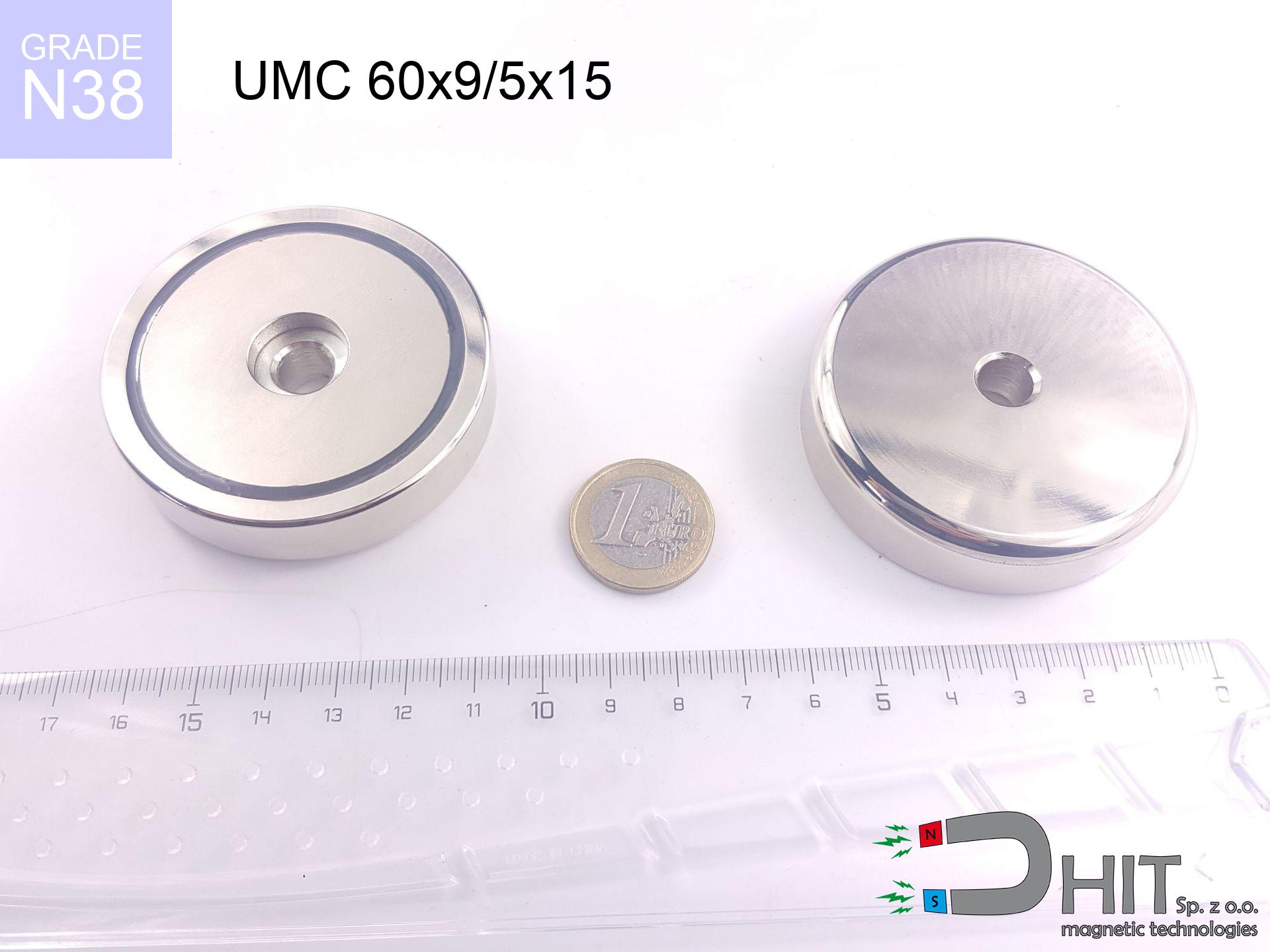

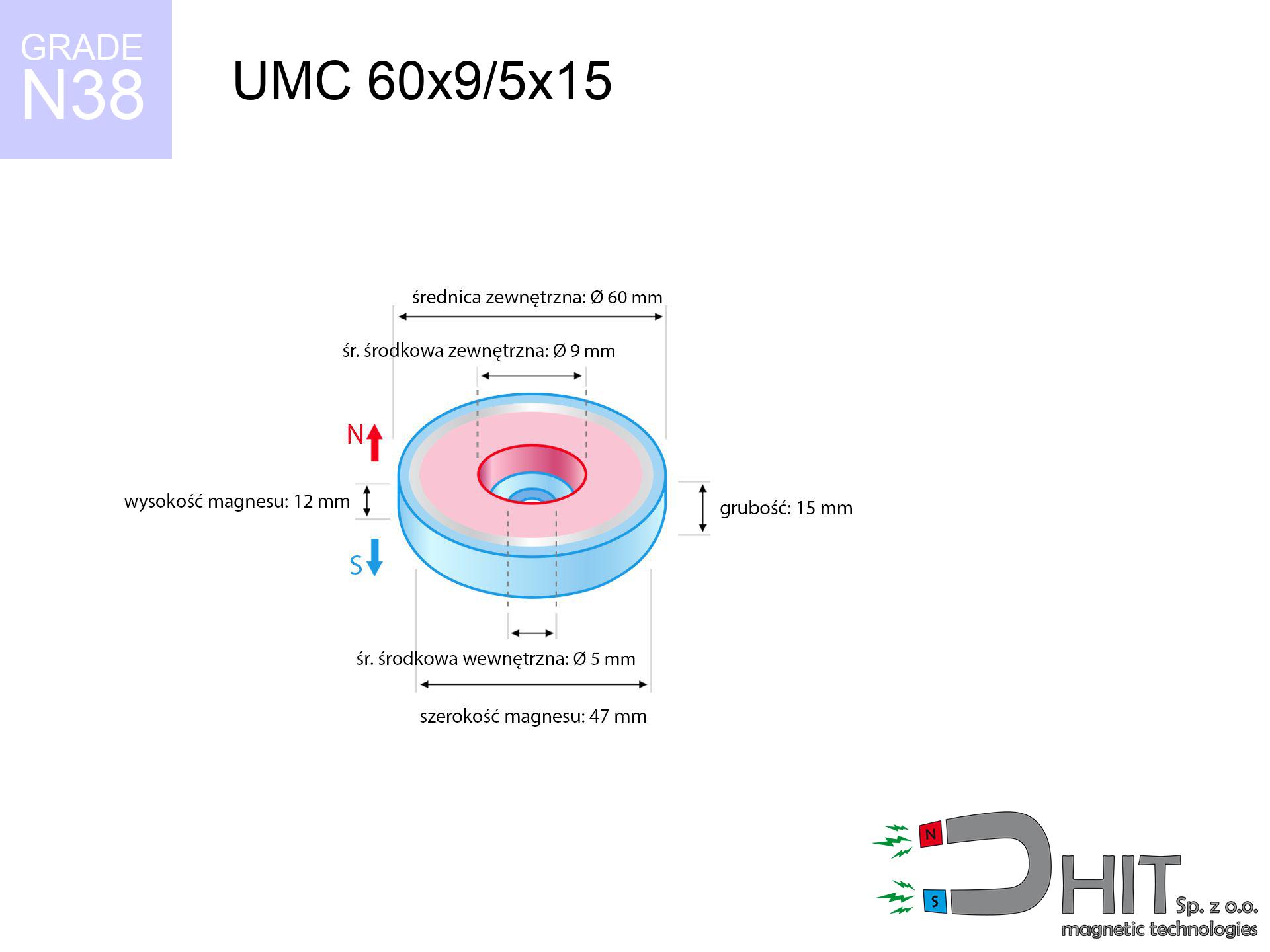

UMC 60x9/5x15 / N38 - cylindrical magnetic holder

cylindrical magnetic holder

Catalog no 320413

GTIN/EAN: 5906301814696

Diameter

60 mm [±1 mm]

internal diameter Ø

9/5 mm [±1 mm]

Height

15 mm [±1 mm]

Weight

240 g

Load capacity

95.00 kg / 931.63 N

Coating

[NiCuNi] Nickel

64.94 ZŁ with VAT / pcs + price for transport

52.80 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

if you prefer drop us a message via

inquiry form

our website.

Parameters and appearance of neodymium magnets can be reviewed using our

power calculator.

Same-day processing for orders placed before 14:00.

Detailed specification - UMC 60x9/5x15 / N38 - cylindrical magnetic holder

Specification / characteristics - UMC 60x9/5x15 / N38 - cylindrical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 320413 |

| GTIN/EAN | 5906301814696 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 60 mm [±1 mm] |

| internal diameter Ø | 9/5 mm [±1 mm] |

| Height | 15 mm [±1 mm] |

| Weight | 240 g |

| Load capacity ~ ? | 95.00 kg / 931.63 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out more deals

Strengths and weaknesses of Nd2Fe14B magnets.

Advantages

- They have unchanged lifting capacity, and over more than 10 years their attraction force decreases symbolically – ~1% (according to theory),

- They maintain their magnetic properties even under external field action,

- The use of an shiny layer of noble metals (nickel, gold, silver) causes the element to look better,

- The surface of neodymium magnets generates a strong magnetic field – this is a distinguishing feature,

- Thanks to resistance to high temperature, they are able to function (depending on the form) even at temperatures up to 230°C and higher...

- Thanks to the possibility of precise forming and adaptation to custom projects, magnetic components can be produced in a variety of geometric configurations, which increases their versatility,

- Huge importance in electronics industry – they serve a role in hard drives, electric drive systems, medical devices, as well as complex engineering applications.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Cons

- At very strong impacts they can crack, therefore we recommend placing them in special holders. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- Neodymium magnets lose their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- When exposed to humidity, magnets start to rust. For applications outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation and corrosion.

- Limited possibility of creating threads in the magnet and complicated shapes - preferred is casing - mounting mechanism.

- Possible danger to health – tiny shards of magnets pose a threat, in case of ingestion, which becomes key in the context of child safety. Additionally, small components of these devices are able to disrupt the diagnostic process medical in case of swallowing.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Pull force analysis

Best holding force of the magnet in ideal parameters – what contributes to it?

- with the contact of a sheet made of special test steel, ensuring full magnetic saturation

- whose transverse dimension reaches at least 10 mm

- with an ground contact surface

- with total lack of distance (no coatings)

- under vertical force direction (90-degree angle)

- at standard ambient temperature

Lifting capacity in real conditions – factors

- Distance (between the magnet and the metal), since even a microscopic distance (e.g. 0.5 mm) results in a drastic drop in force by up to 50% (this also applies to paint, corrosion or dirt).

- Force direction – declared lifting capacity refers to detachment vertically. When attempting to slide, the magnet exhibits much less (typically approx. 20-30% of maximum force).

- Element thickness – for full efficiency, the steel must be adequately massive. Thin sheet limits the lifting capacity (the magnet "punches through" it).

- Plate material – low-carbon steel attracts best. Alloy steels lower magnetic properties and lifting capacity.

- Surface finish – ideal contact is obtained only on smooth steel. Any scratches and bumps create air cushions, weakening the magnet.

- Thermal environment – temperature increase causes a temporary drop of induction. It is worth remembering the maximum operating temperature for a given model.

Lifting capacity testing was conducted on a smooth plate of optimal thickness, under a perpendicular pulling force, in contrast under parallel forces the load capacity is reduced by as much as 75%. In addition, even a minimal clearance between the magnet’s surface and the plate decreases the holding force.

Safety rules for work with NdFeB magnets

Nickel coating and allergies

A percentage of the population suffer from a hypersensitivity to nickel, which is the standard coating for neodymium magnets. Frequent touching might lead to an allergic reaction. We strongly advise use protective gloves.

Bone fractures

Risk of injury: The pulling power is so great that it can cause blood blisters, pinching, and even bone fractures. Protective gloves are recommended.

Safe distance

Do not bring magnets near a wallet, laptop, or TV. The magnetic field can destroy these devices and wipe information from cards.

Eye protection

Watch out for shards. Magnets can explode upon violent connection, launching shards into the air. We recommend safety glasses.

Phone sensors

An intense magnetic field disrupts the operation of magnetometers in phones and navigation systems. Maintain magnets close to a device to prevent breaking the sensors.

Do not overheat magnets

Control the heat. Heating the magnet to high heat will permanently weaken its magnetic structure and pulling force.

Handling guide

Exercise caution. Neodymium magnets act from a long distance and snap with huge force, often faster than you can move away.

Machining danger

Machining of neodymium magnets carries a risk of fire risk. Neodymium dust oxidizes rapidly with oxygen and is difficult to extinguish.

Warning for heart patients

Health Alert: Strong magnets can deactivate heart devices and defibrillators. Do not approach if you have electronic implants.

Danger to the youngest

Only for adults. Tiny parts can be swallowed, leading to intestinal necrosis. Store away from children and animals.

![SM 32x300 [2xM8] / N42 - magnetic separator SM 32x300 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x300-2xm8-pel.jpg)