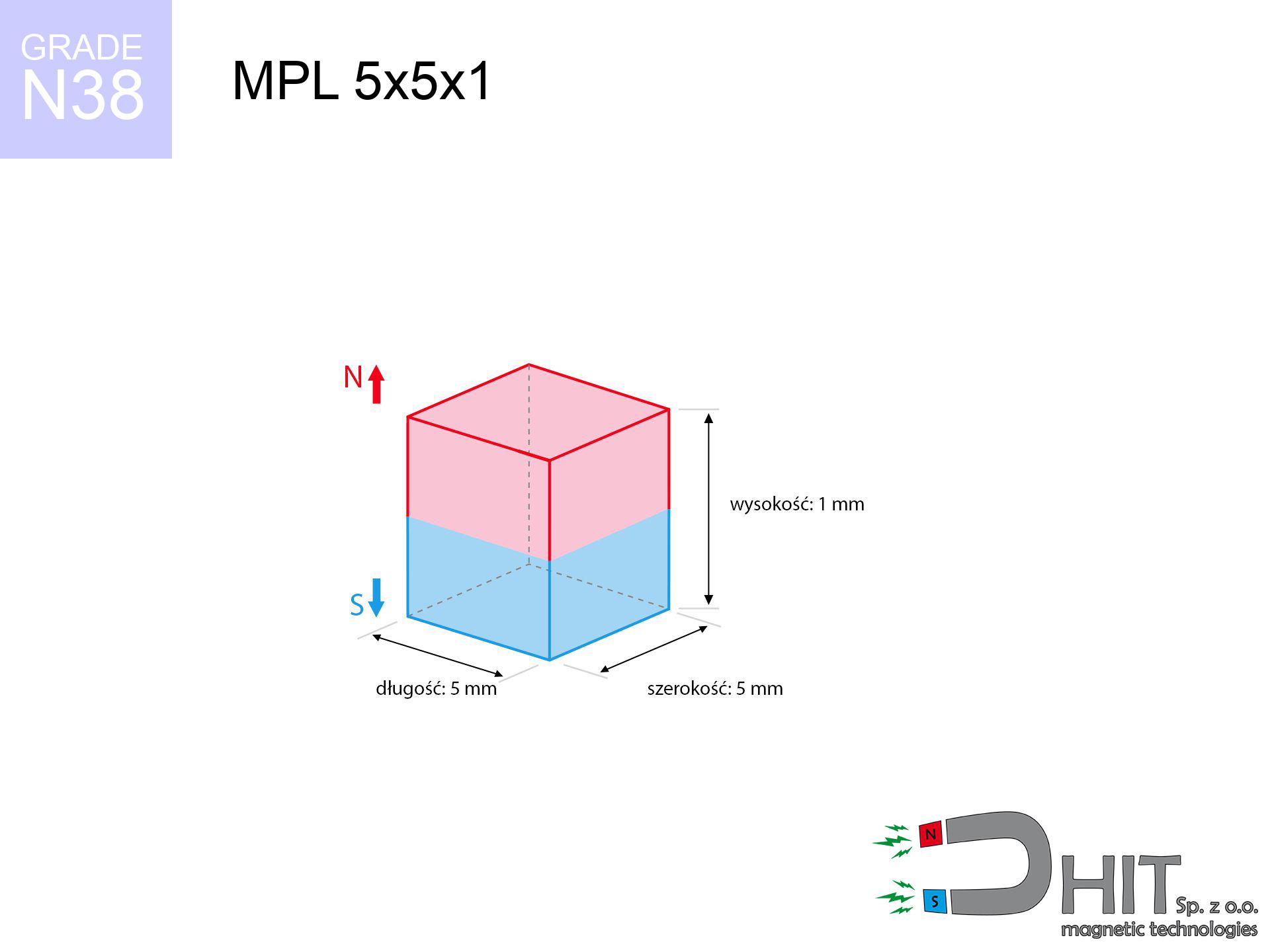

MPL 5x5x1 / N38 - lamellar magnet

lamellar magnet

Catalog no 020170

GTIN/EAN: 5906301811763

length

5 mm [±0,1 mm]

Width

5 mm [±0,1 mm]

Height

1 mm [±0,1 mm]

Weight

0.19 g

Magnetization Direction

↑ axial

Load capacity

0.34 kg / 3.30 N

Magnetic Induction

209.53 mT / 2095 Gs

Coating

[NiCuNi] Nickel

0.1845 ZŁ with VAT / pcs + price for transport

0.1500 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

alternatively contact us through

form

the contact section.

Parameters along with form of magnets can be checked using our

online calculation tool.

Order by 14:00 and we’ll ship today!

Technical parameters of the product - MPL 5x5x1 / N38 - lamellar magnet

Specification / characteristics - MPL 5x5x1 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020170 |

| GTIN/EAN | 5906301811763 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 5 mm [±0,1 mm] |

| Width | 5 mm [±0,1 mm] |

| Height | 1 mm [±0,1 mm] |

| Weight | 0.19 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.34 kg / 3.30 N |

| Magnetic Induction ~ ? | 209.53 mT / 2095 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the product - technical parameters

Presented values are the outcome of a physical analysis. Values were calculated on models for the material Nd2Fe14B. Operational conditions might slightly deviate from the simulation results. Treat these data as a supplementary guide when designing systems.

Table 1: Static pull force (force vs distance) - interaction chart

MPL 5x5x1 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2094 Gs

209.4 mT

|

0.34 kg / 0.75 lbs

340.0 g / 3.3 N

|

safe |

| 1 mm |

1514 Gs

151.4 mT

|

0.18 kg / 0.39 lbs

177.8 g / 1.7 N

|

safe |

| 2 mm |

922 Gs

92.2 mT

|

0.07 kg / 0.15 lbs

65.9 g / 0.6 N

|

safe |

| 3 mm |

543 Gs

54.3 mT

|

0.02 kg / 0.05 lbs

22.9 g / 0.2 N

|

safe |

| 5 mm |

209 Gs

20.9 mT

|

0.00 kg / 0.01 lbs

3.4 g / 0.0 N

|

safe |

| 10 mm |

38 Gs

3.8 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

safe |

| 15 mm |

13 Gs

1.3 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

| 20 mm |

6 Gs

0.6 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

| 30 mm |

2 Gs

0.2 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

| 50 mm |

0 Gs

0.0 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

Table 2: Sliding force (wall)

MPL 5x5x1 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.07 kg / 0.15 lbs

68.0 g / 0.7 N

|

| 1 mm | Stal (~0.2) |

0.04 kg / 0.08 lbs

36.0 g / 0.4 N

|

| 2 mm | Stal (~0.2) |

0.01 kg / 0.03 lbs

14.0 g / 0.1 N

|

| 3 mm | Stal (~0.2) |

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MPL 5x5x1 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.10 kg / 0.22 lbs

102.0 g / 1.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.07 kg / 0.15 lbs

68.0 g / 0.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.03 kg / 0.07 lbs

34.0 g / 0.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.17 kg / 0.37 lbs

170.0 g / 1.7 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MPL 5x5x1 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.03 kg / 0.07 lbs

34.0 g / 0.3 N

|

| 1 mm |

|

0.09 kg / 0.19 lbs

85.0 g / 0.8 N

|

| 2 mm |

|

0.17 kg / 0.37 lbs

170.0 g / 1.7 N

|

| 3 mm |

|

0.26 kg / 0.56 lbs

255.0 g / 2.5 N

|

| 5 mm |

|

0.34 kg / 0.75 lbs

340.0 g / 3.3 N

|

| 10 mm |

|

0.34 kg / 0.75 lbs

340.0 g / 3.3 N

|

| 11 mm |

|

0.34 kg / 0.75 lbs

340.0 g / 3.3 N

|

| 12 mm |

|

0.34 kg / 0.75 lbs

340.0 g / 3.3 N

|

Table 5: Thermal resistance (stability) - resistance threshold

MPL 5x5x1 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.34 kg / 0.75 lbs

340.0 g / 3.3 N

|

OK |

| 40 °C | -2.2% |

0.33 kg / 0.73 lbs

332.5 g / 3.3 N

|

OK |

| 60 °C | -4.4% |

0.33 kg / 0.72 lbs

325.0 g / 3.2 N

|

|

| 80 °C | -6.6% |

0.32 kg / 0.70 lbs

317.6 g / 3.1 N

|

|

| 100 °C | -28.8% |

0.24 kg / 0.53 lbs

242.1 g / 2.4 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MPL 5x5x1 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

0.68 kg / 1.49 lbs

3 601 Gs

|

0.10 kg / 0.22 lbs

101 g / 1.0 N

|

N/A |

| 1 mm |

0.52 kg / 1.15 lbs

3 682 Gs

|

0.08 kg / 0.17 lbs

78 g / 0.8 N

|

0.47 kg / 1.04 lbs

~0 Gs

|

| 2 mm |

0.35 kg / 0.78 lbs

3 028 Gs

|

0.05 kg / 0.12 lbs

53 g / 0.5 N

|

0.32 kg / 0.70 lbs

~0 Gs

|

| 3 mm |

0.22 kg / 0.48 lbs

2 388 Gs

|

0.03 kg / 0.07 lbs

33 g / 0.3 N

|

0.20 kg / 0.44 lbs

~0 Gs

|

| 5 mm |

0.08 kg / 0.17 lbs

1 413 Gs

|

0.01 kg / 0.03 lbs

12 g / 0.1 N

|

0.07 kg / 0.15 lbs

~0 Gs

|

| 10 mm |

0.01 kg / 0.01 lbs

417 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 lbs

77 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

6 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

3 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

2 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

1 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

1 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

1 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Safety (HSE) (implants) - precautionary measures

MPL 5x5x1 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 2.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 1.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 1.0 cm |

| Car key | 50 Gs (5.0 mT) | 1.0 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Impact energy (kinetic energy) - warning

MPL 5x5x1 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

42.67 km/h

(11.85 m/s)

|

0.01 J | |

| 30 mm |

73.89 km/h

(20.53 m/s)

|

0.04 J | |

| 50 mm |

95.40 km/h

(26.50 m/s)

|

0.07 J | |

| 100 mm |

134.91 km/h

(37.48 m/s)

|

0.13 J |

Table 9: Surface protection spec

MPL 5x5x1 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MPL 5x5x1 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 615 Mx | 6.2 µWb |

| Pc Coefficient | 0.26 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MPL 5x5x1 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.34 kg | Standard |

| Water (riverbed) |

0.39 kg

(+0.05 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical surface, the magnet holds only approx. 20-30% of its nominal pull.

2. Efficiency vs thickness

*Thin steel (e.g. computer case) drastically weakens the holding force.

3. Power loss vs temp

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.26

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Strengths and weaknesses of rare earth magnets.

Strengths

- Their strength is maintained, and after approximately 10 years it decreases only by ~1% (theoretically),

- They maintain their magnetic properties even under strong external field,

- By covering with a decorative layer of silver, the element acquires an aesthetic look,

- Neodymium magnets ensure maximum magnetic induction on a small surface, which ensures high operational effectiveness,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Thanks to modularity in constructing and the ability to customize to unusual requirements,

- Fundamental importance in future technologies – they are used in computer drives, drive modules, medical equipment, also multitasking production systems.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Weaknesses

- They are prone to damage upon too strong impacts. To avoid cracks, it is worth securing magnets in special housings. Such protection not only shields the magnet but also increases its resistance to damage

- When exposed to high temperature, neodymium magnets suffer a drop in strength. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- They rust in a humid environment - during use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- Due to limitations in producing nuts and complex shapes in magnets, we propose using cover - magnetic mount.

- Possible danger related to microscopic parts of magnets pose a threat, when accidentally swallowed, which becomes key in the context of child health protection. It is also worth noting that small elements of these products are able to complicate diagnosis medical after entering the body.

- Due to neodymium price, their price is relatively high,

Lifting parameters

Highest magnetic holding force – what it depends on?

- with the application of a yoke made of low-carbon steel, guaranteeing maximum field concentration

- with a thickness of at least 10 mm

- characterized by smoothness

- under conditions of ideal adhesion (metal-to-metal)

- under perpendicular force direction (90-degree angle)

- at standard ambient temperature

Determinants of lifting force in real conditions

- Distance (between the magnet and the plate), as even a tiny distance (e.g. 0.5 mm) can cause a drastic drop in force by up to 50% (this also applies to paint, rust or dirt).

- Loading method – declared lifting capacity refers to detachment vertically. When attempting to slide, the magnet holds significantly lower power (typically approx. 20-30% of nominal force).

- Substrate thickness – to utilize 100% power, the steel must be sufficiently thick. Thin sheet restricts the attraction force (the magnet "punches through" it).

- Chemical composition of the base – mild steel gives the best results. Alloy admixtures decrease magnetic permeability and lifting capacity.

- Base smoothness – the more even the plate, the larger the contact zone and higher the lifting capacity. Unevenness acts like micro-gaps.

- Temperature influence – high temperature weakens magnetic field. Too high temperature can permanently demagnetize the magnet.

Lifting capacity was measured using a steel plate with a smooth surface of optimal thickness (min. 20 mm), under perpendicular pulling force, in contrast under shearing force the lifting capacity is smaller. In addition, even a minimal clearance between the magnet’s surface and the plate decreases the lifting capacity.

Warnings

Handling guide

Before starting, check safety instructions. Sudden snapping can destroy the magnet or hurt your hand. Be predictive.

Thermal limits

Control the heat. Heating the magnet above 80 degrees Celsius will ruin its properties and strength.

Risk of cracking

NdFeB magnets are sintered ceramics, which means they are fragile like glass. Collision of two magnets leads to them cracking into small pieces.

Threat to electronics

Avoid bringing magnets near a wallet, computer, or screen. The magnetism can destroy these devices and wipe information from cards.

Impact on smartphones

Navigation devices and smartphones are highly susceptible to magnetism. Direct contact with a strong magnet can ruin the internal compass in your phone.

Health Danger

For implant holders: Powerful magnets affect electronics. Keep at least 30 cm distance or ask another person to work with the magnets.

Allergic reactions

It is widely known that the nickel plating (standard magnet coating) is a strong allergen. For allergy sufferers, prevent touching magnets with bare hands and select versions in plastic housing.

Fire risk

Machining of NdFeB material poses a fire hazard. Neodymium dust reacts violently with oxygen and is hard to extinguish.

Do not give to children

Adult use only. Small elements can be swallowed, leading to serious injuries. Keep away from children and animals.

Pinching danger

Mind your fingers. Two powerful magnets will snap together immediately with a force of several hundred kilograms, crushing everything in their path. Exercise extreme caution!

![UMGW 16x13x5 [M4] GW / N38 - magnetic holder internal thread UMGW 16x13x5 [M4] GW / N38 - magnetic holder internal thread](https://cdn3.dhit.pl/graphics/products/um-16x13x5-m4-gw-fig.jpg)

![HH 16x5.3 [M3] / N38 - through hole magnetic holder HH 16x5.3 [M3] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-16x5.3-m3-sud.jpg)