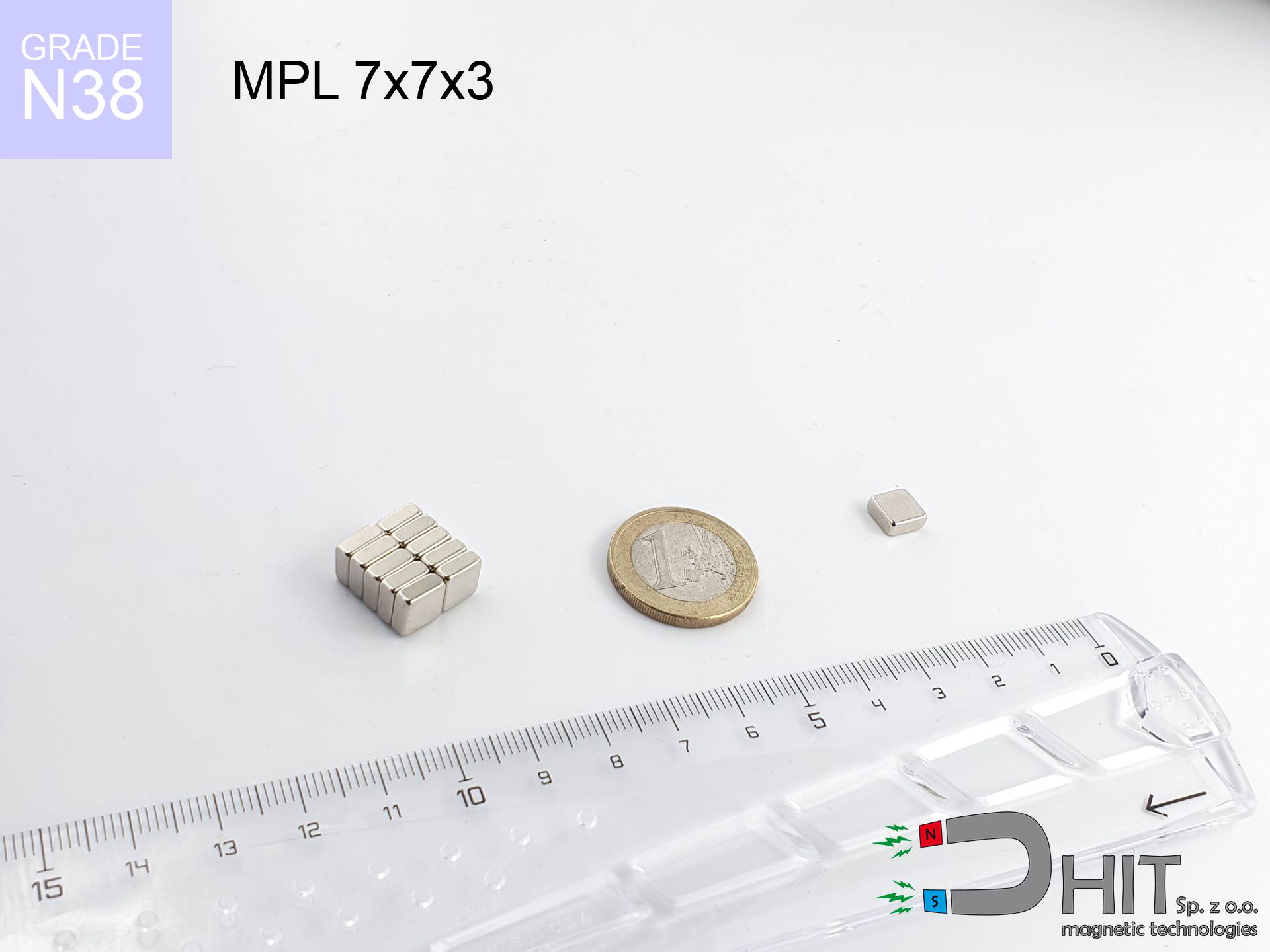

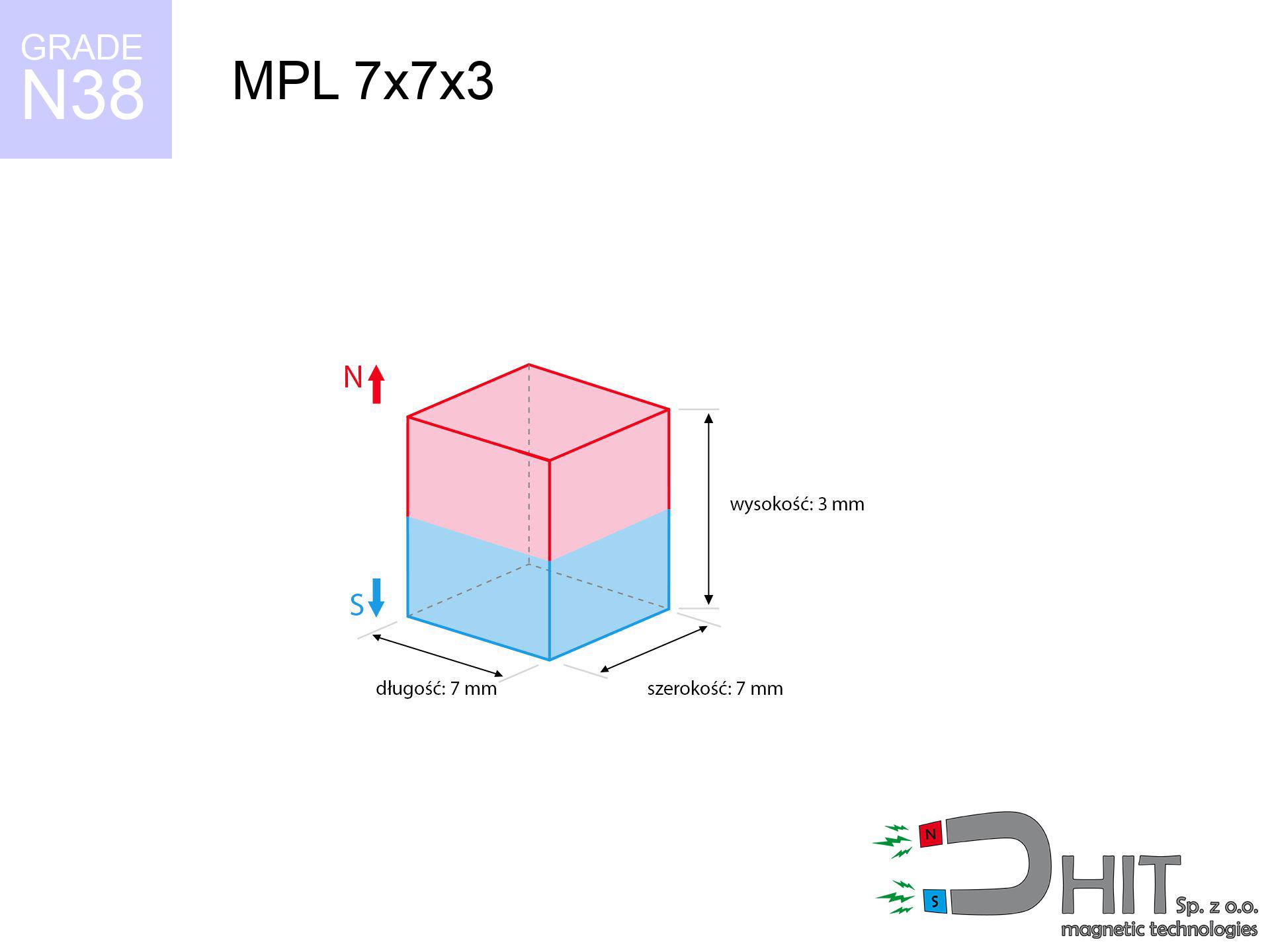

MPL 7x7x3 / N38 - lamellar magnet

lamellar magnet

Catalog no 020176

GTIN/EAN: 5906301811824

length

7 mm [±0,1 mm]

Width

7 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

1.1 g

Magnetization Direction

↑ axial

Load capacity

1.60 kg / 15.70 N

Magnetic Induction

376.99 mT / 3770 Gs

Coating

[NiCuNi] Nickel

0.541 ZŁ with VAT / pcs + price for transport

0.440 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

alternatively contact us via

request form

our website.

Weight and form of neodymium magnets can be estimated using our

modular calculator.

Orders submitted before 14:00 will be dispatched today!

Technical - MPL 7x7x3 / N38 - lamellar magnet

Specification / characteristics - MPL 7x7x3 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020176 |

| GTIN/EAN | 5906301811824 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 7 mm [±0,1 mm] |

| Width | 7 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 1.1 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.60 kg / 15.70 N |

| Magnetic Induction ~ ? | 376.99 mT / 3770 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the magnet - technical parameters

The following values are the direct effect of a engineering simulation. Results were calculated on models for the material Nd2Fe14B. Actual performance may differ from theoretical values. Please consider these calculations as a preliminary roadmap during assembly planning.

Table 1: Static force (pull vs distance) - characteristics

MPL 7x7x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3767 Gs

376.7 mT

|

1.60 kg / 3.53 LBS

1600.0 g / 15.7 N

|

weak grip |

| 1 mm |

2886 Gs

288.6 mT

|

0.94 kg / 2.07 LBS

939.5 g / 9.2 N

|

weak grip |

| 2 mm |

2048 Gs

204.8 mT

|

0.47 kg / 1.04 LBS

472.8 g / 4.6 N

|

weak grip |

| 3 mm |

1412 Gs

141.2 mT

|

0.22 kg / 0.50 LBS

224.8 g / 2.2 N

|

weak grip |

| 5 mm |

686 Gs

68.6 mT

|

0.05 kg / 0.12 LBS

53.0 g / 0.5 N

|

weak grip |

| 10 mm |

165 Gs

16.5 mT

|

0.00 kg / 0.01 LBS

3.1 g / 0.0 N

|

weak grip |

| 15 mm |

60 Gs

6.0 mT

|

0.00 kg / 0.00 LBS

0.4 g / 0.0 N

|

weak grip |

| 20 mm |

28 Gs

2.8 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

weak grip |

| 30 mm |

9 Gs

0.9 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

| 50 mm |

2 Gs

0.2 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

Table 2: Slippage load (wall)

MPL 7x7x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.32 kg / 0.71 LBS

320.0 g / 3.1 N

|

| 1 mm | Stal (~0.2) |

0.19 kg / 0.41 LBS

188.0 g / 1.8 N

|

| 2 mm | Stal (~0.2) |

0.09 kg / 0.21 LBS

94.0 g / 0.9 N

|

| 3 mm | Stal (~0.2) |

0.04 kg / 0.10 LBS

44.0 g / 0.4 N

|

| 5 mm | Stal (~0.2) |

0.01 kg / 0.02 LBS

10.0 g / 0.1 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MPL 7x7x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.48 kg / 1.06 LBS

480.0 g / 4.7 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.32 kg / 0.71 LBS

320.0 g / 3.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.16 kg / 0.35 LBS

160.0 g / 1.6 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.80 kg / 1.76 LBS

800.0 g / 7.8 N

|

Table 4: Material efficiency (substrate influence) - power losses

MPL 7x7x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.16 kg / 0.35 LBS

160.0 g / 1.6 N

|

| 1 mm |

|

0.40 kg / 0.88 LBS

400.0 g / 3.9 N

|

| 2 mm |

|

0.80 kg / 1.76 LBS

800.0 g / 7.8 N

|

| 3 mm |

|

1.20 kg / 2.65 LBS

1200.0 g / 11.8 N

|

| 5 mm |

|

1.60 kg / 3.53 LBS

1600.0 g / 15.7 N

|

| 10 mm |

|

1.60 kg / 3.53 LBS

1600.0 g / 15.7 N

|

| 11 mm |

|

1.60 kg / 3.53 LBS

1600.0 g / 15.7 N

|

| 12 mm |

|

1.60 kg / 3.53 LBS

1600.0 g / 15.7 N

|

Table 5: Thermal stability (stability) - resistance threshold

MPL 7x7x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.60 kg / 3.53 LBS

1600.0 g / 15.7 N

|

OK |

| 40 °C | -2.2% |

1.56 kg / 3.45 LBS

1564.8 g / 15.4 N

|

OK |

| 60 °C | -4.4% |

1.53 kg / 3.37 LBS

1529.6 g / 15.0 N

|

|

| 80 °C | -6.6% |

1.49 kg / 3.29 LBS

1494.4 g / 14.7 N

|

|

| 100 °C | -28.8% |

1.14 kg / 2.51 LBS

1139.2 g / 11.2 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MPL 7x7x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

4.29 kg / 9.45 LBS

5 173 Gs

|

0.64 kg / 1.42 LBS

643 g / 6.3 N

|

N/A |

| 1 mm |

3.38 kg / 7.44 LBS

6 685 Gs

|

0.51 kg / 1.12 LBS

506 g / 5.0 N

|

3.04 kg / 6.70 LBS

~0 Gs

|

| 2 mm |

2.52 kg / 5.55 LBS

5 773 Gs

|

0.38 kg / 0.83 LBS

378 g / 3.7 N

|

2.27 kg / 4.99 LBS

~0 Gs

|

| 3 mm |

1.81 kg / 3.99 LBS

4 893 Gs

|

0.27 kg / 0.60 LBS

271 g / 2.7 N

|

1.63 kg / 3.59 LBS

~0 Gs

|

| 5 mm |

0.88 kg / 1.93 LBS

3 405 Gs

|

0.13 kg / 0.29 LBS

131 g / 1.3 N

|

0.79 kg / 1.74 LBS

~0 Gs

|

| 10 mm |

0.14 kg / 0.31 LBS

1 372 Gs

|

0.02 kg / 0.05 LBS

21 g / 0.2 N

|

0.13 kg / 0.28 LBS

~0 Gs

|

| 20 mm |

0.01 kg / 0.02 LBS

329 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

30 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

18 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

12 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

8 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

6 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

4 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (implants) - warnings

MPL 7x7x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 2.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.0 cm |

| Car key | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (kinetic energy) - warning

MPL 7x7x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

38.51 km/h

(10.70 m/s)

|

0.06 J | |

| 30 mm |

66.62 km/h

(18.51 m/s)

|

0.19 J | |

| 50 mm |

86.01 km/h

(23.89 m/s)

|

0.31 J | |

| 100 mm |

121.63 km/h

(33.79 m/s)

|

0.63 J |

Table 9: Coating parameters (durability)

MPL 7x7x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MPL 7x7x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 909 Mx | 19.1 µWb |

| Pc Coefficient | 0.48 | Low (Flat) |

Table 11: Submerged application

MPL 7x7x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.60 kg | Standard |

| Water (riverbed) |

1.83 kg

(+0.23 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Warning: On a vertical wall, the magnet retains just approx. 20-30% of its max power.

2. Steel thickness impact

*Thin steel (e.g. computer case) drastically limits the holding force.

3. Temperature resistance

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.48

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also deals

Strengths as well as weaknesses of rare earth magnets.

Pros

- They retain attractive force for around ten years – the drop is just ~1% (in theory),

- They are noted for resistance to demagnetization induced by presence of other magnetic fields,

- Thanks to the reflective finish, the layer of Ni-Cu-Ni, gold-plated, or silver-plated gives an visually attractive appearance,

- Neodymium magnets create maximum magnetic induction on a small area, which ensures high operational effectiveness,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Possibility of individual shaping and optimizing to complex conditions,

- Key role in innovative solutions – they find application in hard drives, electromotive mechanisms, medical devices, and modern systems.

- Thanks to concentrated force, small magnets offer high operating force, with minimal size,

Weaknesses

- At very strong impacts they can crack, therefore we recommend placing them in steel cases. A metal housing provides additional protection against damage and increases the magnet's durability.

- Neodymium magnets lose their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation and corrosion.

- Limited possibility of creating threads in the magnet and complex shapes - preferred is casing - mounting mechanism.

- Health risk resulting from small fragments of magnets can be dangerous, in case of ingestion, which becomes key in the aspect of protecting the youngest. It is also worth noting that tiny parts of these magnets are able to be problematic in diagnostics medical in case of swallowing.

- Due to complex production process, their price exceeds standard values,

Holding force characteristics

Detachment force of the magnet in optimal conditions – what affects it?

- on a block made of mild steel, effectively closing the magnetic field

- whose transverse dimension reaches at least 10 mm

- with an ideally smooth contact surface

- under conditions of ideal adhesion (surface-to-surface)

- for force acting at a right angle (pull-off, not shear)

- at temperature room level

Practical aspects of lifting capacity – factors

- Gap between magnet and steel – every millimeter of separation (caused e.g. by veneer or dirt) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Direction of force – maximum parameter is available only during perpendicular pulling. The resistance to sliding of the magnet along the plate is standardly several times lower (approx. 1/5 of the lifting capacity).

- Base massiveness – insufficiently thick plate does not close the flux, causing part of the power to be lost to the other side.

- Metal type – different alloys attracts identically. Alloy additives weaken the attraction effect.

- Surface structure – the more even the plate, the larger the contact zone and higher the lifting capacity. Roughness acts like micro-gaps.

- Temperature – temperature increase causes a temporary drop of induction. It is worth remembering the maximum operating temperature for a given model.

Lifting capacity was determined with the use of a smooth steel plate of optimal thickness (min. 20 mm), under perpendicular pulling force, whereas under attempts to slide the magnet the holding force is lower. In addition, even a small distance between the magnet and the plate decreases the holding force.

H&S for magnets

Dust explosion hazard

Mechanical processing of NdFeB material poses a fire risk. Magnetic powder oxidizes rapidly with oxygen and is hard to extinguish.

Caution required

Be careful. Neodymium magnets act from a long distance and snap with massive power, often quicker than you can react.

This is not a toy

These products are not toys. Swallowing multiple magnets can lead to them pinching intestinal walls, which poses a severe health hazard and requires immediate surgery.

Data carriers

Do not bring magnets close to a wallet, computer, or screen. The magnetism can destroy these devices and wipe information from cards.

Material brittleness

Despite the nickel coating, neodymium is delicate and cannot withstand shocks. Do not hit, as the magnet may shatter into sharp, dangerous pieces.

Nickel allergy

It is widely known that the nickel plating (standard magnet coating) is a potent allergen. For allergy sufferers, refrain from direct skin contact or opt for versions in plastic housing.

Finger safety

Mind your fingers. Two large magnets will snap together instantly with a force of several hundred kilograms, crushing everything in their path. Be careful!

Heat sensitivity

Monitor thermal conditions. Exposing the magnet above 80 degrees Celsius will ruin its magnetic structure and pulling force.

Warning for heart patients

Medical warning: Strong magnets can deactivate heart devices and defibrillators. Stay away if you have medical devices.

Compass and GPS

An intense magnetic field negatively affects the operation of compasses in phones and GPS navigation. Do not bring magnets close to a device to prevent damaging the sensors.

![UMP 94x28 [3xM10] GW F300 GOLD Lina / N38 - search holder UMP 94x28 [3xM10] GW F300 GOLD Lina / N38 - search holder](https://cdn3.dhit.pl/graphics/products/ump-94x28-m10-gw-f300-+lina-kac.jpg)