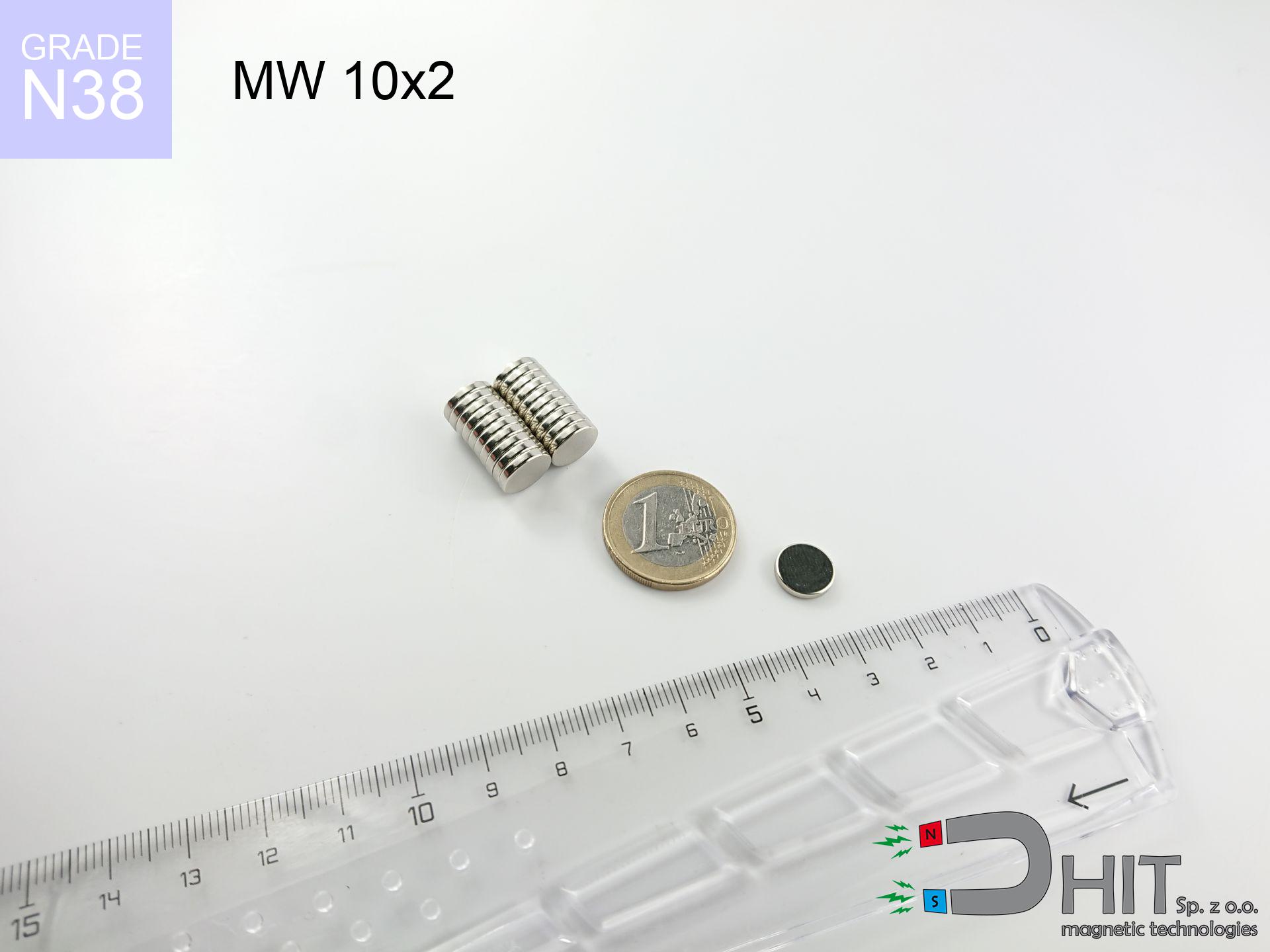

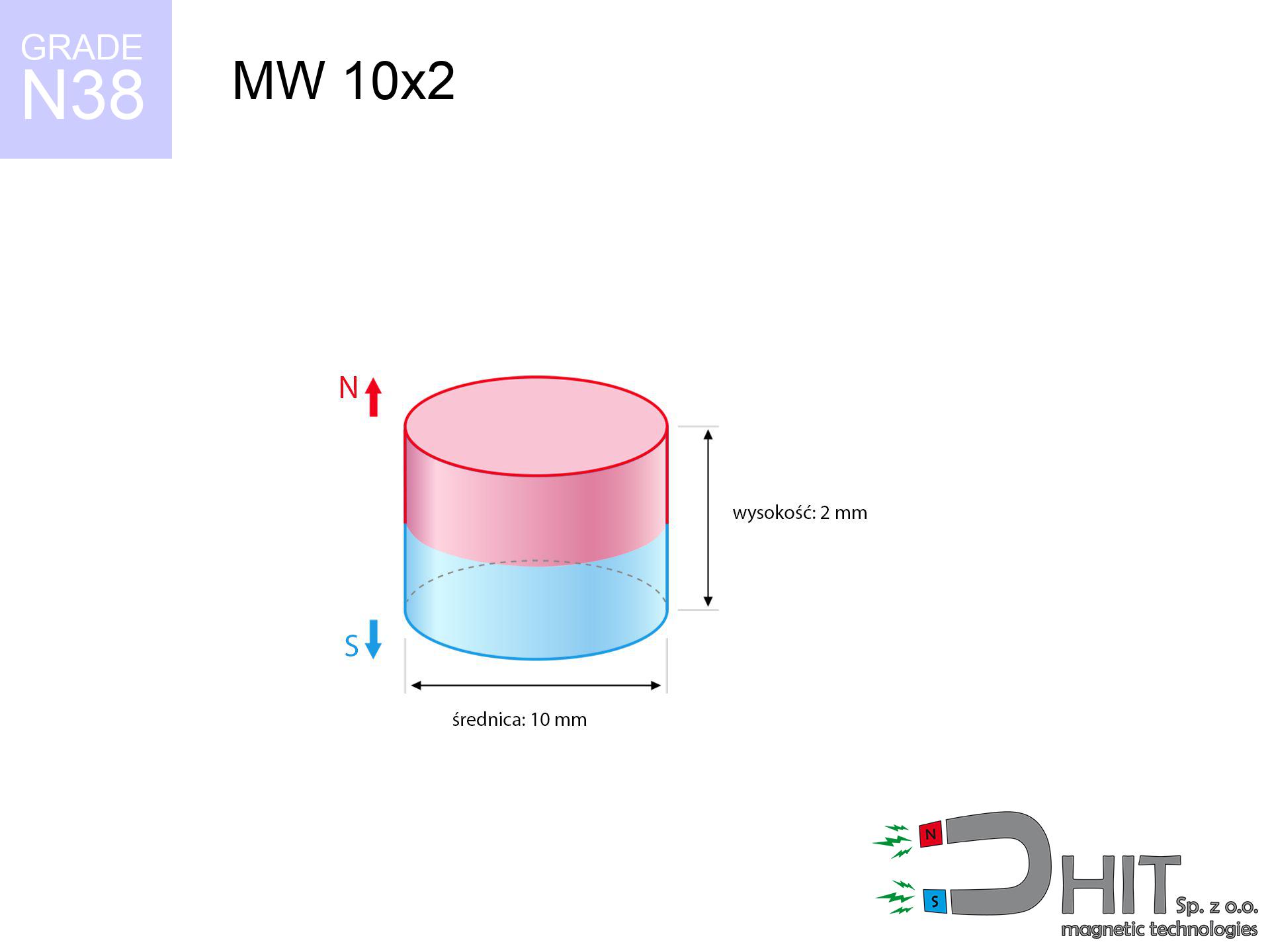

MW 10x2 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010006

GTIN/EAN: 5906301810056

Diameter Ø

10 mm [±0,1 mm]

Height

2 mm [±0,1 mm]

Weight

1.18 g

Magnetization Direction

↑ axial

Load capacity

1.27 kg / 12.50 N

Magnetic Induction

230.11 mT / 2301 Gs

Coating

[NiCuNi] Nickel

0.467 ZŁ with VAT / pcs + price for transport

0.380 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

alternatively send us a note using

our online form

the contact page.

Strength along with structure of a neodymium magnet can be estimated on our

magnetic mass calculator.

Order by 14:00 and we’ll ship today!

Technical data - MW 10x2 / N38 - cylindrical magnet

Specification / characteristics - MW 10x2 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010006 |

| GTIN/EAN | 5906301810056 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 10 mm [±0,1 mm] |

| Height | 2 mm [±0,1 mm] |

| Weight | 1.18 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.27 kg / 12.50 N |

| Magnetic Induction ~ ? | 230.11 mT / 2301 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the magnet - report

These data constitute the direct effect of a mathematical simulation. Values are based on algorithms for the class Nd2Fe14B. Operational performance may differ from theoretical values. Use these data as a preliminary roadmap during assembly planning.

Table 1: Static pull force (pull vs gap) - characteristics

MW 10x2 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2300 Gs

230.0 mT

|

1.27 kg / 2.80 pounds

1270.0 g / 12.5 N

|

safe |

| 1 mm |

1974 Gs

197.4 mT

|

0.94 kg / 2.06 pounds

935.3 g / 9.2 N

|

safe |

| 2 mm |

1570 Gs

157.0 mT

|

0.59 kg / 1.31 pounds

592.1 g / 5.8 N

|

safe |

| 3 mm |

1194 Gs

119.4 mT

|

0.34 kg / 0.75 pounds

342.3 g / 3.4 N

|

safe |

| 5 mm |

661 Gs

66.1 mT

|

0.10 kg / 0.23 pounds

104.9 g / 1.0 N

|

safe |

| 10 mm |

178 Gs

17.8 mT

|

0.01 kg / 0.02 pounds

7.6 g / 0.1 N

|

safe |

| 15 mm |

66 Gs

6.6 mT

|

0.00 kg / 0.00 pounds

1.1 g / 0.0 N

|

safe |

| 20 mm |

31 Gs

3.1 mT

|

0.00 kg / 0.00 pounds

0.2 g / 0.0 N

|

safe |

| 30 mm |

10 Gs

1.0 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

| 50 mm |

2 Gs

0.2 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

Table 2: Vertical hold (wall)

MW 10x2 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.25 kg / 0.56 pounds

254.0 g / 2.5 N

|

| 1 mm | Stal (~0.2) |

0.19 kg / 0.41 pounds

188.0 g / 1.8 N

|

| 2 mm | Stal (~0.2) |

0.12 kg / 0.26 pounds

118.0 g / 1.2 N

|

| 3 mm | Stal (~0.2) |

0.07 kg / 0.15 pounds

68.0 g / 0.7 N

|

| 5 mm | Stal (~0.2) |

0.02 kg / 0.04 pounds

20.0 g / 0.2 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MW 10x2 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.38 kg / 0.84 pounds

381.0 g / 3.7 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.25 kg / 0.56 pounds

254.0 g / 2.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.13 kg / 0.28 pounds

127.0 g / 1.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.64 kg / 1.40 pounds

635.0 g / 6.2 N

|

Table 4: Material efficiency (substrate influence) - power losses

MW 10x2 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.13 kg / 0.28 pounds

127.0 g / 1.2 N

|

| 1 mm |

|

0.32 kg / 0.70 pounds

317.5 g / 3.1 N

|

| 2 mm |

|

0.64 kg / 1.40 pounds

635.0 g / 6.2 N

|

| 3 mm |

|

0.95 kg / 2.10 pounds

952.5 g / 9.3 N

|

| 5 mm |

|

1.27 kg / 2.80 pounds

1270.0 g / 12.5 N

|

| 10 mm |

|

1.27 kg / 2.80 pounds

1270.0 g / 12.5 N

|

| 11 mm |

|

1.27 kg / 2.80 pounds

1270.0 g / 12.5 N

|

| 12 mm |

|

1.27 kg / 2.80 pounds

1270.0 g / 12.5 N

|

Table 5: Thermal stability (stability) - resistance threshold

MW 10x2 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.27 kg / 2.80 pounds

1270.0 g / 12.5 N

|

OK |

| 40 °C | -2.2% |

1.24 kg / 2.74 pounds

1242.1 g / 12.2 N

|

OK |

| 60 °C | -4.4% |

1.21 kg / 2.68 pounds

1214.1 g / 11.9 N

|

|

| 80 °C | -6.6% |

1.19 kg / 2.62 pounds

1186.2 g / 11.6 N

|

|

| 100 °C | -28.8% |

0.90 kg / 1.99 pounds

904.2 g / 8.9 N

|

Table 6: Magnet-Magnet interaction (repulsion) - forces in the system

MW 10x2 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

2.56 kg / 5.65 pounds

3 867 Gs

|

0.38 kg / 0.85 pounds

384 g / 3.8 N

|

N/A |

| 1 mm |

2.25 kg / 4.96 pounds

4 312 Gs

|

0.34 kg / 0.74 pounds

338 g / 3.3 N

|

2.03 kg / 4.46 pounds

~0 Gs

|

| 2 mm |

1.89 kg / 4.16 pounds

3 948 Gs

|

0.28 kg / 0.62 pounds

283 g / 2.8 N

|

1.70 kg / 3.74 pounds

~0 Gs

|

| 3 mm |

1.52 kg / 3.36 pounds

3 548 Gs

|

0.23 kg / 0.50 pounds

229 g / 2.2 N

|

1.37 kg / 3.02 pounds

~0 Gs

|

| 5 mm |

0.92 kg / 2.02 pounds

2 750 Gs

|

0.14 kg / 0.30 pounds

137 g / 1.3 N

|

0.82 kg / 1.82 pounds

~0 Gs

|

| 10 mm |

0.21 kg / 0.47 pounds

1 322 Gs

|

0.03 kg / 0.07 pounds

32 g / 0.3 N

|

0.19 kg / 0.42 pounds

~0 Gs

|

| 20 mm |

0.02 kg / 0.03 pounds

355 Gs

|

0.00 kg / 0.01 pounds

2 g / 0.0 N

|

0.01 kg / 0.03 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

33 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

20 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

13 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

9 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

6 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

5 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Hazards (implants) - warnings

MW 10x2 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 2.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.0 cm |

| Car key | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MW 10x2 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

33.21 km/h

(9.22 m/s)

|

0.05 J | |

| 30 mm |

57.31 km/h

(15.92 m/s)

|

0.15 J | |

| 50 mm |

73.98 km/h

(20.55 m/s)

|

0.25 J | |

| 100 mm |

104.63 km/h

(29.06 m/s)

|

0.50 J |

Table 9: Anti-corrosion coating durability

MW 10x2 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 10x2 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 2 097 Mx | 21.0 µWb |

| Pc Coefficient | 0.29 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MW 10x2 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.27 kg | Standard |

| Water (riverbed) |

1.45 kg

(+0.18 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Warning: On a vertical wall, the magnet holds merely ~20% of its perpendicular strength.

2. Steel saturation

*Thin metal sheet (e.g. computer case) significantly reduces the holding force.

3. Temperature resistance

*For N38 grade, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.29

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Strengths as well as weaknesses of neodymium magnets.

Advantages

- They do not lose power, even during nearly ten years – the decrease in strength is only ~1% (theoretically),

- They are resistant to demagnetization induced by external magnetic fields,

- In other words, due to the glossy layer of nickel, the element gains a professional look,

- The surface of neodymium magnets generates a concentrated magnetic field – this is one of their assets,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Considering the option of flexible shaping and customization to custom needs, neodymium magnets can be manufactured in a wide range of geometric configurations, which expands the range of possible applications,

- Wide application in innovative solutions – they find application in mass storage devices, motor assemblies, precision medical tools, and other advanced devices.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Weaknesses

- To avoid cracks under impact, we suggest using special steel holders. Such a solution secures the magnet and simultaneously improves its durability.

- When exposed to high temperature, neodymium magnets suffer a drop in force. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore while using outdoors, we recommend using waterproof magnets made of rubber, plastic or other material protecting against moisture

- We suggest casing - magnetic mechanism, due to difficulties in creating threads inside the magnet and complicated forms.

- Possible danger resulting from small fragments of magnets can be dangerous, if swallowed, which becomes key in the aspect of protecting the youngest. Additionally, small components of these devices are able to disrupt the diagnostic process medical after entering the body.

- With budget limitations the cost of neodymium magnets is a challenge,

Lifting parameters

Maximum lifting force for a neodymium magnet – what affects it?

- on a block made of structural steel, perfectly concentrating the magnetic flux

- whose transverse dimension reaches at least 10 mm

- with an ground contact surface

- without the slightest air gap between the magnet and steel

- for force acting at a right angle (pull-off, not shear)

- at standard ambient temperature

Practical aspects of lifting capacity – factors

- Gap between surfaces – even a fraction of a millimeter of distance (caused e.g. by veneer or dirt) diminishes the pulling force, often by half at just 0.5 mm.

- Angle of force application – maximum parameter is reached only during pulling at a 90° angle. The resistance to sliding of the magnet along the plate is usually several times smaller (approx. 1/5 of the lifting capacity).

- Steel thickness – too thin sheet causes magnetic saturation, causing part of the power to be wasted into the air.

- Material type – the best choice is pure iron steel. Cast iron may attract less.

- Base smoothness – the smoother and more polished the surface, the larger the contact zone and stronger the hold. Unevenness creates an air distance.

- Thermal conditions – NdFeB sinters have a negative temperature coefficient. When it is hot they are weaker, and in frost gain strength (up to a certain limit).

Lifting capacity was measured by applying a steel plate with a smooth surface of optimal thickness (min. 20 mm), under perpendicular detachment force, in contrast under attempts to slide the magnet the holding force is lower. In addition, even a minimal clearance between the magnet and the plate decreases the holding force.

Safe handling of neodymium magnets

Power loss in heat

Avoid heat. NdFeB magnets are sensitive to temperature. If you need operation above 80°C, ask us about special high-temperature series (H, SH, UH).

Medical interference

Warning for patients: Strong magnetic fields disrupt electronics. Maintain at least 30 cm distance or ask another person to handle the magnets.

Handling rules

Use magnets consciously. Their immense force can shock even professionals. Be vigilant and respect their force.

Hand protection

Big blocks can crush fingers in a fraction of a second. Never put your hand between two attracting surfaces.

Flammability

Powder generated during cutting of magnets is combustible. Do not drill into magnets unless you are an expert.

Protect data

Equipment safety: Strong magnets can ruin payment cards and sensitive devices (pacemakers, hearing aids, timepieces).

Beware of splinters

Despite the nickel coating, neodymium is brittle and cannot withstand shocks. Do not hit, as the magnet may crumble into sharp, dangerous pieces.

Impact on smartphones

GPS units and smartphones are highly sensitive to magnetism. Direct contact with a powerful NdFeB magnet can ruin the sensors in your phone.

Nickel coating and allergies

Some people have a hypersensitivity to nickel, which is the standard coating for neodymium magnets. Extended handling might lead to a rash. We recommend wear protective gloves.

Swallowing risk

Neodymium magnets are not intended for children. Swallowing multiple magnets can lead to them connecting inside the digestive tract, which poses a critical condition and requires urgent medical intervention.

![SM 32x200 [2xM8] / N52 - magnetic separator SM 32x200 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x200-2xm8-tus.jpg)