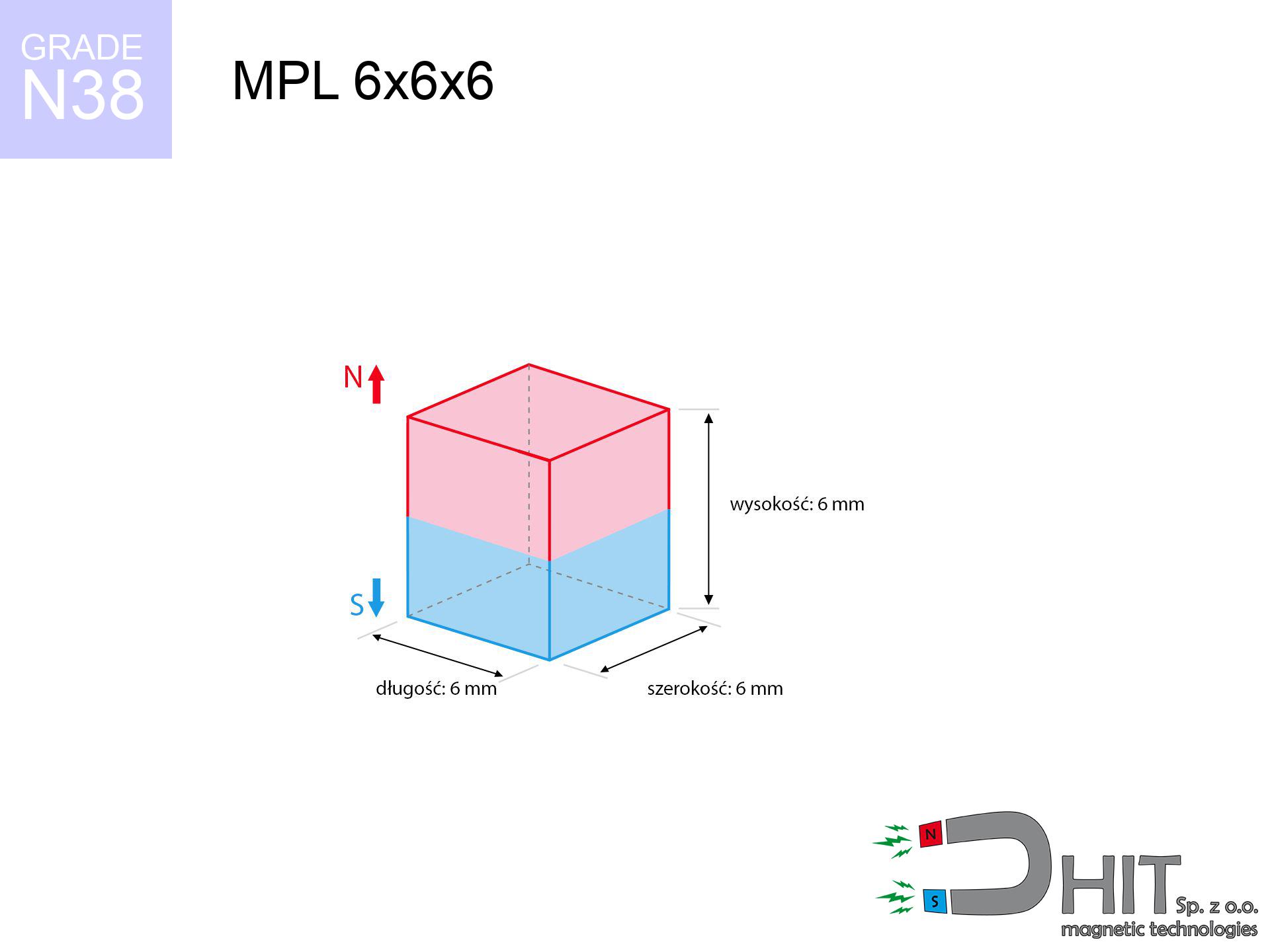

MPL 6x6x6 / N38 - lamellar magnet

lamellar magnet

Catalog no 020175

GTIN/EAN: 5906301811817

length

6 mm [±0,1 mm]

Width

6 mm [±0,1 mm]

Height

6 mm [±0,1 mm]

Weight

1.62 g

Magnetization Direction

↑ axial

Load capacity

1.38 kg / 13.54 N

Magnetic Induction

539.50 mT / 5395 Gs

Coating

[NiCuNi] Nickel

0.898 ZŁ with VAT / pcs + price for transport

0.730 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

if you prefer drop us a message by means of

contact form

the contact page.

Force and appearance of a neodymium magnet can be analyzed on our

modular calculator.

Orders submitted before 14:00 will be dispatched today!

Technical parameters of the product - MPL 6x6x6 / N38 - lamellar magnet

Specification / characteristics - MPL 6x6x6 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020175 |

| GTIN/EAN | 5906301811817 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 6 mm [±0,1 mm] |

| Width | 6 mm [±0,1 mm] |

| Height | 6 mm [±0,1 mm] |

| Weight | 1.62 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.38 kg / 13.54 N |

| Magnetic Induction ~ ? | 539.50 mT / 5395 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the product - report

These values are the direct effect of a mathematical calculation. Results were calculated on algorithms for the material Nd2Fe14B. Operational performance may differ. Use these data as a reference point for designers.

Table 1: Static force (pull vs distance) - power drop

MPL 6x6x6 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5389 Gs

538.9 mT

|

1.38 kg / 3.04 pounds

1380.0 g / 13.5 N

|

low risk |

| 1 mm |

3805 Gs

380.5 mT

|

0.69 kg / 1.52 pounds

688.0 g / 6.7 N

|

low risk |

| 2 mm |

2530 Gs

253.0 mT

|

0.30 kg / 0.67 pounds

304.3 g / 3.0 N

|

low risk |

| 3 mm |

1671 Gs

167.1 mT

|

0.13 kg / 0.29 pounds

132.7 g / 1.3 N

|

low risk |

| 5 mm |

784 Gs

78.4 mT

|

0.03 kg / 0.06 pounds

29.2 g / 0.3 N

|

low risk |

| 10 mm |

192 Gs

19.2 mT

|

0.00 kg / 0.00 pounds

1.8 g / 0.0 N

|

low risk |

| 15 mm |

73 Gs

7.3 mT

|

0.00 kg / 0.00 pounds

0.3 g / 0.0 N

|

low risk |

| 20 mm |

35 Gs

3.5 mT

|

0.00 kg / 0.00 pounds

0.1 g / 0.0 N

|

low risk |

| 30 mm |

12 Gs

1.2 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

low risk |

| 50 mm |

3 Gs

0.3 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

low risk |

Table 2: Sliding force (wall)

MPL 6x6x6 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.28 kg / 0.61 pounds

276.0 g / 2.7 N

|

| 1 mm | Stal (~0.2) |

0.14 kg / 0.30 pounds

138.0 g / 1.4 N

|

| 2 mm | Stal (~0.2) |

0.06 kg / 0.13 pounds

60.0 g / 0.6 N

|

| 3 mm | Stal (~0.2) |

0.03 kg / 0.06 pounds

26.0 g / 0.3 N

|

| 5 mm | Stal (~0.2) |

0.01 kg / 0.01 pounds

6.0 g / 0.1 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - vertical pull

MPL 6x6x6 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.41 kg / 0.91 pounds

414.0 g / 4.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.28 kg / 0.61 pounds

276.0 g / 2.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.14 kg / 0.30 pounds

138.0 g / 1.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.69 kg / 1.52 pounds

690.0 g / 6.8 N

|

Table 4: Steel thickness (substrate influence) - power losses

MPL 6x6x6 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.14 kg / 0.30 pounds

138.0 g / 1.4 N

|

| 1 mm |

|

0.35 kg / 0.76 pounds

345.0 g / 3.4 N

|

| 2 mm |

|

0.69 kg / 1.52 pounds

690.0 g / 6.8 N

|

| 3 mm |

|

1.04 kg / 2.28 pounds

1035.0 g / 10.2 N

|

| 5 mm |

|

1.38 kg / 3.04 pounds

1380.0 g / 13.5 N

|

| 10 mm |

|

1.38 kg / 3.04 pounds

1380.0 g / 13.5 N

|

| 11 mm |

|

1.38 kg / 3.04 pounds

1380.0 g / 13.5 N

|

| 12 mm |

|

1.38 kg / 3.04 pounds

1380.0 g / 13.5 N

|

Table 5: Thermal stability (material behavior) - thermal limit

MPL 6x6x6 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.38 kg / 3.04 pounds

1380.0 g / 13.5 N

|

OK |

| 40 °C | -2.2% |

1.35 kg / 2.98 pounds

1349.6 g / 13.2 N

|

OK |

| 60 °C | -4.4% |

1.32 kg / 2.91 pounds

1319.3 g / 12.9 N

|

OK |

| 80 °C | -6.6% |

1.29 kg / 2.84 pounds

1288.9 g / 12.6 N

|

|

| 100 °C | -28.8% |

0.98 kg / 2.17 pounds

982.6 g / 9.6 N

|

Table 6: Two magnets (attraction) - field collision

MPL 6x6x6 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

6.44 kg / 14.21 pounds

5 949 Gs

|

0.97 kg / 2.13 pounds

967 g / 9.5 N

|

N/A |

| 1 mm |

4.66 kg / 10.28 pounds

9 167 Gs

|

0.70 kg / 1.54 pounds

699 g / 6.9 N

|

4.20 kg / 9.25 pounds

~0 Gs

|

| 2 mm |

3.21 kg / 7.08 pounds

7 610 Gs

|

0.48 kg / 1.06 pounds

482 g / 4.7 N

|

2.89 kg / 6.38 pounds

~0 Gs

|

| 3 mm |

2.15 kg / 4.74 pounds

6 228 Gs

|

0.32 kg / 0.71 pounds

323 g / 3.2 N

|

1.94 kg / 4.27 pounds

~0 Gs

|

| 5 mm |

0.94 kg / 2.06 pounds

4 107 Gs

|

0.14 kg / 0.31 pounds

140 g / 1.4 N

|

0.84 kg / 1.86 pounds

~0 Gs

|

| 10 mm |

0.14 kg / 0.30 pounds

1 568 Gs

|

0.02 kg / 0.05 pounds

20 g / 0.2 N

|

0.12 kg / 0.27 pounds

~0 Gs

|

| 20 mm |

0.01 kg / 0.02 pounds

384 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

39 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

24 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

16 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

11 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

8 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

6 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Safety (HSE) (implants) - precautionary measures

MPL 6x6x6 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 2.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 2.0 cm |

| Remote | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (kinetic energy) - collision effects

MPL 6x6x6 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

29.46 km/h

(8.18 m/s)

|

0.05 J | |

| 30 mm |

50.98 km/h

(14.16 m/s)

|

0.16 J | |

| 50 mm |

65.82 km/h

(18.28 m/s)

|

0.27 J | |

| 100 mm |

93.08 km/h

(25.86 m/s)

|

0.54 J |

Table 9: Anti-corrosion coating durability

MPL 6x6x6 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MPL 6x6x6 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 982 Mx | 19.8 µWb |

| Pc Coefficient | 0.84 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MPL 6x6x6 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.38 kg | Standard |

| Water (riverbed) |

1.58 kg

(+0.20 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical wall, the magnet holds just a fraction of its nominal pull.

2. Plate thickness effect

*Thin steel (e.g. computer case) significantly weakens the holding force.

3. Heat tolerance

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.84

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also proposals

Pros as well as cons of rare earth magnets.

Pros

- They do not lose strength, even after nearly ten years – the drop in power is only ~1% (according to tests),

- They show high resistance to demagnetization induced by external magnetic fields,

- In other words, due to the glossy surface of silver, the element is aesthetically pleasing,

- Magnetic induction on the working part of the magnet remains exceptional,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and are able to act (depending on the form) even at a temperature of 230°C or more...

- Possibility of accurate machining as well as adjusting to precise applications,

- Significant place in innovative solutions – they are commonly used in data components, brushless drives, diagnostic systems, also modern systems.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Limitations

- They are fragile upon too strong impacts. To avoid cracks, it is worth protecting magnets using a steel holder. Such protection not only protects the magnet but also increases its resistance to damage

- We warn that neodymium magnets can lose their power at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material stable to moisture, when using outdoors

- Due to limitations in realizing threads and complex forms in magnets, we propose using a housing - magnetic holder.

- Possible danger related to microscopic parts of magnets are risky, if swallowed, which is particularly important in the context of child safety. Furthermore, small elements of these devices are able to complicate diagnosis medical in case of swallowing.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Holding force characteristics

Magnetic strength at its maximum – what affects it?

- on a plate made of structural steel, optimally conducting the magnetic flux

- with a thickness of at least 10 mm

- characterized by smoothness

- with total lack of distance (no impurities)

- during detachment in a direction vertical to the plane

- in neutral thermal conditions

Lifting capacity in practice – influencing factors

- Air gap (between the magnet and the metal), since even a tiny distance (e.g. 0.5 mm) results in a drastic drop in lifting capacity by up to 50% (this also applies to paint, corrosion or debris).

- Force direction – declared lifting capacity refers to detachment vertically. When applying parallel force, the magnet exhibits significantly lower power (typically approx. 20-30% of nominal force).

- Metal thickness – the thinner the sheet, the weaker the hold. Magnetic flux passes through the material instead of generating force.

- Plate material – low-carbon steel attracts best. Alloy steels reduce magnetic permeability and holding force.

- Base smoothness – the smoother and more polished the plate, the larger the contact zone and stronger the hold. Roughness creates an air distance.

- Thermal factor – hot environment reduces pulling force. Exceeding the limit temperature can permanently demagnetize the magnet.

Lifting capacity was measured with the use of a polished steel plate of optimal thickness (min. 20 mm), under perpendicular pulling force, in contrast under shearing force the load capacity is reduced by as much as 5 times. Additionally, even a minimal clearance between the magnet and the plate reduces the lifting capacity.

Safe handling of neodymium magnets

Mechanical processing

Machining of NdFeB material carries a risk of fire risk. Neodymium dust oxidizes rapidly with oxygen and is difficult to extinguish.

Handling rules

Before starting, check safety instructions. Sudden snapping can destroy the magnet or injure your hand. Be predictive.

Protect data

Avoid bringing magnets near a purse, laptop, or screen. The magnetic field can irreversibly ruin these devices and erase data from cards.

Phone sensors

Navigation devices and smartphones are extremely susceptible to magnetic fields. Direct contact with a powerful NdFeB magnet can permanently damage the sensors in your phone.

Demagnetization risk

Watch the temperature. Exposing the magnet above 80 degrees Celsius will ruin its magnetic structure and pulling force.

Swallowing risk

Neodymium magnets are not intended for children. Accidental ingestion of multiple magnets can lead to them attracting across intestines, which poses a severe health hazard and requires urgent medical intervention.

Bodily injuries

Pinching hazard: The attraction force is so immense that it can result in hematomas, pinching, and even bone fractures. Protective gloves are recommended.

Shattering risk

Despite metallic appearance, neodymium is brittle and cannot withstand shocks. Do not hit, as the magnet may shatter into hazardous fragments.

Allergy Warning

Certain individuals have a contact allergy to nickel, which is the common plating for neodymium magnets. Frequent touching may cause skin redness. It is best to wear protective gloves.

Warning for heart patients

People with a heart stimulator must keep an large gap from magnets. The magnetic field can interfere with the operation of the life-saving device.

![UMGGW 34x8 [M4] GW / N38 - magnetic holder rubber internal thread UMGGW 34x8 [M4] GW / N38 - magnetic holder rubber internal thread](https://cdn3.dhit.pl/graphics/products/umg-34x8-m4-gw-kek.jpg)