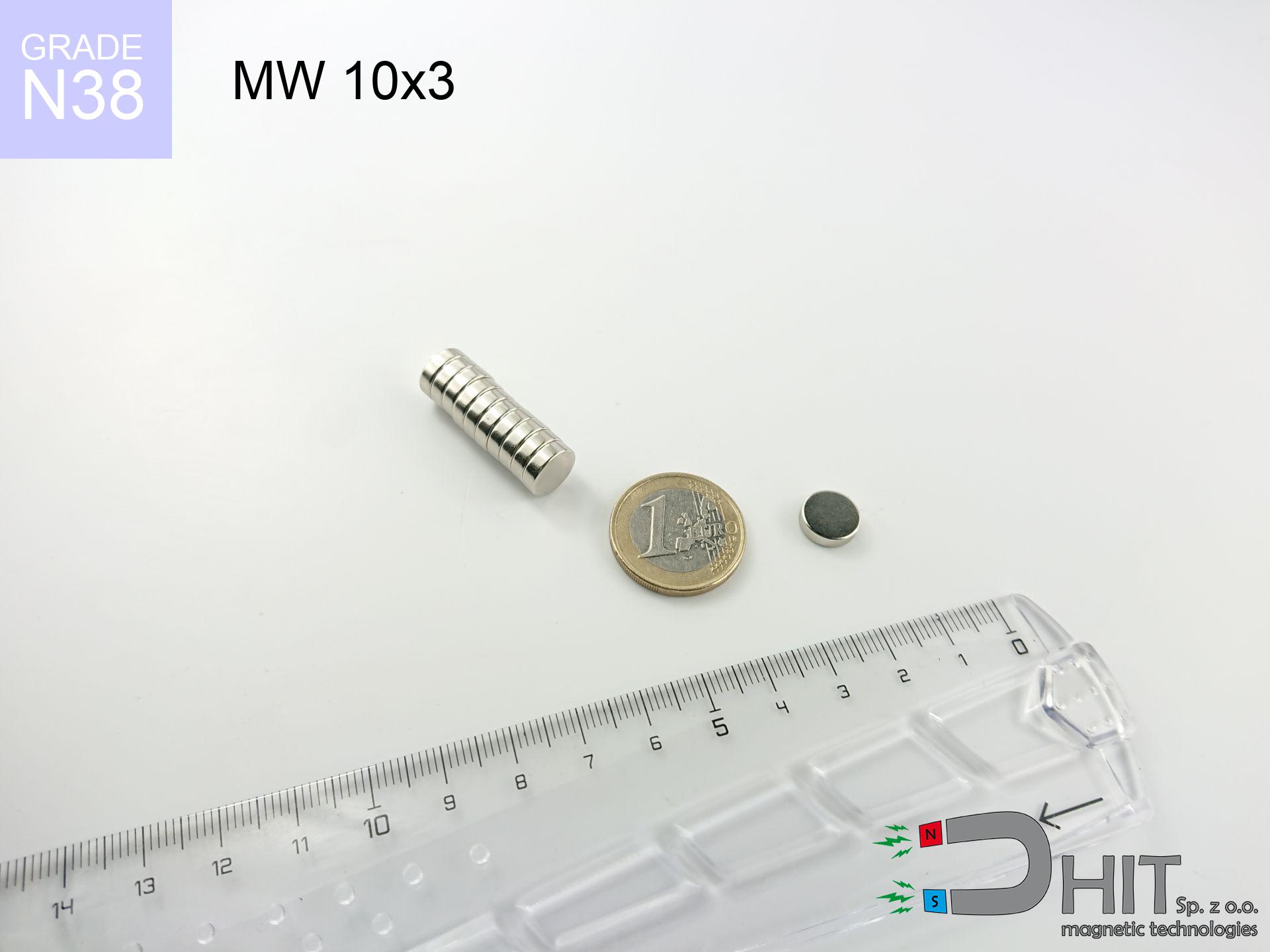

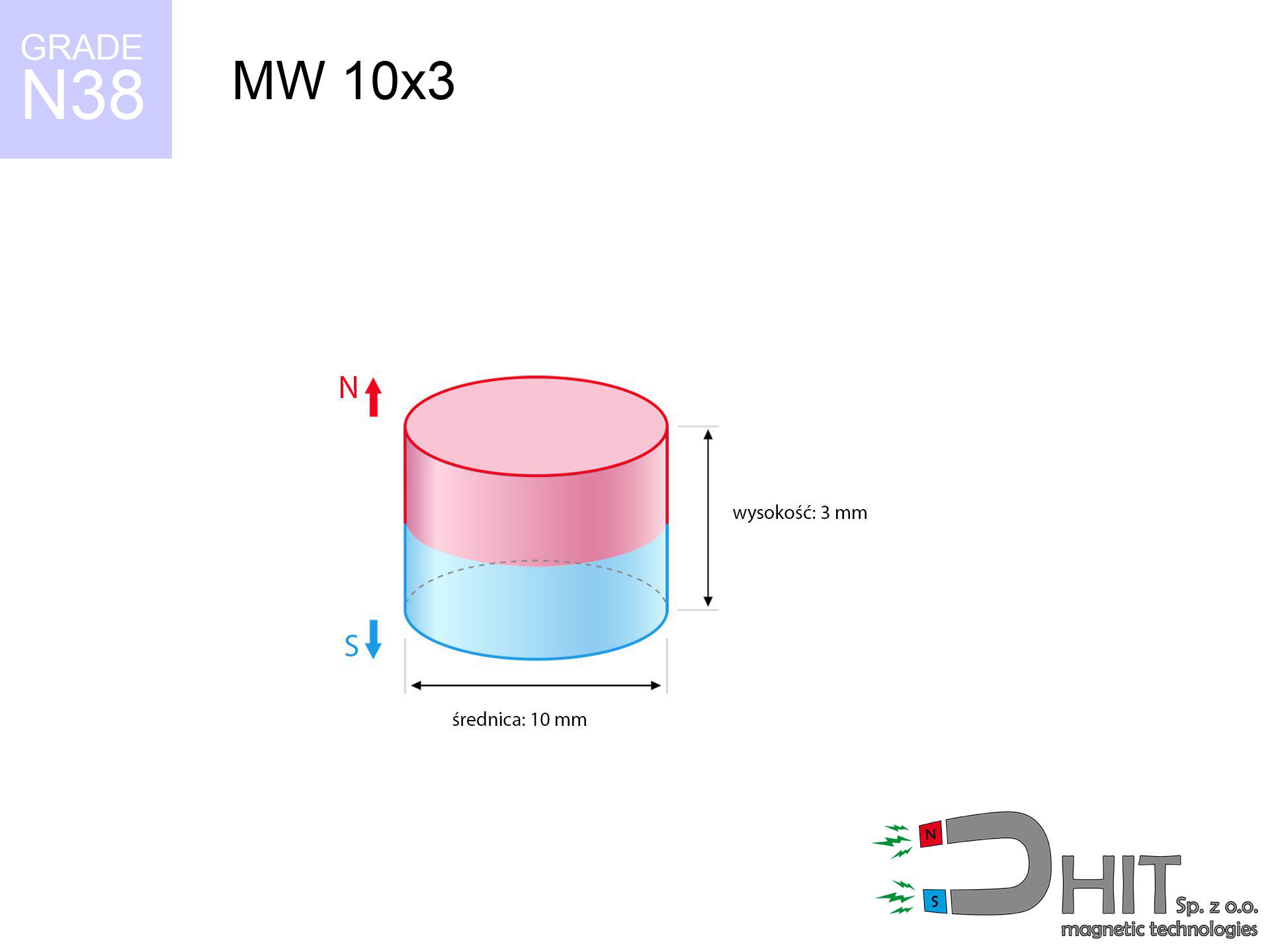

MW 10x3 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010008

GTIN/EAN: 5906301810070

Diameter Ø

10 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

1.77 g

Magnetization Direction

↑ axial

Load capacity

2.15 kg / 21.04 N

Magnetic Induction

318.70 mT / 3187 Gs

Coating

[NiCuNi] Nickel

0.726 ZŁ with VAT / pcs + price for transport

0.590 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

otherwise drop us a message through

request form

through our site.

Force as well as appearance of a magnet can be calculated on our

online calculation tool.

Same-day processing for orders placed before 14:00.

Technical data - MW 10x3 / N38 - cylindrical magnet

Specification / characteristics - MW 10x3 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010008 |

| GTIN/EAN | 5906301810070 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 10 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 1.77 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.15 kg / 21.04 N |

| Magnetic Induction ~ ? | 318.70 mT / 3187 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the product - data

The following values are the result of a physical analysis. Results were calculated on algorithms for the class Nd2Fe14B. Actual conditions may differ. Treat these calculations as a supplementary guide for designers.

Table 1: Static pull force (pull vs distance) - interaction chart

MW 10x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3185 Gs

318.5 mT

|

2.15 kg / 4.74 lbs

2150.0 g / 21.1 N

|

medium risk |

| 1 mm |

2657 Gs

265.7 mT

|

1.50 kg / 3.30 lbs

1496.2 g / 14.7 N

|

weak grip |

| 2 mm |

2081 Gs

208.1 mT

|

0.92 kg / 2.02 lbs

918.1 g / 9.0 N

|

weak grip |

| 3 mm |

1573 Gs

157.3 mT

|

0.52 kg / 1.16 lbs

524.4 g / 5.1 N

|

weak grip |

| 5 mm |

874 Gs

87.4 mT

|

0.16 kg / 0.36 lbs

161.7 g / 1.6 N

|

weak grip |

| 10 mm |

241 Gs

24.1 mT

|

0.01 kg / 0.03 lbs

12.3 g / 0.1 N

|

weak grip |

| 15 mm |

92 Gs

9.2 mT

|

0.00 kg / 0.00 lbs

1.8 g / 0.0 N

|

weak grip |

| 20 mm |

44 Gs

4.4 mT

|

0.00 kg / 0.00 lbs

0.4 g / 0.0 N

|

weak grip |

| 30 mm |

14 Gs

1.4 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

| 50 mm |

3 Gs

0.3 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

Table 2: Slippage load (wall)

MW 10x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.43 kg / 0.95 lbs

430.0 g / 4.2 N

|

| 1 mm | Stal (~0.2) |

0.30 kg / 0.66 lbs

300.0 g / 2.9 N

|

| 2 mm | Stal (~0.2) |

0.18 kg / 0.41 lbs

184.0 g / 1.8 N

|

| 3 mm | Stal (~0.2) |

0.10 kg / 0.23 lbs

104.0 g / 1.0 N

|

| 5 mm | Stal (~0.2) |

0.03 kg / 0.07 lbs

32.0 g / 0.3 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MW 10x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.64 kg / 1.42 lbs

645.0 g / 6.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.43 kg / 0.95 lbs

430.0 g / 4.2 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.22 kg / 0.47 lbs

215.0 g / 2.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.08 kg / 2.37 lbs

1075.0 g / 10.5 N

|

Table 4: Steel thickness (substrate influence) - power losses

MW 10x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.22 kg / 0.47 lbs

215.0 g / 2.1 N

|

| 1 mm |

|

0.54 kg / 1.18 lbs

537.5 g / 5.3 N

|

| 2 mm |

|

1.08 kg / 2.37 lbs

1075.0 g / 10.5 N

|

| 3 mm |

|

1.61 kg / 3.55 lbs

1612.5 g / 15.8 N

|

| 5 mm |

|

2.15 kg / 4.74 lbs

2150.0 g / 21.1 N

|

| 10 mm |

|

2.15 kg / 4.74 lbs

2150.0 g / 21.1 N

|

| 11 mm |

|

2.15 kg / 4.74 lbs

2150.0 g / 21.1 N

|

| 12 mm |

|

2.15 kg / 4.74 lbs

2150.0 g / 21.1 N

|

Table 5: Thermal stability (stability) - power drop

MW 10x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.15 kg / 4.74 lbs

2150.0 g / 21.1 N

|

OK |

| 40 °C | -2.2% |

2.10 kg / 4.64 lbs

2102.7 g / 20.6 N

|

OK |

| 60 °C | -4.4% |

2.06 kg / 4.53 lbs

2055.4 g / 20.2 N

|

|

| 80 °C | -6.6% |

2.01 kg / 4.43 lbs

2008.1 g / 19.7 N

|

|

| 100 °C | -28.8% |

1.53 kg / 3.37 lbs

1530.8 g / 15.0 N

|

Table 6: Two magnets (repulsion) - field collision

MW 10x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

4.91 kg / 10.83 lbs

4 754 Gs

|

0.74 kg / 1.62 lbs

737 g / 7.2 N

|

N/A |

| 1 mm |

4.18 kg / 9.22 lbs

5 877 Gs

|

0.63 kg / 1.38 lbs

627 g / 6.2 N

|

3.76 kg / 8.30 lbs

~0 Gs

|

| 2 mm |

3.42 kg / 7.54 lbs

5 314 Gs

|

0.51 kg / 1.13 lbs

513 g / 5.0 N

|

3.08 kg / 6.78 lbs

~0 Gs

|

| 3 mm |

2.71 kg / 5.98 lbs

4 732 Gs

|

0.41 kg / 0.90 lbs

407 g / 4.0 N

|

2.44 kg / 5.38 lbs

~0 Gs

|

| 5 mm |

1.59 kg / 3.52 lbs

3 630 Gs

|

0.24 kg / 0.53 lbs

239 g / 2.3 N

|

1.44 kg / 3.16 lbs

~0 Gs

|

| 10 mm |

0.37 kg / 0.81 lbs

1 747 Gs

|

0.06 kg / 0.12 lbs

55 g / 0.5 N

|

0.33 kg / 0.73 lbs

~0 Gs

|

| 20 mm |

0.03 kg / 0.06 lbs

483 Gs

|

0.00 kg / 0.01 lbs

4 g / 0.0 N

|

0.03 kg / 0.06 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

48 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

29 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

19 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

13 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

9 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

7 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (electronics) - warnings

MW 10x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 3.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 2.5 cm |

| Car key | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (kinetic energy) - collision effects

MW 10x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

35.27 km/h

(9.80 m/s)

|

0.08 J | |

| 30 mm |

60.88 km/h

(16.91 m/s)

|

0.25 J | |

| 50 mm |

78.60 km/h

(21.83 m/s)

|

0.42 J | |

| 100 mm |

111.15 km/h

(30.88 m/s)

|

0.84 J |

Table 9: Anti-corrosion coating durability

MW 10x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 10x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 2 694 Mx | 26.9 µWb |

| Pc Coefficient | 0.40 | Low (Flat) |

Table 11: Physics of underwater searching

MW 10x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.15 kg | Standard |

| Water (riverbed) |

2.46 kg

(+0.31 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Warning: On a vertical wall, the magnet holds merely ~20% of its nominal pull.

2. Steel thickness impact

*Thin steel (e.g. 0.5mm PC case) drastically reduces the holding force.

3. Temperature resistance

*For N38 grade, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.40

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also proposals

Pros as well as cons of rare earth magnets.

Pros

- They retain full power for around 10 years – the drop is just ~1% (according to analyses),

- Magnets perfectly resist against demagnetization caused by external fields,

- By using a smooth layer of nickel, the element gains an aesthetic look,

- Neodymium magnets deliver maximum magnetic induction on a small area, which allows for strong attraction,

- Through (adequate) combination of ingredients, they can achieve high thermal resistance, enabling action at temperatures reaching 230°C and above...

- Thanks to flexibility in shaping and the ability to modify to client solutions,

- Key role in electronics industry – they serve a role in computer drives, brushless drives, diagnostic systems, as well as technologically advanced constructions.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in tiny dimensions, which allows their use in miniature devices

Weaknesses

- Brittleness is one of their disadvantages. Upon strong impact they can fracture. We advise keeping them in a steel housing, which not only protects them against impacts but also increases their durability

- We warn that neodymium magnets can reduce their strength at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material immune to moisture, when using outdoors

- We recommend cover - magnetic mechanism, due to difficulties in producing threads inside the magnet and complex forms.

- Possible danger related to microscopic parts of magnets are risky, when accidentally swallowed, which is particularly important in the context of child health protection. It is also worth noting that tiny parts of these devices are able to be problematic in diagnostics medical when they are in the body.

- High unit price – neodymium magnets cost more than other types of magnets (e.g. ferrite), which hinders application in large quantities

Lifting parameters

Breakaway strength of the magnet in ideal conditions – what it depends on?

- with the use of a sheet made of special test steel, ensuring maximum field concentration

- whose thickness reaches at least 10 mm

- with a plane perfectly flat

- under conditions of no distance (metal-to-metal)

- for force acting at a right angle (in the magnet axis)

- in temp. approx. 20°C

Practical aspects of lifting capacity – factors

- Distance – the presence of any layer (paint, dirt, air) interrupts the magnetic circuit, which lowers capacity steeply (even by 50% at 0.5 mm).

- Load vector – highest force is reached only during perpendicular pulling. The shear force of the magnet along the surface is standardly many times smaller (approx. 1/5 of the lifting capacity).

- Metal thickness – thin material does not allow full use of the magnet. Magnetic flux passes through the material instead of converting into lifting capacity.

- Plate material – mild steel attracts best. Alloy admixtures reduce magnetic properties and lifting capacity.

- Plate texture – smooth surfaces guarantee perfect abutment, which increases force. Uneven metal weaken the grip.

- Temperature influence – high temperature reduces magnetic field. Too high temperature can permanently damage the magnet.

Lifting capacity was assessed using a smooth steel plate of optimal thickness (min. 20 mm), under vertically applied force, in contrast under parallel forces the lifting capacity is smaller. Moreover, even a minimal clearance between the magnet’s surface and the plate reduces the lifting capacity.

H&S for magnets

Keep away from electronics

Remember: neodymium magnets produce a field that disrupts precision electronics. Maintain a safe distance from your phone, device, and navigation systems.

Magnets are brittle

Neodymium magnets are sintered ceramics, meaning they are very brittle. Clashing of two magnets will cause them cracking into shards.

Dust is flammable

Machining of NdFeB material poses a fire risk. Magnetic powder oxidizes rapidly with oxygen and is hard to extinguish.

Health Danger

Individuals with a ICD have to maintain an safe separation from magnets. The magnetism can stop the functioning of the implant.

Nickel coating and allergies

Medical facts indicate that the nickel plating (the usual finish) is a strong allergen. If you have an allergy, prevent touching magnets with bare hands and select versions in plastic housing.

Keep away from children

These products are not toys. Eating a few magnets can lead to them connecting inside the digestive tract, which constitutes a critical condition and requires immediate surgery.

Power loss in heat

Standard neodymium magnets (grade N) undergo demagnetization when the temperature goes above 80°C. This process is irreversible.

Respect the power

Use magnets consciously. Their immense force can surprise even experienced users. Plan your moves and do not underestimate their force.

Magnetic media

Very strong magnetic fields can corrupt files on payment cards, HDDs, and storage devices. Stay away of min. 10 cm.

Finger safety

Risk of injury: The pulling power is so immense that it can cause blood blisters, crushing, and even bone fractures. Use thick gloves.

![SM 25x100 [2xM8] / N52 - magnetic separator SM 25x100 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x100-2xm8-fin.jpg)