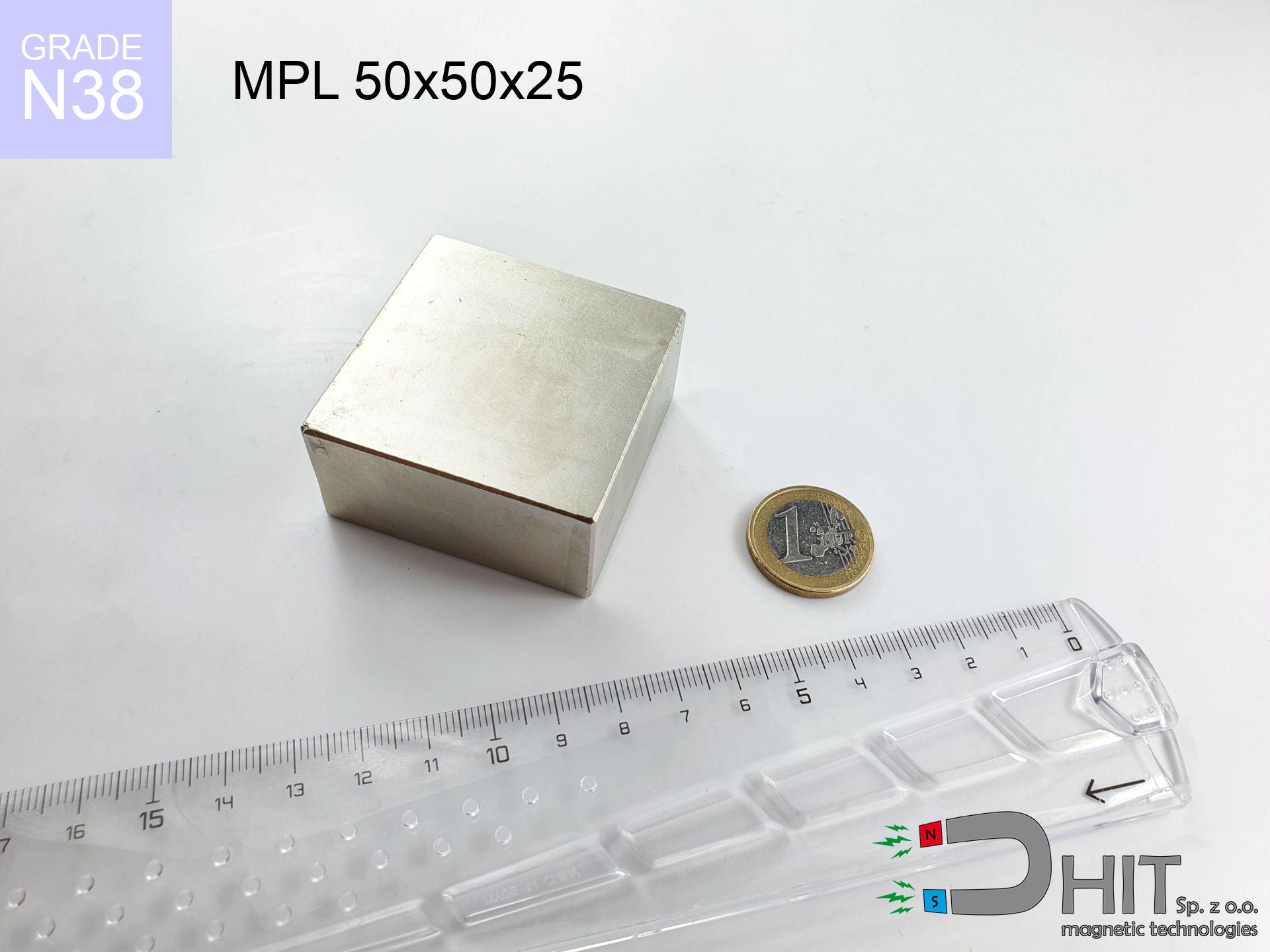

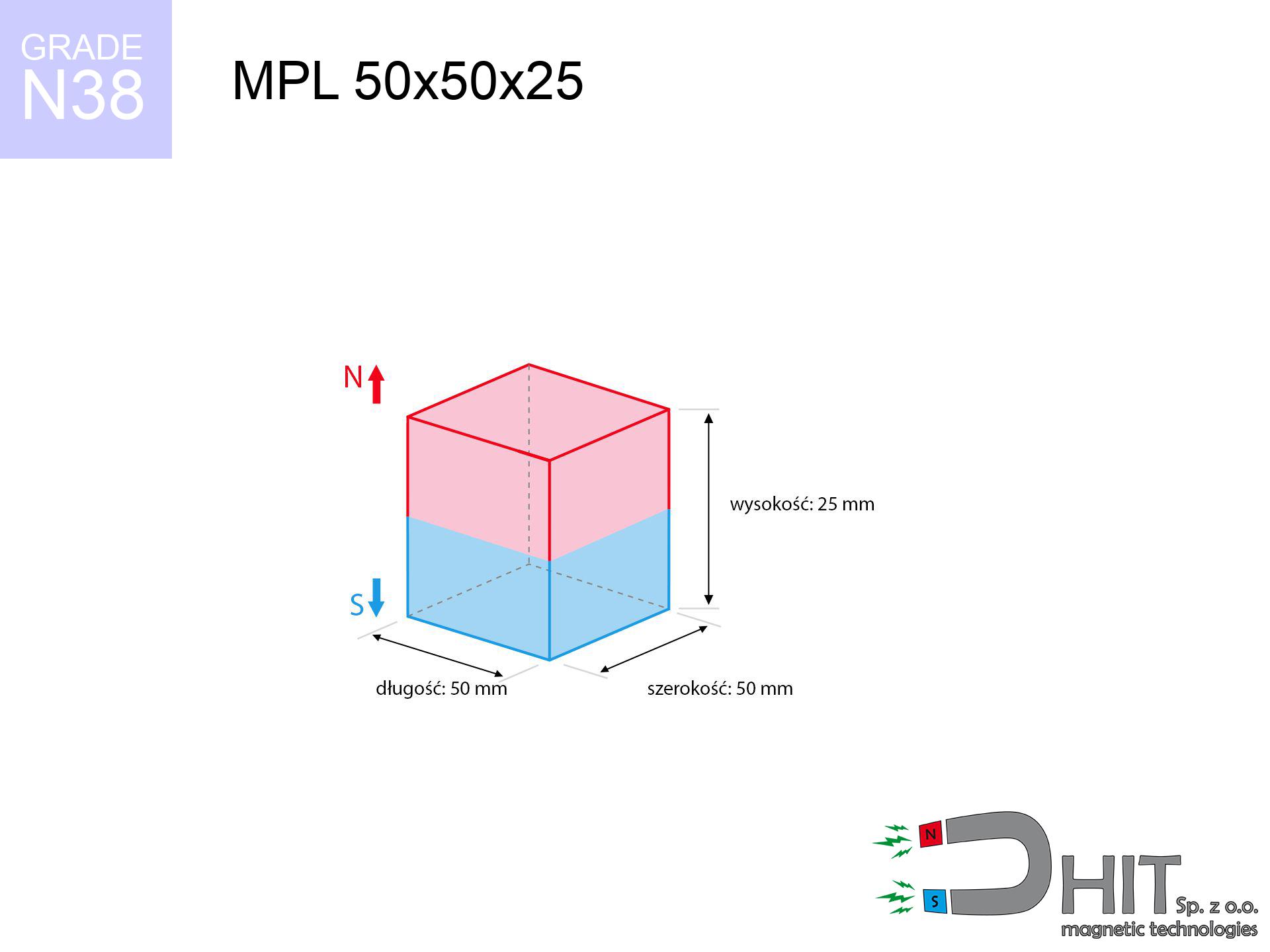

MPL 50x50x25 / N38 - lamellar magnet

lamellar magnet

Catalog no 020168

GTIN/EAN: 5906301811749

length

50 mm [±0,1 mm]

Width

50 mm [±0,1 mm]

Height

25 mm [±0,1 mm]

Weight

468.75 g

Magnetization Direction

↑ axial

Load capacity

90.53 kg / 888.15 N

Magnetic Induction

413.25 mT / 4133 Gs

Coating

[NiCuNi] Nickel

159.90 ZŁ with VAT / pcs + price for transport

130.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

or send us a note via

inquiry form

the contact section.

Force along with appearance of neodymium magnets can be tested on our

modular calculator.

Same-day processing for orders placed before 14:00.

Product card - MPL 50x50x25 / N38 - lamellar magnet

Specification / characteristics - MPL 50x50x25 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020168 |

| GTIN/EAN | 5906301811749 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 50 mm [±0,1 mm] |

| Width | 50 mm [±0,1 mm] |

| Height | 25 mm [±0,1 mm] |

| Weight | 468.75 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 90.53 kg / 888.15 N |

| Magnetic Induction ~ ? | 413.25 mT / 4133 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the product - technical parameters

Presented data are the outcome of a mathematical calculation. Results were calculated on algorithms for the class Nd2Fe14B. Real-world parameters may differ. Treat these calculations as a preliminary roadmap during assembly planning.

Table 1: Static pull force (pull vs gap) - interaction chart

MPL 50x50x25 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4132 Gs

413.2 mT

|

90.53 kg / 199.58 LBS

90530.0 g / 888.1 N

|

dangerous! |

| 1 mm |

3999 Gs

399.9 mT

|

84.79 kg / 186.94 LBS

84794.0 g / 831.8 N

|

dangerous! |

| 2 mm |

3861 Gs

386.1 mT

|

79.04 kg / 174.25 LBS

79038.6 g / 775.4 N

|

dangerous! |

| 3 mm |

3720 Gs

372.0 mT

|

73.38 kg / 161.78 LBS

73381.8 g / 719.9 N

|

dangerous! |

| 5 mm |

3435 Gs

343.5 mT

|

62.56 kg / 137.93 LBS

62564.2 g / 613.8 N

|

dangerous! |

| 10 mm |

2742 Gs

274.2 mT

|

39.87 kg / 87.90 LBS

39868.7 g / 391.1 N

|

dangerous! |

| 15 mm |

2137 Gs

213.7 mT

|

24.21 kg / 53.37 LBS

24210.4 g / 237.5 N

|

dangerous! |

| 20 mm |

1649 Gs

164.9 mT

|

14.41 kg / 31.77 LBS

14409.9 g / 141.4 N

|

dangerous! |

| 30 mm |

988 Gs

98.8 mT

|

5.17 kg / 11.40 LBS

5170.9 g / 50.7 N

|

medium risk |

| 50 mm |

399 Gs

39.9 mT

|

0.85 kg / 1.86 LBS

845.8 g / 8.3 N

|

safe |

Table 2: Shear capacity (vertical surface)

MPL 50x50x25 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

18.11 kg / 39.92 LBS

18106.0 g / 177.6 N

|

| 1 mm | Stal (~0.2) |

16.96 kg / 37.39 LBS

16958.0 g / 166.4 N

|

| 2 mm | Stal (~0.2) |

15.81 kg / 34.85 LBS

15808.0 g / 155.1 N

|

| 3 mm | Stal (~0.2) |

14.68 kg / 32.36 LBS

14676.0 g / 144.0 N

|

| 5 mm | Stal (~0.2) |

12.51 kg / 27.58 LBS

12512.0 g / 122.7 N

|

| 10 mm | Stal (~0.2) |

7.97 kg / 17.58 LBS

7974.0 g / 78.2 N

|

| 15 mm | Stal (~0.2) |

4.84 kg / 10.67 LBS

4842.0 g / 47.5 N

|

| 20 mm | Stal (~0.2) |

2.88 kg / 6.35 LBS

2882.0 g / 28.3 N

|

| 30 mm | Stal (~0.2) |

1.03 kg / 2.28 LBS

1034.0 g / 10.1 N

|

| 50 mm | Stal (~0.2) |

0.17 kg / 0.37 LBS

170.0 g / 1.7 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MPL 50x50x25 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

27.16 kg / 59.88 LBS

27159.0 g / 266.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

18.11 kg / 39.92 LBS

18106.0 g / 177.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

9.05 kg / 19.96 LBS

9053.0 g / 88.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

45.27 kg / 99.79 LBS

45265.0 g / 444.0 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MPL 50x50x25 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

3.02 kg / 6.65 LBS

3017.7 g / 29.6 N

|

| 1 mm |

|

7.54 kg / 16.63 LBS

7544.2 g / 74.0 N

|

| 2 mm |

|

15.09 kg / 33.26 LBS

15088.3 g / 148.0 N

|

| 3 mm |

|

22.63 kg / 49.90 LBS

22632.5 g / 222.0 N

|

| 5 mm |

|

37.72 kg / 83.16 LBS

37720.8 g / 370.0 N

|

| 10 mm |

|

75.44 kg / 166.32 LBS

75441.7 g / 740.1 N

|

| 11 mm |

|

82.99 kg / 182.95 LBS

82985.8 g / 814.1 N

|

| 12 mm |

|

90.53 kg / 199.58 LBS

90530.0 g / 888.1 N

|

Table 5: Thermal stability (material behavior) - thermal limit

MPL 50x50x25 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

90.53 kg / 199.58 LBS

90530.0 g / 888.1 N

|

OK |

| 40 °C | -2.2% |

88.54 kg / 195.19 LBS

88538.3 g / 868.6 N

|

OK |

| 60 °C | -4.4% |

86.55 kg / 190.80 LBS

86546.7 g / 849.0 N

|

|

| 80 °C | -6.6% |

84.56 kg / 186.41 LBS

84555.0 g / 829.5 N

|

|

| 100 °C | -28.8% |

64.46 kg / 142.10 LBS

64457.4 g / 632.3 N

|

Table 6: Two magnets (repulsion) - forces in the system

MPL 50x50x25 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

263.15 kg / 580.14 LBS

5 403 Gs

|

39.47 kg / 87.02 LBS

39472 g / 387.2 N

|

N/A |

| 1 mm |

254.89 kg / 561.94 LBS

8 133 Gs

|

38.23 kg / 84.29 LBS

38234 g / 375.1 N

|

229.40 kg / 505.75 LBS

~0 Gs

|

| 2 mm |

246.47 kg / 543.38 LBS

7 998 Gs

|

36.97 kg / 81.51 LBS

36971 g / 362.7 N

|

221.83 kg / 489.04 LBS

~0 Gs

|

| 3 mm |

238.08 kg / 524.88 LBS

7 861 Gs

|

35.71 kg / 78.73 LBS

35713 g / 350.3 N

|

214.28 kg / 472.40 LBS

~0 Gs

|

| 5 mm |

221.48 kg / 488.27 LBS

7 582 Gs

|

33.22 kg / 73.24 LBS

33222 g / 325.9 N

|

199.33 kg / 439.45 LBS

~0 Gs

|

| 10 mm |

181.86 kg / 400.93 LBS

6 870 Gs

|

27.28 kg / 60.14 LBS

27279 g / 267.6 N

|

163.67 kg / 360.83 LBS

~0 Gs

|

| 20 mm |

115.89 kg / 255.49 LBS

5 484 Gs

|

17.38 kg / 38.32 LBS

17383 g / 170.5 N

|

104.30 kg / 229.94 LBS

~0 Gs

|

| 50 mm |

24.93 kg / 54.97 LBS

2 544 Gs

|

3.74 kg / 8.25 LBS

3740 g / 36.7 N

|

22.44 kg / 49.47 LBS

~0 Gs

|

| 60 mm |

15.03 kg / 33.14 LBS

1 975 Gs

|

2.25 kg / 4.97 LBS

2255 g / 22.1 N

|

13.53 kg / 29.82 LBS

~0 Gs

|

| 70 mm |

9.24 kg / 20.37 LBS

1 548 Gs

|

1.39 kg / 3.05 LBS

1386 g / 13.6 N

|

8.31 kg / 18.33 LBS

~0 Gs

|

| 80 mm |

5.81 kg / 12.80 LBS

1 228 Gs

|

0.87 kg / 1.92 LBS

871 g / 8.5 N

|

5.23 kg / 11.52 LBS

~0 Gs

|

| 90 mm |

3.74 kg / 8.24 LBS

985 Gs

|

0.56 kg / 1.24 LBS

560 g / 5.5 N

|

3.36 kg / 7.41 LBS

~0 Gs

|

| 100 mm |

2.46 kg / 5.42 LBS

799 Gs

|

0.37 kg / 0.81 LBS

369 g / 3.6 N

|

2.21 kg / 4.88 LBS

~0 Gs

|

Table 7: Hazards (electronics) - precautionary measures

MPL 50x50x25 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 28.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 22.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 17.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 13.5 cm |

| Remote | 50 Gs (5.0 mT) | 12.5 cm |

| Payment card | 400 Gs (40.0 mT) | 5.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 4.5 cm |

Table 8: Dynamics (cracking risk) - collision effects

MPL 50x50x25 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

17.45 km/h

(4.85 m/s)

|

5.51 J | |

| 30 mm |

25.13 km/h

(6.98 m/s)

|

11.42 J | |

| 50 mm |

31.52 km/h

(8.76 m/s)

|

17.97 J | |

| 100 mm |

44.33 km/h

(12.31 m/s)

|

35.54 J |

Table 9: Corrosion resistance

MPL 50x50x25 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MPL 50x50x25 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 105 093 Mx | 1050.9 µWb |

| Pc Coefficient | 0.54 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MPL 50x50x25 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 90.53 kg | Standard |

| Water (riverbed) |

103.66 kg

(+13.13 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Warning: On a vertical surface, the magnet retains only a fraction of its perpendicular strength.

2. Steel saturation

*Thin steel (e.g. 0.5mm PC case) significantly weakens the holding force.

3. Power loss vs temp

*For standard magnets, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.54

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Pros as well as cons of neodymium magnets.

Strengths

- They retain attractive force for around 10 years – the drop is just ~1% (according to analyses),

- They are extremely resistant to demagnetization induced by external disturbances,

- A magnet with a smooth nickel surface looks better,

- They feature high magnetic induction at the operating surface, which improves attraction properties,

- Through (appropriate) combination of ingredients, they can achieve high thermal strength, allowing for functioning at temperatures reaching 230°C and above...

- Possibility of custom forming as well as adapting to individual conditions,

- Versatile presence in modern technologies – they find application in magnetic memories, drive modules, precision medical tools, as well as industrial machines.

- Relatively small size with high pulling force – neodymium magnets offer high power in compact dimensions, which allows their use in small systems

Weaknesses

- At very strong impacts they can break, therefore we advise placing them in steel cases. A metal housing provides additional protection against damage and increases the magnet's durability.

- Neodymium magnets lose their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore when using outdoors, we advise using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- We suggest casing - magnetic mount, due to difficulties in realizing nuts inside the magnet and complicated shapes.

- Possible danger resulting from small fragments of magnets pose a threat, in case of ingestion, which gains importance in the context of child health protection. It is also worth noting that small components of these devices are able to complicate diagnosis medical after entering the body.

- With budget limitations the cost of neodymium magnets is a challenge,

Lifting parameters

Maximum magnetic pulling force – what contributes to it?

- with the contact of a yoke made of low-carbon steel, guaranteeing full magnetic saturation

- possessing a massiveness of at least 10 mm to avoid saturation

- with an ideally smooth touching surface

- under conditions of ideal adhesion (metal-to-metal)

- during detachment in a direction vertical to the mounting surface

- at temperature room level

Lifting capacity in practice – influencing factors

- Gap between magnet and steel – even a fraction of a millimeter of separation (caused e.g. by veneer or dirt) diminishes the magnet efficiency, often by half at just 0.5 mm.

- Force direction – note that the magnet holds strongest perpendicularly. Under shear forces, the capacity drops significantly, often to levels of 20-30% of the nominal value.

- Metal thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field penetrates through instead of converting into lifting capacity.

- Material type – the best choice is pure iron steel. Hardened steels may attract less.

- Surface finish – ideal contact is obtained only on polished steel. Any scratches and bumps reduce the real contact area, reducing force.

- Temperature – temperature increase results in weakening of induction. It is worth remembering the thermal limit for a given model.

Lifting capacity was assessed by applying a polished steel plate of suitable thickness (min. 20 mm), under perpendicular pulling force, however under parallel forces the holding force is lower. Additionally, even a small distance between the magnet’s surface and the plate decreases the load capacity.

Warnings

Crushing risk

Watch your fingers. Two large magnets will join immediately with a force of massive weight, destroying everything in their path. Exercise extreme caution!

Pacemakers

Warning for patients: Powerful magnets affect medical devices. Maintain at least 30 cm distance or ask another person to handle the magnets.

Impact on smartphones

A strong magnetic field negatively affects the functioning of magnetometers in smartphones and GPS navigation. Do not bring magnets near a device to prevent damaging the sensors.

Dust is flammable

Mechanical processing of neodymium magnets carries a risk of fire hazard. Magnetic powder oxidizes rapidly with oxygen and is difficult to extinguish.

Safe distance

Powerful magnetic fields can corrupt files on credit cards, hard drives, and storage devices. Maintain a gap of at least 10 cm.

Heat sensitivity

Monitor thermal conditions. Exposing the magnet above 80 degrees Celsius will destroy its properties and pulling force.

Material brittleness

NdFeB magnets are ceramic materials, which means they are very brittle. Collision of two magnets leads to them cracking into small pieces.

Handling rules

Before starting, check safety instructions. Sudden snapping can break the magnet or injure your hand. Think ahead.

Warning for allergy sufferers

Warning for allergy sufferers: The Ni-Cu-Ni coating contains nickel. If an allergic reaction appears, cease working with magnets and use protective gear.

Keep away from children

Product intended for adults. Small elements pose a choking risk, causing severe trauma. Store out of reach of children and animals.

![HH 16x5.3 [M3] / N38 - through hole magnetic holder HH 16x5.3 [M3] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-16x5.3-m3-sud.jpg)