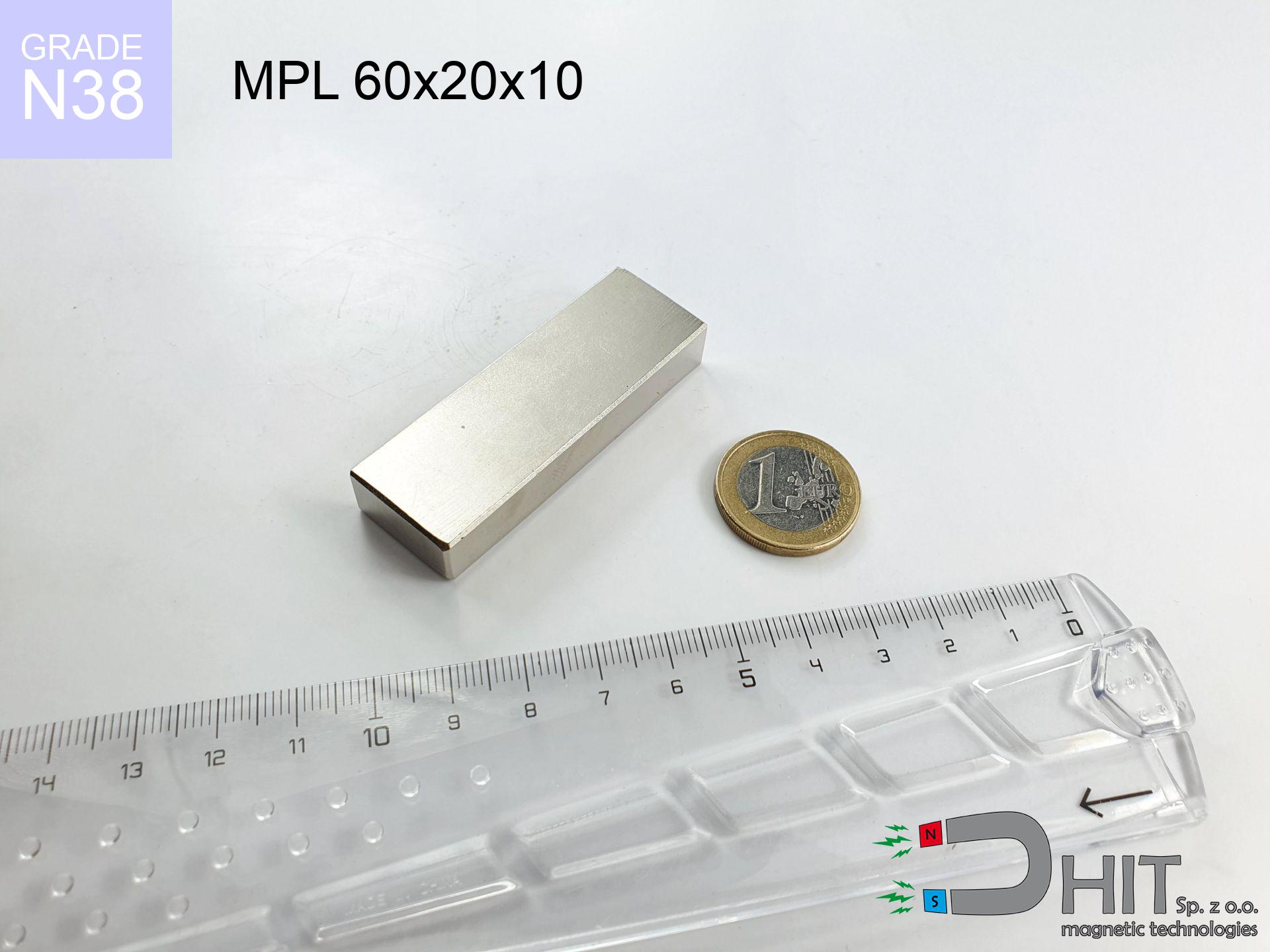

MPL 60x20x10 / N38 - lamellar magnet

lamellar magnet

Catalog no 020174

GTIN/EAN: 5906301811800

length

60 mm [±0,1 mm]

Width

20 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

90 g

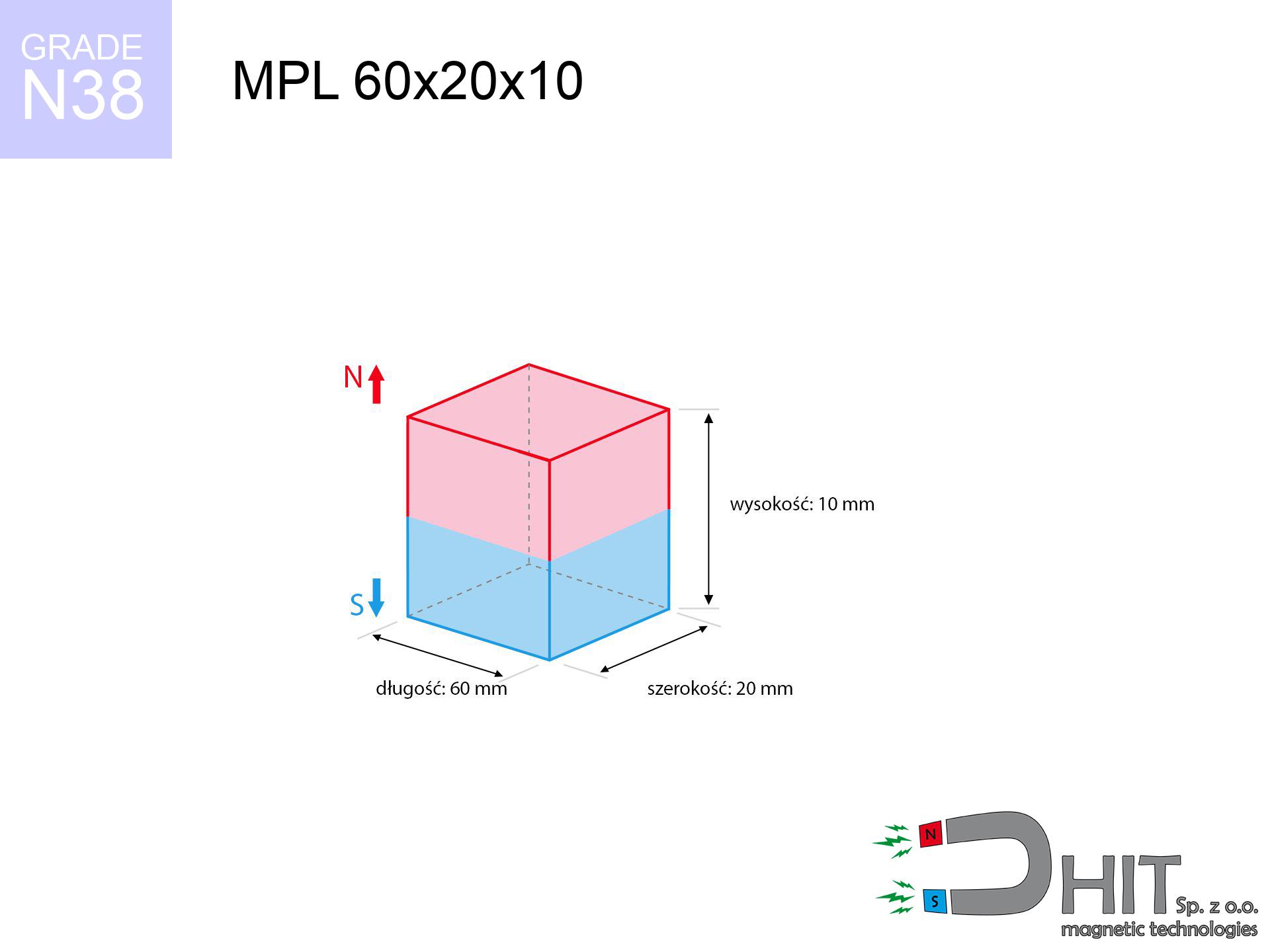

Magnetization Direction

↑ axial

Load capacity

35.61 kg / 349.34 N

Magnetic Induction

329.64 mT / 3296 Gs

Coating

[NiCuNi] Nickel

68.27 ZŁ with VAT / pcs + price for transport

55.50 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

otherwise get in touch through

request form

the contact section.

Specifications along with form of a neodymium magnet can be tested on our

our magnetic calculator.

Same-day processing for orders placed before 14:00.

Physical properties - MPL 60x20x10 / N38 - lamellar magnet

Specification / characteristics - MPL 60x20x10 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020174 |

| GTIN/EAN | 5906301811800 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 60 mm [±0,1 mm] |

| Width | 20 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 90 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 35.61 kg / 349.34 N |

| Magnetic Induction ~ ? | 329.64 mT / 3296 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the magnet - data

Presented information constitute the direct effect of a engineering calculation. Results are based on algorithms for the class Nd2Fe14B. Operational performance might slightly differ from theoretical values. Use these data as a preliminary roadmap when designing systems.

Table 1: Static force (force vs distance) - power drop

MPL 60x20x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3296 Gs

329.6 mT

|

35.61 kg / 78.51 lbs

35610.0 g / 349.3 N

|

critical level |

| 1 mm |

3087 Gs

308.7 mT

|

31.25 kg / 68.89 lbs

31248.2 g / 306.5 N

|

critical level |

| 2 mm |

2866 Gs

286.6 mT

|

26.93 kg / 59.37 lbs

26929.3 g / 264.2 N

|

critical level |

| 3 mm |

2643 Gs

264.3 mT

|

22.90 kg / 50.48 lbs

22895.5 g / 224.6 N

|

critical level |

| 5 mm |

2216 Gs

221.6 mT

|

16.10 kg / 35.50 lbs

16103.3 g / 158.0 N

|

critical level |

| 10 mm |

1397 Gs

139.7 mT

|

6.40 kg / 14.11 lbs

6402.3 g / 62.8 N

|

medium risk |

| 15 mm |

907 Gs

90.7 mT

|

2.70 kg / 5.95 lbs

2697.7 g / 26.5 N

|

medium risk |

| 20 mm |

615 Gs

61.5 mT

|

1.24 kg / 2.73 lbs

1239.2 g / 12.2 N

|

weak grip |

| 30 mm |

314 Gs

31.4 mT

|

0.32 kg / 0.71 lbs

322.6 g / 3.2 N

|

weak grip |

| 50 mm |

108 Gs

10.8 mT

|

0.04 kg / 0.09 lbs

38.6 g / 0.4 N

|

weak grip |

Table 2: Vertical load (wall)

MPL 60x20x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

7.12 kg / 15.70 lbs

7122.0 g / 69.9 N

|

| 1 mm | Stal (~0.2) |

6.25 kg / 13.78 lbs

6250.0 g / 61.3 N

|

| 2 mm | Stal (~0.2) |

5.39 kg / 11.87 lbs

5386.0 g / 52.8 N

|

| 3 mm | Stal (~0.2) |

4.58 kg / 10.10 lbs

4580.0 g / 44.9 N

|

| 5 mm | Stal (~0.2) |

3.22 kg / 7.10 lbs

3220.0 g / 31.6 N

|

| 10 mm | Stal (~0.2) |

1.28 kg / 2.82 lbs

1280.0 g / 12.6 N

|

| 15 mm | Stal (~0.2) |

0.54 kg / 1.19 lbs

540.0 g / 5.3 N

|

| 20 mm | Stal (~0.2) |

0.25 kg / 0.55 lbs

248.0 g / 2.4 N

|

| 30 mm | Stal (~0.2) |

0.06 kg / 0.14 lbs

64.0 g / 0.6 N

|

| 50 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

8.0 g / 0.1 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MPL 60x20x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

10.68 kg / 23.55 lbs

10683.0 g / 104.8 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

7.12 kg / 15.70 lbs

7122.0 g / 69.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

3.56 kg / 7.85 lbs

3561.0 g / 34.9 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

17.81 kg / 39.25 lbs

17805.0 g / 174.7 N

|

Table 4: Steel thickness (saturation) - power losses

MPL 60x20x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.78 kg / 3.93 lbs

1780.5 g / 17.5 N

|

| 1 mm |

|

4.45 kg / 9.81 lbs

4451.3 g / 43.7 N

|

| 2 mm |

|

8.90 kg / 19.63 lbs

8902.5 g / 87.3 N

|

| 3 mm |

|

13.35 kg / 29.44 lbs

13353.8 g / 131.0 N

|

| 5 mm |

|

22.26 kg / 49.07 lbs

22256.3 g / 218.3 N

|

| 10 mm |

|

35.61 kg / 78.51 lbs

35610.0 g / 349.3 N

|

| 11 mm |

|

35.61 kg / 78.51 lbs

35610.0 g / 349.3 N

|

| 12 mm |

|

35.61 kg / 78.51 lbs

35610.0 g / 349.3 N

|

Table 5: Thermal resistance (stability) - power drop

MPL 60x20x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

35.61 kg / 78.51 lbs

35610.0 g / 349.3 N

|

OK |

| 40 °C | -2.2% |

34.83 kg / 76.78 lbs

34826.6 g / 341.6 N

|

OK |

| 60 °C | -4.4% |

34.04 kg / 75.05 lbs

34043.2 g / 334.0 N

|

|

| 80 °C | -6.6% |

33.26 kg / 73.33 lbs

33259.7 g / 326.3 N

|

|

| 100 °C | -28.8% |

25.35 kg / 55.90 lbs

25354.3 g / 248.7 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MPL 60x20x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

80.35 kg / 177.15 lbs

4 692 Gs

|

12.05 kg / 26.57 lbs

12053 g / 118.2 N

|

N/A |

| 1 mm |

75.49 kg / 166.43 lbs

6 389 Gs

|

11.32 kg / 24.96 lbs

11324 g / 111.1 N

|

67.94 kg / 149.79 lbs

~0 Gs

|

| 2 mm |

70.51 kg / 155.45 lbs

6 174 Gs

|

10.58 kg / 23.32 lbs

10577 g / 103.8 N

|

63.46 kg / 139.90 lbs

~0 Gs

|

| 3 mm |

65.58 kg / 144.58 lbs

5 955 Gs

|

9.84 kg / 21.69 lbs

9837 g / 96.5 N

|

59.02 kg / 130.12 lbs

~0 Gs

|

| 5 mm |

56.11 kg / 123.71 lbs

5 508 Gs

|

8.42 kg / 18.56 lbs

8417 g / 82.6 N

|

50.50 kg / 111.34 lbs

~0 Gs

|

| 10 mm |

36.34 kg / 80.11 lbs

4 432 Gs

|

5.45 kg / 12.02 lbs

5450 g / 53.5 N

|

32.70 kg / 72.10 lbs

~0 Gs

|

| 20 mm |

14.45 kg / 31.85 lbs

2 795 Gs

|

2.17 kg / 4.78 lbs

2167 g / 21.3 N

|

13.00 kg / 28.66 lbs

~0 Gs

|

| 50 mm |

1.38 kg / 3.05 lbs

865 Gs

|

0.21 kg / 0.46 lbs

208 g / 2.0 N

|

1.25 kg / 2.75 lbs

~0 Gs

|

| 60 mm |

0.73 kg / 1.60 lbs

627 Gs

|

0.11 kg / 0.24 lbs

109 g / 1.1 N

|

0.66 kg / 1.44 lbs

~0 Gs

|

| 70 mm |

0.40 kg / 0.89 lbs

467 Gs

|

0.06 kg / 0.13 lbs

60 g / 0.6 N

|

0.36 kg / 0.80 lbs

~0 Gs

|

| 80 mm |

0.23 kg / 0.51 lbs

355 Gs

|

0.03 kg / 0.08 lbs

35 g / 0.3 N

|

0.21 kg / 0.46 lbs

~0 Gs

|

| 90 mm |

0.14 kg / 0.31 lbs

275 Gs

|

0.02 kg / 0.05 lbs

21 g / 0.2 N

|

0.13 kg / 0.28 lbs

~0 Gs

|

| 100 mm |

0.09 kg / 0.19 lbs

217 Gs

|

0.01 kg / 0.03 lbs

13 g / 0.1 N

|

0.08 kg / 0.17 lbs

~0 Gs

|

Table 7: Safety (HSE) (implants) - warnings

MPL 60x20x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 16.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 13.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 10.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 8.0 cm |

| Remote | 50 Gs (5.0 mT) | 7.0 cm |

| Payment card | 400 Gs (40.0 mT) | 3.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.5 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MPL 60x20x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.20 km/h

(6.17 m/s)

|

1.71 J | |

| 30 mm |

34.94 km/h

(9.71 m/s)

|

4.24 J | |

| 50 mm |

44.89 km/h

(12.47 m/s)

|

7.00 J | |

| 100 mm |

63.44 km/h

(17.62 m/s)

|

13.97 J |

Table 9: Coating parameters (durability)

MPL 60x20x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MPL 60x20x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 37 480 Mx | 374.8 µWb |

| Pc Coefficient | 0.35 | Low (Flat) |

Table 11: Submerged application

MPL 60x20x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 35.61 kg | Standard |

| Water (riverbed) |

40.77 kg

(+5.16 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Caution: On a vertical surface, the magnet retains just ~20% of its perpendicular strength.

2. Plate thickness effect

*Thin metal sheet (e.g. 0.5mm PC case) drastically weakens the holding force.

3. Power loss vs temp

*For N38 grade, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.35

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also deals

Strengths as well as weaknesses of rare earth magnets.

Strengths

- Their power remains stable, and after approximately 10 years it drops only by ~1% (theoretically),

- They feature excellent resistance to magnetism drop when exposed to external fields,

- By applying a reflective coating of nickel, the element gains an elegant look,

- Neodymium magnets ensure maximum magnetic induction on a small area, which allows for strong attraction,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Possibility of custom modeling and adapting to individual requirements,

- Wide application in high-tech industry – they are commonly used in data components, electromotive mechanisms, advanced medical instruments, as well as modern systems.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Disadvantages

- They are fragile upon heavy impacts. To avoid cracks, it is worth securing magnets in a protective case. Such protection not only protects the magnet but also improves its resistance to damage

- When exposed to high temperature, neodymium magnets suffer a drop in strength. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material resistant to moisture, when using outdoors

- Due to limitations in creating nuts and complex shapes in magnets, we recommend using a housing - magnetic holder.

- Potential hazard related to microscopic parts of magnets are risky, when accidentally swallowed, which becomes key in the context of child safety. Additionally, tiny parts of these products are able to complicate diagnosis medical after entering the body.

- High unit price – neodymium magnets cost more than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Holding force characteristics

Maximum magnetic pulling force – what it depends on?

- with the use of a yoke made of special test steel, guaranteeing maximum field concentration

- with a thickness no less than 10 mm

- with an ground contact surface

- with total lack of distance (without impurities)

- under perpendicular force direction (90-degree angle)

- at ambient temperature room level

Magnet lifting force in use – key factors

- Clearance – existence of foreign body (paint, tape, gap) acts as an insulator, which reduces capacity steeply (even by 50% at 0.5 mm).

- Direction of force – highest force is reached only during pulling at a 90° angle. The resistance to sliding of the magnet along the surface is standardly many times lower (approx. 1/5 of the lifting capacity).

- Wall thickness – thin material does not allow full use of the magnet. Part of the magnetic field passes through the material instead of converting into lifting capacity.

- Steel grade – the best choice is high-permeability steel. Stainless steels may attract less.

- Plate texture – smooth surfaces ensure maximum contact, which improves field saturation. Uneven metal weaken the grip.

- Thermal environment – heating the magnet results in weakening of force. It is worth remembering the thermal limit for a given model.

Holding force was tested on the plate surface of 20 mm thickness, when a perpendicular force was applied, whereas under shearing force the load capacity is reduced by as much as fivefold. In addition, even a slight gap between the magnet and the plate reduces the holding force.

Safe handling of NdFeB magnets

Finger safety

Danger of trauma: The pulling power is so immense that it can cause blood blisters, pinching, and broken bones. Use thick gloves.

Data carriers

Intense magnetic fields can corrupt files on payment cards, HDDs, and storage devices. Keep a distance of min. 10 cm.

Thermal limits

Avoid heat. NdFeB magnets are sensitive to temperature. If you need resistance above 80°C, ask us about HT versions (H, SH, UH).

GPS and phone interference

Navigation devices and smartphones are highly sensitive to magnetism. Direct contact with a powerful NdFeB magnet can permanently damage the sensors in your phone.

Fire warning

Dust produced during cutting of magnets is flammable. Do not drill into magnets unless you are an expert.

Handling rules

Handle magnets with awareness. Their huge power can shock even experienced users. Stay alert and respect their force.

Allergic reactions

Warning for allergy sufferers: The nickel-copper-nickel coating consists of nickel. If redness happens, immediately stop handling magnets and use protective gear.

Adults only

NdFeB magnets are not toys. Swallowing a few magnets may result in them connecting inside the digestive tract, which constitutes a direct threat to life and requires urgent medical intervention.

Magnets are brittle

Despite the nickel coating, the material is brittle and not impact-resistant. Do not hit, as the magnet may shatter into hazardous fragments.

Medical implants

Life threat: Strong magnets can deactivate heart devices and defibrillators. Do not approach if you have electronic implants.