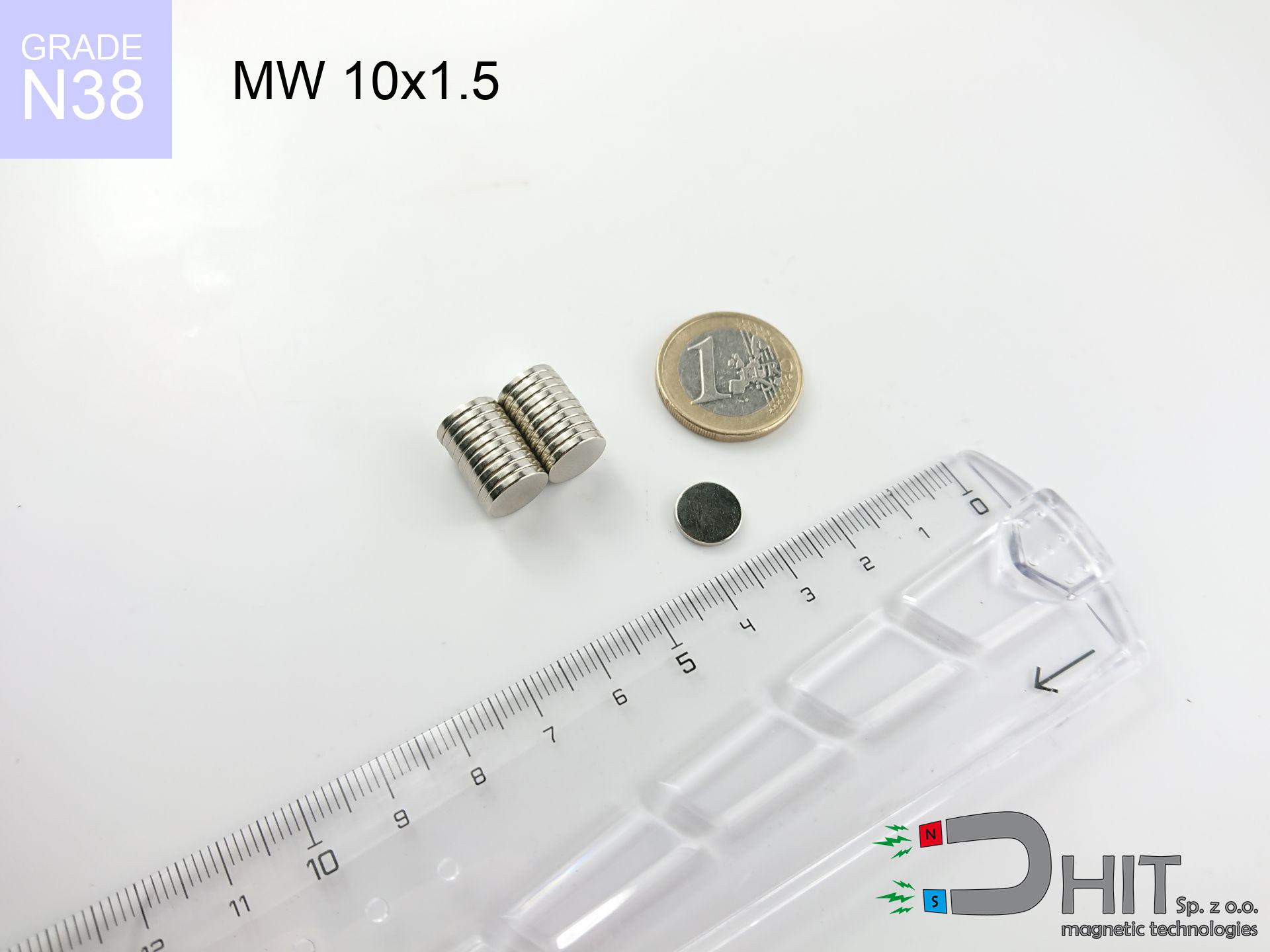

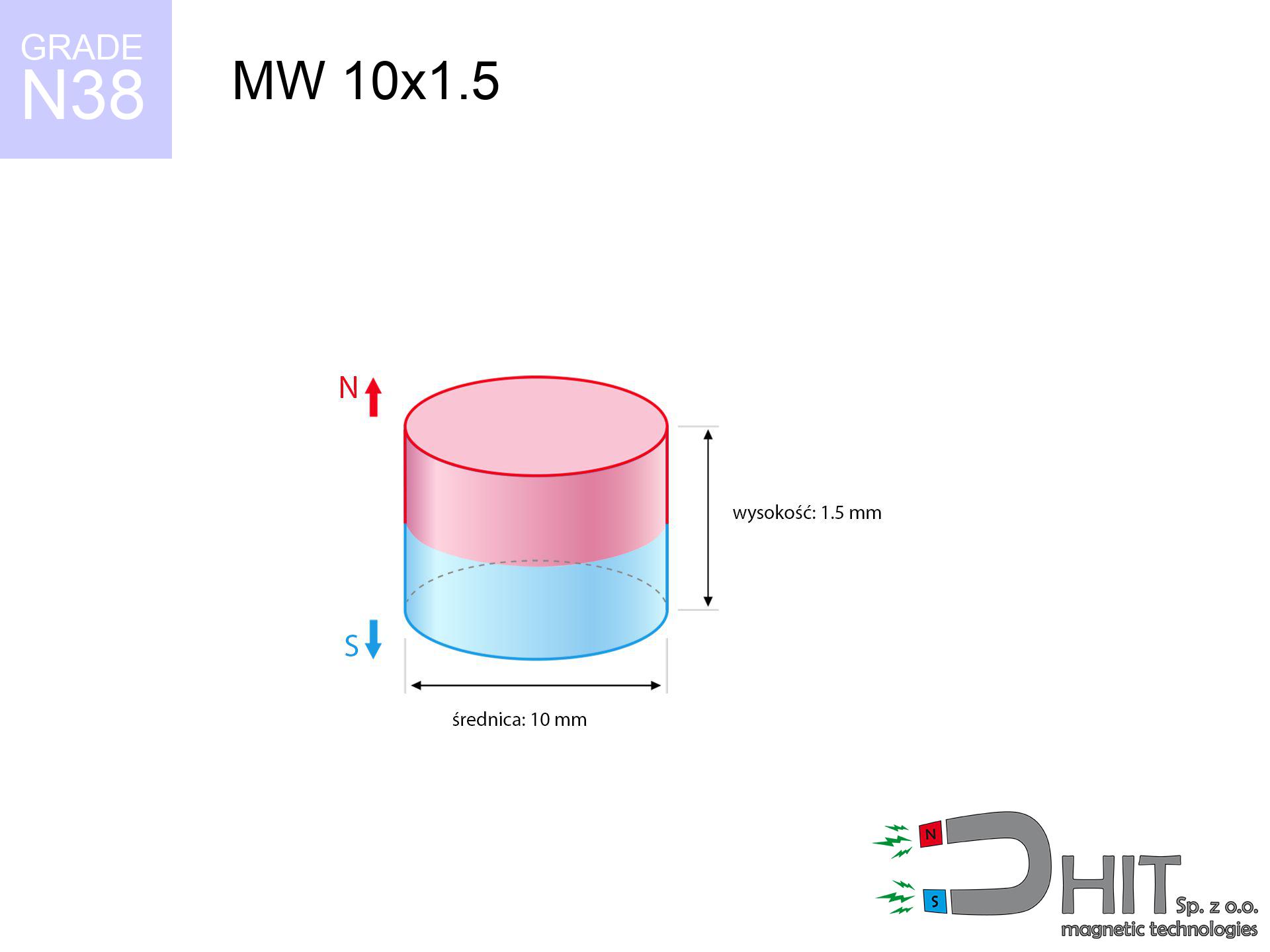

MW 10x1.5 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010003

GTIN/EAN: 5906301810001

Diameter Ø

10 mm [±0,1 mm]

Height

1.5 mm [±0,1 mm]

Weight

0.88 g

Magnetization Direction

↑ axial

Load capacity

0.82 kg / 8.01 N

Magnetic Induction

178.06 mT / 1781 Gs

Coating

[NiCuNi] Nickel

0.431 ZŁ with VAT / pcs + price for transport

0.350 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

otherwise send us a note via

inquiry form

the contact section.

Strength along with structure of magnets can be checked using our

magnetic mass calculator.

Orders placed before 14:00 will be shipped the same business day.

Physical properties - MW 10x1.5 / N38 - cylindrical magnet

Specification / characteristics - MW 10x1.5 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010003 |

| GTIN/EAN | 5906301810001 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 10 mm [±0,1 mm] |

| Height | 1.5 mm [±0,1 mm] |

| Weight | 0.88 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.82 kg / 8.01 N |

| Magnetic Induction ~ ? | 178.06 mT / 1781 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the assembly - technical parameters

Presented data are the result of a mathematical simulation. Results were calculated on algorithms for the material Nd2Fe14B. Operational performance may deviate from the simulation results. Please consider these calculations as a supplementary guide when designing systems.

Table 1: Static pull force (pull vs gap) - characteristics

MW 10x1.5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1780 Gs

178.0 mT

|

0.82 kg / 1.81 lbs

820.0 g / 8.0 N

|

low risk |

| 1 mm |

1557 Gs

155.7 mT

|

0.63 kg / 1.38 lbs

627.2 g / 6.2 N

|

low risk |

| 2 mm |

1253 Gs

125.3 mT

|

0.41 kg / 0.90 lbs

406.2 g / 4.0 N

|

low risk |

| 3 mm |

958 Gs

95.8 mT

|

0.24 kg / 0.52 lbs

237.4 g / 2.3 N

|

low risk |

| 5 mm |

530 Gs

53.0 mT

|

0.07 kg / 0.16 lbs

72.8 g / 0.7 N

|

low risk |

| 10 mm |

140 Gs

14.0 mT

|

0.01 kg / 0.01 lbs

5.1 g / 0.1 N

|

low risk |

| 15 mm |

52 Gs

5.2 mT

|

0.00 kg / 0.00 lbs

0.7 g / 0.0 N

|

low risk |

| 20 mm |

24 Gs

2.4 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

low risk |

| 30 mm |

8 Gs

0.8 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

low risk |

| 50 mm |

2 Gs

0.2 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

low risk |

Table 2: Vertical capacity (vertical surface)

MW 10x1.5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.16 kg / 0.36 lbs

164.0 g / 1.6 N

|

| 1 mm | Stal (~0.2) |

0.13 kg / 0.28 lbs

126.0 g / 1.2 N

|

| 2 mm | Stal (~0.2) |

0.08 kg / 0.18 lbs

82.0 g / 0.8 N

|

| 3 mm | Stal (~0.2) |

0.05 kg / 0.11 lbs

48.0 g / 0.5 N

|

| 5 mm | Stal (~0.2) |

0.01 kg / 0.03 lbs

14.0 g / 0.1 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MW 10x1.5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.25 kg / 0.54 lbs

246.0 g / 2.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.16 kg / 0.36 lbs

164.0 g / 1.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.08 kg / 0.18 lbs

82.0 g / 0.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.41 kg / 0.90 lbs

410.0 g / 4.0 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MW 10x1.5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.08 kg / 0.18 lbs

82.0 g / 0.8 N

|

| 1 mm |

|

0.21 kg / 0.45 lbs

205.0 g / 2.0 N

|

| 2 mm |

|

0.41 kg / 0.90 lbs

410.0 g / 4.0 N

|

| 3 mm |

|

0.62 kg / 1.36 lbs

615.0 g / 6.0 N

|

| 5 mm |

|

0.82 kg / 1.81 lbs

820.0 g / 8.0 N

|

| 10 mm |

|

0.82 kg / 1.81 lbs

820.0 g / 8.0 N

|

| 11 mm |

|

0.82 kg / 1.81 lbs

820.0 g / 8.0 N

|

| 12 mm |

|

0.82 kg / 1.81 lbs

820.0 g / 8.0 N

|

Table 5: Thermal stability (stability) - thermal limit

MW 10x1.5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.82 kg / 1.81 lbs

820.0 g / 8.0 N

|

OK |

| 40 °C | -2.2% |

0.80 kg / 1.77 lbs

802.0 g / 7.9 N

|

OK |

| 60 °C | -4.4% |

0.78 kg / 1.73 lbs

783.9 g / 7.7 N

|

|

| 80 °C | -6.6% |

0.77 kg / 1.69 lbs

765.9 g / 7.5 N

|

|

| 100 °C | -28.8% |

0.58 kg / 1.29 lbs

583.8 g / 5.7 N

|

Table 6: Magnet-Magnet interaction (attraction) - field range

MW 10x1.5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

1.53 kg / 3.38 lbs

3 185 Gs

|

0.23 kg / 0.51 lbs

230 g / 2.3 N

|

N/A |

| 1 mm |

1.38 kg / 3.03 lbs

3 371 Gs

|

0.21 kg / 0.45 lbs

206 g / 2.0 N

|

1.24 kg / 2.73 lbs

~0 Gs

|

| 2 mm |

1.17 kg / 2.59 lbs

3 114 Gs

|

0.18 kg / 0.39 lbs

176 g / 1.7 N

|

1.06 kg / 2.33 lbs

~0 Gs

|

| 3 mm |

0.96 kg / 2.12 lbs

2 817 Gs

|

0.14 kg / 0.32 lbs

144 g / 1.4 N

|

0.86 kg / 1.91 lbs

~0 Gs

|

| 5 mm |

0.59 kg / 1.29 lbs

2 201 Gs

|

0.09 kg / 0.19 lbs

88 g / 0.9 N

|

0.53 kg / 1.16 lbs

~0 Gs

|

| 10 mm |

0.14 kg / 0.30 lbs

1 060 Gs

|

0.02 kg / 0.05 lbs

20 g / 0.2 N

|

0.12 kg / 0.27 lbs

~0 Gs

|

| 20 mm |

0.01 kg / 0.02 lbs

281 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

26 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

15 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

10 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

7 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

5 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

4 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (electronics) - warnings

MW 10x1.5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 3.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 2.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.0 cm |

| Car key | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MW 10x1.5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

30.91 km/h

(8.58 m/s)

|

0.03 J | |

| 30 mm |

53.32 km/h

(14.81 m/s)

|

0.10 J | |

| 50 mm |

68.84 km/h

(19.12 m/s)

|

0.16 J | |

| 100 mm |

97.35 km/h

(27.04 m/s)

|

0.32 J |

Table 9: Corrosion resistance

MW 10x1.5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 10x1.5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 717 Mx | 17.2 µWb |

| Pc Coefficient | 0.22 | Low (Flat) |

Table 11: Submerged application

MW 10x1.5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.82 kg | Standard |

| Water (riverbed) |

0.94 kg

(+0.12 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Warning: On a vertical wall, the magnet retains just approx. 20-30% of its nominal pull.

2. Plate thickness effect

*Thin metal sheet (e.g. computer case) drastically reduces the holding force.

3. Heat tolerance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.22

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also proposals

Advantages and disadvantages of rare earth magnets.

Pros

- They do not lose power, even during nearly ten years – the reduction in lifting capacity is only ~1% (theoretically),

- Neodymium magnets are characterized by extremely resistant to magnetic field loss caused by external magnetic fields,

- In other words, due to the smooth surface of nickel, the element is aesthetically pleasing,

- They feature high magnetic induction at the operating surface, which improves attraction properties,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can function (depending on the form) even at a temperature of 230°C or more...

- Possibility of detailed forming as well as adapting to concrete conditions,

- Key role in modern industrial fields – they are commonly used in data components, drive modules, precision medical tools, and multitasking production systems.

- Relatively small size with high pulling force – neodymium magnets offer high power in compact dimensions, which makes them useful in miniature devices

Cons

- They are fragile upon heavy impacts. To avoid cracks, it is worth securing magnets in special housings. Such protection not only shields the magnet but also improves its resistance to damage

- NdFeB magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- They rust in a humid environment. For use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- Limited ability of making nuts in the magnet and complicated shapes - recommended is a housing - magnetic holder.

- Possible danger related to microscopic parts of magnets pose a threat, when accidentally swallowed, which is particularly important in the aspect of protecting the youngest. Additionally, small elements of these products can complicate diagnosis medical in case of swallowing.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Holding force characteristics

Best holding force of the magnet in ideal parameters – what contributes to it?

- on a base made of structural steel, effectively closing the magnetic field

- with a thickness minimum 10 mm

- with a plane cleaned and smooth

- without the slightest insulating layer between the magnet and steel

- under axial force vector (90-degree angle)

- in neutral thermal conditions

Lifting capacity in practice – influencing factors

- Distance – existence of foreign body (paint, dirt, gap) interrupts the magnetic circuit, which reduces capacity rapidly (even by 50% at 0.5 mm).

- Force direction – catalog parameter refers to pulling vertically. When slipping, the magnet exhibits much less (often approx. 20-30% of maximum force).

- Substrate thickness – to utilize 100% power, the steel must be adequately massive. Paper-thin metal limits the attraction force (the magnet "punches through" it).

- Material composition – different alloys attracts identically. High carbon content weaken the attraction effect.

- Plate texture – smooth surfaces ensure maximum contact, which increases field saturation. Rough surfaces weaken the grip.

- Operating temperature – neodymium magnets have a negative temperature coefficient. When it is hot they lose power, and at low temperatures they can be stronger (up to a certain limit).

Holding force was measured on the plate surface of 20 mm thickness, when a perpendicular force was applied, whereas under parallel forces the holding force is lower. In addition, even a small distance between the magnet and the plate decreases the holding force.

Safe handling of NdFeB magnets

Fragile material

Protect your eyes. Magnets can fracture upon uncontrolled impact, ejecting shards into the air. We recommend safety glasses.

Physical harm

Mind your fingers. Two large magnets will join immediately with a force of massive weight, destroying anything in their path. Exercise extreme caution!

Caution required

Before starting, check safety instructions. Sudden snapping can destroy the magnet or hurt your hand. Be predictive.

Medical implants

Warning for patients: Powerful magnets affect medical devices. Keep minimum 30 cm distance or request help to work with the magnets.

Combustion hazard

Mechanical processing of neodymium magnets carries a risk of fire risk. Neodymium dust oxidizes rapidly with oxygen and is difficult to extinguish.

Adults only

NdFeB magnets are not intended for children. Accidental ingestion of several magnets can lead to them attracting across intestines, which constitutes a critical condition and necessitates urgent medical intervention.

Safe distance

Do not bring magnets near a wallet, laptop, or TV. The magnetism can permanently damage these devices and erase data from cards.

Thermal limits

Do not overheat. NdFeB magnets are sensitive to temperature. If you require operation above 80°C, inquire about special high-temperature series (H, SH, UH).

Avoid contact if allergic

Warning for allergy sufferers: The nickel-copper-nickel coating contains nickel. If an allergic reaction occurs, immediately stop working with magnets and use protective gear.

Threat to navigation

Navigation devices and mobile phones are highly sensitive to magnetism. Close proximity with a powerful NdFeB magnet can permanently damage the sensors in your phone.

![SM 25x375 [2xM8] / N52 - magnetic separator SM 25x375 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x375-2xm8-soh.jpg)