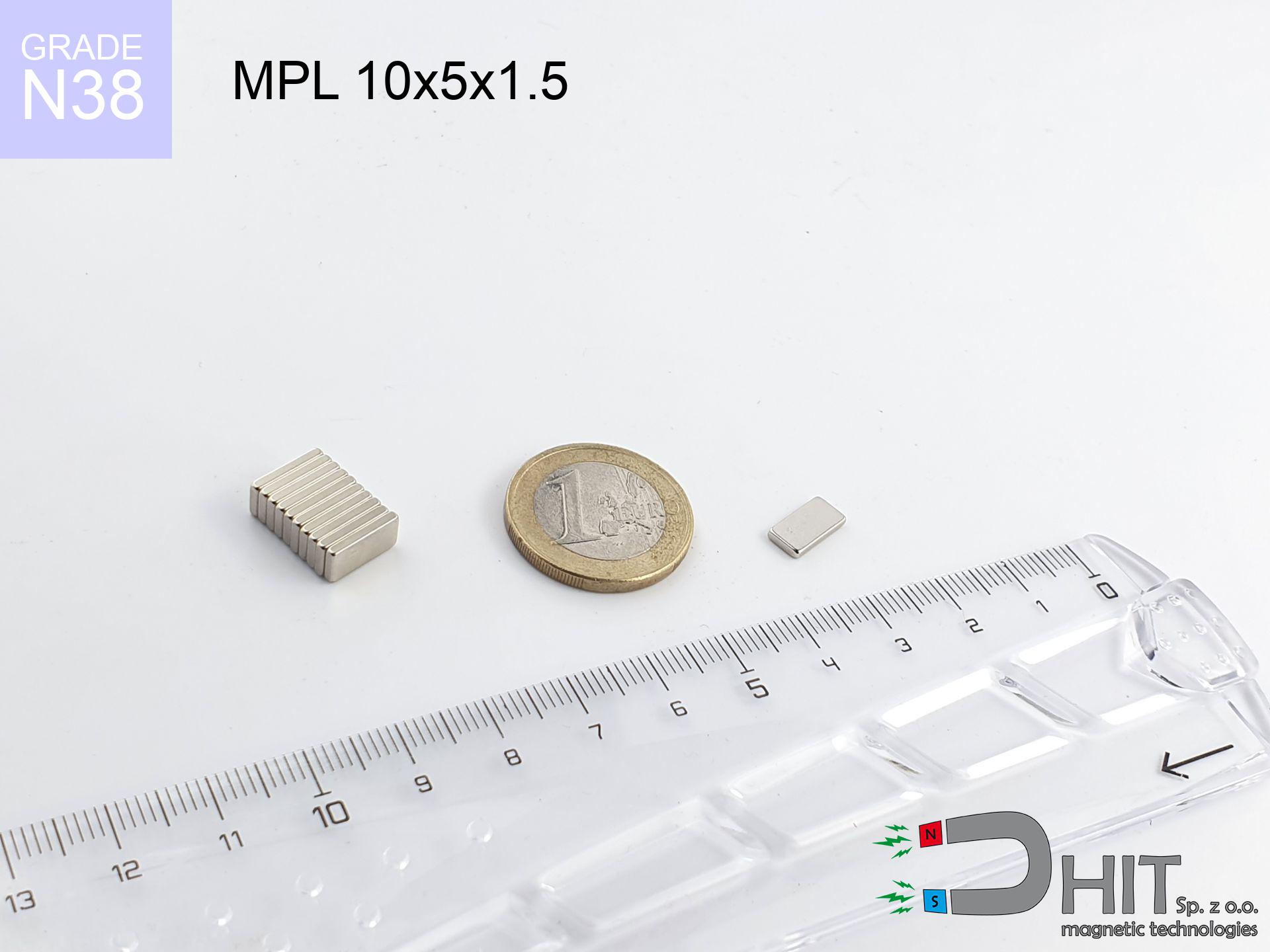

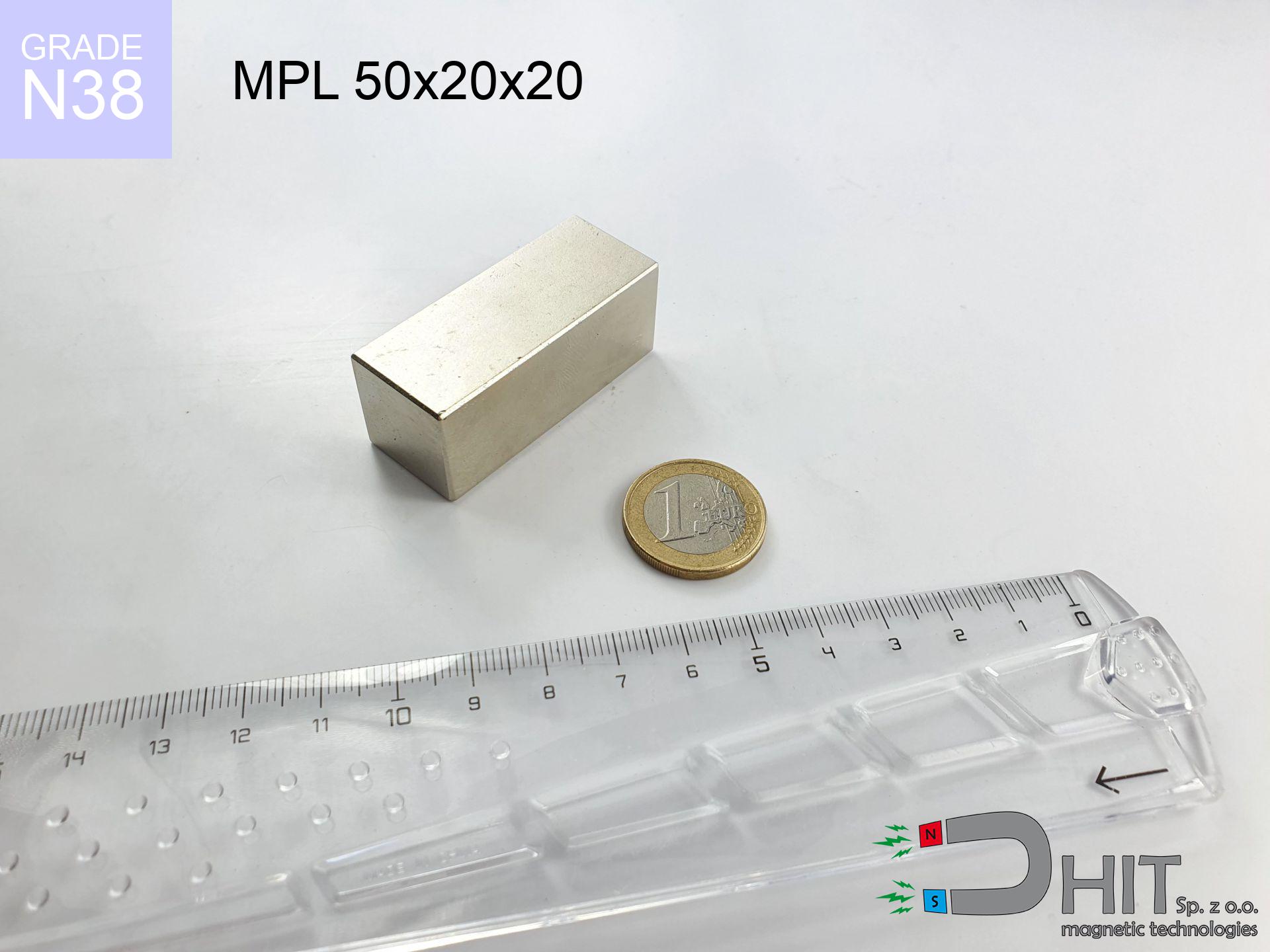

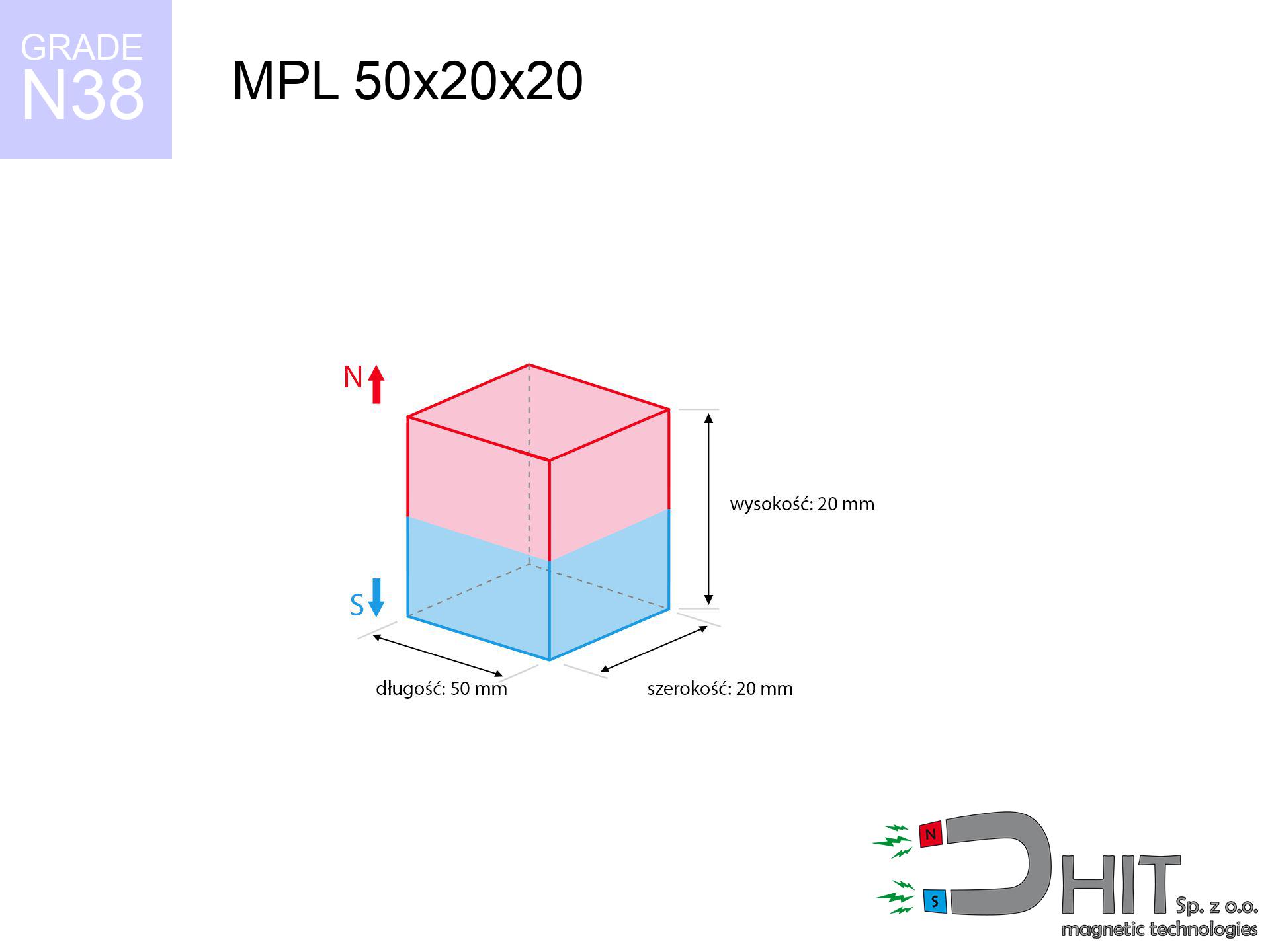

MPL 50x20x20 / N38 - lamellar magnet

lamellar magnet

Catalog no 020166

GTIN/EAN: 5906301811725

length

50 mm [±0,1 mm]

Width

20 mm [±0,1 mm]

Height

20 mm [±0,1 mm]

Weight

150 g

Magnetization Direction

↑ axial

Load capacity

42.18 kg / 413.81 N

Magnetic Induction

478.99 mT / 4790 Gs

Coating

[NiCuNi] Nickel

47.32 ZŁ with VAT / pcs + price for transport

38.47 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

or get in touch using

our online form

our website.

Weight and appearance of magnets can be tested on our

force calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical of the product - MPL 50x20x20 / N38 - lamellar magnet

Specification / characteristics - MPL 50x20x20 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020166 |

| GTIN/EAN | 5906301811725 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 50 mm [±0,1 mm] |

| Width | 20 mm [±0,1 mm] |

| Height | 20 mm [±0,1 mm] |

| Weight | 150 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 42.18 kg / 413.81 N |

| Magnetic Induction ~ ? | 478.99 mT / 4790 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the product - report

The following data are the result of a engineering simulation. Results are based on algorithms for the material Nd2Fe14B. Operational parameters might slightly differ. Please consider these data as a reference point when designing systems.

Table 1: Static pull force (pull vs gap) - power drop

MPL 50x20x20 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4789 Gs

478.9 mT

|

42.18 kg / 92.99 pounds

42180.0 g / 413.8 N

|

crushing |

| 1 mm |

4452 Gs

445.2 mT

|

36.46 kg / 80.38 pounds

36461.5 g / 357.7 N

|

crushing |

| 2 mm |

4114 Gs

411.4 mT

|

31.13 kg / 68.62 pounds

31126.5 g / 305.4 N

|

crushing |

| 3 mm |

3784 Gs

378.4 mT

|

26.34 kg / 58.06 pounds

26336.3 g / 258.4 N

|

crushing |

| 5 mm |

3173 Gs

317.3 mT

|

18.52 kg / 40.84 pounds

18523.4 g / 181.7 N

|

crushing |

| 10 mm |

2022 Gs

202.2 mT

|

7.52 kg / 16.59 pounds

7522.9 g / 73.8 N

|

medium risk |

| 15 mm |

1324 Gs

132.4 mT

|

3.22 kg / 7.10 pounds

3222.6 g / 31.6 N

|

medium risk |

| 20 mm |

899 Gs

89.9 mT

|

1.49 kg / 3.28 pounds

1487.5 g / 14.6 N

|

low risk |

| 30 mm |

458 Gs

45.8 mT

|

0.39 kg / 0.85 pounds

385.8 g / 3.8 N

|

low risk |

| 50 mm |

159 Gs

15.9 mT

|

0.05 kg / 0.10 pounds

46.4 g / 0.5 N

|

low risk |

Table 2: Slippage load (wall)

MPL 50x20x20 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

8.44 kg / 18.60 pounds

8436.0 g / 82.8 N

|

| 1 mm | Stal (~0.2) |

7.29 kg / 16.08 pounds

7292.0 g / 71.5 N

|

| 2 mm | Stal (~0.2) |

6.23 kg / 13.73 pounds

6226.0 g / 61.1 N

|

| 3 mm | Stal (~0.2) |

5.27 kg / 11.61 pounds

5268.0 g / 51.7 N

|

| 5 mm | Stal (~0.2) |

3.70 kg / 8.17 pounds

3704.0 g / 36.3 N

|

| 10 mm | Stal (~0.2) |

1.50 kg / 3.32 pounds

1504.0 g / 14.8 N

|

| 15 mm | Stal (~0.2) |

0.64 kg / 1.42 pounds

644.0 g / 6.3 N

|

| 20 mm | Stal (~0.2) |

0.30 kg / 0.66 pounds

298.0 g / 2.9 N

|

| 30 mm | Stal (~0.2) |

0.08 kg / 0.17 pounds

78.0 g / 0.8 N

|

| 50 mm | Stal (~0.2) |

0.01 kg / 0.02 pounds

10.0 g / 0.1 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MPL 50x20x20 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

12.65 kg / 27.90 pounds

12654.0 g / 124.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

8.44 kg / 18.60 pounds

8436.0 g / 82.8 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

4.22 kg / 9.30 pounds

4218.0 g / 41.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

21.09 kg / 46.50 pounds

21090.0 g / 206.9 N

|

Table 4: Material efficiency (substrate influence) - power losses

MPL 50x20x20 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

2.11 kg / 4.65 pounds

2109.0 g / 20.7 N

|

| 1 mm |

|

5.27 kg / 11.62 pounds

5272.5 g / 51.7 N

|

| 2 mm |

|

10.55 kg / 23.25 pounds

10545.0 g / 103.4 N

|

| 3 mm |

|

15.82 kg / 34.87 pounds

15817.5 g / 155.2 N

|

| 5 mm |

|

26.36 kg / 58.12 pounds

26362.5 g / 258.6 N

|

| 10 mm |

|

42.18 kg / 92.99 pounds

42180.0 g / 413.8 N

|

| 11 mm |

|

42.18 kg / 92.99 pounds

42180.0 g / 413.8 N

|

| 12 mm |

|

42.18 kg / 92.99 pounds

42180.0 g / 413.8 N

|

Table 5: Working in heat (stability) - power drop

MPL 50x20x20 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

42.18 kg / 92.99 pounds

42180.0 g / 413.8 N

|

OK |

| 40 °C | -2.2% |

41.25 kg / 90.95 pounds

41252.0 g / 404.7 N

|

OK |

| 60 °C | -4.4% |

40.32 kg / 88.90 pounds

40324.1 g / 395.6 N

|

OK |

| 80 °C | -6.6% |

39.40 kg / 86.85 pounds

39396.1 g / 386.5 N

|

|

| 100 °C | -28.8% |

30.03 kg / 66.21 pounds

30032.2 g / 294.6 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MPL 50x20x20 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

141.37 kg / 311.66 pounds

5 687 Gs

|

21.21 kg / 46.75 pounds

21205 g / 208.0 N

|

N/A |

| 1 mm |

131.73 kg / 290.41 pounds

9 245 Gs

|

19.76 kg / 43.56 pounds

19759 g / 193.8 N

|

118.55 kg / 261.37 pounds

~0 Gs

|

| 2 mm |

122.20 kg / 269.41 pounds

8 904 Gs

|

18.33 kg / 40.41 pounds

18330 g / 179.8 N

|

109.98 kg / 242.47 pounds

~0 Gs

|

| 3 mm |

113.05 kg / 249.23 pounds

8 564 Gs

|

16.96 kg / 37.38 pounds

16957 g / 166.4 N

|

101.74 kg / 224.31 pounds

~0 Gs

|

| 5 mm |

96.05 kg / 211.76 pounds

7 894 Gs

|

14.41 kg / 31.76 pounds

14408 g / 141.3 N

|

86.45 kg / 190.58 pounds

~0 Gs

|

| 10 mm |

62.08 kg / 136.87 pounds

6 347 Gs

|

9.31 kg / 20.53 pounds

9312 g / 91.4 N

|

55.87 kg / 123.18 pounds

~0 Gs

|

| 20 mm |

25.21 kg / 55.59 pounds

4 045 Gs

|

3.78 kg / 8.34 pounds

3782 g / 37.1 N

|

22.69 kg / 50.03 pounds

~0 Gs

|

| 50 mm |

2.46 kg / 5.43 pounds

1 264 Gs

|

0.37 kg / 0.81 pounds

370 g / 3.6 N

|

2.22 kg / 4.89 pounds

~0 Gs

|

| 60 mm |

1.29 kg / 2.85 pounds

916 Gs

|

0.19 kg / 0.43 pounds

194 g / 1.9 N

|

1.16 kg / 2.57 pounds

~0 Gs

|

| 70 mm |

0.71 kg / 1.58 pounds

681 Gs

|

0.11 kg / 0.24 pounds

107 g / 1.1 N

|

0.64 kg / 1.42 pounds

~0 Gs

|

| 80 mm |

0.41 kg / 0.91 pounds

518 Gs

|

0.06 kg / 0.14 pounds

62 g / 0.6 N

|

0.37 kg / 0.82 pounds

~0 Gs

|

| 90 mm |

0.25 kg / 0.55 pounds

402 Gs

|

0.04 kg / 0.08 pounds

37 g / 0.4 N

|

0.22 kg / 0.49 pounds

~0 Gs

|

| 100 mm |

0.16 kg / 0.34 pounds

318 Gs

|

0.02 kg / 0.05 pounds

23 g / 0.2 N

|

0.14 kg / 0.31 pounds

~0 Gs

|

Table 7: Safety (HSE) (electronics) - warnings

MPL 50x20x20 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 19.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 15.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 11.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 9.0 cm |

| Car key | 50 Gs (5.0 mT) | 8.5 cm |

| Payment card | 400 Gs (40.0 mT) | 3.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 3.0 cm |

Table 8: Dynamics (cracking risk) - collision effects

MPL 50x20x20 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

18.70 km/h

(5.20 m/s)

|

2.02 J | |

| 30 mm |

29.46 km/h

(8.18 m/s)

|

5.02 J | |

| 50 mm |

37.84 km/h

(10.51 m/s)

|

8.29 J | |

| 100 mm |

53.48 km/h

(14.86 m/s)

|

16.55 J |

Table 9: Anti-corrosion coating durability

MPL 50x20x20 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 50x20x20 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 46 654 Mx | 466.5 µWb |

| Pc Coefficient | 0.63 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MPL 50x20x20 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 42.18 kg | Standard |

| Water (riverbed) |

48.30 kg

(+6.12 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Note: On a vertical wall, the magnet retains merely ~20% of its max power.

2. Steel thickness impact

*Thin metal sheet (e.g. 0.5mm PC case) severely reduces the holding force.

3. Thermal stability

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.63

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Advantages and disadvantages of rare earth magnets.

Pros

- They retain attractive force for around 10 years – the loss is just ~1% (according to analyses),

- They possess excellent resistance to magnetism drop due to external magnetic sources,

- In other words, due to the aesthetic finish of silver, the element becomes visually attractive,

- Neodymium magnets create maximum magnetic induction on a small area, which ensures high operational effectiveness,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Due to the possibility of flexible shaping and adaptation to individualized solutions, neodymium magnets can be produced in a broad palette of forms and dimensions, which increases their versatility,

- Wide application in advanced technology sectors – they find application in mass storage devices, drive modules, diagnostic systems, as well as other advanced devices.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Disadvantages

- To avoid cracks under impact, we suggest using special steel housings. Such a solution secures the magnet and simultaneously improves its durability.

- NdFeB magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- They rust in a humid environment. For use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- Due to limitations in producing nuts and complex shapes in magnets, we recommend using a housing - magnetic mount.

- Health risk to health – tiny shards of magnets pose a threat, when accidentally swallowed, which becomes key in the context of child safety. Additionally, tiny parts of these devices are able to complicate diagnosis medical when they are in the body.

- Due to complex production process, their price is relatively high,

Lifting parameters

Detachment force of the magnet in optimal conditions – what contributes to it?

- with the use of a sheet made of special test steel, guaranteeing full magnetic saturation

- possessing a thickness of minimum 10 mm to ensure full flux closure

- with an ground touching surface

- without any clearance between the magnet and steel

- during pulling in a direction vertical to the mounting surface

- in neutral thermal conditions

Determinants of practical lifting force of a magnet

- Clearance – existence of any layer (paint, dirt, gap) acts as an insulator, which lowers capacity rapidly (even by 50% at 0.5 mm).

- Pull-off angle – remember that the magnet has greatest strength perpendicularly. Under shear forces, the holding force drops significantly, often to levels of 20-30% of the maximum value.

- Steel thickness – too thin steel causes magnetic saturation, causing part of the flux to be escaped into the air.

- Chemical composition of the base – low-carbon steel gives the best results. Higher carbon content lower magnetic properties and holding force.

- Smoothness – full contact is obtained only on polished steel. Rough texture create air cushions, reducing force.

- Heat – NdFeB sinters have a negative temperature coefficient. When it is hot they lose power, and in frost they can be stronger (up to a certain limit).

Holding force was checked on the plate surface of 20 mm thickness, when a perpendicular force was applied, whereas under shearing force the lifting capacity is smaller. In addition, even a slight gap between the magnet and the plate lowers the lifting capacity.

Safety rules for work with NdFeB magnets

Operating temperature

Standard neodymium magnets (grade N) lose power when the temperature goes above 80°C. The loss of strength is permanent.

Bodily injuries

Mind your fingers. Two powerful magnets will join immediately with a force of massive weight, crushing everything in their path. Be careful!

Nickel coating and allergies

Some people suffer from a sensitization to nickel, which is the typical protective layer for neodymium magnets. Prolonged contact may cause dermatitis. We strongly advise use safety gloves.

Threat to navigation

Navigation devices and smartphones are extremely susceptible to magnetic fields. Direct contact with a powerful NdFeB magnet can permanently damage the internal compass in your phone.

Protective goggles

Watch out for shards. Magnets can fracture upon violent connection, launching sharp fragments into the air. Wear goggles.

Danger to pacemakers

Medical warning: Neodymium magnets can deactivate heart devices and defibrillators. Stay away if you have medical devices.

Product not for children

Adult use only. Tiny parts can be swallowed, causing serious injuries. Keep away from children and animals.

Keep away from computers

Intense magnetic fields can erase data on payment cards, HDDs, and storage devices. Stay away of at least 10 cm.

Immense force

Be careful. Rare earth magnets act from a long distance and snap with huge force, often faster than you can move away.

Fire warning

Fire warning: Rare earth powder is explosive. Do not process magnets in home conditions as this may cause fire.

![SM 25x150 [2xM8] / N42 - magnetic separator SM 25x150 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x150-2xm8-cim.jpg)