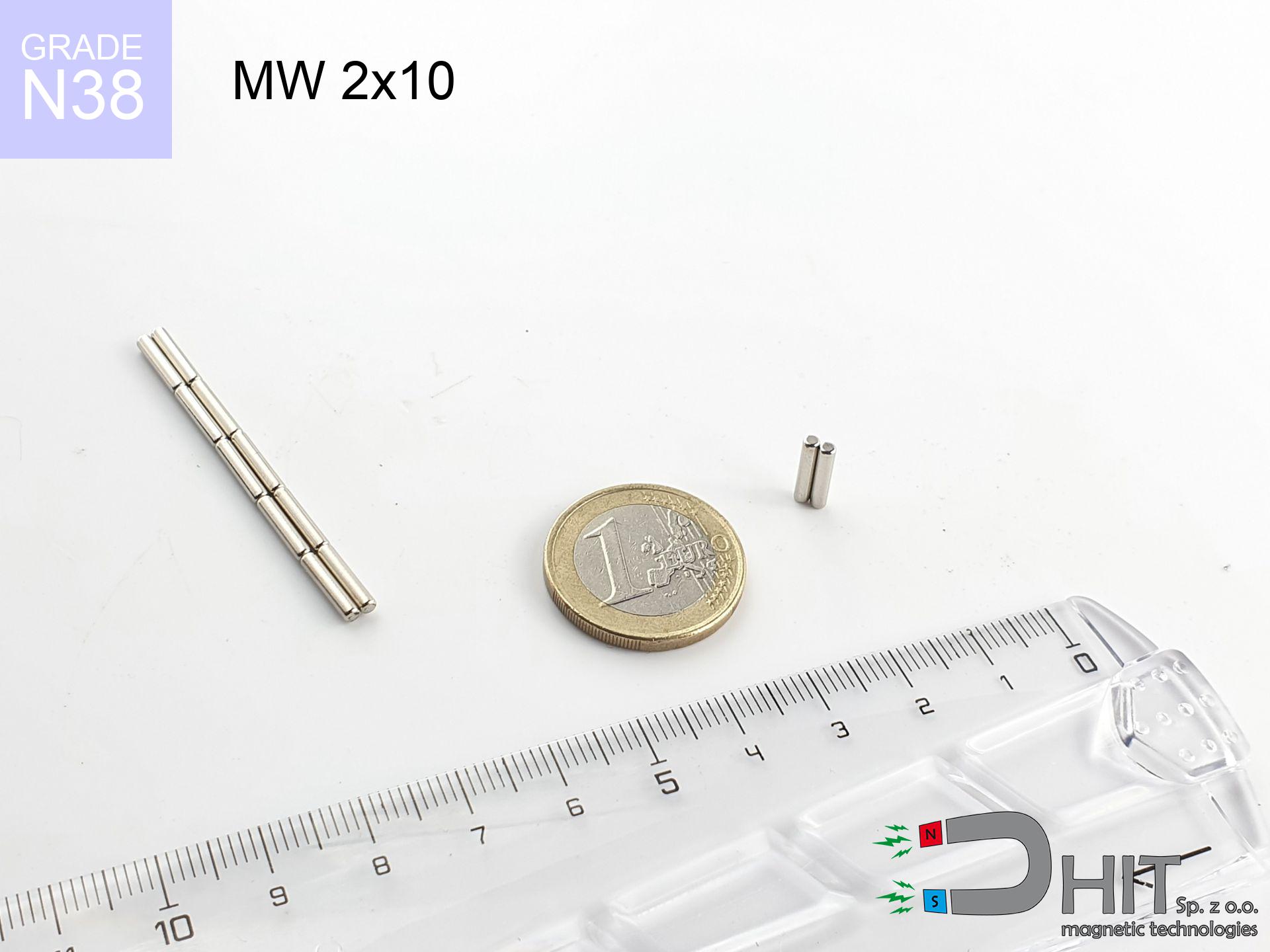

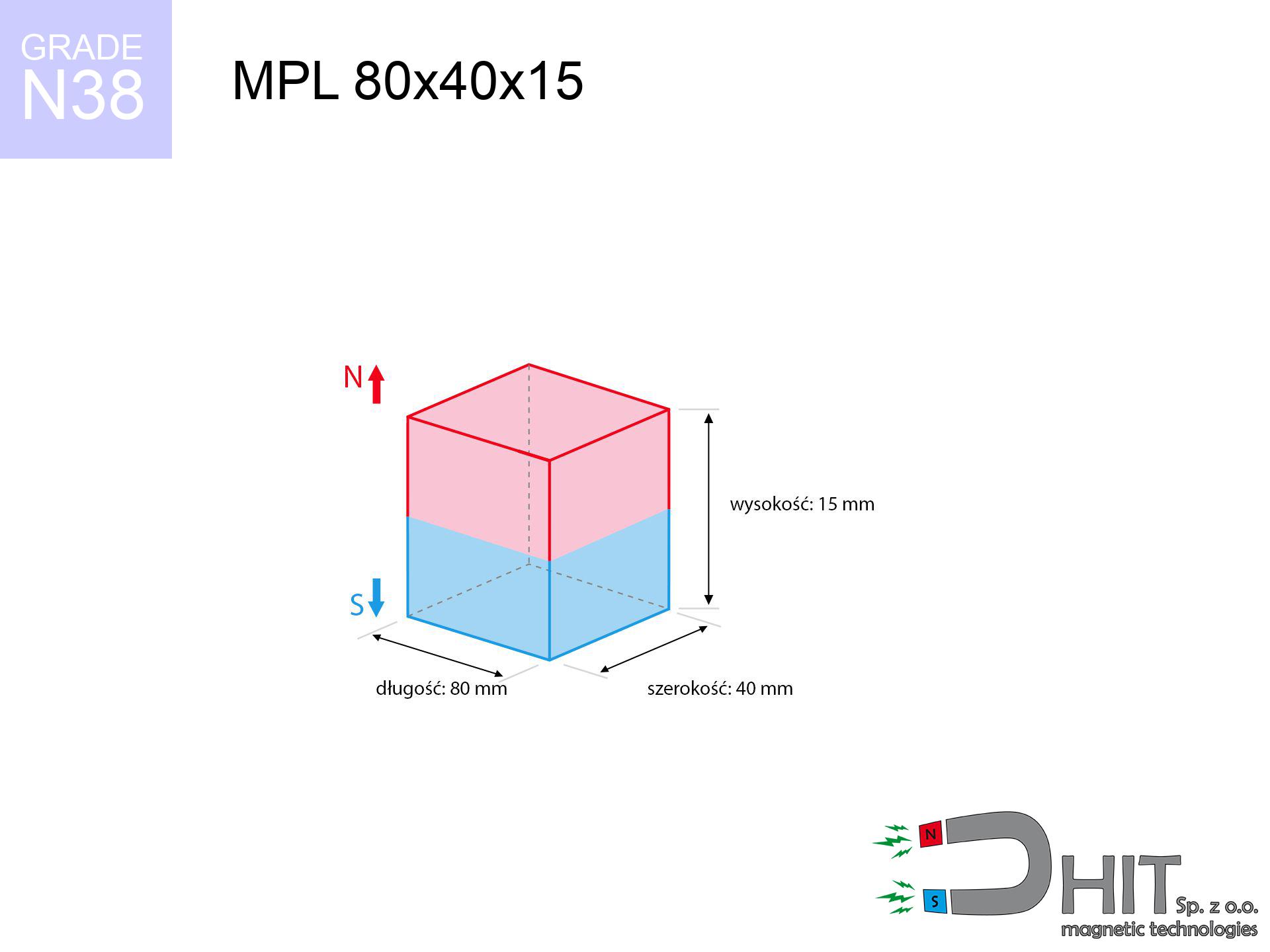

MPL 80x40x15 / N38 - lamellar magnet

lamellar magnet

Catalog no 020177

GTIN/EAN: 5906301811831

length

80 mm [±0,1 mm]

Width

40 mm [±0,1 mm]

Height

15 mm [±0,1 mm]

Weight

360 g

Magnetization Direction

↑ axial

Load capacity

73.57 kg / 721.75 N

Magnetic Induction

285.78 mT / 2858 Gs

Coating

[NiCuNi] Nickel

139.54 ZŁ with VAT / pcs + price for transport

113.45 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

if you prefer get in touch through

form

through our site.

Strength along with structure of magnets can be estimated on our

force calculator.

Same-day shipping for orders placed before 14:00.

Product card - MPL 80x40x15 / N38 - lamellar magnet

Specification / characteristics - MPL 80x40x15 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020177 |

| GTIN/EAN | 5906301811831 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 80 mm [±0,1 mm] |

| Width | 40 mm [±0,1 mm] |

| Height | 15 mm [±0,1 mm] |

| Weight | 360 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 73.57 kg / 721.75 N |

| Magnetic Induction ~ ? | 285.78 mT / 2858 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the product - technical parameters

Presented information are the result of a engineering calculation. Results are based on models for the class Nd2Fe14B. Actual conditions might slightly deviate from the simulation results. Use these data as a preliminary roadmap during assembly planning.

Table 1: Static force (pull vs distance) - interaction chart

MPL 80x40x15 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2857 Gs

285.7 mT

|

73.57 kg / 162.19 lbs

73570.0 g / 721.7 N

|

crushing |

| 1 mm |

2778 Gs

277.8 mT

|

69.55 kg / 153.32 lbs

69546.1 g / 682.2 N

|

crushing |

| 2 mm |

2693 Gs

269.3 mT

|

65.33 kg / 144.03 lbs

65331.2 g / 640.9 N

|

crushing |

| 3 mm |

2603 Gs

260.3 mT

|

61.05 kg / 134.59 lbs

61047.5 g / 598.9 N

|

crushing |

| 5 mm |

2415 Gs

241.5 mT

|

52.56 kg / 115.87 lbs

52559.7 g / 515.6 N

|

crushing |

| 10 mm |

1943 Gs

194.3 mT

|

34.02 kg / 75.00 lbs

34021.1 g / 333.7 N

|

crushing |

| 15 mm |

1527 Gs

152.7 mT

|

21.01 kg / 46.31 lbs

21007.7 g / 206.1 N

|

crushing |

| 20 mm |

1192 Gs

119.2 mT

|

12.81 kg / 28.24 lbs

12808.1 g / 125.6 N

|

crushing |

| 30 mm |

736 Gs

73.6 mT

|

4.89 kg / 10.77 lbs

4886.6 g / 47.9 N

|

medium risk |

| 50 mm |

313 Gs

31.3 mT

|

0.88 kg / 1.95 lbs

884.8 g / 8.7 N

|

safe |

Table 2: Shear hold (vertical surface)

MPL 80x40x15 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

14.71 kg / 32.44 lbs

14714.0 g / 144.3 N

|

| 1 mm | Stal (~0.2) |

13.91 kg / 30.67 lbs

13910.0 g / 136.5 N

|

| 2 mm | Stal (~0.2) |

13.07 kg / 28.81 lbs

13066.0 g / 128.2 N

|

| 3 mm | Stal (~0.2) |

12.21 kg / 26.92 lbs

12210.0 g / 119.8 N

|

| 5 mm | Stal (~0.2) |

10.51 kg / 23.17 lbs

10512.0 g / 103.1 N

|

| 10 mm | Stal (~0.2) |

6.80 kg / 15.00 lbs

6804.0 g / 66.7 N

|

| 15 mm | Stal (~0.2) |

4.20 kg / 9.26 lbs

4202.0 g / 41.2 N

|

| 20 mm | Stal (~0.2) |

2.56 kg / 5.65 lbs

2562.0 g / 25.1 N

|

| 30 mm | Stal (~0.2) |

0.98 kg / 2.16 lbs

978.0 g / 9.6 N

|

| 50 mm | Stal (~0.2) |

0.18 kg / 0.39 lbs

176.0 g / 1.7 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MPL 80x40x15 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

22.07 kg / 48.66 lbs

22071.0 g / 216.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

14.71 kg / 32.44 lbs

14714.0 g / 144.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

7.36 kg / 16.22 lbs

7357.0 g / 72.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

36.79 kg / 81.10 lbs

36785.0 g / 360.9 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MPL 80x40x15 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

2.45 kg / 5.41 lbs

2452.3 g / 24.1 N

|

| 1 mm |

|

6.13 kg / 13.52 lbs

6130.8 g / 60.1 N

|

| 2 mm |

|

12.26 kg / 27.03 lbs

12261.7 g / 120.3 N

|

| 3 mm |

|

18.39 kg / 40.55 lbs

18392.5 g / 180.4 N

|

| 5 mm |

|

30.65 kg / 67.58 lbs

30654.2 g / 300.7 N

|

| 10 mm |

|

61.31 kg / 135.16 lbs

61308.3 g / 601.4 N

|

| 11 mm |

|

67.44 kg / 148.68 lbs

67439.2 g / 661.6 N

|

| 12 mm |

|

73.57 kg / 162.19 lbs

73570.0 g / 721.7 N

|

Table 5: Working in heat (stability) - resistance threshold

MPL 80x40x15 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

73.57 kg / 162.19 lbs

73570.0 g / 721.7 N

|

OK |

| 40 °C | -2.2% |

71.95 kg / 158.63 lbs

71951.5 g / 705.8 N

|

OK |

| 60 °C | -4.4% |

70.33 kg / 155.06 lbs

70332.9 g / 690.0 N

|

|

| 80 °C | -6.6% |

68.71 kg / 151.49 lbs

68714.4 g / 674.1 N

|

|

| 100 °C | -28.8% |

52.38 kg / 115.48 lbs

52381.8 g / 513.9 N

|

Table 6: Two magnets (repulsion) - forces in the system

MPL 80x40x15 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

161.08 kg / 355.13 lbs

4 384 Gs

|

24.16 kg / 53.27 lbs

24163 g / 237.0 N

|

N/A |

| 1 mm |

156.77 kg / 345.63 lbs

5 638 Gs

|

23.52 kg / 51.84 lbs

23516 g / 230.7 N

|

141.10 kg / 311.07 lbs

~0 Gs

|

| 2 mm |

152.27 kg / 335.70 lbs

5 556 Gs

|

22.84 kg / 50.36 lbs

22841 g / 224.1 N

|

137.05 kg / 302.13 lbs

~0 Gs

|

| 3 mm |

147.69 kg / 325.60 lbs

5 472 Gs

|

22.15 kg / 48.84 lbs

22153 g / 217.3 N

|

132.92 kg / 293.04 lbs

~0 Gs

|

| 5 mm |

138.36 kg / 305.04 lbs

5 297 Gs

|

20.75 kg / 45.76 lbs

20754 g / 203.6 N

|

124.53 kg / 274.53 lbs

~0 Gs

|

| 10 mm |

115.08 kg / 253.71 lbs

4 830 Gs

|

17.26 kg / 38.06 lbs

17262 g / 169.3 N

|

103.57 kg / 228.34 lbs

~0 Gs

|

| 20 mm |

74.49 kg / 164.22 lbs

3 886 Gs

|

11.17 kg / 24.63 lbs

11174 g / 109.6 N

|

67.04 kg / 147.80 lbs

~0 Gs

|

| 50 mm |

17.20 kg / 37.91 lbs

1 867 Gs

|

2.58 kg / 5.69 lbs

2580 g / 25.3 N

|

15.48 kg / 34.12 lbs

~0 Gs

|

| 60 mm |

10.70 kg / 23.59 lbs

1 473 Gs

|

1.60 kg / 3.54 lbs

1605 g / 15.7 N

|

9.63 kg / 21.23 lbs

~0 Gs

|

| 70 mm |

6.78 kg / 14.94 lbs

1 172 Gs

|

1.02 kg / 2.24 lbs

1017 g / 10.0 N

|

6.10 kg / 13.45 lbs

~0 Gs

|

| 80 mm |

4.38 kg / 9.65 lbs

942 Gs

|

0.66 kg / 1.45 lbs

657 g / 6.4 N

|

3.94 kg / 8.69 lbs

~0 Gs

|

| 90 mm |

2.89 kg / 6.36 lbs

765 Gs

|

0.43 kg / 0.95 lbs

433 g / 4.2 N

|

2.60 kg / 5.72 lbs

~0 Gs

|

| 100 mm |

1.94 kg / 4.27 lbs

627 Gs

|

0.29 kg / 0.64 lbs

291 g / 2.9 N

|

1.74 kg / 3.84 lbs

~0 Gs

|

Table 7: Safety (HSE) (implants) - precautionary measures

MPL 80x40x15 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 26.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 20.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 16.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 12.5 cm |

| Remote | 50 Gs (5.0 mT) | 11.5 cm |

| Payment card | 400 Gs (40.0 mT) | 4.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 3.5 cm |

Table 8: Impact energy (cracking risk) - warning

MPL 80x40x15 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

18.11 km/h

(5.03 m/s)

|

4.56 J | |

| 30 mm |

25.99 km/h

(7.22 m/s)

|

9.38 J | |

| 50 mm |

32.48 km/h

(9.02 m/s)

|

14.65 J | |

| 100 mm |

45.61 km/h

(12.67 m/s)

|

28.89 J |

Table 9: Anti-corrosion coating durability

MPL 80x40x15 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 80x40x15 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 94 833 Mx | 948.3 µWb |

| Pc Coefficient | 0.33 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MPL 80x40x15 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 73.57 kg | Standard |

| Water (riverbed) |

84.24 kg

(+10.67 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical wall, the magnet retains merely a fraction of its max power.

2. Steel saturation

*Thin steel (e.g. computer case) severely weakens the holding force.

3. Power loss vs temp

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.33

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Pros as well as cons of neodymium magnets.

Advantages

- Their power is durable, and after approximately ten years it decreases only by ~1% (theoretically),

- They retain their magnetic properties even under close interference source,

- By applying a smooth layer of silver, the element acquires an aesthetic look,

- The surface of neodymium magnets generates a powerful magnetic field – this is one of their assets,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the form) even at high temperatures reaching 230°C or more...

- Thanks to versatility in shaping and the capacity to customize to specific needs,

- Huge importance in high-tech industry – they serve a role in HDD drives, drive modules, advanced medical instruments, also technologically advanced constructions.

- Thanks to concentrated force, small magnets offer high operating force, in miniature format,

Weaknesses

- They are prone to damage upon too strong impacts. To avoid cracks, it is worth protecting magnets using a steel holder. Such protection not only protects the magnet but also improves its resistance to damage

- Neodymium magnets decrease their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material immune to moisture, in case of application outdoors

- Due to limitations in realizing threads and complicated shapes in magnets, we propose using cover - magnetic mechanism.

- Potential hazard related to microscopic parts of magnets are risky, in case of ingestion, which gains importance in the aspect of protecting the youngest. It is also worth noting that small elements of these magnets can complicate diagnosis medical when they are in the body.

- High unit price – neodymium magnets cost more than other types of magnets (e.g. ferrite), which hinders application in large quantities

Holding force characteristics

Maximum holding power of the magnet – what contributes to it?

- using a sheet made of high-permeability steel, serving as a magnetic yoke

- possessing a thickness of minimum 10 mm to ensure full flux closure

- with a surface cleaned and smooth

- under conditions of gap-free contact (surface-to-surface)

- during pulling in a direction perpendicular to the plane

- at ambient temperature room level

Key elements affecting lifting force

- Gap between surfaces – every millimeter of distance (caused e.g. by varnish or dirt) significantly weakens the pulling force, often by half at just 0.5 mm.

- Force direction – declared lifting capacity refers to detachment vertically. When applying parallel force, the magnet holds significantly lower power (often approx. 20-30% of nominal force).

- Plate thickness – too thin sheet causes magnetic saturation, causing part of the flux to be wasted into the air.

- Plate material – mild steel attracts best. Higher carbon content lower magnetic properties and holding force.

- Surface finish – full contact is possible only on smooth steel. Any scratches and bumps create air cushions, weakening the magnet.

- Temperature influence – hot environment reduces magnetic field. Exceeding the limit temperature can permanently damage the magnet.

Lifting capacity testing was conducted on plates with a smooth surface of suitable thickness, under perpendicular forces, in contrast under parallel forces the holding force is lower. Additionally, even a slight gap between the magnet and the plate lowers the lifting capacity.

Safety rules for work with neodymium magnets

Handling rules

Handle with care. Rare earth magnets act from a distance and connect with huge force, often faster than you can move away.

Adults only

Always store magnets out of reach of children. Choking hazard is high, and the effects of magnets connecting inside the body are life-threatening.

Thermal limits

Standard neodymium magnets (grade N) lose power when the temperature exceeds 80°C. This process is irreversible.

Bone fractures

Large magnets can break fingers instantly. Do not put your hand between two strong magnets.

Dust is flammable

Mechanical processing of NdFeB material carries a risk of fire risk. Magnetic powder oxidizes rapidly with oxygen and is hard to extinguish.

Medical implants

For implant holders: Strong magnetic fields disrupt medical devices. Keep minimum 30 cm distance or ask another person to handle the magnets.

Electronic hazard

Powerful magnetic fields can erase data on payment cards, hard drives, and storage devices. Maintain a gap of min. 10 cm.

Fragile material

Despite the nickel coating, the material is delicate and not impact-resistant. Do not hit, as the magnet may crumble into sharp, dangerous pieces.

GPS Danger

An intense magnetic field negatively affects the operation of compasses in phones and navigation systems. Keep magnets near a smartphone to prevent breaking the sensors.

Nickel coating and allergies

It is widely known that the nickel plating (standard magnet coating) is a potent allergen. For allergy sufferers, refrain from touching magnets with bare hands and choose versions in plastic housing.

![UMGGZ 22x6 [M4] GZ / N38 - rubber magnetic holder external thread UMGGZ 22x6 [M4] GZ / N38 - rubber magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umg-22x6-m4-gz-hiw.jpg)

![SM 32x125 [2xM8] / N42 - magnetic separator SM 32x125 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x125-2xm8-pul.jpg)

![SM 32x425 [2xM8] / N42 - magnetic separator SM 32x425 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x425-2xm8-woj.jpg)