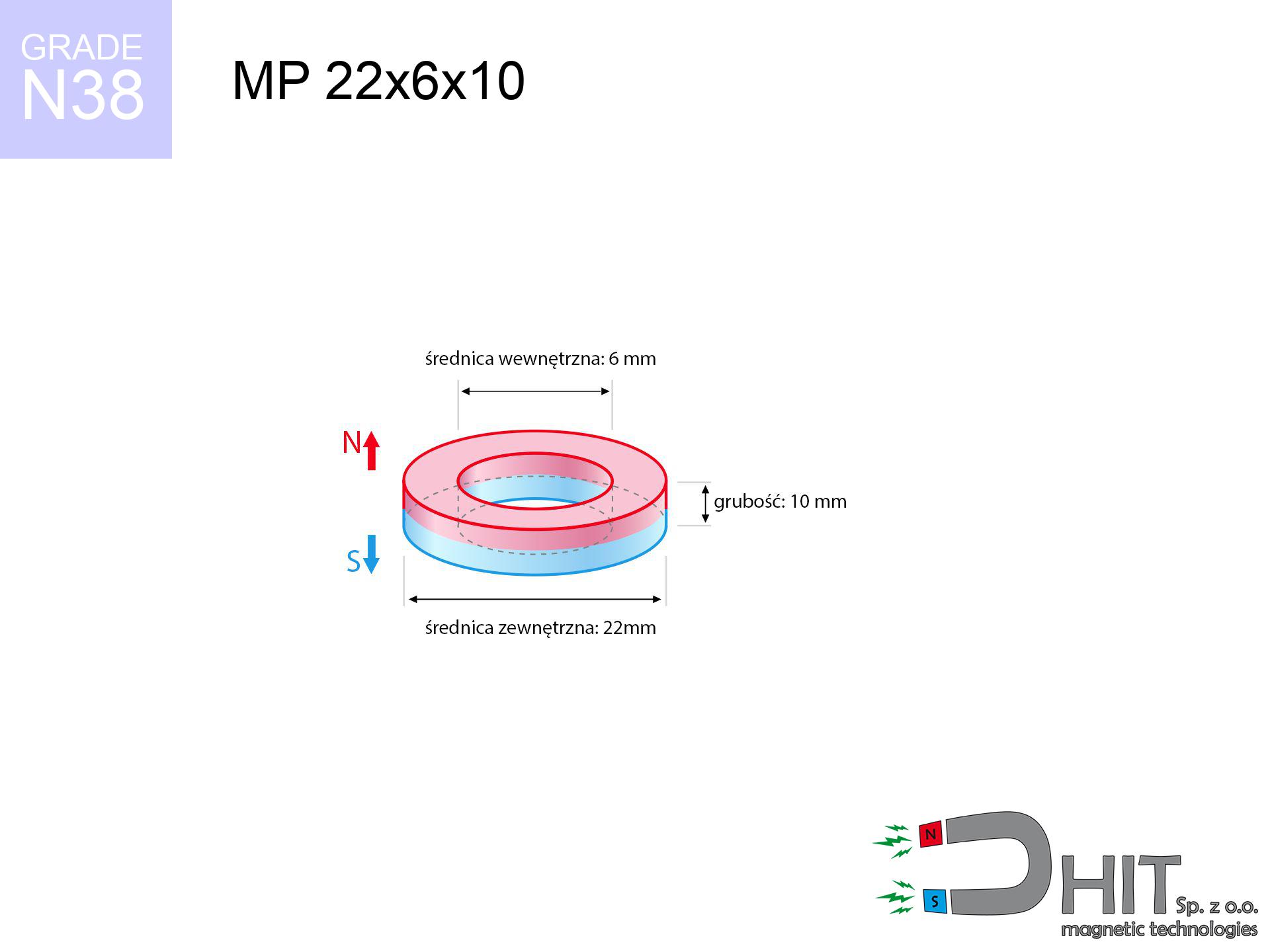

MP 22x6x10 / N38 - ring magnet

ring magnet

Catalog no 030394

GTIN/EAN: 5906301812319

Diameter

22 mm [±0,1 mm]

internal diameter Ø

6 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

26.39 g

Magnetization Direction

↑ axial

Load capacity

13.65 kg / 133.89 N

Magnetic Induction

416.85 mT / 4168 Gs

Coating

[NiCuNi] Nickel

13.95 ZŁ with VAT / pcs + price for transport

11.34 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

or send us a note through

inquiry form

our website.

Specifications as well as shape of magnetic components can be calculated on our

online calculation tool.

Orders submitted before 14:00 will be dispatched today!

Technical specification - MP 22x6x10 / N38 - ring magnet

Specification / characteristics - MP 22x6x10 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030394 |

| GTIN/EAN | 5906301812319 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 22 mm [±0,1 mm] |

| internal diameter Ø | 6 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 26.39 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 13.65 kg / 133.89 N |

| Magnetic Induction ~ ? | 416.85 mT / 4168 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the magnet - report

These values constitute the outcome of a physical analysis. Results rely on models for the class Nd2Fe14B. Operational parameters might slightly differ from theoretical values. Use these calculations as a preliminary roadmap when designing systems.

Table 1: Static force (pull vs gap) - interaction chart

MP 22x6x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5864 Gs

586.4 mT

|

13.65 kg / 30.09 pounds

13650.0 g / 133.9 N

|

crushing |

| 1 mm |

5326 Gs

532.6 mT

|

11.26 kg / 24.83 pounds

11261.1 g / 110.5 N

|

crushing |

| 2 mm |

4795 Gs

479.5 mT

|

9.13 kg / 20.12 pounds

9127.3 g / 89.5 N

|

strong |

| 3 mm |

4288 Gs

428.8 mT

|

7.30 kg / 16.09 pounds

7299.8 g / 71.6 N

|

strong |

| 5 mm |

3381 Gs

338.1 mT

|

4.54 kg / 10.01 pounds

4539.0 g / 44.5 N

|

strong |

| 10 mm |

1830 Gs

183.0 mT

|

1.33 kg / 2.93 pounds

1329.4 g / 13.0 N

|

weak grip |

| 15 mm |

1039 Gs

103.9 mT

|

0.43 kg / 0.95 pounds

428.7 g / 4.2 N

|

weak grip |

| 20 mm |

635 Gs

63.5 mT

|

0.16 kg / 0.35 pounds

159.9 g / 1.6 N

|

weak grip |

| 30 mm |

285 Gs

28.5 mT

|

0.03 kg / 0.07 pounds

32.1 g / 0.3 N

|

weak grip |

| 50 mm |

90 Gs

9.0 mT

|

0.00 kg / 0.01 pounds

3.2 g / 0.0 N

|

weak grip |

Table 2: Slippage capacity (vertical surface)

MP 22x6x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

2.73 kg / 6.02 pounds

2730.0 g / 26.8 N

|

| 1 mm | Stal (~0.2) |

2.25 kg / 4.96 pounds

2252.0 g / 22.1 N

|

| 2 mm | Stal (~0.2) |

1.83 kg / 4.03 pounds

1826.0 g / 17.9 N

|

| 3 mm | Stal (~0.2) |

1.46 kg / 3.22 pounds

1460.0 g / 14.3 N

|

| 5 mm | Stal (~0.2) |

0.91 kg / 2.00 pounds

908.0 g / 8.9 N

|

| 10 mm | Stal (~0.2) |

0.27 kg / 0.59 pounds

266.0 g / 2.6 N

|

| 15 mm | Stal (~0.2) |

0.09 kg / 0.19 pounds

86.0 g / 0.8 N

|

| 20 mm | Stal (~0.2) |

0.03 kg / 0.07 pounds

32.0 g / 0.3 N

|

| 30 mm | Stal (~0.2) |

0.01 kg / 0.01 pounds

6.0 g / 0.1 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MP 22x6x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

4.10 kg / 9.03 pounds

4095.0 g / 40.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

2.73 kg / 6.02 pounds

2730.0 g / 26.8 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.37 kg / 3.01 pounds

1365.0 g / 13.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

6.83 kg / 15.05 pounds

6825.0 g / 67.0 N

|

Table 4: Steel thickness (substrate influence) - power losses

MP 22x6x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.68 kg / 1.50 pounds

682.5 g / 6.7 N

|

| 1 mm |

|

1.71 kg / 3.76 pounds

1706.3 g / 16.7 N

|

| 2 mm |

|

3.41 kg / 7.52 pounds

3412.5 g / 33.5 N

|

| 3 mm |

|

5.12 kg / 11.28 pounds

5118.8 g / 50.2 N

|

| 5 mm |

|

8.53 kg / 18.81 pounds

8531.3 g / 83.7 N

|

| 10 mm |

|

13.65 kg / 30.09 pounds

13650.0 g / 133.9 N

|

| 11 mm |

|

13.65 kg / 30.09 pounds

13650.0 g / 133.9 N

|

| 12 mm |

|

13.65 kg / 30.09 pounds

13650.0 g / 133.9 N

|

Table 5: Thermal stability (stability) - resistance threshold

MP 22x6x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

13.65 kg / 30.09 pounds

13650.0 g / 133.9 N

|

OK |

| 40 °C | -2.2% |

13.35 kg / 29.43 pounds

13349.7 g / 131.0 N

|

OK |

| 60 °C | -4.4% |

13.05 kg / 28.77 pounds

13049.4 g / 128.0 N

|

OK |

| 80 °C | -6.6% |

12.75 kg / 28.11 pounds

12749.1 g / 125.1 N

|

|

| 100 °C | -28.8% |

9.72 kg / 21.43 pounds

9718.8 g / 95.3 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MP 22x6x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

54.34 kg / 119.79 pounds

6 106 Gs

|

8.15 kg / 17.97 pounds

8151 g / 80.0 N

|

N/A |

| 1 mm |

49.50 kg / 109.14 pounds

11 193 Gs

|

7.43 kg / 16.37 pounds

7426 g / 72.8 N

|

44.55 kg / 98.22 pounds

~0 Gs

|

| 2 mm |

44.83 kg / 98.83 pounds

10 652 Gs

|

6.72 kg / 14.82 pounds

6724 g / 66.0 N

|

40.34 kg / 88.94 pounds

~0 Gs

|

| 3 mm |

40.43 kg / 89.14 pounds

10 116 Gs

|

6.06 kg / 13.37 pounds

6065 g / 59.5 N

|

36.39 kg / 80.22 pounds

~0 Gs

|

| 5 mm |

32.54 kg / 71.74 pounds

9 075 Gs

|

4.88 kg / 10.76 pounds

4881 g / 47.9 N

|

29.29 kg / 64.57 pounds

~0 Gs

|

| 10 mm |

18.07 kg / 39.83 pounds

6 762 Gs

|

2.71 kg / 5.98 pounds

2710 g / 26.6 N

|

16.26 kg / 35.85 pounds

~0 Gs

|

| 20 mm |

5.29 kg / 11.67 pounds

3 660 Gs

|

0.79 kg / 1.75 pounds

794 g / 7.8 N

|

4.76 kg / 10.50 pounds

~0 Gs

|

| 50 mm |

0.27 kg / 0.60 pounds

828 Gs

|

0.04 kg / 0.09 pounds

41 g / 0.4 N

|

0.24 kg / 0.54 pounds

~0 Gs

|

| 60 mm |

0.13 kg / 0.28 pounds

569 Gs

|

0.02 kg / 0.04 pounds

19 g / 0.2 N

|

0.12 kg / 0.25 pounds

~0 Gs

|

| 70 mm |

0.07 kg / 0.15 pounds

408 Gs

|

0.01 kg / 0.02 pounds

10 g / 0.1 N

|

0.06 kg / 0.13 pounds

~0 Gs

|

| 80 mm |

0.04 kg / 0.08 pounds

303 Gs

|

0.01 kg / 0.01 pounds

5 g / 0.1 N

|

0.03 kg / 0.07 pounds

~0 Gs

|

| 90 mm |

0.02 kg / 0.05 pounds

231 Gs

|

0.00 kg / 0.01 pounds

3 g / 0.0 N

|

0.02 kg / 0.04 pounds

~0 Gs

|

| 100 mm |

0.01 kg / 0.03 pounds

180 Gs

|

0.00 kg / 0.00 pounds

2 g / 0.0 N

|

0.01 kg / 0.03 pounds

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MP 22x6x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 15.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 12.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 9.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 7.0 cm |

| Car key | 50 Gs (5.0 mT) | 6.5 cm |

| Payment card | 400 Gs (40.0 mT) | 3.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.5 cm |

Table 8: Impact energy (cracking risk) - collision effects

MP 22x6x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

24.29 km/h

(6.75 m/s)

|

0.60 J | |

| 30 mm |

39.79 km/h

(11.05 m/s)

|

1.61 J | |

| 50 mm |

51.30 km/h

(14.25 m/s)

|

2.68 J | |

| 100 mm |

72.53 km/h

(20.15 m/s)

|

5.36 J |

Table 9: Coating parameters (durability)

MP 22x6x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MP 22x6x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 16 465 Mx | 164.7 µWb |

| Pc Coefficient | 1.13 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MP 22x6x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 13.65 kg | Standard |

| Water (riverbed) |

15.63 kg

(+1.98 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Caution: On a vertical surface, the magnet retains only ~20% of its max power.

2. Plate thickness effect

*Thin steel (e.g. 0.5mm PC case) drastically limits the holding force.

3. Heat tolerance

*For standard magnets, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.13

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more deals

Advantages as well as disadvantages of neodymium magnets.

Pros

- They virtually do not lose strength, because even after ten years the decline in efficiency is only ~1% (based on calculations),

- They are extremely resistant to demagnetization induced by external disturbances,

- By covering with a decorative coating of nickel, the element presents an professional look,

- Magnets possess huge magnetic induction on the working surface,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can function (depending on the form) even at a temperature of 230°C or more...

- Thanks to freedom in constructing and the capacity to modify to unusual requirements,

- Versatile presence in modern industrial fields – they are commonly used in mass storage devices, brushless drives, medical devices, as well as technologically advanced constructions.

- Thanks to efficiency per cm³, small magnets offer high operating force, with minimal size,

Disadvantages

- To avoid cracks upon strong impacts, we suggest using special steel housings. Such a solution protects the magnet and simultaneously improves its durability.

- When exposed to high temperature, neodymium magnets experience a drop in power. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets usually rust. For applications outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation as well as corrosion.

- Due to limitations in creating nuts and complex shapes in magnets, we propose using cover - magnetic mount.

- Possible danger related to microscopic parts of magnets can be dangerous, when accidentally swallowed, which is particularly important in the aspect of protecting the youngest. Additionally, small elements of these products can be problematic in diagnostics medical in case of swallowing.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Lifting parameters

Optimal lifting capacity of a neodymium magnet – what affects it?

- on a block made of structural steel, optimally conducting the magnetic field

- possessing a massiveness of minimum 10 mm to ensure full flux closure

- characterized by lack of roughness

- without the slightest insulating layer between the magnet and steel

- during pulling in a direction perpendicular to the mounting surface

- at ambient temperature room level

Impact of factors on magnetic holding capacity in practice

- Distance – the presence of foreign body (paint, dirt, gap) interrupts the magnetic circuit, which lowers power steeply (even by 50% at 0.5 mm).

- Direction of force – maximum parameter is obtained only during perpendicular pulling. The resistance to sliding of the magnet along the surface is typically many times smaller (approx. 1/5 of the lifting capacity).

- Element thickness – for full efficiency, the steel must be sufficiently thick. Paper-thin metal limits the attraction force (the magnet "punches through" it).

- Chemical composition of the base – low-carbon steel attracts best. Alloy steels reduce magnetic permeability and lifting capacity.

- Surface structure – the smoother and more polished the plate, the better the adhesion and higher the lifting capacity. Roughness creates an air distance.

- Heat – NdFeB sinters have a sensitivity to temperature. At higher temperatures they are weaker, and at low temperatures gain strength (up to a certain limit).

Holding force was measured on the plate surface of 20 mm thickness, when a perpendicular force was applied, in contrast under attempts to slide the magnet the holding force is lower. Moreover, even a minimal clearance between the magnet and the plate lowers the load capacity.

Precautions when working with NdFeB magnets

Allergic reactions

Certain individuals suffer from a hypersensitivity to nickel, which is the standard coating for NdFeB magnets. Frequent touching might lead to dermatitis. It is best to wear safety gloves.

Swallowing risk

Adult use only. Tiny parts can be swallowed, causing serious injuries. Keep away from children and animals.

Safe distance

Powerful magnetic fields can erase data on payment cards, hard drives, and storage devices. Keep a distance of min. 10 cm.

Warning for heart patients

Life threat: Neodymium magnets can turn off pacemakers and defibrillators. Do not approach if you have electronic implants.

Magnetic interference

A powerful magnetic field disrupts the functioning of compasses in phones and navigation systems. Maintain magnets close to a smartphone to prevent damaging the sensors.

Power loss in heat

Control the heat. Heating the magnet to high heat will ruin its magnetic structure and pulling force.

Pinching danger

Large magnets can smash fingers instantly. Do not put your hand betwixt two strong magnets.

Do not underestimate power

Exercise caution. Rare earth magnets act from a long distance and connect with huge force, often faster than you can move away.

Flammability

Combustion risk: Rare earth powder is highly flammable. Do not process magnets in home conditions as this risks ignition.

Fragile material

Watch out for shards. Magnets can explode upon uncontrolled impact, launching sharp fragments into the air. We recommend safety glasses.

![UMGGW 22x6 [M4] GW / N38 - magnetic holder rubber internal thread UMGGW 22x6 [M4] GW / N38 - magnetic holder rubber internal thread](https://cdn3.dhit.pl/graphics/products/umg-22x6-m4-gw-jek.jpg)