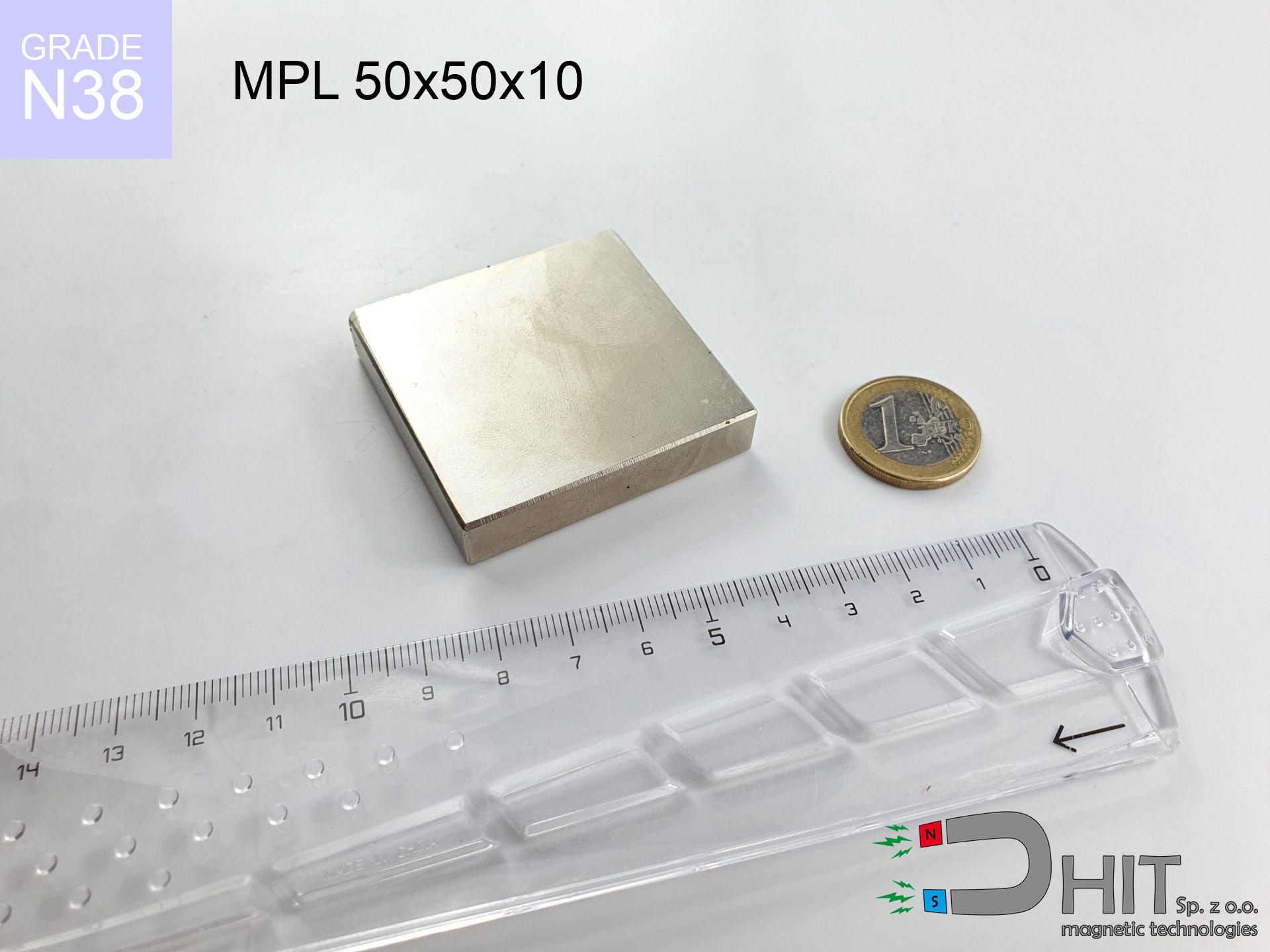

MPL 50x50x10 / N38 - lamellar magnet

lamellar magnet

Catalog no 020167

GTIN/EAN: 5906301811732

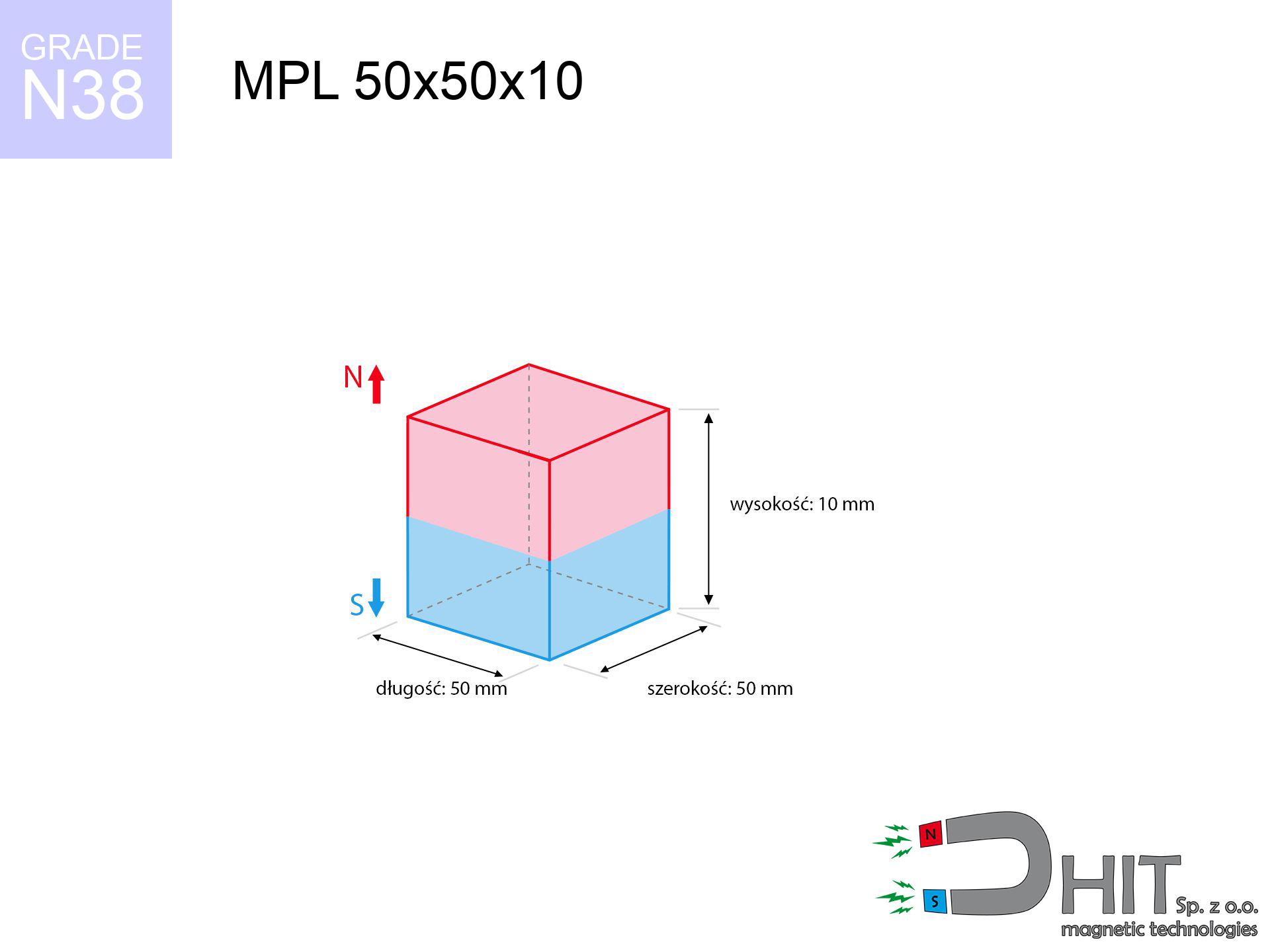

length

50 mm [±0,1 mm]

Width

50 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

187.5 g

Magnetization Direction

↑ axial

Load capacity

33.73 kg / 330.92 N

Magnetic Induction

209.75 mT / 2097 Gs

Coating

[NiCuNi] Nickel

42.88 ZŁ with VAT / pcs + price for transport

34.86 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

if you prefer contact us by means of

our online form

the contact form page.

Weight as well as shape of magnetic components can be verified using our

modular calculator.

Order by 14:00 and we’ll ship today!

Product card - MPL 50x50x10 / N38 - lamellar magnet

Specification / characteristics - MPL 50x50x10 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020167 |

| GTIN/EAN | 5906301811732 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 50 mm [±0,1 mm] |

| Width | 50 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 187.5 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 33.73 kg / 330.92 N |

| Magnetic Induction ~ ? | 209.75 mT / 2097 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the magnet - report

These data constitute the direct effect of a mathematical calculation. Results are based on algorithms for the material Nd2Fe14B. Real-world performance may differ from theoretical values. Please consider these data as a supplementary guide during assembly planning.

Table 1: Static pull force (force vs distance) - power drop

MPL 50x50x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2097 Gs

209.7 mT

|

33.73 kg / 74.36 lbs

33730.0 g / 330.9 N

|

dangerous! |

| 1 mm |

2056 Gs

205.6 mT

|

32.43 kg / 71.50 lbs

32430.0 g / 318.1 N

|

dangerous! |

| 2 mm |

2009 Gs

200.9 mT

|

30.96 kg / 68.27 lbs

30964.6 g / 303.8 N

|

dangerous! |

| 3 mm |

1957 Gs

195.7 mT

|

29.38 kg / 64.77 lbs

29380.4 g / 288.2 N

|

dangerous! |

| 5 mm |

1841 Gs

184.1 mT

|

25.99 kg / 57.30 lbs

25992.3 g / 255.0 N

|

dangerous! |

| 10 mm |

1514 Gs

151.4 mT

|

17.58 kg / 38.75 lbs

17577.6 g / 172.4 N

|

dangerous! |

| 15 mm |

1194 Gs

119.4 mT

|

10.93 kg / 24.10 lbs

10931.8 g / 107.2 N

|

dangerous! |

| 20 mm |

922 Gs

92.2 mT

|

6.51 kg / 14.36 lbs

6512.2 g / 63.9 N

|

medium risk |

| 30 mm |

543 Gs

54.3 mT

|

2.26 kg / 4.98 lbs

2260.0 g / 22.2 N

|

medium risk |

| 50 mm |

209 Gs

20.9 mT

|

0.33 kg / 0.74 lbs

334.1 g / 3.3 N

|

weak grip |

Table 2: Sliding capacity (vertical surface)

MPL 50x50x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

6.75 kg / 14.87 lbs

6746.0 g / 66.2 N

|

| 1 mm | Stal (~0.2) |

6.49 kg / 14.30 lbs

6486.0 g / 63.6 N

|

| 2 mm | Stal (~0.2) |

6.19 kg / 13.65 lbs

6192.0 g / 60.7 N

|

| 3 mm | Stal (~0.2) |

5.88 kg / 12.95 lbs

5876.0 g / 57.6 N

|

| 5 mm | Stal (~0.2) |

5.20 kg / 11.46 lbs

5198.0 g / 51.0 N

|

| 10 mm | Stal (~0.2) |

3.52 kg / 7.75 lbs

3516.0 g / 34.5 N

|

| 15 mm | Stal (~0.2) |

2.19 kg / 4.82 lbs

2186.0 g / 21.4 N

|

| 20 mm | Stal (~0.2) |

1.30 kg / 2.87 lbs

1302.0 g / 12.8 N

|

| 30 mm | Stal (~0.2) |

0.45 kg / 1.00 lbs

452.0 g / 4.4 N

|

| 50 mm | Stal (~0.2) |

0.07 kg / 0.15 lbs

66.0 g / 0.6 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MPL 50x50x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

10.12 kg / 22.31 lbs

10119.0 g / 99.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

6.75 kg / 14.87 lbs

6746.0 g / 66.2 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

3.37 kg / 7.44 lbs

3373.0 g / 33.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

16.87 kg / 37.18 lbs

16865.0 g / 165.4 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MPL 50x50x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.69 kg / 3.72 lbs

1686.5 g / 16.5 N

|

| 1 mm |

|

4.22 kg / 9.30 lbs

4216.3 g / 41.4 N

|

| 2 mm |

|

8.43 kg / 18.59 lbs

8432.5 g / 82.7 N

|

| 3 mm |

|

12.65 kg / 27.89 lbs

12648.8 g / 124.1 N

|

| 5 mm |

|

21.08 kg / 46.48 lbs

21081.2 g / 206.8 N

|

| 10 mm |

|

33.73 kg / 74.36 lbs

33730.0 g / 330.9 N

|

| 11 mm |

|

33.73 kg / 74.36 lbs

33730.0 g / 330.9 N

|

| 12 mm |

|

33.73 kg / 74.36 lbs

33730.0 g / 330.9 N

|

Table 5: Thermal stability (stability) - power drop

MPL 50x50x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

33.73 kg / 74.36 lbs

33730.0 g / 330.9 N

|

OK |

| 40 °C | -2.2% |

32.99 kg / 72.73 lbs

32987.9 g / 323.6 N

|

OK |

| 60 °C | -4.4% |

32.25 kg / 71.09 lbs

32245.9 g / 316.3 N

|

|

| 80 °C | -6.6% |

31.50 kg / 69.45 lbs

31503.8 g / 309.1 N

|

|

| 100 °C | -28.8% |

24.02 kg / 52.95 lbs

24015.8 g / 235.6 N

|

Table 6: Two magnets (repulsion) - forces in the system

MPL 50x50x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

67.80 kg / 149.46 lbs

3 611 Gs

|

10.17 kg / 22.42 lbs

10169 g / 99.8 N

|

N/A |

| 1 mm |

66.54 kg / 146.70 lbs

4 156 Gs

|

9.98 kg / 22.01 lbs

9982 g / 97.9 N

|

59.89 kg / 132.03 lbs

~0 Gs

|

| 2 mm |

65.18 kg / 143.70 lbs

4 113 Gs

|

9.78 kg / 21.56 lbs

9777 g / 95.9 N

|

58.66 kg / 129.33 lbs

~0 Gs

|

| 3 mm |

63.74 kg / 140.53 lbs

4 067 Gs

|

9.56 kg / 21.08 lbs

9562 g / 93.8 N

|

57.37 kg / 126.48 lbs

~0 Gs

|

| 5 mm |

60.67 kg / 133.75 lbs

3 968 Gs

|

9.10 kg / 20.06 lbs

9101 g / 89.3 N

|

54.60 kg / 120.38 lbs

~0 Gs

|

| 10 mm |

52.24 kg / 115.18 lbs

3 682 Gs

|

7.84 kg / 17.28 lbs

7836 g / 76.9 N

|

47.02 kg / 103.66 lbs

~0 Gs

|

| 20 mm |

35.33 kg / 77.89 lbs

3 028 Gs

|

5.30 kg / 11.68 lbs

5299 g / 52.0 N

|

31.80 kg / 70.10 lbs

~0 Gs

|

| 50 mm |

7.69 kg / 16.96 lbs

1 413 Gs

|

1.15 kg / 2.54 lbs

1154 g / 11.3 N

|

6.92 kg / 15.26 lbs

~0 Gs

|

| 60 mm |

4.54 kg / 10.01 lbs

1 086 Gs

|

0.68 kg / 1.50 lbs

681 g / 6.7 N

|

4.09 kg / 9.01 lbs

~0 Gs

|

| 70 mm |

2.72 kg / 6.01 lbs

841 Gs

|

0.41 kg / 0.90 lbs

409 g / 4.0 N

|

2.45 kg / 5.41 lbs

~0 Gs

|

| 80 mm |

1.67 kg / 3.68 lbs

658 Gs

|

0.25 kg / 0.55 lbs

250 g / 2.5 N

|

1.50 kg / 3.31 lbs

~0 Gs

|

| 90 mm |

1.05 kg / 2.31 lbs

521 Gs

|

0.16 kg / 0.35 lbs

157 g / 1.5 N

|

0.94 kg / 2.08 lbs

~0 Gs

|

| 100 mm |

0.67 kg / 1.48 lbs

417 Gs

|

0.10 kg / 0.22 lbs

101 g / 1.0 N

|

0.60 kg / 1.33 lbs

~0 Gs

|

Table 7: Protective zones (implants) - warnings

MPL 50x50x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 21.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 16.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 13.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 10.0 cm |

| Car key | 50 Gs (5.0 mT) | 9.5 cm |

| Payment card | 400 Gs (40.0 mT) | 4.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 3.0 cm |

Table 8: Dynamics (kinetic energy) - warning

MPL 50x50x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

17.38 km/h

(4.83 m/s)

|

2.19 J | |

| 30 mm |

24.39 km/h

(6.78 m/s)

|

4.30 J | |

| 50 mm |

30.43 km/h

(8.45 m/s)

|

6.70 J | |

| 100 mm |

42.78 km/h

(11.88 m/s)

|

13.24 J |

Table 9: Surface protection spec

MPL 50x50x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 50x50x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 61 501 Mx | 615.0 µWb |

| Pc Coefficient | 0.26 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 50x50x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 33.73 kg | Standard |

| Water (riverbed) |

38.62 kg

(+4.89 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Warning: On a vertical surface, the magnet retains merely a fraction of its max power.

2. Plate thickness effect

*Thin metal sheet (e.g. computer case) drastically weakens the holding force.

3. Heat tolerance

*For standard magnets, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.26

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Strengths as well as weaknesses of rare earth magnets.

Benefits

- They virtually do not lose strength, because even after 10 years the performance loss is only ~1% (according to literature),

- They retain their magnetic properties even under close interference source,

- In other words, due to the smooth finish of silver, the element is aesthetically pleasing,

- They feature high magnetic induction at the operating surface, which improves attraction properties,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can function (depending on the shape) even at a temperature of 230°C or more...

- Thanks to modularity in forming and the ability to customize to client solutions,

- Wide application in modern technologies – they serve a role in hard drives, electromotive mechanisms, medical equipment, also modern systems.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Weaknesses

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth securing magnets in a protective case. Such protection not only protects the magnet but also increases its resistance to damage

- When exposed to high temperature, neodymium magnets experience a drop in power. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- They rust in a humid environment. For use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- Limited possibility of creating threads in the magnet and complex shapes - recommended is a housing - magnetic holder.

- Possible danger to health – tiny shards of magnets pose a threat, when accidentally swallowed, which becomes key in the context of child safety. Furthermore, small elements of these devices are able to complicate diagnosis medical in case of swallowing.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Holding force characteristics

Highest magnetic holding force – what affects it?

- with the application of a sheet made of low-carbon steel, guaranteeing maximum field concentration

- with a cross-section no less than 10 mm

- with an ideally smooth touching surface

- under conditions of gap-free contact (surface-to-surface)

- under perpendicular application of breakaway force (90-degree angle)

- at standard ambient temperature

Impact of factors on magnetic holding capacity in practice

- Gap between surfaces – even a fraction of a millimeter of separation (caused e.g. by varnish or dirt) drastically reduces the magnet efficiency, often by half at just 0.5 mm.

- Loading method – declared lifting capacity refers to detachment vertically. When applying parallel force, the magnet exhibits much less (typically approx. 20-30% of nominal force).

- Steel thickness – too thin steel does not close the flux, causing part of the flux to be escaped into the air.

- Metal type – not every steel reacts the same. High carbon content weaken the interaction with the magnet.

- Surface structure – the more even the surface, the larger the contact zone and stronger the hold. Unevenness creates an air distance.

- Thermal factor – hot environment weakens pulling force. Too high temperature can permanently damage the magnet.

Lifting capacity testing was carried out on plates with a smooth surface of suitable thickness, under perpendicular forces, in contrast under shearing force the holding force is lower. In addition, even a small distance between the magnet and the plate reduces the holding force.

Safety rules for work with NdFeB magnets

Powerful field

Handle magnets consciously. Their immense force can shock even experienced users. Plan your moves and respect their power.

Fragile material

Despite metallic appearance, neodymium is delicate and not impact-resistant. Avoid impacts, as the magnet may shatter into hazardous fragments.

Maximum temperature

Keep cool. NdFeB magnets are susceptible to heat. If you need operation above 80°C, look for HT versions (H, SH, UH).

Do not give to children

Neodymium magnets are not suitable for play. Eating a few magnets may result in them connecting inside the digestive tract, which poses a critical condition and requires urgent medical intervention.

GPS Danger

Remember: rare earth magnets produce a field that interferes with sensitive sensors. Maintain a safe distance from your mobile, device, and GPS.

Flammability

Mechanical processing of neodymium magnets carries a risk of fire risk. Magnetic powder oxidizes rapidly with oxygen and is hard to extinguish.

Crushing force

Big blocks can smash fingers instantly. Never put your hand between two attracting surfaces.

Avoid contact if allergic

Nickel alert: The nickel-copper-nickel coating consists of nickel. If skin irritation occurs, immediately stop working with magnets and wear gloves.

Magnetic media

Do not bring magnets close to a wallet, computer, or screen. The magnetism can permanently damage these devices and wipe information from cards.

Danger to pacemakers

People with a heart stimulator must maintain an safe separation from magnets. The magnetism can interfere with the functioning of the life-saving device.

![SM 32x300 [2xM8] / N42 - magnetic separator SM 32x300 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x300-2xm8-pel.jpg)

![SM 32x125 [2xM8] / N52 - magnetic separator SM 32x125 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x125-2xm8-moj.jpg)