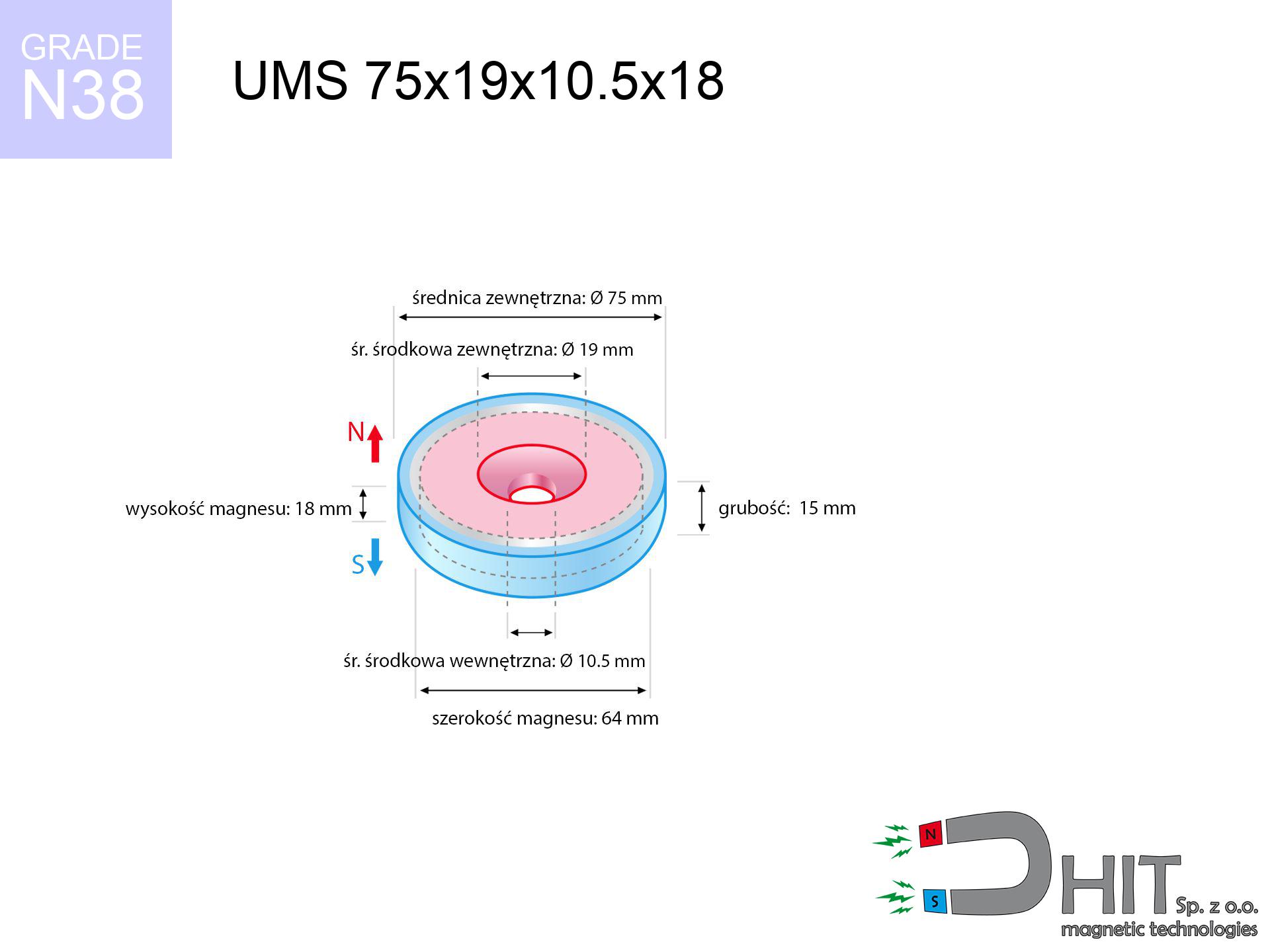

UMS 75x19x10.5x18 / N38 - conical magnetic holder

conical magnetic holder

Catalog no 220405

GTIN/EAN: 5906301814245

Diameter Ø

75 mm [±1 mm]

cone dimension Ø

19x10.5 mm [±1 mm]

Height

18 mm [±1 mm]

Weight

465 g

Magnetization Direction

↑ axial

Load capacity

162.00 kg / 1588.68 N

Coating

[NiCuNi] Nickel

125.56 ZŁ with VAT / pcs + price for transport

102.08 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

if you prefer send us a note using

contact form

the contact section.

Weight and form of neodymium magnets can be calculated using our

magnetic calculator.

Orders placed before 14:00 will be shipped the same business day.

Detailed specification - UMS 75x19x10.5x18 / N38 - conical magnetic holder

Specification / characteristics - UMS 75x19x10.5x18 / N38 - conical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 220405 |

| GTIN/EAN | 5906301814245 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 75 mm [±1 mm] |

| cone dimension Ø | 19x10.5 mm [±1 mm] |

| Height | 18 mm [±1 mm] |

| Weight | 465 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 162.00 kg / 1588.68 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Strengths as well as weaknesses of rare earth magnets.

Pros

- They do not lose magnetism, even after around 10 years – the reduction in lifting capacity is only ~1% (theoretically),

- They maintain their magnetic properties even under close interference source,

- The use of an aesthetic coating of noble metals (nickel, gold, silver) causes the element to be more visually attractive,

- Magnets exhibit extremely high magnetic induction on the outer side,

- Thanks to resistance to high temperature, they are capable of working (depending on the form) even at temperatures up to 230°C and higher...

- Possibility of individual modeling as well as optimizing to concrete conditions,

- Fundamental importance in innovative solutions – they are commonly used in magnetic memories, drive modules, advanced medical instruments, as well as modern systems.

- Relatively small size with high pulling force – neodymium magnets offer high power in compact dimensions, which makes them useful in compact constructions

Weaknesses

- At very strong impacts they can crack, therefore we recommend placing them in special holders. A metal housing provides additional protection against damage and increases the magnet's durability.

- Neodymium magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material immune to moisture, when using outdoors

- Limited ability of creating nuts in the magnet and complex forms - recommended is cover - magnetic holder.

- Potential hazard to health – tiny shards of magnets pose a threat, when accidentally swallowed, which is particularly important in the context of child safety. It is also worth noting that small elements of these devices can complicate diagnosis medical after entering the body.

- With large orders the cost of neodymium magnets is a challenge,

Lifting parameters

Maximum lifting force for a neodymium magnet – what it depends on?

- on a base made of structural steel, effectively closing the magnetic flux

- possessing a thickness of minimum 10 mm to ensure full flux closure

- characterized by lack of roughness

- under conditions of no distance (surface-to-surface)

- under vertical force vector (90-degree angle)

- at conditions approx. 20°C

Lifting capacity in real conditions – factors

- Gap between magnet and steel – even a fraction of a millimeter of separation (caused e.g. by veneer or dirt) significantly weakens the pulling force, often by half at just 0.5 mm.

- Loading method – declared lifting capacity refers to pulling vertically. When attempting to slide, the magnet exhibits much less (often approx. 20-30% of nominal force).

- Steel thickness – insufficiently thick steel causes magnetic saturation, causing part of the flux to be escaped to the other side.

- Material type – the best choice is high-permeability steel. Hardened steels may generate lower lifting capacity.

- Surface condition – ground elements ensure maximum contact, which increases field saturation. Rough surfaces weaken the grip.

- Heat – NdFeB sinters have a sensitivity to temperature. At higher temperatures they are weaker, and at low temperatures gain strength (up to a certain limit).

Lifting capacity testing was carried out on plates with a smooth surface of suitable thickness, under perpendicular forces, however under parallel forces the holding force is lower. In addition, even a slight gap between the magnet and the plate reduces the load capacity.

Safety rules for work with neodymium magnets

Pinching danger

Big blocks can crush fingers instantly. Under no circumstances put your hand between two attracting surfaces.

No play value

Absolutely keep magnets out of reach of children. Choking hazard is high, and the effects of magnets connecting inside the body are life-threatening.

Thermal limits

Avoid heat. NdFeB magnets are sensitive to heat. If you need operation above 80°C, look for HT versions (H, SH, UH).

Skin irritation risks

It is widely known that nickel (the usual finish) is a strong allergen. For allergy sufferers, avoid touching magnets with bare hands or select encased magnets.

Life threat

Medical warning: Strong magnets can turn off pacemakers and defibrillators. Do not approach if you have electronic implants.

Conscious usage

Exercise caution. Neodymium magnets act from a long distance and snap with huge force, often faster than you can react.

Magnetic media

Very strong magnetic fields can erase data on credit cards, HDDs, and storage devices. Maintain a gap of at least 10 cm.

Flammability

Dust generated during cutting of magnets is self-igniting. Avoid drilling into magnets unless you are an expert.

Compass and GPS

Note: rare earth magnets generate a field that interferes with sensitive sensors. Keep a separation from your mobile, device, and GPS.

Eye protection

Beware of splinters. Magnets can explode upon violent connection, ejecting sharp fragments into the air. We recommend safety glasses.

![SM 25x400 [2xM8] / N52 - magnetic separator SM 25x400 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x400-2xm8-hoj.jpg)

![SM 32x150 [2xM8] / N52 - magnetic separator SM 32x150 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x150-2xm8-xuc.jpg)