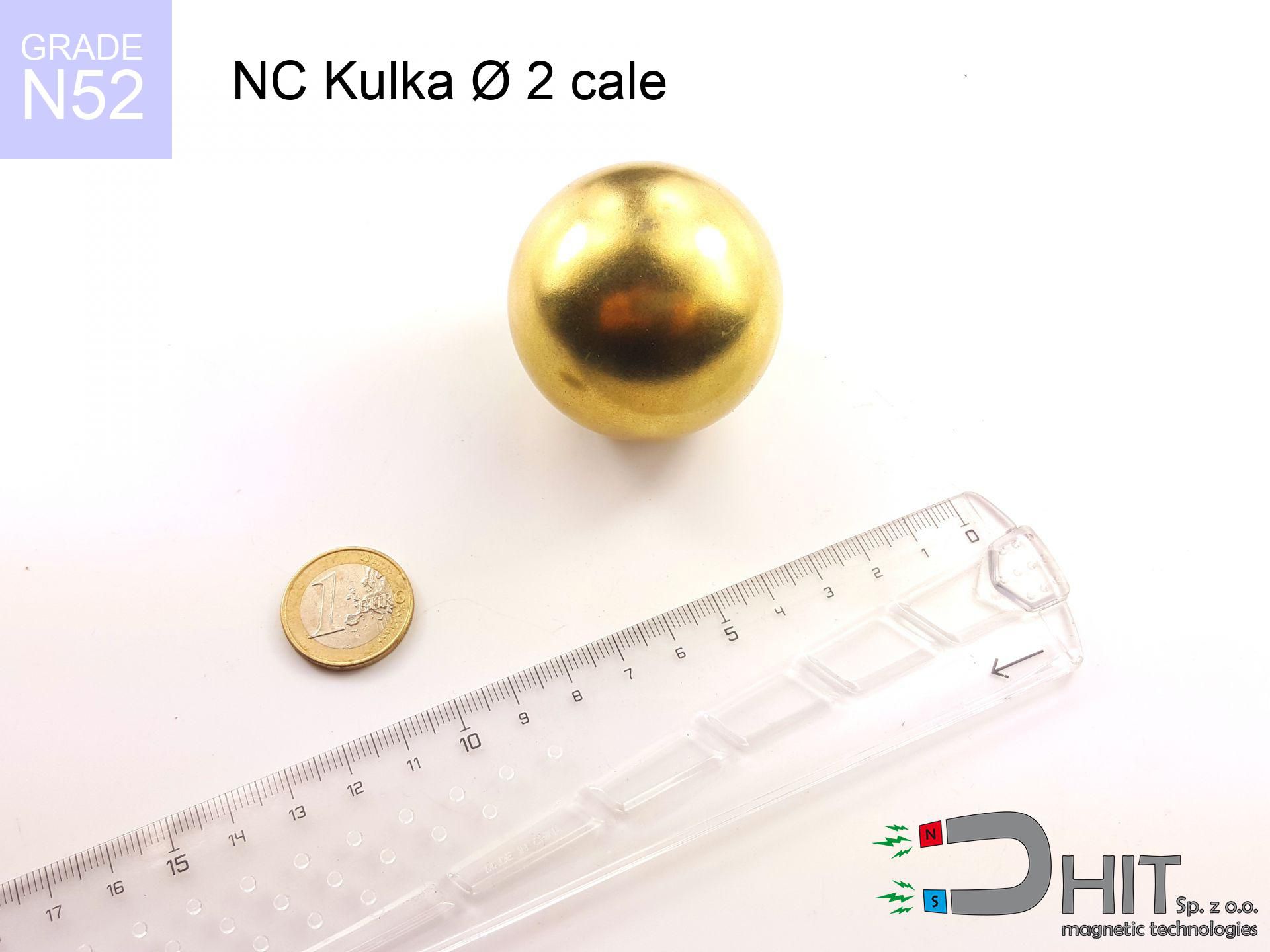

NC kulka fi 2 cale / N52 - neocube

neocube

Catalog no 120453

GTIN/EAN: 5906301812692

Weight

1098 g

Magnetization Direction

↑ axial

Coating

[Gold] Gold

1200.00 ZŁ with VAT / pcs + price for transport

975.61 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

or drop us a message using

our online form

through our site.

Weight along with form of magnets can be analyzed on our

online calculation tool.

Orders submitted before 14:00 will be dispatched today!

Physical properties - NC kulka fi 2 cale / N52 - neocube

Specification / characteristics - NC kulka fi 2 cale / N52 - neocube

| properties | values |

|---|---|

| Cat. no. | 120453 |

| GTIN/EAN | 5906301812692 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Weight | 1098 g |

| Magnetization Direction | ↑ axial |

| Coating | [Gold] Gold |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N52

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 14.2-14.7 | kGs |

| remenance Br [min. - max.] ? | 1420-1470 | mT |

| coercivity bHc ? | 10.8-12.5 | kOe |

| coercivity bHc ? | 860-995 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 48-53 | BH max MGOe |

| energy density [min. - max.] ? | 380-422 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Pros as well as cons of neodymium magnets.

Benefits

- They virtually do not lose power, because even after ten years the decline in efficiency is only ~1% (according to literature),

- Neodymium magnets prove to be highly resistant to magnetic field loss caused by external magnetic fields,

- A magnet with a metallic silver surface looks better,

- The surface of neodymium magnets generates a maximum magnetic field – this is a key feature,

- Through (adequate) combination of ingredients, they can achieve high thermal strength, allowing for functioning at temperatures approaching 230°C and above...

- Possibility of detailed machining as well as adapting to complex applications,

- Significant place in future technologies – they are utilized in computer drives, electric motors, medical devices, and other advanced devices.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Disadvantages

- To avoid cracks under impact, we recommend using special steel holders. Such a solution protects the magnet and simultaneously improves its durability.

- We warn that neodymium magnets can lose their power at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- They oxidize in a humid environment. For use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- We recommend a housing - magnetic holder, due to difficulties in producing nuts inside the magnet and complicated shapes.

- Possible danger to health – tiny shards of magnets are risky, in case of ingestion, which is particularly important in the context of child safety. It is also worth noting that small components of these magnets are able to be problematic in diagnostics medical when they are in the body.

- With budget limitations the cost of neodymium magnets is a challenge,

Pull force analysis

Detachment force of the magnet in optimal conditions – what it depends on?

- on a base made of structural steel, optimally conducting the magnetic flux

- possessing a thickness of min. 10 mm to ensure full flux closure

- characterized by lack of roughness

- with total lack of distance (without impurities)

- for force applied at a right angle (in the magnet axis)

- at temperature room level

Practical lifting capacity: influencing factors

- Distance – existence of foreign body (paint, dirt, gap) interrupts the magnetic circuit, which reduces capacity steeply (even by 50% at 0.5 mm).

- Force direction – remember that the magnet has greatest strength perpendicularly. Under sliding down, the capacity drops drastically, often to levels of 20-30% of the maximum value.

- Element thickness – for full efficiency, the steel must be adequately massive. Paper-thin metal limits the attraction force (the magnet "punches through" it).

- Chemical composition of the base – mild steel gives the best results. Higher carbon content decrease magnetic permeability and lifting capacity.

- Surface condition – ground elements guarantee perfect abutment, which increases force. Rough surfaces reduce efficiency.

- Thermal conditions – neodymium magnets have a negative temperature coefficient. When it is hot they lose power, and in frost gain strength (up to a certain limit).

Lifting capacity testing was carried out on plates with a smooth surface of optimal thickness, under perpendicular forces, whereas under parallel forces the load capacity is reduced by as much as 5 times. Moreover, even a small distance between the magnet and the plate lowers the lifting capacity.

Warnings

Electronic hazard

Powerful magnetic fields can erase data on payment cards, HDDs, and storage devices. Maintain a gap of at least 10 cm.

Skin irritation risks

A percentage of the population have a sensitization to nickel, which is the standard coating for neodymium magnets. Prolonged contact may cause an allergic reaction. We suggest use protective gloves.

Do not give to children

These products are not suitable for play. Accidental ingestion of several magnets may result in them attracting across intestines, which constitutes a critical condition and requires urgent medical intervention.

Beware of splinters

Despite the nickel coating, neodymium is delicate and cannot withstand shocks. Avoid impacts, as the magnet may crumble into hazardous fragments.

Conscious usage

Use magnets consciously. Their huge power can shock even experienced users. Plan your moves and respect their force.

Physical harm

Mind your fingers. Two large magnets will snap together instantly with a force of massive weight, crushing anything in their path. Exercise extreme caution!

GPS Danger

Be aware: neodymium magnets produce a field that confuses precision electronics. Maintain a safe distance from your mobile, tablet, and GPS.

Danger to pacemakers

For implant holders: Powerful magnets affect medical devices. Keep minimum 30 cm distance or request help to work with the magnets.

Permanent damage

Do not overheat. Neodymium magnets are sensitive to heat. If you require operation above 80°C, look for special high-temperature series (H, SH, UH).

Dust explosion hazard

Mechanical processing of neodymium magnets poses a fire hazard. Magnetic powder oxidizes rapidly with oxygen and is difficult to extinguish.