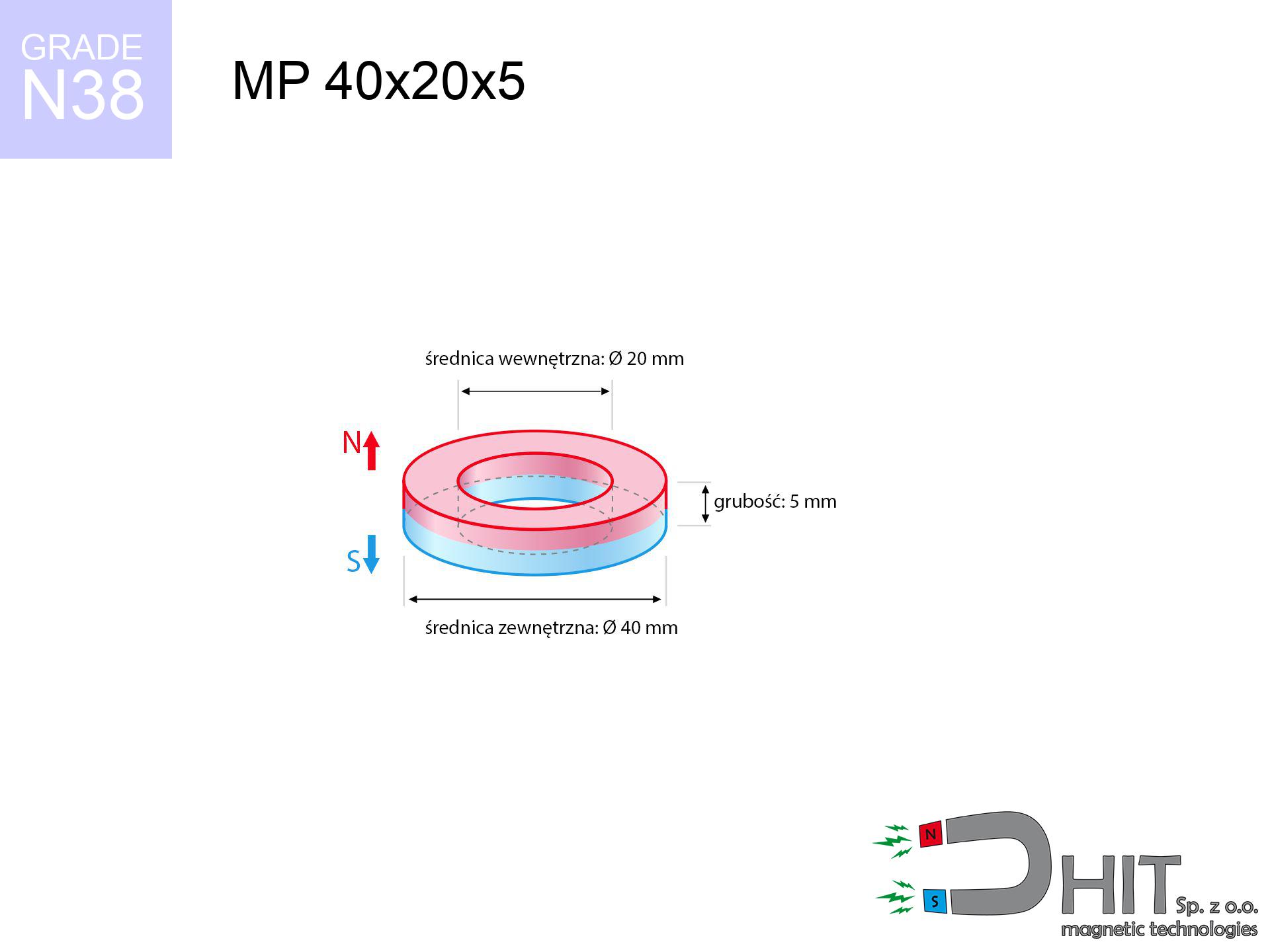

MP 40x20x5 / N38 - ring magnet

ring magnet

Catalog no 030199

GTIN/EAN: 5906301812166

Diameter

40 mm [±0,1 mm]

internal diameter Ø

20 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

35.34 g

Magnetization Direction

↑ axial

Load capacity

7.24 kg / 70.98 N

Magnetic Induction

150.36 mT / 1504 Gs

Coating

[NiCuNi] Nickel

12.24 ZŁ with VAT / pcs + price for transport

9.95 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

alternatively let us know using

contact form

the contact form page.

Strength along with shape of magnets can be estimated on our

force calculator.

Same-day processing for orders placed before 14:00.

Detailed specification - MP 40x20x5 / N38 - ring magnet

Specification / characteristics - MP 40x20x5 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030199 |

| GTIN/EAN | 5906301812166 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 40 mm [±0,1 mm] |

| internal diameter Ø | 20 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 35.34 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 7.24 kg / 70.98 N |

| Magnetic Induction ~ ? | 150.36 mT / 1504 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the magnet - data

The following data are the outcome of a mathematical calculation. Results rely on algorithms for the material Nd2Fe14B. Actual performance may deviate from the simulation results. Treat these data as a preliminary roadmap when designing systems.

Table 1: Static force (force vs gap) - interaction chart

MP 40x20x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5269 Gs

526.9 mT

|

7.24 kg / 15.96 lbs

7240.0 g / 71.0 N

|

warning |

| 1 mm |

5005 Gs

500.5 mT

|

6.53 kg / 14.41 lbs

6534.7 g / 64.1 N

|

warning |

| 2 mm |

4739 Gs

473.9 mT

|

5.86 kg / 12.91 lbs

5857.7 g / 57.5 N

|

warning |

| 3 mm |

4475 Gs

447.5 mT

|

5.22 kg / 11.51 lbs

5222.2 g / 51.2 N

|

warning |

| 5 mm |

3960 Gs

396.0 mT

|

4.09 kg / 9.02 lbs

4090.8 g / 40.1 N

|

warning |

| 10 mm |

2832 Gs

283.2 mT

|

2.09 kg / 4.61 lbs

2092.3 g / 20.5 N

|

warning |

| 15 mm |

1990 Gs

199.0 mT

|

1.03 kg / 2.28 lbs

1033.4 g / 10.1 N

|

low risk |

| 20 mm |

1407 Gs

140.7 mT

|

0.52 kg / 1.14 lbs

516.3 g / 5.1 N

|

low risk |

| 30 mm |

745 Gs

74.5 mT

|

0.14 kg / 0.32 lbs

144.6 g / 1.4 N

|

low risk |

| 50 mm |

268 Gs

26.8 mT

|

0.02 kg / 0.04 lbs

18.7 g / 0.2 N

|

low risk |

Table 2: Sliding capacity (vertical surface)

MP 40x20x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.45 kg / 3.19 lbs

1448.0 g / 14.2 N

|

| 1 mm | Stal (~0.2) |

1.31 kg / 2.88 lbs

1306.0 g / 12.8 N

|

| 2 mm | Stal (~0.2) |

1.17 kg / 2.58 lbs

1172.0 g / 11.5 N

|

| 3 mm | Stal (~0.2) |

1.04 kg / 2.30 lbs

1044.0 g / 10.2 N

|

| 5 mm | Stal (~0.2) |

0.82 kg / 1.80 lbs

818.0 g / 8.0 N

|

| 10 mm | Stal (~0.2) |

0.42 kg / 0.92 lbs

418.0 g / 4.1 N

|

| 15 mm | Stal (~0.2) |

0.21 kg / 0.45 lbs

206.0 g / 2.0 N

|

| 20 mm | Stal (~0.2) |

0.10 kg / 0.23 lbs

104.0 g / 1.0 N

|

| 30 mm | Stal (~0.2) |

0.03 kg / 0.06 lbs

28.0 g / 0.3 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MP 40x20x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.17 kg / 4.79 lbs

2172.0 g / 21.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.45 kg / 3.19 lbs

1448.0 g / 14.2 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.72 kg / 1.60 lbs

724.0 g / 7.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.62 kg / 7.98 lbs

3620.0 g / 35.5 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MP 40x20x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.72 kg / 1.60 lbs

724.0 g / 7.1 N

|

| 1 mm |

|

1.81 kg / 3.99 lbs

1810.0 g / 17.8 N

|

| 2 mm |

|

3.62 kg / 7.98 lbs

3620.0 g / 35.5 N

|

| 3 mm |

|

5.43 kg / 11.97 lbs

5430.0 g / 53.3 N

|

| 5 mm |

|

7.24 kg / 15.96 lbs

7240.0 g / 71.0 N

|

| 10 mm |

|

7.24 kg / 15.96 lbs

7240.0 g / 71.0 N

|

| 11 mm |

|

7.24 kg / 15.96 lbs

7240.0 g / 71.0 N

|

| 12 mm |

|

7.24 kg / 15.96 lbs

7240.0 g / 71.0 N

|

Table 5: Working in heat (material behavior) - thermal limit

MP 40x20x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

7.24 kg / 15.96 lbs

7240.0 g / 71.0 N

|

OK |

| 40 °C | -2.2% |

7.08 kg / 15.61 lbs

7080.7 g / 69.5 N

|

OK |

| 60 °C | -4.4% |

6.92 kg / 15.26 lbs

6921.4 g / 67.9 N

|

OK |

| 80 °C | -6.6% |

6.76 kg / 14.91 lbs

6762.2 g / 66.3 N

|

|

| 100 °C | -28.8% |

5.15 kg / 11.36 lbs

5154.9 g / 50.6 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MP 40x20x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

179.94 kg / 396.69 lbs

5 920 Gs

|

26.99 kg / 59.50 lbs

26991 g / 264.8 N

|

N/A |

| 1 mm |

171.16 kg / 377.35 lbs

10 277 Gs

|

25.67 kg / 56.60 lbs

25675 g / 251.9 N

|

154.05 kg / 339.62 lbs

~0 Gs

|

| 2 mm |

162.41 kg / 358.05 lbs

10 011 Gs

|

24.36 kg / 53.71 lbs

24361 g / 239.0 N

|

146.17 kg / 322.24 lbs

~0 Gs

|

| 3 mm |

153.87 kg / 339.24 lbs

9 744 Gs

|

23.08 kg / 50.89 lbs

23081 g / 226.4 N

|

138.49 kg / 305.31 lbs

~0 Gs

|

| 5 mm |

137.55 kg / 303.25 lbs

9 213 Gs

|

20.63 kg / 45.49 lbs

20633 g / 202.4 N

|

123.80 kg / 272.92 lbs

~0 Gs

|

| 10 mm |

101.67 kg / 224.14 lbs

7 921 Gs

|

15.25 kg / 33.62 lbs

15251 g / 149.6 N

|

91.50 kg / 201.73 lbs

~0 Gs

|

| 20 mm |

52.00 kg / 114.64 lbs

5 665 Gs

|

7.80 kg / 17.20 lbs

7800 g / 76.5 N

|

46.80 kg / 103.18 lbs

~0 Gs

|

| 50 mm |

6.64 kg / 14.64 lbs

2 025 Gs

|

1.00 kg / 2.20 lbs

996 g / 9.8 N

|

5.98 kg / 13.18 lbs

~0 Gs

|

| 60 mm |

3.59 kg / 7.92 lbs

1 489 Gs

|

0.54 kg / 1.19 lbs

539 g / 5.3 N

|

3.23 kg / 7.13 lbs

~0 Gs

|

| 70 mm |

2.03 kg / 4.48 lbs

1 120 Gs

|

0.30 kg / 0.67 lbs

305 g / 3.0 N

|

1.83 kg / 4.03 lbs

~0 Gs

|

| 80 mm |

1.20 kg / 2.64 lbs

860 Gs

|

0.18 kg / 0.40 lbs

180 g / 1.8 N

|

1.08 kg / 2.38 lbs

~0 Gs

|

| 90 mm |

0.73 kg / 1.62 lbs

673 Gs

|

0.11 kg / 0.24 lbs

110 g / 1.1 N

|

0.66 kg / 1.46 lbs

~0 Gs

|

| 100 mm |

0.47 kg / 1.03 lbs

536 Gs

|

0.07 kg / 0.15 lbs

70 g / 0.7 N

|

0.42 kg / 0.92 lbs

~0 Gs

|

Table 7: Protective zones (implants) - warnings

MP 40x20x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 24.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 18.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 14.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 11.0 cm |

| Car key | 50 Gs (5.0 mT) | 10.5 cm |

| Payment card | 400 Gs (40.0 mT) | 4.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 3.5 cm |

Table 8: Collisions (kinetic energy) - warning

MP 40x20x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

16.84 km/h

(4.68 m/s)

|

0.39 J | |

| 30 mm |

25.31 km/h

(7.03 m/s)

|

0.87 J | |

| 50 mm |

32.33 km/h

(8.98 m/s)

|

1.43 J | |

| 100 mm |

45.65 km/h

(12.68 m/s)

|

2.84 J |

Table 9: Surface protection spec

MP 40x20x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MP 40x20x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 56 325 Mx | 563.3 µWb |

| Pc Coefficient | 0.80 | High (Stable) |

Table 11: Submerged application

MP 40x20x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 7.24 kg | Standard |

| Water (riverbed) |

8.29 kg

(+1.05 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Note: On a vertical surface, the magnet holds just approx. 20-30% of its max power.

2. Efficiency vs thickness

*Thin metal sheet (e.g. computer case) drastically reduces the holding force.

3. Heat tolerance

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.80

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also products

Advantages and disadvantages of neodymium magnets.

Strengths

- They retain full power for nearly ten years – the drop is just ~1% (according to analyses),

- They are resistant to demagnetization induced by external magnetic fields,

- The use of an shiny finish of noble metals (nickel, gold, silver) causes the element to have aesthetics,

- Neodymium magnets deliver maximum magnetic induction on a their surface, which ensures high operational effectiveness,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and are able to act (depending on the form) even at a temperature of 230°C or more...

- In view of the option of accurate shaping and adaptation to individualized solutions, neodymium magnets can be modeled in a variety of forms and dimensions, which makes them more universal,

- Significant place in innovative solutions – they find application in HDD drives, brushless drives, advanced medical instruments, as well as multitasking production systems.

- Thanks to their power density, small magnets offer high operating force, in miniature format,

Limitations

- Brittleness is one of their disadvantages. Upon strong impact they can fracture. We recommend keeping them in a steel housing, which not only protects them against impacts but also raises their durability

- Neodymium magnets decrease their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material stable to moisture, when using outdoors

- We suggest a housing - magnetic holder, due to difficulties in producing nuts inside the magnet and complex forms.

- Possible danger to health – tiny shards of magnets can be dangerous, when accidentally swallowed, which is particularly important in the context of child health protection. It is also worth noting that small components of these devices are able to disrupt the diagnostic process medical when they are in the body.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Pull force analysis

Maximum lifting capacity of the magnet – what it depends on?

- on a plate made of mild steel, effectively closing the magnetic field

- possessing a thickness of min. 10 mm to avoid saturation

- characterized by even structure

- with direct contact (without impurities)

- for force applied at a right angle (in the magnet axis)

- at standard ambient temperature

Determinants of lifting force in real conditions

- Space between magnet and steel – every millimeter of separation (caused e.g. by varnish or dirt) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Direction of force – highest force is reached only during pulling at a 90° angle. The resistance to sliding of the magnet along the surface is typically many times smaller (approx. 1/5 of the lifting capacity).

- Plate thickness – insufficiently thick steel causes magnetic saturation, causing part of the flux to be wasted into the air.

- Steel grade – ideal substrate is pure iron steel. Hardened steels may have worse magnetic properties.

- Surface condition – ground elements ensure maximum contact, which increases field saturation. Rough surfaces reduce efficiency.

- Temperature – heating the magnet causes a temporary drop of induction. It is worth remembering the thermal limit for a given model.

Lifting capacity was measured with the use of a smooth steel plate of suitable thickness (min. 20 mm), under perpendicular pulling force, however under parallel forces the holding force is lower. In addition, even a small distance between the magnet and the plate reduces the lifting capacity.

Safety rules for work with NdFeB magnets

Powerful field

Before use, check safety instructions. Uncontrolled attraction can break the magnet or injure your hand. Think ahead.

Protect data

Avoid bringing magnets near a purse, laptop, or screen. The magnetic field can permanently damage these devices and wipe information from cards.

Material brittleness

Protect your eyes. Magnets can fracture upon violent connection, ejecting shards into the air. Wear goggles.

Choking Hazard

Always store magnets out of reach of children. Choking hazard is significant, and the effects of magnets clamping inside the body are very dangerous.

Keep away from electronics

A powerful magnetic field negatively affects the functioning of magnetometers in phones and navigation systems. Maintain magnets close to a smartphone to avoid breaking the sensors.

Sensitization to coating

Certain individuals suffer from a sensitization to Ni, which is the common plating for neodymium magnets. Frequent touching may cause dermatitis. We strongly advise use safety gloves.

Do not overheat magnets

Do not overheat. NdFeB magnets are sensitive to heat. If you require operation above 80°C, ask us about special high-temperature series (H, SH, UH).

Machining danger

Dust created during machining of magnets is self-igniting. Avoid drilling into magnets without proper cooling and knowledge.

Pacemakers

Warning for patients: Powerful magnets disrupt medical devices. Keep minimum 30 cm distance or request help to work with the magnets.

Crushing force

Big blocks can crush fingers instantly. Under no circumstances place your hand between two attracting surfaces.

![HH 20x7.2 [M4] / N38 - through hole magnetic holder HH 20x7.2 [M4] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-20x7.2-m4-luc.jpg)