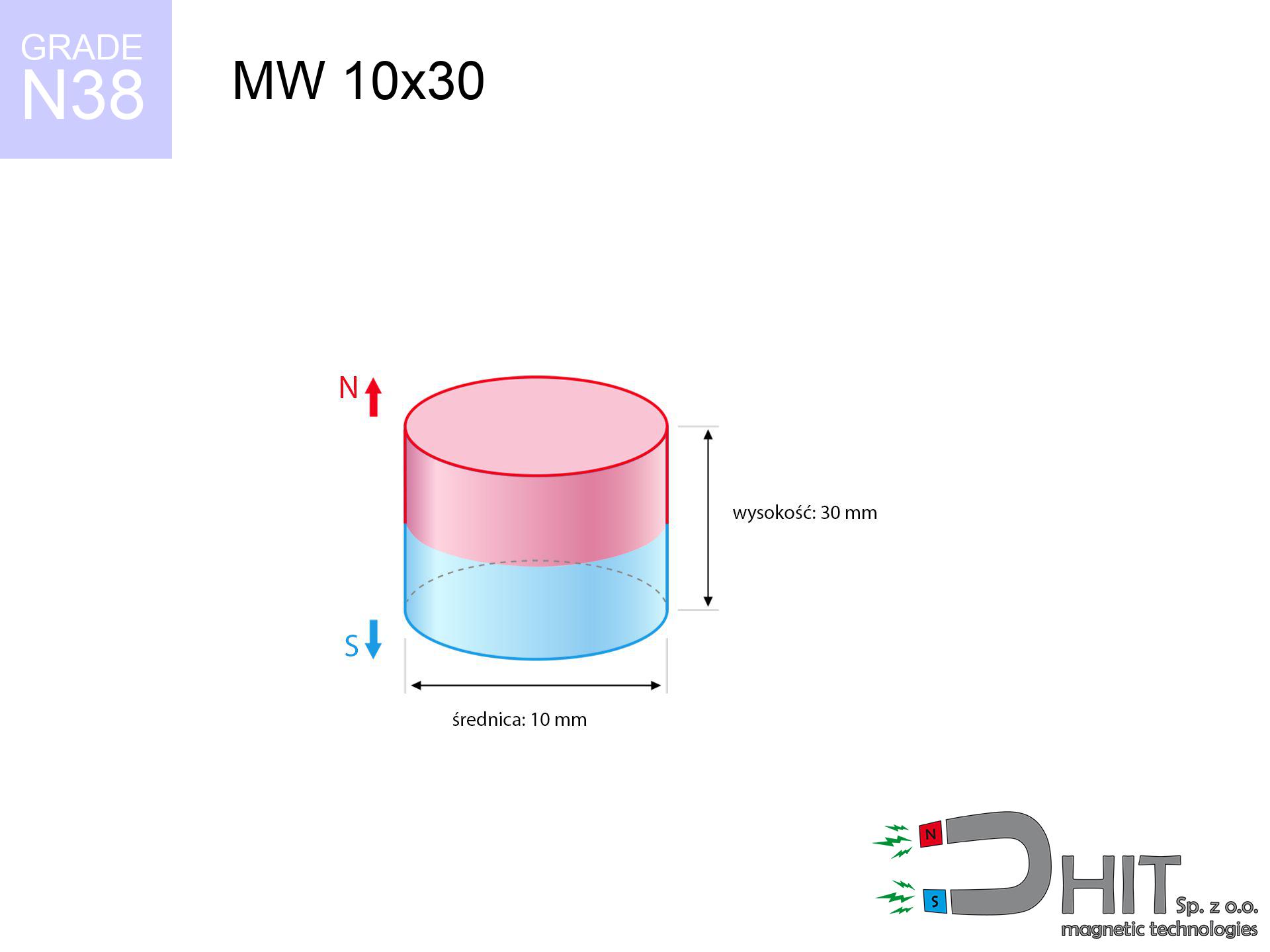

MW 10x30 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010009

GTIN/EAN: 5906301810087

Diameter Ø

10 mm [±0,1 mm]

Height

30 mm [±0,1 mm]

Weight

17.67 g

Magnetization Direction

↑ axial

Load capacity

1.92 kg / 18.79 N

Magnetic Induction

610.80 mT / 6108 Gs

Coating

[NiCuNi] Nickel

8.61 ZŁ with VAT / pcs + price for transport

7.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

or contact us via

request form

the contact page.

Strength along with appearance of neodymium magnets can be tested with our

our magnetic calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical data of the product - MW 10x30 / N38 - cylindrical magnet

Specification / characteristics - MW 10x30 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010009 |

| GTIN/EAN | 5906301810087 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 10 mm [±0,1 mm] |

| Height | 30 mm [±0,1 mm] |

| Weight | 17.67 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.92 kg / 18.79 N |

| Magnetic Induction ~ ? | 610.80 mT / 6108 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the assembly - report

These data constitute the result of a mathematical calculation. Values rely on models for the class Nd2Fe14B. Real-world parameters might slightly differ. Treat these data as a preliminary roadmap during assembly planning.

Table 1: Static pull force (force vs distance) - characteristics

MW 10x30 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

6103 Gs

610.3 mT

|

1.92 kg / 4.23 LBS

1920.0 g / 18.8 N

|

low risk |

| 1 mm |

4905 Gs

490.5 mT

|

1.24 kg / 2.73 LBS

1240.1 g / 12.2 N

|

low risk |

| 2 mm |

3823 Gs

382.3 mT

|

0.75 kg / 1.66 LBS

753.3 g / 7.4 N

|

low risk |

| 3 mm |

2940 Gs

294.0 mT

|

0.45 kg / 0.98 LBS

445.6 g / 4.4 N

|

low risk |

| 5 mm |

1754 Gs

175.4 mT

|

0.16 kg / 0.35 LBS

158.5 g / 1.6 N

|

low risk |

| 10 mm |

607 Gs

60.7 mT

|

0.02 kg / 0.04 LBS

19.0 g / 0.2 N

|

low risk |

| 15 mm |

280 Gs

28.0 mT

|

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

low risk |

| 20 mm |

154 Gs

15.4 mT

|

0.00 kg / 0.00 LBS

1.2 g / 0.0 N

|

low risk |

| 30 mm |

63 Gs

6.3 mT

|

0.00 kg / 0.00 LBS

0.2 g / 0.0 N

|

low risk |

| 50 mm |

19 Gs

1.9 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

Table 2: Slippage load (vertical surface)

MW 10x30 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.38 kg / 0.85 LBS

384.0 g / 3.8 N

|

| 1 mm | Stal (~0.2) |

0.25 kg / 0.55 LBS

248.0 g / 2.4 N

|

| 2 mm | Stal (~0.2) |

0.15 kg / 0.33 LBS

150.0 g / 1.5 N

|

| 3 mm | Stal (~0.2) |

0.09 kg / 0.20 LBS

90.0 g / 0.9 N

|

| 5 mm | Stal (~0.2) |

0.03 kg / 0.07 LBS

32.0 g / 0.3 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MW 10x30 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.58 kg / 1.27 LBS

576.0 g / 5.7 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.38 kg / 0.85 LBS

384.0 g / 3.8 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.19 kg / 0.42 LBS

192.0 g / 1.9 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.96 kg / 2.12 LBS

960.0 g / 9.4 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MW 10x30 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.19 kg / 0.42 LBS

192.0 g / 1.9 N

|

| 1 mm |

|

0.48 kg / 1.06 LBS

480.0 g / 4.7 N

|

| 2 mm |

|

0.96 kg / 2.12 LBS

960.0 g / 9.4 N

|

| 3 mm |

|

1.44 kg / 3.17 LBS

1440.0 g / 14.1 N

|

| 5 mm |

|

1.92 kg / 4.23 LBS

1920.0 g / 18.8 N

|

| 10 mm |

|

1.92 kg / 4.23 LBS

1920.0 g / 18.8 N

|

| 11 mm |

|

1.92 kg / 4.23 LBS

1920.0 g / 18.8 N

|

| 12 mm |

|

1.92 kg / 4.23 LBS

1920.0 g / 18.8 N

|

Table 5: Thermal resistance (stability) - resistance threshold

MW 10x30 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.92 kg / 4.23 LBS

1920.0 g / 18.8 N

|

OK |

| 40 °C | -2.2% |

1.88 kg / 4.14 LBS

1877.8 g / 18.4 N

|

OK |

| 60 °C | -4.4% |

1.84 kg / 4.05 LBS

1835.5 g / 18.0 N

|

OK |

| 80 °C | -6.6% |

1.79 kg / 3.95 LBS

1793.3 g / 17.6 N

|

|

| 100 °C | -28.8% |

1.37 kg / 3.01 LBS

1367.0 g / 13.4 N

|

Table 6: Two magnets (attraction) - field range

MW 10x30 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

18.04 kg / 39.76 LBS

6 166 Gs

|

2.71 kg / 5.96 LBS

2705 g / 26.5 N

|

N/A |

| 1 mm |

14.65 kg / 32.31 LBS

11 003 Gs

|

2.20 kg / 4.85 LBS

2198 g / 21.6 N

|

13.19 kg / 29.08 LBS

~0 Gs

|

| 2 mm |

11.65 kg / 25.68 LBS

9 810 Gs

|

1.75 kg / 3.85 LBS

1747 g / 17.1 N

|

10.48 kg / 23.11 LBS

~0 Gs

|

| 3 mm |

9.13 kg / 20.12 LBS

8 684 Gs

|

1.37 kg / 3.02 LBS

1369 g / 13.4 N

|

8.21 kg / 18.11 LBS

~0 Gs

|

| 5 mm |

5.45 kg / 12.02 LBS

6 710 Gs

|

0.82 kg / 1.80 LBS

818 g / 8.0 N

|

4.91 kg / 10.82 LBS

~0 Gs

|

| 10 mm |

1.49 kg / 3.28 LBS

3 507 Gs

|

0.22 kg / 0.49 LBS

223 g / 2.2 N

|

1.34 kg / 2.95 LBS

~0 Gs

|

| 20 mm |

0.18 kg / 0.39 LBS

1 213 Gs

|

0.03 kg / 0.06 LBS

27 g / 0.3 N

|

0.16 kg / 0.35 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.01 LBS

190 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

126 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

88 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

64 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

48 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

37 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Hazards (electronics) - precautionary measures

MW 10x30 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 8.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 6.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 5.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 4.0 cm |

| Car key | 50 Gs (5.0 mT) | 3.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Collisions (kinetic energy) - collision effects

MW 10x30 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

10.58 km/h

(2.94 m/s)

|

0.08 J | |

| 30 mm |

18.21 km/h

(5.06 m/s)

|

0.23 J | |

| 50 mm |

23.51 km/h

(6.53 m/s)

|

0.38 J | |

| 100 mm |

33.24 km/h

(9.23 m/s)

|

0.75 J |

Table 9: Surface protection spec

MW 10x30 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 10x30 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 5 528 Mx | 55.3 µWb |

| Pc Coefficient | 1.38 | High (Stable) |

Table 11: Physics of underwater searching

MW 10x30 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.92 kg | Standard |

| Water (riverbed) |

2.20 kg

(+0.28 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Warning: On a vertical wall, the magnet holds only ~20% of its max power.

2. Efficiency vs thickness

*Thin metal sheet (e.g. computer case) severely reduces the holding force.

3. Heat tolerance

*For N38 grade, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.38

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

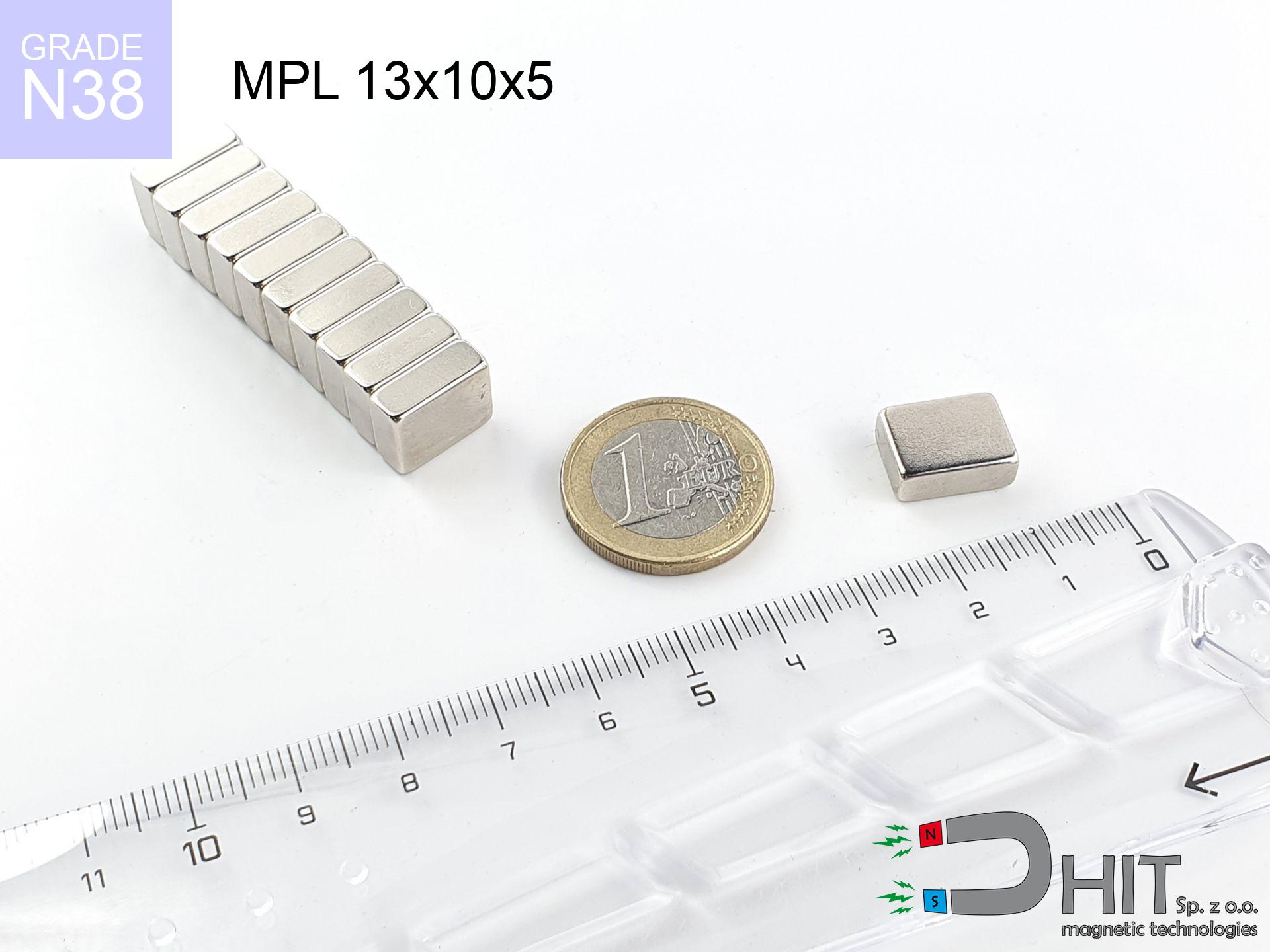

Other proposals

Strengths and weaknesses of rare earth magnets.

Pros

- Their power remains stable, and after approximately ten years it decreases only by ~1% (theoretically),

- Neodymium magnets are distinguished by extremely resistant to loss of magnetic properties caused by magnetic disturbances,

- In other words, due to the glossy layer of silver, the element looks attractive,

- The surface of neodymium magnets generates a intense magnetic field – this is a key feature,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and can work (depending on the form) even at a temperature of 230°C or more...

- Possibility of exact machining and adapting to specific applications,

- Huge importance in innovative solutions – they serve a role in mass storage devices, electromotive mechanisms, diagnostic systems, as well as multitasking production systems.

- Thanks to concentrated force, small magnets offer high operating force, with minimal size,

Cons

- Brittleness is one of their disadvantages. Upon strong impact they can fracture. We advise keeping them in a steel housing, which not only secures them against impacts but also raises their durability

- When exposed to high temperature, neodymium magnets experience a drop in force. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets usually rust. For applications outside, it is recommended to use protective magnets, such as those in rubber or plastics, which secure oxidation and corrosion.

- Due to limitations in creating threads and complex forms in magnets, we propose using cover - magnetic mechanism.

- Health risk resulting from small fragments of magnets pose a threat, when accidentally swallowed, which gains importance in the context of child safety. It is also worth noting that small elements of these devices can disrupt the diagnostic process medical in case of swallowing.

- High unit price – neodymium magnets cost more than other types of magnets (e.g. ferrite), which hinders application in large quantities

Lifting parameters

Optimal lifting capacity of a neodymium magnet – what contributes to it?

- with the use of a yoke made of low-carbon steel, guaranteeing maximum field concentration

- whose transverse dimension is min. 10 mm

- characterized by smoothness

- with total lack of distance (no coatings)

- for force applied at a right angle (pull-off, not shear)

- at room temperature

Determinants of practical lifting force of a magnet

- Distance – existence of any layer (rust, tape, gap) interrupts the magnetic circuit, which lowers capacity steeply (even by 50% at 0.5 mm).

- Load vector – highest force is obtained only during perpendicular pulling. The resistance to sliding of the magnet along the plate is usually many times lower (approx. 1/5 of the lifting capacity).

- Metal thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field passes through the material instead of converting into lifting capacity.

- Material composition – not every steel reacts the same. High carbon content weaken the attraction effect.

- Smoothness – ideal contact is obtained only on polished steel. Rough texture create air cushions, reducing force.

- Thermal factor – high temperature weakens magnetic field. Too high temperature can permanently damage the magnet.

Lifting capacity was assessed with the use of a polished steel plate of optimal thickness (min. 20 mm), under perpendicular pulling force, in contrast under parallel forces the load capacity is reduced by as much as 75%. In addition, even a slight gap between the magnet and the plate lowers the load capacity.

Safe handling of NdFeB magnets

Nickel allergy

Allergy Notice: The nickel-copper-nickel coating consists of nickel. If an allergic reaction appears, immediately stop working with magnets and use protective gear.

Crushing force

Danger of trauma: The attraction force is so great that it can result in blood blisters, crushing, and even bone fractures. Protective gloves are recommended.

Fire risk

Powder generated during grinding of magnets is combustible. Avoid drilling into magnets unless you are an expert.

Heat sensitivity

Control the heat. Heating the magnet to high heat will destroy its properties and strength.

Electronic devices

Intense magnetic fields can erase data on credit cards, HDDs, and other magnetic media. Keep a distance of min. 10 cm.

Warning for heart patients

Individuals with a ICD have to maintain an large gap from magnets. The magnetic field can interfere with the functioning of the implant.

Magnets are brittle

NdFeB magnets are ceramic materials, which means they are very brittle. Collision of two magnets leads to them shattering into shards.

Product not for children

Absolutely store magnets away from children. Choking hazard is significant, and the effects of magnets connecting inside the body are tragic.

Do not underestimate power

Use magnets with awareness. Their immense force can shock even experienced users. Be vigilant and respect their power.

Precision electronics

Remember: neodymium magnets generate a field that interferes with sensitive sensors. Maintain a safe distance from your mobile, device, and GPS.

![SM 25x175 [2xM8] / N52 - magnetic separator SM 25x175 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x175-2xm8-gif.jpg)