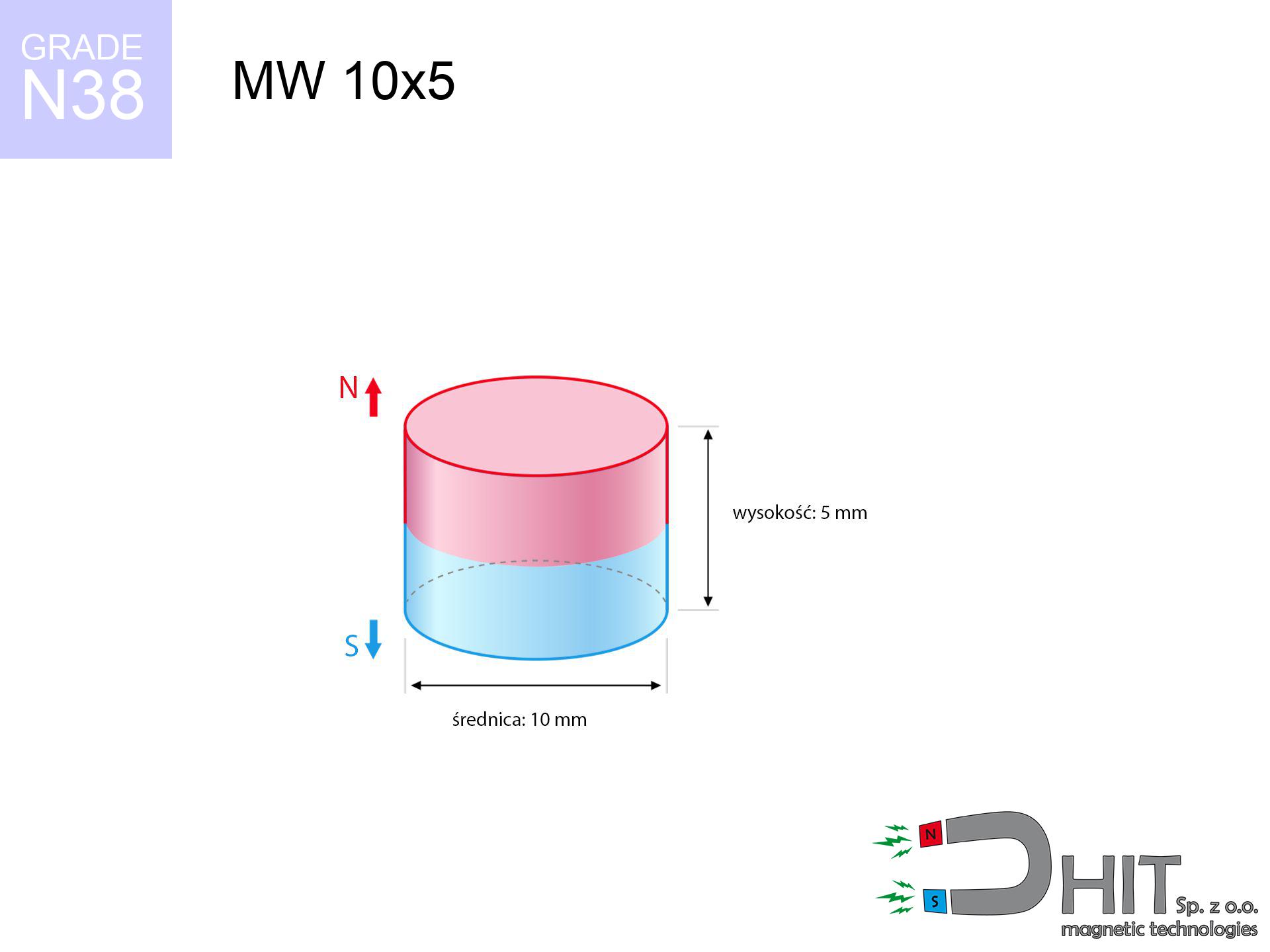

MW 10x5 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010011

GTIN/EAN: 5906301810100

Diameter Ø

10 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

2.95 g

Magnetization Direction

↑ axial

Load capacity

3.19 kg / 31.28 N

Magnetic Induction

437.91 mT / 4379 Gs

Coating

[NiCuNi] Nickel

1.513 ZŁ with VAT / pcs + price for transport

1.230 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

if you prefer drop us a message by means of

our online form

the contact section.

Weight along with structure of a magnet can be estimated using our

our magnetic calculator.

Order by 14:00 and we’ll ship today!

Technical details - MW 10x5 / N38 - cylindrical magnet

Specification / characteristics - MW 10x5 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010011 |

| GTIN/EAN | 5906301810100 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 10 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 2.95 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 3.19 kg / 31.28 N |

| Magnetic Induction ~ ? | 437.91 mT / 4379 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical analysis of the product - report

Presented information constitute the outcome of a physical calculation. Values rely on algorithms for the class Nd2Fe14B. Real-world performance may differ. Treat these calculations as a reference point during assembly planning.

Table 1: Static pull force (pull vs distance) - characteristics

MW 10x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4376 Gs

437.6 mT

|

3.19 kg / 7.03 LBS

3190.0 g / 31.3 N

|

strong |

| 1 mm |

3547 Gs

354.7 mT

|

2.10 kg / 4.62 LBS

2095.9 g / 20.6 N

|

strong |

| 2 mm |

2743 Gs

274.3 mT

|

1.25 kg / 2.76 LBS

1252.9 g / 12.3 N

|

safe |

| 3 mm |

2068 Gs

206.8 mT

|

0.71 kg / 1.57 LBS

712.2 g / 7.0 N

|

safe |

| 5 mm |

1161 Gs

116.1 mT

|

0.22 kg / 0.50 LBS

224.7 g / 2.2 N

|

safe |

| 10 mm |

336 Gs

33.6 mT

|

0.02 kg / 0.04 LBS

18.8 g / 0.2 N

|

safe |

| 15 mm |

133 Gs

13.3 mT

|

0.00 kg / 0.01 LBS

2.9 g / 0.0 N

|

safe |

| 20 mm |

65 Gs

6.5 mT

|

0.00 kg / 0.00 LBS

0.7 g / 0.0 N

|

safe |

| 30 mm |

22 Gs

2.2 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

safe |

| 50 mm |

5 Gs

0.5 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

Table 2: Sliding force (wall)

MW 10x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.64 kg / 1.41 LBS

638.0 g / 6.3 N

|

| 1 mm | Stal (~0.2) |

0.42 kg / 0.93 LBS

420.0 g / 4.1 N

|

| 2 mm | Stal (~0.2) |

0.25 kg / 0.55 LBS

250.0 g / 2.5 N

|

| 3 mm | Stal (~0.2) |

0.14 kg / 0.31 LBS

142.0 g / 1.4 N

|

| 5 mm | Stal (~0.2) |

0.04 kg / 0.10 LBS

44.0 g / 0.4 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MW 10x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.96 kg / 2.11 LBS

957.0 g / 9.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.64 kg / 1.41 LBS

638.0 g / 6.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.32 kg / 0.70 LBS

319.0 g / 3.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.60 kg / 3.52 LBS

1595.0 g / 15.6 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MW 10x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.32 kg / 0.70 LBS

319.0 g / 3.1 N

|

| 1 mm |

|

0.80 kg / 1.76 LBS

797.5 g / 7.8 N

|

| 2 mm |

|

1.60 kg / 3.52 LBS

1595.0 g / 15.6 N

|

| 3 mm |

|

2.39 kg / 5.27 LBS

2392.5 g / 23.5 N

|

| 5 mm |

|

3.19 kg / 7.03 LBS

3190.0 g / 31.3 N

|

| 10 mm |

|

3.19 kg / 7.03 LBS

3190.0 g / 31.3 N

|

| 11 mm |

|

3.19 kg / 7.03 LBS

3190.0 g / 31.3 N

|

| 12 mm |

|

3.19 kg / 7.03 LBS

3190.0 g / 31.3 N

|

Table 5: Working in heat (material behavior) - resistance threshold

MW 10x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

3.19 kg / 7.03 LBS

3190.0 g / 31.3 N

|

OK |

| 40 °C | -2.2% |

3.12 kg / 6.88 LBS

3119.8 g / 30.6 N

|

OK |

| 60 °C | -4.4% |

3.05 kg / 6.72 LBS

3049.6 g / 29.9 N

|

|

| 80 °C | -6.6% |

2.98 kg / 6.57 LBS

2979.5 g / 29.2 N

|

|

| 100 °C | -28.8% |

2.27 kg / 5.01 LBS

2271.3 g / 22.3 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MW 10x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

9.27 kg / 20.44 LBS

5 534 Gs

|

1.39 kg / 3.07 LBS

1391 g / 13.6 N

|

N/A |

| 1 mm |

7.63 kg / 16.83 LBS

7 941 Gs

|

1.15 kg / 2.52 LBS

1145 g / 11.2 N

|

6.87 kg / 15.15 LBS

~0 Gs

|

| 2 mm |

6.09 kg / 13.43 LBS

7 094 Gs

|

0.91 kg / 2.01 LBS

914 g / 9.0 N

|

5.48 kg / 12.09 LBS

~0 Gs

|

| 3 mm |

4.75 kg / 10.48 LBS

6 265 Gs

|

0.71 kg / 1.57 LBS

713 g / 7.0 N

|

4.28 kg / 9.43 LBS

~0 Gs

|

| 5 mm |

2.76 kg / 6.08 LBS

4 772 Gs

|

0.41 kg / 0.91 LBS

413 g / 4.1 N

|

2.48 kg / 5.47 LBS

~0 Gs

|

| 10 mm |

0.65 kg / 1.44 LBS

2 323 Gs

|

0.10 kg / 0.22 LBS

98 g / 1.0 N

|

0.59 kg / 1.30 LBS

~0 Gs

|

| 20 mm |

0.05 kg / 0.12 LBS

673 Gs

|

0.01 kg / 0.02 LBS

8 g / 0.1 N

|

0.05 kg / 0.11 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

72 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

44 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

29 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

20 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

14 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

11 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Safety (HSE) (electronics) - precautionary measures

MW 10x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 3.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 2.5 cm |

| Car key | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (cracking risk) - collision effects

MW 10x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

33.29 km/h

(9.25 m/s)

|

0.13 J | |

| 30 mm |

57.44 km/h

(15.96 m/s)

|

0.38 J | |

| 50 mm |

74.16 km/h

(20.60 m/s)

|

0.63 J | |

| 100 mm |

104.87 km/h

(29.13 m/s)

|

1.25 J |

Table 9: Coating parameters (durability)

MW 10x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 10x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 489 Mx | 34.9 µWb |

| Pc Coefficient | 0.59 | Low (Flat) |

Table 11: Submerged application

MW 10x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 3.19 kg | Standard |

| Water (riverbed) |

3.65 kg

(+0.46 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Warning: On a vertical surface, the magnet holds only ~20% of its perpendicular strength.

2. Efficiency vs thickness

*Thin metal sheet (e.g. computer case) severely limits the holding force.

3. Temperature resistance

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.59

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more deals

Strengths as well as weaknesses of rare earth magnets.

Benefits

- They have constant strength, and over more than ten years their attraction force decreases symbolically – ~1% (in testing),

- They are resistant to demagnetization induced by external disturbances,

- Thanks to the glossy finish, the layer of Ni-Cu-Ni, gold-plated, or silver-plated gives an aesthetic appearance,

- Neodymium magnets generate maximum magnetic induction on a small area, which increases force concentration,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and can work (depending on the shape) even at a temperature of 230°C or more...

- Possibility of individual modeling and optimizing to atypical conditions,

- Versatile presence in future technologies – they are commonly used in HDD drives, brushless drives, advanced medical instruments, also technologically advanced constructions.

- Thanks to their power density, small magnets offer high operating force, in miniature format,

Limitations

- They are fragile upon heavy impacts. To avoid cracks, it is worth protecting magnets in a protective case. Such protection not only protects the magnet but also improves its resistance to damage

- We warn that neodymium magnets can lose their power at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture, in case of application outdoors

- We recommend cover - magnetic mechanism, due to difficulties in creating nuts inside the magnet and complicated forms.

- Possible danger resulting from small fragments of magnets pose a threat, if swallowed, which becomes key in the context of child health protection. It is also worth noting that small elements of these devices are able to be problematic in diagnostics medical after entering the body.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Pull force analysis

Magnetic strength at its maximum – what contributes to it?

- using a sheet made of low-carbon steel, functioning as a circuit closing element

- whose transverse dimension is min. 10 mm

- characterized by smoothness

- under conditions of gap-free contact (surface-to-surface)

- during pulling in a direction vertical to the plane

- at standard ambient temperature

Determinants of lifting force in real conditions

- Space between magnet and steel – even a fraction of a millimeter of separation (caused e.g. by varnish or dirt) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Pull-off angle – note that the magnet holds strongest perpendicularly. Under sliding down, the holding force drops significantly, often to levels of 20-30% of the nominal value.

- Steel thickness – insufficiently thick sheet does not close the flux, causing part of the power to be wasted to the other side.

- Metal type – not every steel attracts identically. High carbon content weaken the interaction with the magnet.

- Surface condition – ground elements ensure maximum contact, which increases force. Rough surfaces weaken the grip.

- Operating temperature – NdFeB sinters have a negative temperature coefficient. When it is hot they are weaker, and in frost gain strength (up to a certain limit).

Lifting capacity was assessed with the use of a polished steel plate of optimal thickness (min. 20 mm), under perpendicular detachment force, whereas under shearing force the lifting capacity is smaller. In addition, even a minimal clearance between the magnet’s surface and the plate reduces the lifting capacity.

H&S for magnets

Keep away from children

Neodymium magnets are not intended for children. Swallowing a few magnets can lead to them pinching intestinal walls, which constitutes a severe health hazard and necessitates immediate surgery.

Maximum temperature

Regular neodymium magnets (grade N) lose power when the temperature goes above 80°C. The loss of strength is permanent.

Mechanical processing

Mechanical processing of NdFeB material poses a fire hazard. Magnetic powder reacts violently with oxygen and is hard to extinguish.

Sensitization to coating

Allergy Notice: The nickel-copper-nickel coating consists of nickel. If an allergic reaction happens, cease working with magnets and wear gloves.

Magnets are brittle

Watch out for shards. Magnets can fracture upon violent connection, ejecting shards into the air. Wear goggles.

Life threat

Life threat: Neodymium magnets can deactivate pacemakers and defibrillators. Do not approach if you have electronic implants.

Electronic hazard

Device Safety: Neodymium magnets can damage payment cards and sensitive devices (heart implants, hearing aids, mechanical watches).

Powerful field

Handle magnets consciously. Their powerful strength can surprise even professionals. Plan your moves and respect their force.

Bodily injuries

Pinching hazard: The attraction force is so immense that it can result in hematomas, pinching, and even bone fractures. Use thick gloves.

Magnetic interference

Note: neodymium magnets generate a field that confuses precision electronics. Maintain a separation from your phone, device, and GPS.

![SM 25x250 [2xM8] / N42 - magnetic separator SM 25x250 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x250-2xm8-ker.jpg)