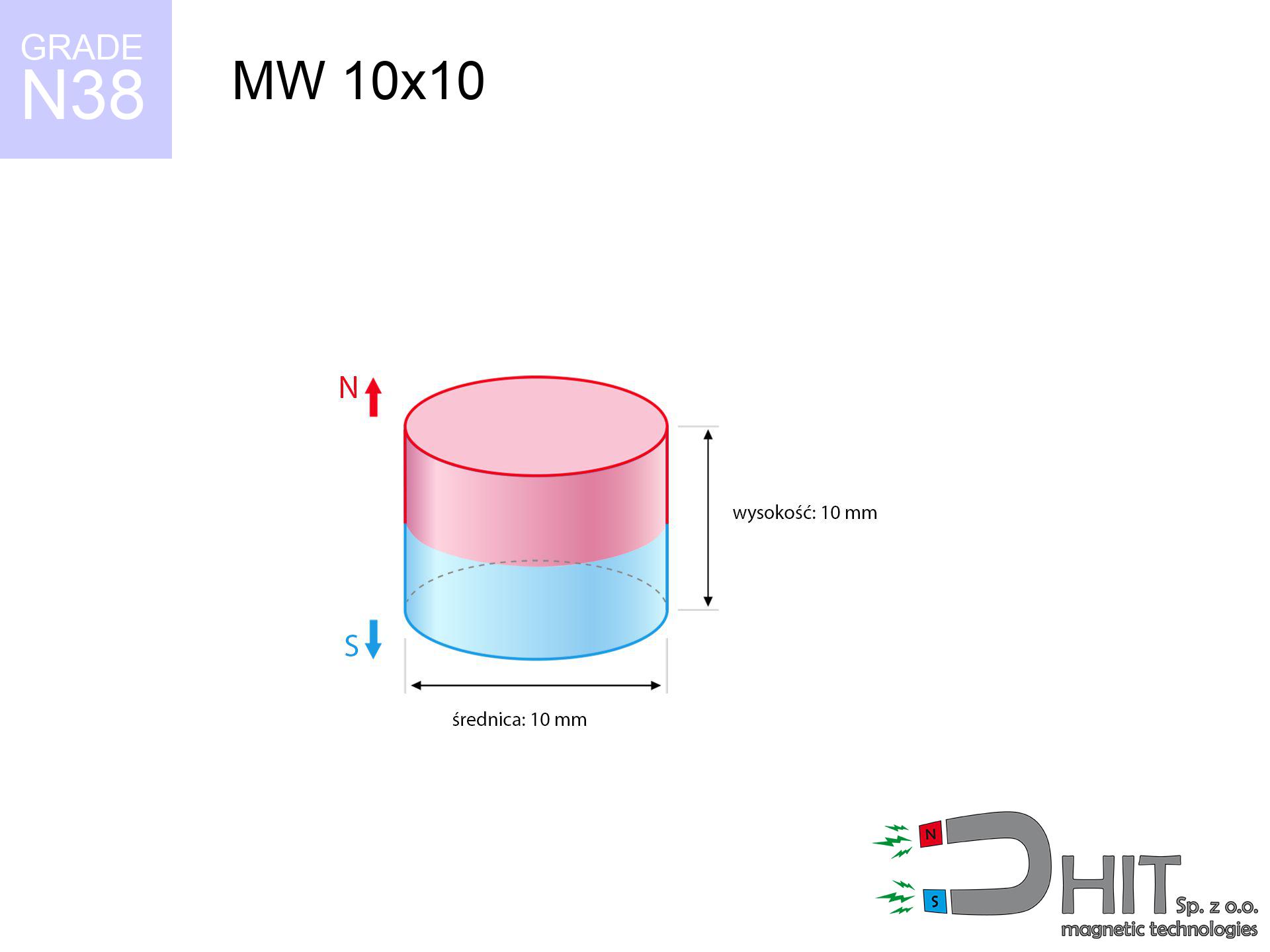

MW 10x10 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010004

GTIN/EAN: 5906301810032

Diameter Ø

10 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

5.89 g

Magnetization Direction

↑ axial

Load capacity

3.18 kg / 31.15 N

Magnetic Induction

553.84 mT / 5538 Gs

Coating

[NiCuNi] Nickel

4.31 ZŁ with VAT / pcs + price for transport

3.50 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

or contact us through

contact form

the contact section.

Weight along with shape of magnetic components can be tested with our

online calculation tool.

Order by 14:00 and we’ll ship today!

Physical properties - MW 10x10 / N38 - cylindrical magnet

Specification / characteristics - MW 10x10 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010004 |

| GTIN/EAN | 5906301810032 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 10 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 5.89 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 3.18 kg / 31.15 N |

| Magnetic Induction ~ ? | 553.84 mT / 5538 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the product - report

Presented data represent the direct effect of a mathematical simulation. Values were calculated on algorithms for the class Nd2Fe14B. Actual performance may differ. Please consider these calculations as a reference point during assembly planning.

Table 1: Static force (force vs distance) - interaction chart

MW 10x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5534 Gs

553.4 mT

|

3.18 kg / 7.01 pounds

3180.0 g / 31.2 N

|

warning |

| 1 mm |

4428 Gs

442.8 mT

|

2.04 kg / 4.49 pounds

2036.1 g / 20.0 N

|

warning |

| 2 mm |

3420 Gs

342.0 mT

|

1.21 kg / 2.68 pounds

1214.8 g / 11.9 N

|

low risk |

| 3 mm |

2597 Gs

259.7 mT

|

0.70 kg / 1.54 pounds

700.2 g / 6.9 N

|

low risk |

| 5 mm |

1498 Gs

149.8 mT

|

0.23 kg / 0.51 pounds

232.9 g / 2.3 N

|

low risk |

| 10 mm |

469 Gs

46.9 mT

|

0.02 kg / 0.05 pounds

22.9 g / 0.2 N

|

low risk |

| 15 mm |

198 Gs

19.8 mT

|

0.00 kg / 0.01 pounds

4.1 g / 0.0 N

|

low risk |

| 20 mm |

101 Gs

10.1 mT

|

0.00 kg / 0.00 pounds

1.1 g / 0.0 N

|

low risk |

| 30 mm |

36 Gs

3.6 mT

|

0.00 kg / 0.00 pounds

0.1 g / 0.0 N

|

low risk |

| 50 mm |

9 Gs

0.9 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

low risk |

Table 2: Vertical capacity (wall)

MW 10x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.64 kg / 1.40 pounds

636.0 g / 6.2 N

|

| 1 mm | Stal (~0.2) |

0.41 kg / 0.90 pounds

408.0 g / 4.0 N

|

| 2 mm | Stal (~0.2) |

0.24 kg / 0.53 pounds

242.0 g / 2.4 N

|

| 3 mm | Stal (~0.2) |

0.14 kg / 0.31 pounds

140.0 g / 1.4 N

|

| 5 mm | Stal (~0.2) |

0.05 kg / 0.10 pounds

46.0 g / 0.5 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.01 pounds

4.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MW 10x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.95 kg / 2.10 pounds

954.0 g / 9.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.64 kg / 1.40 pounds

636.0 g / 6.2 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.32 kg / 0.70 pounds

318.0 g / 3.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.59 kg / 3.51 pounds

1590.0 g / 15.6 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MW 10x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.32 kg / 0.70 pounds

318.0 g / 3.1 N

|

| 1 mm |

|

0.80 kg / 1.75 pounds

795.0 g / 7.8 N

|

| 2 mm |

|

1.59 kg / 3.51 pounds

1590.0 g / 15.6 N

|

| 3 mm |

|

2.39 kg / 5.26 pounds

2385.0 g / 23.4 N

|

| 5 mm |

|

3.18 kg / 7.01 pounds

3180.0 g / 31.2 N

|

| 10 mm |

|

3.18 kg / 7.01 pounds

3180.0 g / 31.2 N

|

| 11 mm |

|

3.18 kg / 7.01 pounds

3180.0 g / 31.2 N

|

| 12 mm |

|

3.18 kg / 7.01 pounds

3180.0 g / 31.2 N

|

Table 5: Working in heat (stability) - thermal limit

MW 10x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

3.18 kg / 7.01 pounds

3180.0 g / 31.2 N

|

OK |

| 40 °C | -2.2% |

3.11 kg / 6.86 pounds

3110.0 g / 30.5 N

|

OK |

| 60 °C | -4.4% |

3.04 kg / 6.70 pounds

3040.1 g / 29.8 N

|

OK |

| 80 °C | -6.6% |

2.97 kg / 6.55 pounds

2970.1 g / 29.1 N

|

|

| 100 °C | -28.8% |

2.26 kg / 4.99 pounds

2264.2 g / 22.2 N

|

Table 6: Two magnets (attraction) - forces in the system

MW 10x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

14.83 kg / 32.69 pounds

6 003 Gs

|

2.22 kg / 4.90 pounds

2224 g / 21.8 N

|

N/A |

| 1 mm |

12.01 kg / 26.48 pounds

9 962 Gs

|

1.80 kg / 3.97 pounds

1802 g / 17.7 N

|

10.81 kg / 23.83 pounds

~0 Gs

|

| 2 mm |

9.50 kg / 20.93 pounds

8 857 Gs

|

1.42 kg / 3.14 pounds

1424 g / 14.0 N

|

8.55 kg / 18.84 pounds

~0 Gs

|

| 3 mm |

7.38 kg / 16.27 pounds

7 809 Gs

|

1.11 kg / 2.44 pounds

1107 g / 10.9 N

|

6.64 kg / 14.64 pounds

~0 Gs

|

| 5 mm |

4.31 kg / 9.50 pounds

5 968 Gs

|

0.65 kg / 1.43 pounds

647 g / 6.3 N

|

3.88 kg / 8.55 pounds

~0 Gs

|

| 10 mm |

1.09 kg / 2.39 pounds

2 996 Gs

|

0.16 kg / 0.36 pounds

163 g / 1.6 N

|

0.98 kg / 2.16 pounds

~0 Gs

|

| 20 mm |

0.11 kg / 0.24 pounds

939 Gs

|

0.02 kg / 0.04 pounds

16 g / 0.2 N

|

0.10 kg / 0.21 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

116 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

73 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

49 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

34 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

25 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

19 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Safety (HSE) (electronics) - warnings

MW 10x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 4.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.0 cm |

| Car key | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (cracking risk) - collision effects

MW 10x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

23.54 km/h

(6.54 m/s)

|

0.13 J | |

| 30 mm |

40.59 km/h

(11.27 m/s)

|

0.37 J | |

| 50 mm |

52.40 km/h

(14.56 m/s)

|

0.62 J | |

| 100 mm |

74.10 km/h

(20.58 m/s)

|

1.25 J |

Table 9: Corrosion resistance

MW 10x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 10x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 4 481 Mx | 44.8 µWb |

| Pc Coefficient | 0.89 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MW 10x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 3.18 kg | Standard |

| Water (riverbed) |

3.64 kg

(+0.46 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Warning: On a vertical wall, the magnet holds just ~20% of its max power.

2. Plate thickness effect

*Thin metal sheet (e.g. computer case) drastically limits the holding force.

3. Heat tolerance

*For N38 grade, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.89

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Strengths as well as weaknesses of rare earth magnets.

Advantages

- They do not lose power, even during nearly ten years – the reduction in lifting capacity is only ~1% (according to tests),

- They are noted for resistance to demagnetization induced by external magnetic fields,

- In other words, due to the aesthetic layer of gold, the element gains a professional look,

- Magnetic induction on the working layer of the magnet turns out to be very high,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Thanks to versatility in forming and the capacity to modify to client solutions,

- Versatile presence in electronics industry – they serve a role in magnetic memories, electric motors, medical devices, also complex engineering applications.

- Thanks to efficiency per cm³, small magnets offer high operating force, with minimal size,

Cons

- To avoid cracks upon strong impacts, we suggest using special steel housings. Such a solution protects the magnet and simultaneously increases its durability.

- Neodymium magnets decrease their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material stable to moisture, when using outdoors

- Due to limitations in creating threads and complex forms in magnets, we recommend using cover - magnetic mount.

- Health risk related to microscopic parts of magnets are risky, if swallowed, which becomes key in the context of child safety. Additionally, small components of these products are able to disrupt the diagnostic process medical after entering the body.

- Due to complex production process, their price exceeds standard values,

Pull force analysis

Maximum lifting capacity of the magnet – what affects it?

- with the use of a sheet made of low-carbon steel, ensuring maximum field concentration

- whose transverse dimension is min. 10 mm

- with an ground touching surface

- without the slightest insulating layer between the magnet and steel

- for force applied at a right angle (in the magnet axis)

- at temperature approx. 20 degrees Celsius

Key elements affecting lifting force

- Space between surfaces – even a fraction of a millimeter of separation (caused e.g. by veneer or unevenness) drastically reduces the magnet efficiency, often by half at just 0.5 mm.

- Loading method – declared lifting capacity refers to pulling vertically. When applying parallel force, the magnet exhibits significantly lower power (often approx. 20-30% of nominal force).

- Steel thickness – too thin sheet causes magnetic saturation, causing part of the flux to be wasted to the other side.

- Steel grade – ideal substrate is high-permeability steel. Hardened steels may generate lower lifting capacity.

- Base smoothness – the more even the surface, the better the adhesion and stronger the hold. Roughness acts like micro-gaps.

- Temperature influence – high temperature weakens pulling force. Exceeding the limit temperature can permanently demagnetize the magnet.

Holding force was tested on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, whereas under shearing force the load capacity is reduced by as much as 75%. Additionally, even a slight gap between the magnet’s surface and the plate decreases the load capacity.

Safety rules for work with NdFeB magnets

Do not drill into magnets

Machining of neodymium magnets carries a risk of fire hazard. Magnetic powder reacts violently with oxygen and is hard to extinguish.

Warning for heart patients

People with a pacemaker have to keep an absolute distance from magnets. The magnetism can stop the operation of the implant.

Avoid contact if allergic

Studies show that the nickel plating (standard magnet coating) is a potent allergen. If your skin reacts to metals, refrain from touching magnets with bare hands or opt for encased magnets.

Power loss in heat

Avoid heat. Neodymium magnets are susceptible to heat. If you need resistance above 80°C, ask us about HT versions (H, SH, UH).

Risk of cracking

Neodymium magnets are ceramic materials, meaning they are fragile like glass. Collision of two magnets will cause them shattering into small pieces.

Magnetic media

Equipment safety: Strong magnets can ruin data carriers and sensitive devices (heart implants, hearing aids, timepieces).

GPS and phone interference

A strong magnetic field negatively affects the operation of compasses in smartphones and GPS navigation. Maintain magnets close to a device to avoid breaking the sensors.

Product not for children

These products are not suitable for play. Accidental ingestion of multiple magnets can lead to them pinching intestinal walls, which constitutes a direct threat to life and necessitates immediate surgery.

Bone fractures

Pinching hazard: The attraction force is so immense that it can result in blood blisters, crushing, and even bone fractures. Protective gloves are recommended.

Safe operation

Handle magnets consciously. Their powerful strength can surprise even experienced users. Stay alert and respect their force.

![SM 32x250 [2xM8] / N42 - magnetic separator SM 32x250 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x250-2xm8-kex.jpg)