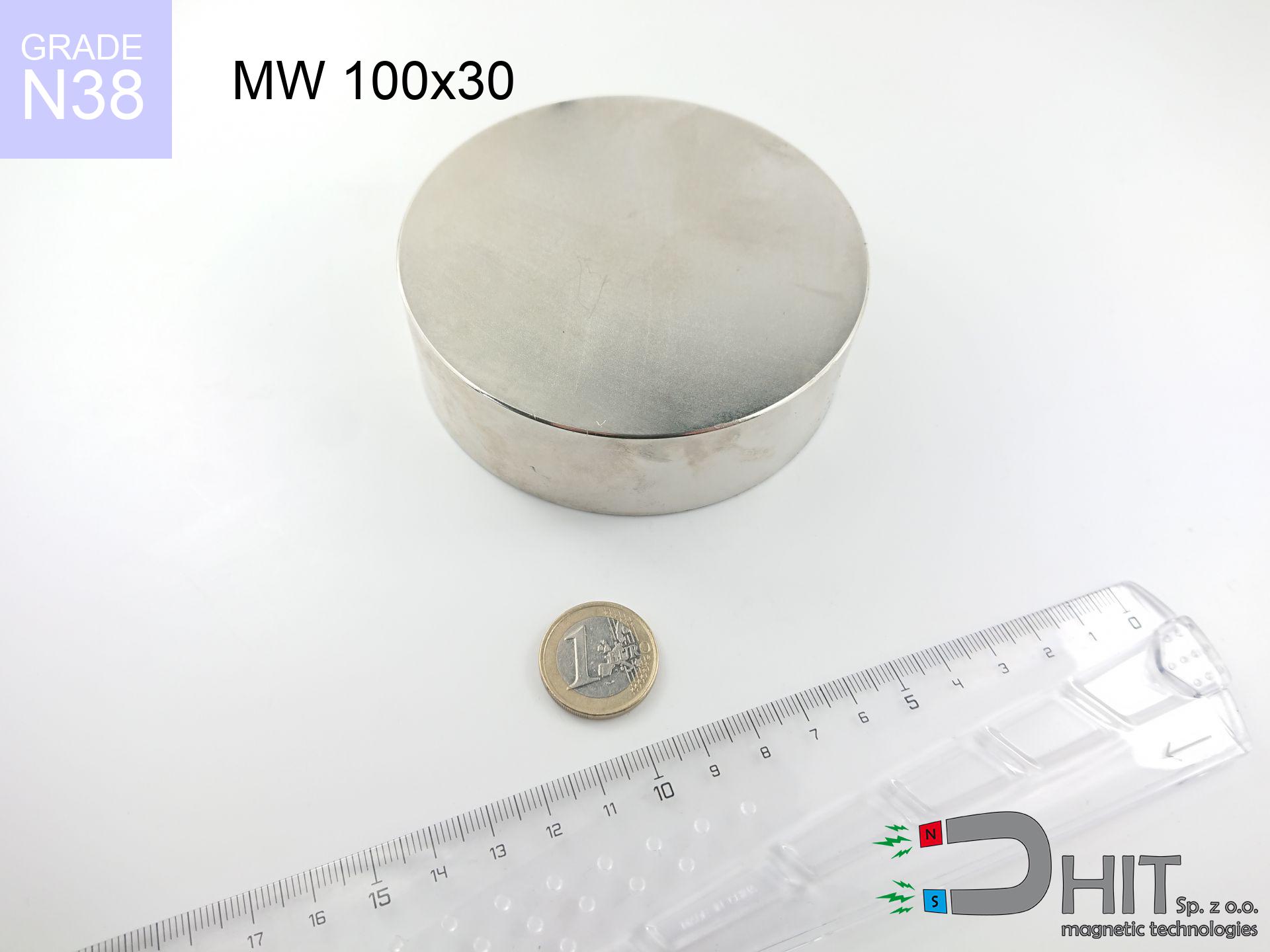

MW 100x30 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010002

GTIN/EAN: 5906301810025

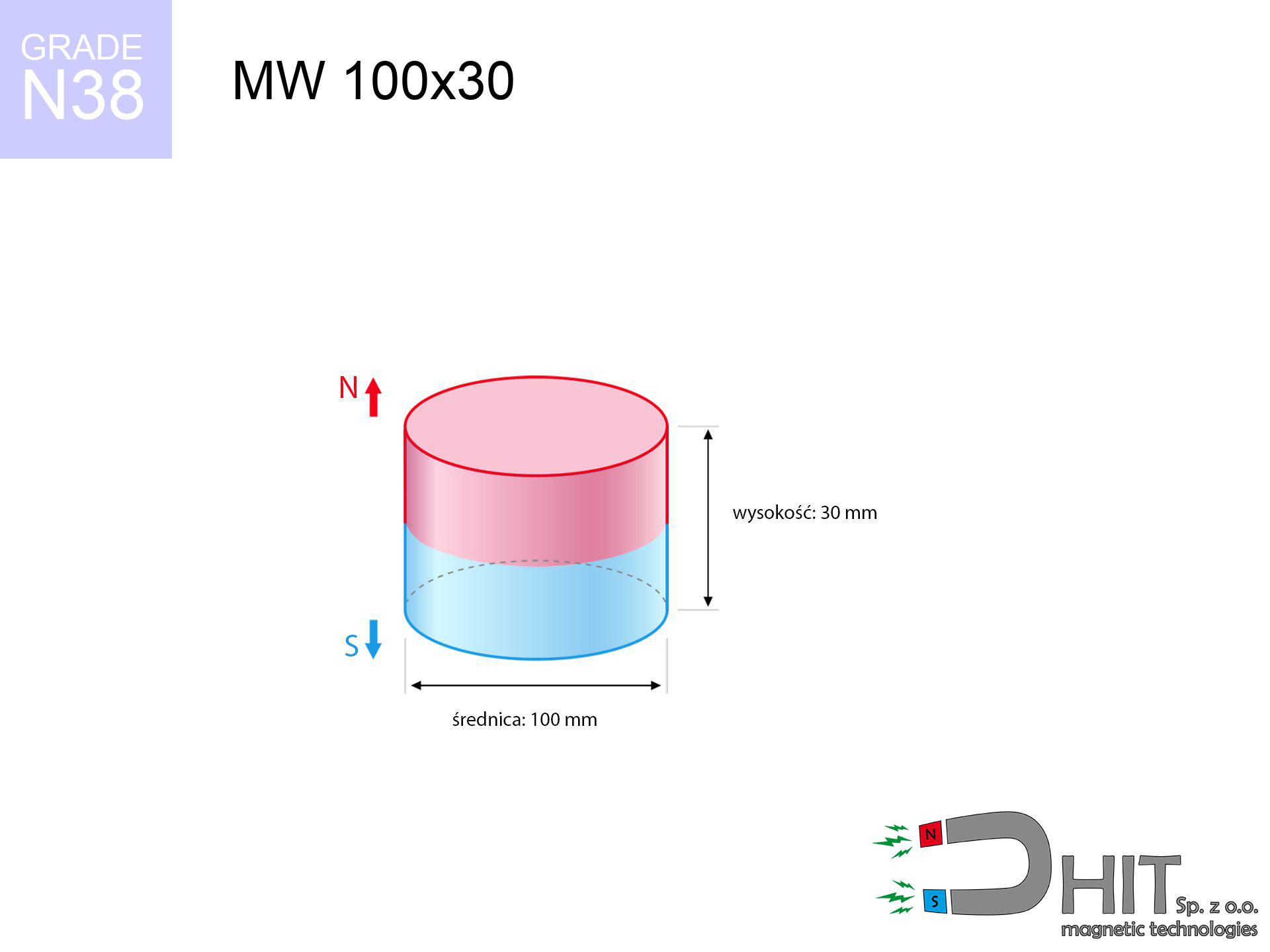

Diameter Ø

100 mm [±0,1 mm]

Height

30 mm [±0,1 mm]

Weight

1767.15 g

Magnetization Direction

↑ axial

Load capacity

215.17 kg / 2110.78 N

Magnetic Induction

318.96 mT / 3190 Gs

Coating

[NiCuNi] Nickel

650.01 ZŁ with VAT / pcs + price for transport

528.46 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

if you prefer let us know via

contact form

the contact form page.

Specifications and structure of magnets can be reviewed using our

magnetic mass calculator.

Orders placed before 14:00 will be shipped the same business day.

Product card - MW 100x30 / N38 - cylindrical magnet

Specification / characteristics - MW 100x30 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010002 |

| GTIN/EAN | 5906301810025 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 100 mm [±0,1 mm] |

| Height | 30 mm [±0,1 mm] |

| Weight | 1767.15 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 215.17 kg / 2110.78 N |

| Magnetic Induction ~ ? | 318.96 mT / 3190 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the product - report

The following values constitute the direct effect of a physical calculation. Results are based on models for the material Nd2Fe14B. Actual performance may differ. Please consider these calculations as a preliminary roadmap for designers.

Table 1: Static pull force (pull vs gap) - interaction chart

MW 100x30 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3189 Gs

318.9 mT

|

215.17 kg / 474.37 lbs

215170.0 g / 2110.8 N

|

crushing |

| 1 mm |

3143 Gs

314.3 mT

|

208.96 kg / 460.68 lbs

208959.6 g / 2049.9 N

|

crushing |

| 2 mm |

3094 Gs

309.4 mT

|

202.53 kg / 446.51 lbs

202531.7 g / 1986.8 N

|

crushing |

| 3 mm |

3044 Gs

304.4 mT

|

195.98 kg / 432.07 lbs

195982.5 g / 1922.6 N

|

crushing |

| 5 mm |

2939 Gs

293.9 mT

|

182.65 kg / 402.68 lbs

182651.7 g / 1791.8 N

|

crushing |

| 10 mm |

2657 Gs

265.7 mT

|

149.35 kg / 329.26 lbs

149349.8 g / 1465.1 N

|

crushing |

| 15 mm |

2366 Gs

236.6 mT

|

118.41 kg / 261.05 lbs

118412.6 g / 1161.6 N

|

crushing |

| 20 mm |

2081 Gs

208.1 mT

|

91.64 kg / 202.03 lbs

91640.5 g / 899.0 N

|

crushing |

| 30 mm |

1573 Gs

157.3 mT

|

52.34 kg / 115.40 lbs

52344.5 g / 513.5 N

|

crushing |

| 50 mm |

874 Gs

87.4 mT

|

16.14 kg / 35.58 lbs

16140.3 g / 158.3 N

|

crushing |

Table 2: Sliding capacity (vertical surface)

MW 100x30 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

43.03 kg / 94.87 lbs

43034.0 g / 422.2 N

|

| 1 mm | Stal (~0.2) |

41.79 kg / 92.14 lbs

41792.0 g / 410.0 N

|

| 2 mm | Stal (~0.2) |

40.51 kg / 89.30 lbs

40506.0 g / 397.4 N

|

| 3 mm | Stal (~0.2) |

39.20 kg / 86.41 lbs

39196.0 g / 384.5 N

|

| 5 mm | Stal (~0.2) |

36.53 kg / 80.53 lbs

36530.0 g / 358.4 N

|

| 10 mm | Stal (~0.2) |

29.87 kg / 65.85 lbs

29870.0 g / 293.0 N

|

| 15 mm | Stal (~0.2) |

23.68 kg / 52.21 lbs

23682.0 g / 232.3 N

|

| 20 mm | Stal (~0.2) |

18.33 kg / 40.41 lbs

18328.0 g / 179.8 N

|

| 30 mm | Stal (~0.2) |

10.47 kg / 23.08 lbs

10468.0 g / 102.7 N

|

| 50 mm | Stal (~0.2) |

3.23 kg / 7.12 lbs

3228.0 g / 31.7 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MW 100x30 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

64.55 kg / 142.31 lbs

64551.0 g / 633.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

43.03 kg / 94.87 lbs

43034.0 g / 422.2 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

21.52 kg / 47.44 lbs

21517.0 g / 211.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

107.59 kg / 237.18 lbs

107585.0 g / 1055.4 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MW 100x30 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

7.17 kg / 15.81 lbs

7172.3 g / 70.4 N

|

| 1 mm |

|

17.93 kg / 39.53 lbs

17930.8 g / 175.9 N

|

| 2 mm |

|

35.86 kg / 79.06 lbs

35861.7 g / 351.8 N

|

| 3 mm |

|

53.79 kg / 118.59 lbs

53792.5 g / 527.7 N

|

| 5 mm |

|

89.65 kg / 197.65 lbs

89654.2 g / 879.5 N

|

| 10 mm |

|

179.31 kg / 395.31 lbs

179308.3 g / 1759.0 N

|

| 11 mm |

|

197.24 kg / 434.84 lbs

197239.2 g / 1934.9 N

|

| 12 mm |

|

215.17 kg / 474.37 lbs

215170.0 g / 2110.8 N

|

Table 5: Thermal resistance (material behavior) - power drop

MW 100x30 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

215.17 kg / 474.37 lbs

215170.0 g / 2110.8 N

|

OK |

| 40 °C | -2.2% |

210.44 kg / 463.93 lbs

210436.3 g / 2064.4 N

|

OK |

| 60 °C | -4.4% |

205.70 kg / 453.50 lbs

205702.5 g / 2017.9 N

|

|

| 80 °C | -6.6% |

200.97 kg / 443.06 lbs

200968.8 g / 1971.5 N

|

|

| 100 °C | -28.8% |

153.20 kg / 337.75 lbs

153201.0 g / 1502.9 N

|

Table 6: Two magnets (repulsion) - field collision

MW 100x30 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

492.55 kg / 1085.88 lbs

4 762 Gs

|

73.88 kg / 162.88 lbs

73882 g / 724.8 N

|

N/A |

| 1 mm |

485.56 kg / 1070.47 lbs

6 333 Gs

|

72.83 kg / 160.57 lbs

72834 g / 714.5 N

|

437.00 kg / 963.42 lbs

~0 Gs

|

| 2 mm |

478.33 kg / 1054.54 lbs

6 286 Gs

|

71.75 kg / 158.18 lbs

71749 g / 703.9 N

|

430.50 kg / 949.08 lbs

~0 Gs

|

| 3 mm |

471.01 kg / 1038.40 lbs

6 238 Gs

|

70.65 kg / 155.76 lbs

70652 g / 693.1 N

|

423.91 kg / 934.56 lbs

~0 Gs

|

| 5 mm |

456.15 kg / 1005.64 lbs

6 139 Gs

|

68.42 kg / 150.85 lbs

68422 g / 671.2 N

|

410.53 kg / 905.07 lbs

~0 Gs

|

| 10 mm |

418.11 kg / 921.77 lbs

5 877 Gs

|

62.72 kg / 138.27 lbs

62716 g / 615.2 N

|

376.30 kg / 829.59 lbs

~0 Gs

|

| 20 mm |

341.88 kg / 753.71 lbs

5 314 Gs

|

51.28 kg / 113.06 lbs

51282 g / 503.1 N

|

307.69 kg / 678.34 lbs

~0 Gs

|

| 50 mm |

159.49 kg / 351.61 lbs

3 630 Gs

|

23.92 kg / 52.74 lbs

23923 g / 234.7 N

|

143.54 kg / 316.45 lbs

~0 Gs

|

| 60 mm |

119.82 kg / 264.16 lbs

3 146 Gs

|

17.97 kg / 39.62 lbs

17973 g / 176.3 N

|

107.84 kg / 237.75 lbs

~0 Gs

|

| 70 mm |

89.40 kg / 197.09 lbs

2 718 Gs

|

13.41 kg / 29.56 lbs

13410 g / 131.6 N

|

80.46 kg / 177.38 lbs

~0 Gs

|

| 80 mm |

66.51 kg / 146.64 lbs

2 344 Gs

|

9.98 kg / 22.00 lbs

9977 g / 97.9 N

|

59.86 kg / 131.97 lbs

~0 Gs

|

| 90 mm |

49.50 kg / 109.14 lbs

2 022 Gs

|

7.43 kg / 16.37 lbs

7426 g / 72.8 N

|

44.55 kg / 98.22 lbs

~0 Gs

|

| 100 mm |

36.95 kg / 81.45 lbs

1 747 Gs

|

5.54 kg / 12.22 lbs

5542 g / 54.4 N

|

33.25 kg / 73.31 lbs

~0 Gs

|

Table 7: Safety (HSE) (electronics) - warnings

MW 100x30 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 44.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 34.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 27.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 21.0 cm |

| Car key | 50 Gs (5.0 mT) | 19.0 cm |

| Payment card | 400 Gs (40.0 mT) | 8.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 6.5 cm |

Table 8: Collisions (kinetic energy) - warning

MW 100x30 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

15.21 km/h

(4.22 m/s)

|

15.77 J | |

| 30 mm |

22.01 km/h

(6.11 m/s)

|

33.03 J | |

| 50 mm |

26.02 km/h

(7.23 m/s)

|

46.17 J | |

| 100 mm |

35.32 km/h

(9.81 m/s)

|

85.04 J |

Table 9: Anti-corrosion coating durability

MW 100x30 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 100x30 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 269 425 Mx | 2694.3 µWb |

| Pc Coefficient | 0.40 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MW 100x30 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 215.17 kg | Standard |

| Water (riverbed) |

246.37 kg

(+31.20 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Warning: On a vertical surface, the magnet retains only approx. 20-30% of its max power.

2. Plate thickness effect

*Thin steel (e.g. 0.5mm PC case) significantly weakens the holding force.

3. Power loss vs temp

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.40

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

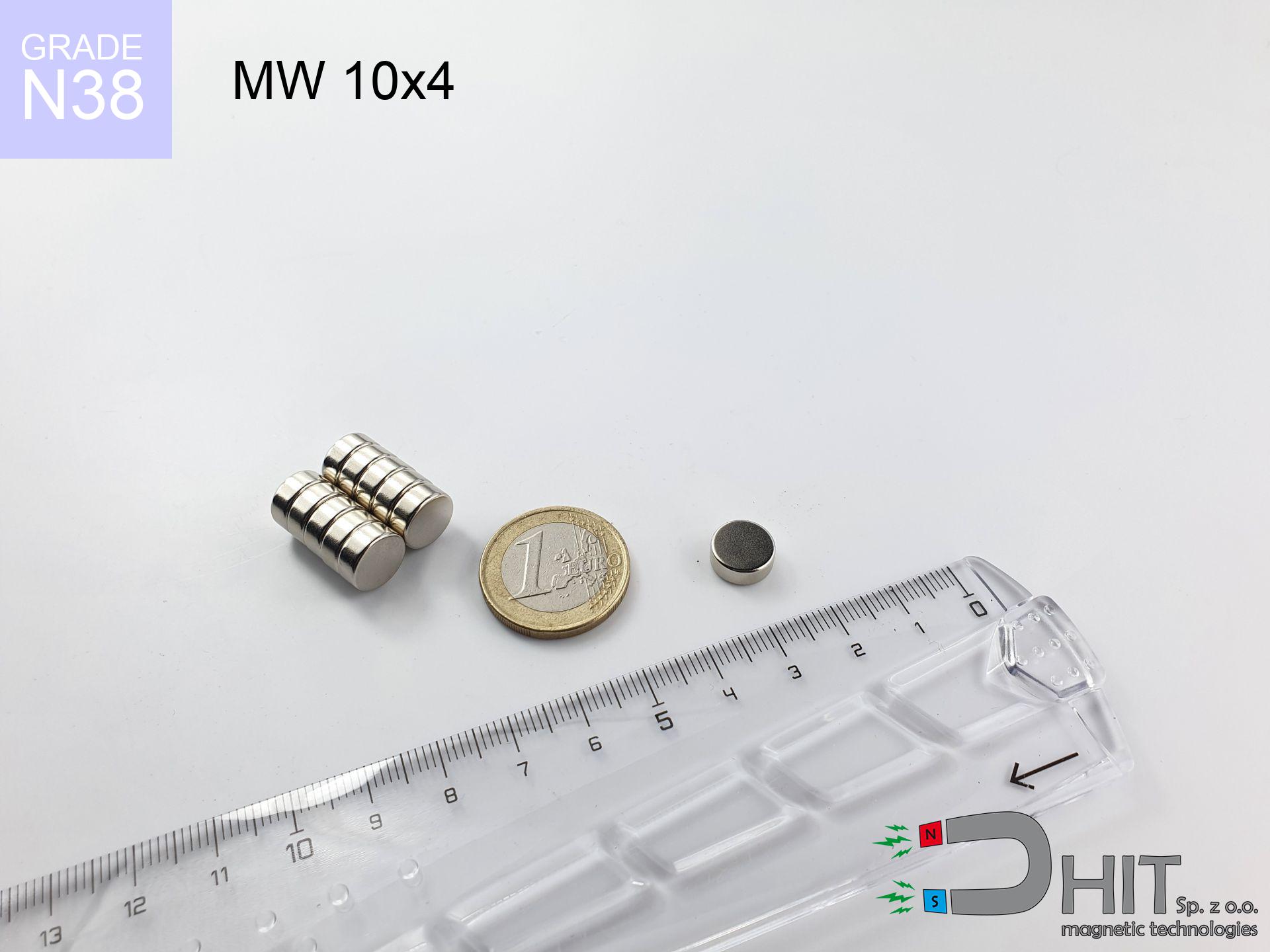

Other products

Strengths as well as weaknesses of rare earth magnets.

Strengths

- They retain attractive force for almost ten years – the drop is just ~1% (according to analyses),

- Magnets effectively resist against loss of magnetization caused by external fields,

- The use of an metallic layer of noble metals (nickel, gold, silver) causes the element to have aesthetics,

- Neodymium magnets generate maximum magnetic induction on a small area, which increases force concentration,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and can function (depending on the form) even at a temperature of 230°C or more...

- Possibility of precise creating and adjusting to specific applications,

- Key role in modern industrial fields – they are commonly used in data components, motor assemblies, diagnostic systems, and other advanced devices.

- Thanks to their power density, small magnets offer high operating force, in miniature format,

Weaknesses

- They are fragile upon heavy impacts. To avoid cracks, it is worth protecting magnets in special housings. Such protection not only shields the magnet but also increases its resistance to damage

- We warn that neodymium magnets can reduce their power at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- Magnets exposed to a humid environment can corrode. Therefore during using outdoors, we recommend using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- We suggest a housing - magnetic mount, due to difficulties in realizing nuts inside the magnet and complex shapes.

- Health risk to health – tiny shards of magnets are risky, if swallowed, which becomes key in the aspect of protecting the youngest. Furthermore, small components of these products can complicate diagnosis medical when they are in the body.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which can limit application in large quantities

Holding force characteristics

Optimal lifting capacity of a neodymium magnet – what it depends on?

- on a base made of structural steel, perfectly concentrating the magnetic field

- whose thickness reaches at least 10 mm

- with a surface free of scratches

- under conditions of gap-free contact (surface-to-surface)

- for force acting at a right angle (in the magnet axis)

- at ambient temperature room level

Key elements affecting lifting force

- Space between surfaces – every millimeter of distance (caused e.g. by veneer or unevenness) diminishes the pulling force, often by half at just 0.5 mm.

- Loading method – catalog parameter refers to detachment vertically. When slipping, the magnet holds significantly lower power (often approx. 20-30% of nominal force).

- Metal thickness – the thinner the sheet, the weaker the hold. Magnetic flux penetrates through instead of converting into lifting capacity.

- Material type – the best choice is high-permeability steel. Stainless steels may have worse magnetic properties.

- Plate texture – smooth surfaces guarantee perfect abutment, which improves field saturation. Rough surfaces reduce efficiency.

- Thermal environment – temperature increase results in weakening of force. It is worth remembering the maximum operating temperature for a given model.

Lifting capacity testing was conducted on a smooth plate of optimal thickness, under perpendicular forces, whereas under shearing force the lifting capacity is smaller. Additionally, even a minimal clearance between the magnet and the plate lowers the load capacity.

Safe handling of NdFeB magnets

Metal Allergy

Warning for allergy sufferers: The nickel-copper-nickel coating contains nickel. If skin irritation appears, cease working with magnets and use protective gear.

Keep away from children

These products are not toys. Eating multiple magnets can lead to them pinching intestinal walls, which poses a direct threat to life and necessitates immediate surgery.

Do not drill into magnets

Mechanical processing of NdFeB material poses a fire risk. Neodymium dust oxidizes rapidly with oxygen and is hard to extinguish.

Implant safety

Warning for patients: Powerful magnets affect electronics. Keep minimum 30 cm distance or request help to handle the magnets.

Fragile material

Protect your eyes. Magnets can fracture upon uncontrolled impact, launching sharp fragments into the air. Eye protection is mandatory.

Safe operation

Be careful. Neodymium magnets act from a long distance and snap with huge force, often faster than you can move away.

Do not overheat magnets

Standard neodymium magnets (N-type) lose magnetization when the temperature exceeds 80°C. Damage is permanent.

Cards and drives

Avoid bringing magnets near a purse, computer, or screen. The magnetic field can destroy these devices and erase data from cards.

Pinching danger

Protect your hands. Two powerful magnets will join instantly with a force of massive weight, crushing anything in their path. Be careful!

GPS Danger

A strong magnetic field interferes with the operation of compasses in smartphones and navigation systems. Keep magnets near a device to prevent damaging the sensors.

![BM 550x180x70 [4x M8] - magnetic beam BM 550x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-550x180x70-4x-m8-nic.jpg)

![SM 32x300 [2xM8] / N52 - magnetic separator SM 32x300 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x300-2xm8-luf.jpg)