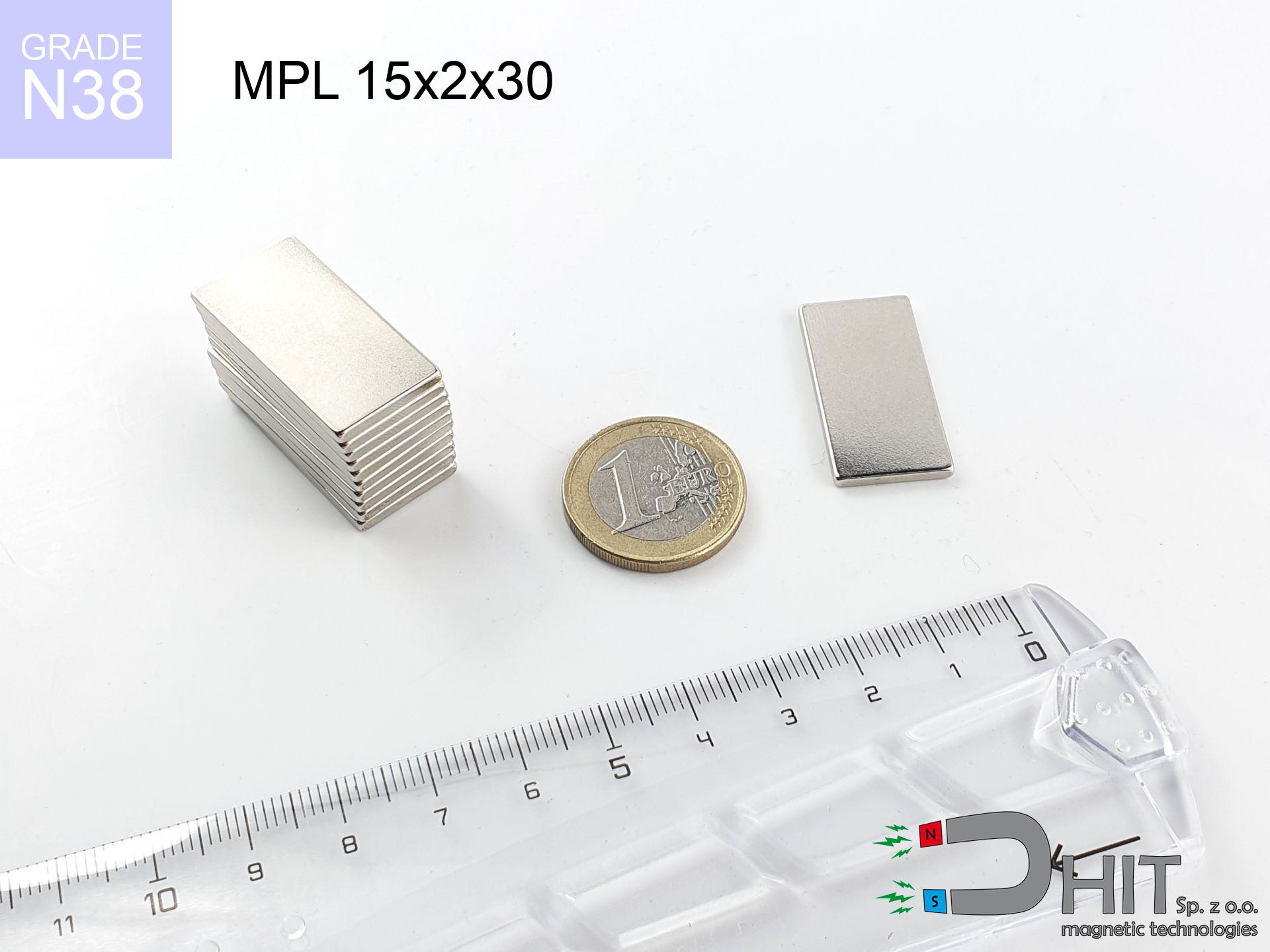

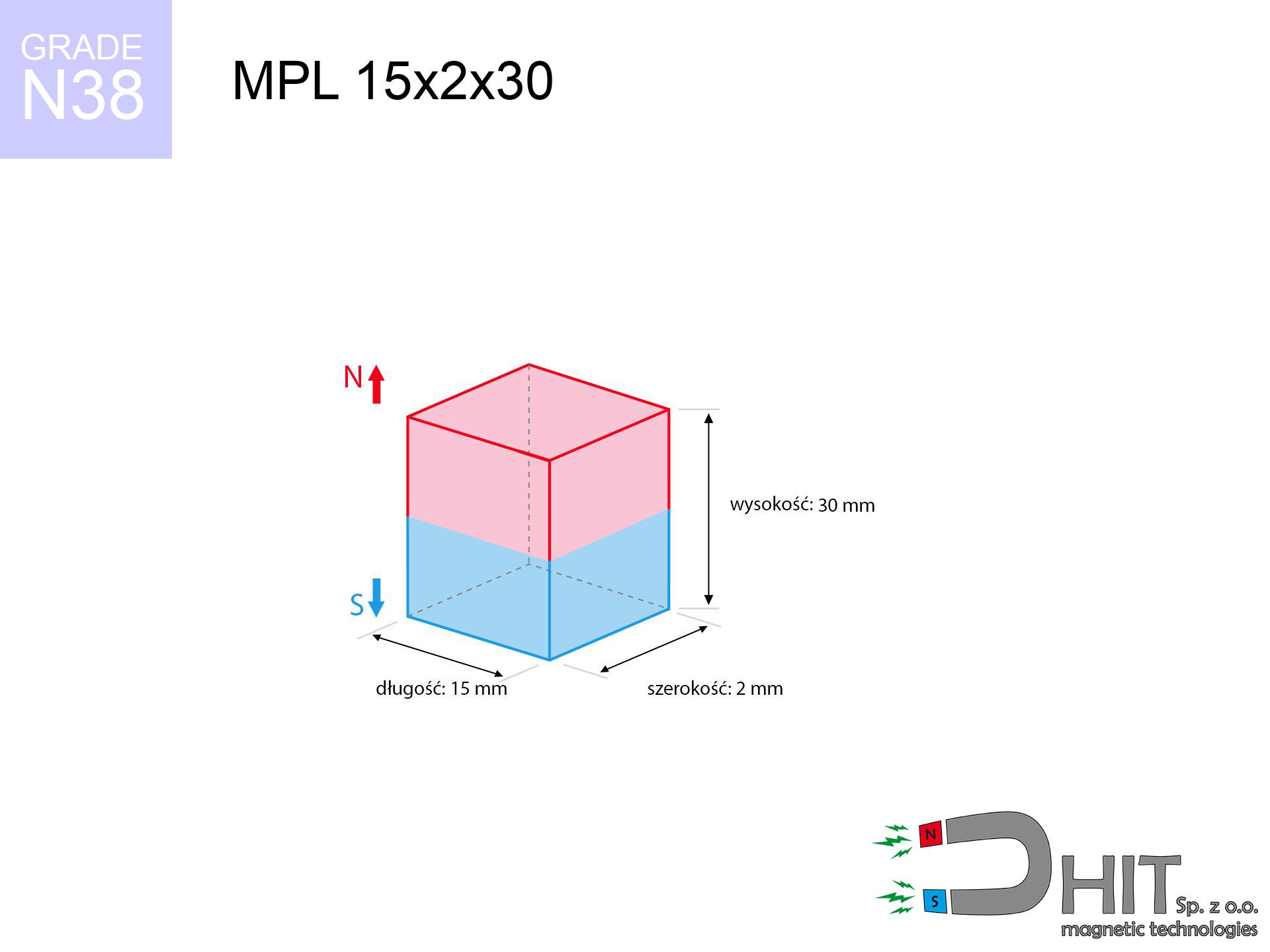

MPL 15x2x30 / N38 - lamellar magnet

lamellar magnet

Catalog no 020121

GTIN/EAN: 5906301811275

length

15 mm [±0,1 mm]

Width

2 mm [±0,1 mm]

Height

30 mm [±0,1 mm]

Weight

6.75 g

Magnetization Direction

→ diametrical

Load capacity

0.68 kg / 6.68 N

Magnetic Induction

614.34 mT / 6143 Gs

Coating

[NiCuNi] Nickel

4.75 ZŁ with VAT / pcs + price for transport

3.86 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

otherwise send us a note through

our online form

the contact page.

Lifting power and appearance of a neodymium magnet can be reviewed on our

online calculation tool.

Orders submitted before 14:00 will be dispatched today!

Technical data of the product - MPL 15x2x30 / N38 - lamellar magnet

Specification / characteristics - MPL 15x2x30 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020121 |

| GTIN/EAN | 5906301811275 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 15 mm [±0,1 mm] |

| Width | 2 mm [±0,1 mm] |

| Height | 30 mm [±0,1 mm] |

| Weight | 6.75 g |

| Magnetization Direction | → diametrical |

| Load capacity ~ ? | 0.68 kg / 6.68 N |

| Magnetic Induction ~ ? | 614.34 mT / 6143 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the magnet - technical parameters

Presented values constitute the result of a physical calculation. Results were calculated on algorithms for the class Nd2Fe14B. Real-world performance may deviate from the simulation results. Treat these calculations as a reference point for designers.

Table 1: Static pull force (force vs distance) - characteristics

MPL 15x2x30 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

6128 Gs

612.8 mT

|

0.68 kg / 1.50 lbs

680.0 g / 6.7 N

|

safe |

| 1 mm |

3036 Gs

303.6 mT

|

0.17 kg / 0.37 lbs

166.8 g / 1.6 N

|

safe |

| 2 mm |

1736 Gs

173.6 mT

|

0.05 kg / 0.12 lbs

54.5 g / 0.5 N

|

safe |

| 3 mm |

1150 Gs

115.0 mT

|

0.02 kg / 0.05 lbs

23.9 g / 0.2 N

|

safe |

| 5 mm |

623 Gs

62.3 mT

|

0.01 kg / 0.02 lbs

7.0 g / 0.1 N

|

safe |

| 10 mm |

218 Gs

21.8 mT

|

0.00 kg / 0.00 lbs

0.9 g / 0.0 N

|

safe |

| 15 mm |

103 Gs

10.3 mT

|

0.00 kg / 0.00 lbs

0.2 g / 0.0 N

|

safe |

| 20 mm |

58 Gs

5.8 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

safe |

| 30 mm |

24 Gs

2.4 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

| 50 mm |

7 Gs

0.7 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

Table 2: Vertical force (wall)

MPL 15x2x30 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.14 kg / 0.30 lbs

136.0 g / 1.3 N

|

| 1 mm | Stal (~0.2) |

0.03 kg / 0.07 lbs

34.0 g / 0.3 N

|

| 2 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

10.0 g / 0.1 N

|

| 3 mm | Stal (~0.2) |

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MPL 15x2x30 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.20 kg / 0.45 lbs

204.0 g / 2.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.14 kg / 0.30 lbs

136.0 g / 1.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.07 kg / 0.15 lbs

68.0 g / 0.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.34 kg / 0.75 lbs

340.0 g / 3.3 N

|

Table 4: Material efficiency (saturation) - power losses

MPL 15x2x30 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.07 kg / 0.15 lbs

68.0 g / 0.7 N

|

| 1 mm |

|

0.17 kg / 0.37 lbs

170.0 g / 1.7 N

|

| 2 mm |

|

0.34 kg / 0.75 lbs

340.0 g / 3.3 N

|

| 3 mm |

|

0.51 kg / 1.12 lbs

510.0 g / 5.0 N

|

| 5 mm |

|

0.68 kg / 1.50 lbs

680.0 g / 6.7 N

|

| 10 mm |

|

0.68 kg / 1.50 lbs

680.0 g / 6.7 N

|

| 11 mm |

|

0.68 kg / 1.50 lbs

680.0 g / 6.7 N

|

| 12 mm |

|

0.68 kg / 1.50 lbs

680.0 g / 6.7 N

|

Table 5: Thermal resistance (material behavior) - resistance threshold

MPL 15x2x30 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.68 kg / 1.50 lbs

680.0 g / 6.7 N

|

OK |

| 40 °C | -2.2% |

0.67 kg / 1.47 lbs

665.0 g / 6.5 N

|

OK |

| 60 °C | -4.4% |

0.65 kg / 1.43 lbs

650.1 g / 6.4 N

|

OK |

| 80 °C | -6.6% |

0.64 kg / 1.40 lbs

635.1 g / 6.2 N

|

|

| 100 °C | -28.8% |

0.48 kg / 1.07 lbs

484.2 g / 4.7 N

|

Table 6: Two magnets (repulsion) - field range

MPL 15x2x30 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

6.95 kg / 15.31 lbs

6 152 Gs

|

1.04 kg / 2.30 lbs

1042 g / 10.2 N

|

N/A |

| 1 mm |

3.45 kg / 7.62 lbs

8 643 Gs

|

0.52 kg / 1.14 lbs

518 g / 5.1 N

|

3.11 kg / 6.85 lbs

~0 Gs

|

| 2 mm |

1.70 kg / 3.76 lbs

6 071 Gs

|

0.26 kg / 0.56 lbs

256 g / 2.5 N

|

1.53 kg / 3.38 lbs

~0 Gs

|

| 3 mm |

0.93 kg / 2.05 lbs

4 482 Gs

|

0.14 kg / 0.31 lbs

139 g / 1.4 N

|

0.84 kg / 1.84 lbs

~0 Gs

|

| 5 mm |

0.36 kg / 0.79 lbs

2 788 Gs

|

0.05 kg / 0.12 lbs

54 g / 0.5 N

|

0.32 kg / 0.71 lbs

~0 Gs

|

| 10 mm |

0.07 kg / 0.16 lbs

1 247 Gs

|

0.01 kg / 0.02 lbs

11 g / 0.1 N

|

0.06 kg / 0.14 lbs

~0 Gs

|

| 20 mm |

0.01 kg / 0.02 lbs

435 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

71 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

47 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

33 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

24 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

18 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

14 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Protective zones (implants) - warnings

MPL 15x2x30 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 3.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.5 cm |

| Remote | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (cracking risk) - collision effects

MPL 15x2x30 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

10.13 km/h

(2.81 m/s)

|

0.03 J | |

| 30 mm |

17.53 km/h

(4.87 m/s)

|

0.08 J | |

| 50 mm |

22.63 km/h

(6.29 m/s)

|

0.13 J | |

| 100 mm |

32.01 km/h

(8.89 m/s)

|

0.27 J |

Table 9: Surface protection spec

MPL 15x2x30 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MPL 15x2x30 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 2 210 Mx | 22.1 µWb |

| Pc Coefficient | 1.54 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MPL 15x2x30 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.68 kg | Standard |

| Water (riverbed) |

0.78 kg

(+0.10 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical wall, the magnet holds just ~20% of its perpendicular strength.

2. Efficiency vs thickness

*Thin metal sheet (e.g. 0.5mm PC case) significantly weakens the holding force.

3. Thermal stability

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.54

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

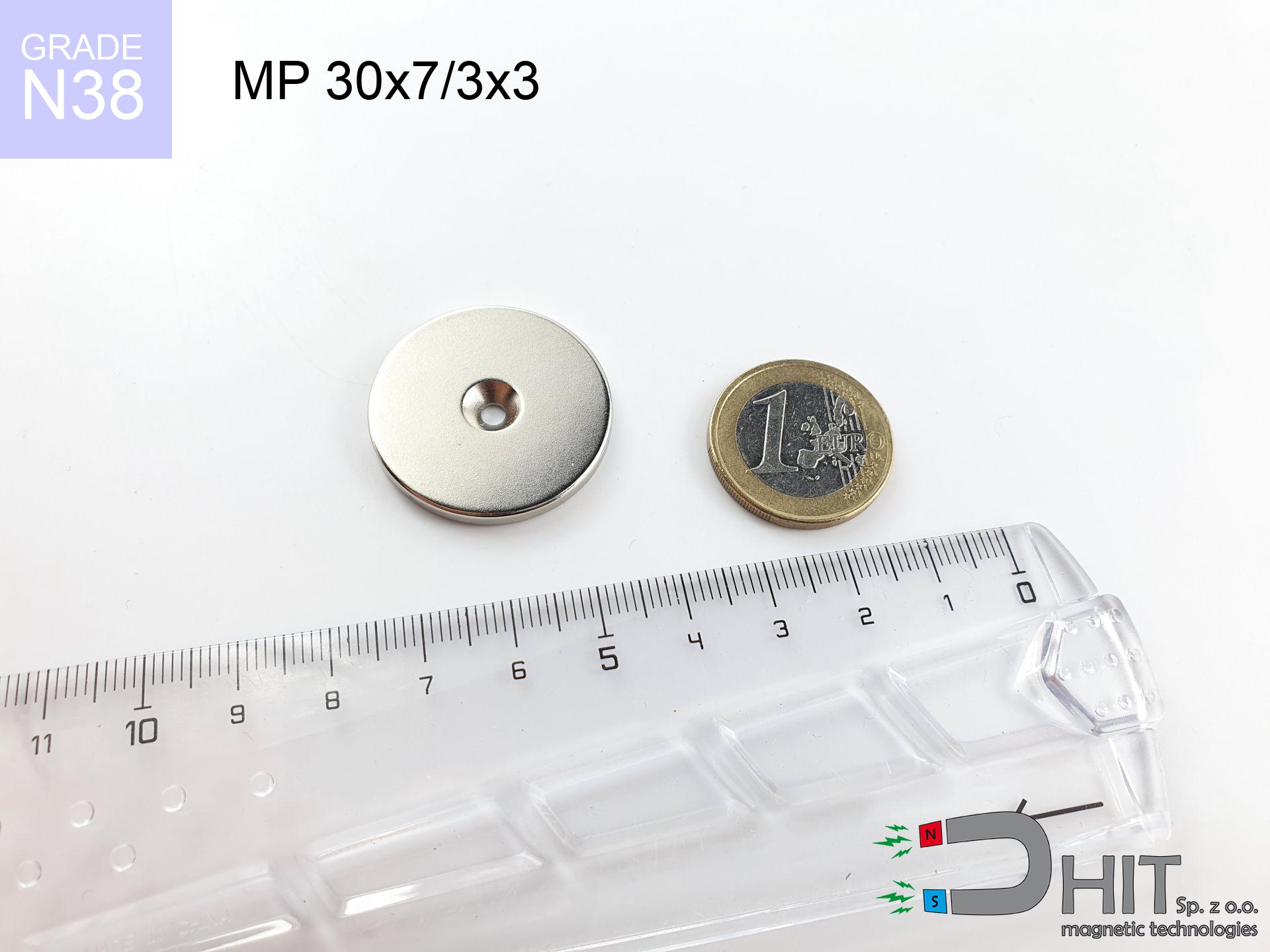

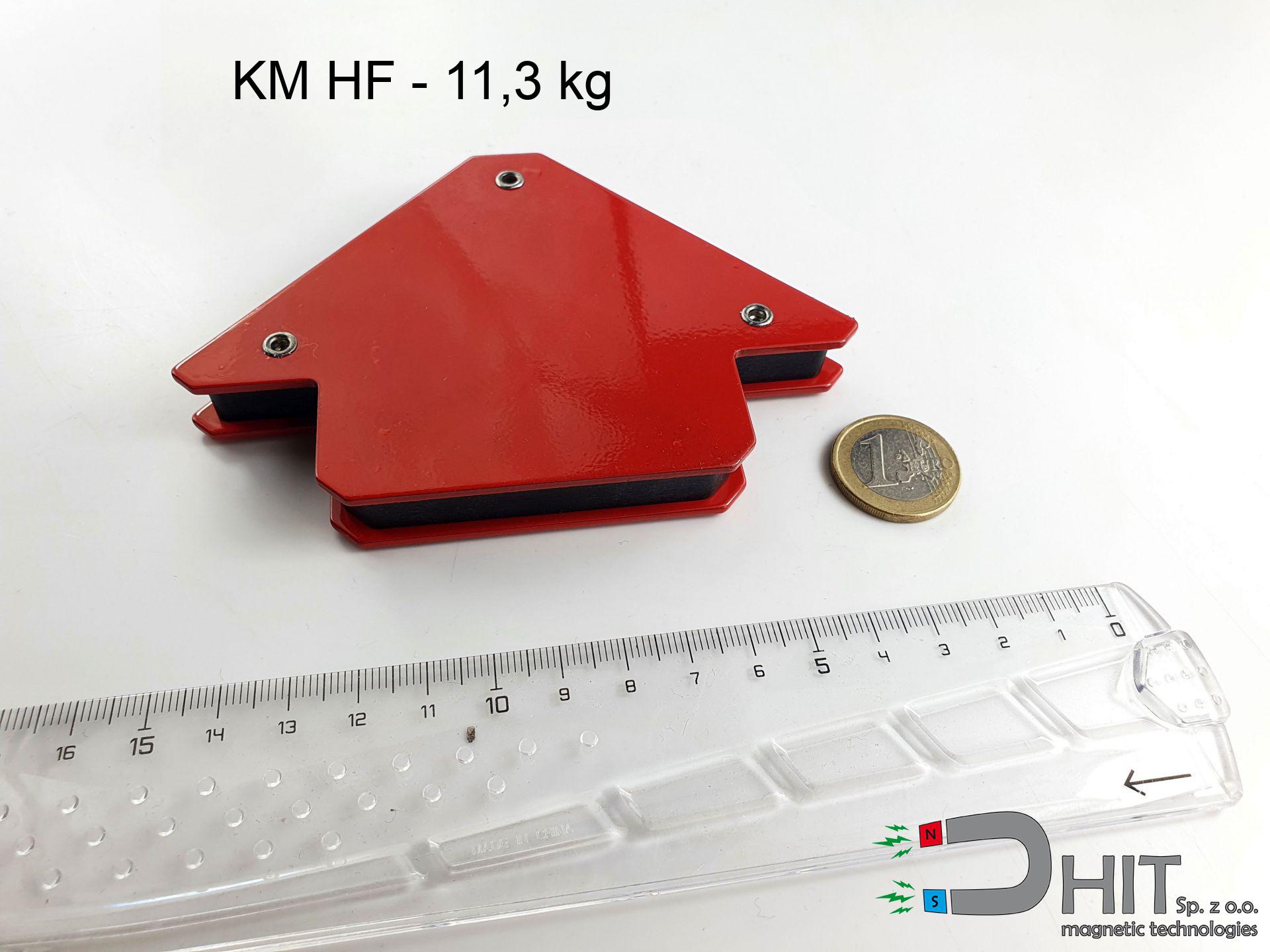

Other products

Pros and cons of Nd2Fe14B magnets.

Advantages

- They have unchanged lifting capacity, and over more than 10 years their attraction force decreases symbolically – ~1% (according to theory),

- They feature excellent resistance to weakening of magnetic properties due to opposing magnetic fields,

- The use of an metallic finish of noble metals (nickel, gold, silver) causes the element to be more visually attractive,

- The surface of neodymium magnets generates a concentrated magnetic field – this is a distinguishing feature,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the form) even at high temperatures reaching 230°C or more...

- Possibility of exact creating and modifying to defined needs,

- Universal use in modern technologies – they are commonly used in magnetic memories, electric drive systems, precision medical tools, also complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer high power in tiny dimensions, which enables their usage in compact constructions

Cons

- To avoid cracks under impact, we suggest using special steel holders. Such a solution secures the magnet and simultaneously improves its durability.

- When exposed to high temperature, neodymium magnets experience a drop in force. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can rust. Therefore during using outdoors, we suggest using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- Due to limitations in realizing threads and complicated shapes in magnets, we recommend using cover - magnetic mount.

- Health risk resulting from small fragments of magnets are risky, in case of ingestion, which becomes key in the context of child health protection. It is also worth noting that small components of these products can complicate diagnosis medical after entering the body.

- Due to complex production process, their price exceeds standard values,

Pull force analysis

Maximum lifting force for a neodymium magnet – what contributes to it?

- with the use of a yoke made of special test steel, guaranteeing maximum field concentration

- whose transverse dimension equals approx. 10 mm

- with an polished contact surface

- without any air gap between the magnet and steel

- for force applied at a right angle (in the magnet axis)

- in temp. approx. 20°C

Practical lifting capacity: influencing factors

- Space between magnet and steel – even a fraction of a millimeter of separation (caused e.g. by varnish or unevenness) diminishes the magnet efficiency, often by half at just 0.5 mm.

- Loading method – catalog parameter refers to detachment vertically. When slipping, the magnet exhibits significantly lower power (often approx. 20-30% of maximum force).

- Element thickness – to utilize 100% power, the steel must be sufficiently thick. Thin sheet limits the lifting capacity (the magnet "punches through" it).

- Material type – ideal substrate is high-permeability steel. Cast iron may generate lower lifting capacity.

- Surface finish – ideal contact is obtained only on polished steel. Rough texture reduce the real contact area, weakening the magnet.

- Heat – NdFeB sinters have a sensitivity to temperature. At higher temperatures they are weaker, and in frost they can be stronger (up to a certain limit).

Lifting capacity testing was conducted on plates with a smooth surface of suitable thickness, under perpendicular forces, however under attempts to slide the magnet the holding force is lower. Moreover, even a minimal clearance between the magnet and the plate lowers the holding force.

Precautions when working with NdFeB magnets

Demagnetization risk

Standard neodymium magnets (N-type) lose power when the temperature surpasses 80°C. The loss of strength is permanent.

Threat to navigation

Note: rare earth magnets generate a field that interferes with precision electronics. Maintain a safe distance from your mobile, device, and navigation systems.

Fire warning

Drilling and cutting of NdFeB material carries a risk of fire hazard. Neodymium dust reacts violently with oxygen and is difficult to extinguish.

Keep away from computers

Intense magnetic fields can corrupt files on payment cards, HDDs, and other magnetic media. Maintain a gap of min. 10 cm.

Material brittleness

Despite metallic appearance, neodymium is delicate and not impact-resistant. Avoid impacts, as the magnet may shatter into sharp, dangerous pieces.

Pinching danger

Protect your hands. Two powerful magnets will join instantly with a force of massive weight, crushing everything in their path. Exercise extreme caution!

Adults only

Adult use only. Tiny parts can be swallowed, leading to intestinal necrosis. Keep away from children and animals.

Allergy Warning

Some people experience a contact allergy to Ni, which is the common plating for NdFeB magnets. Prolonged contact may cause dermatitis. We strongly advise wear protective gloves.

Implant safety

For implant holders: Strong magnetic fields affect medical devices. Keep minimum 30 cm distance or request help to handle the magnets.

Caution required

Be careful. Rare earth magnets attract from a long distance and connect with huge force, often faster than you can react.

![SM 25x200 [2xM8] / N42 - magnetic separator SM 25x200 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x200-2xm8-dos.jpg)