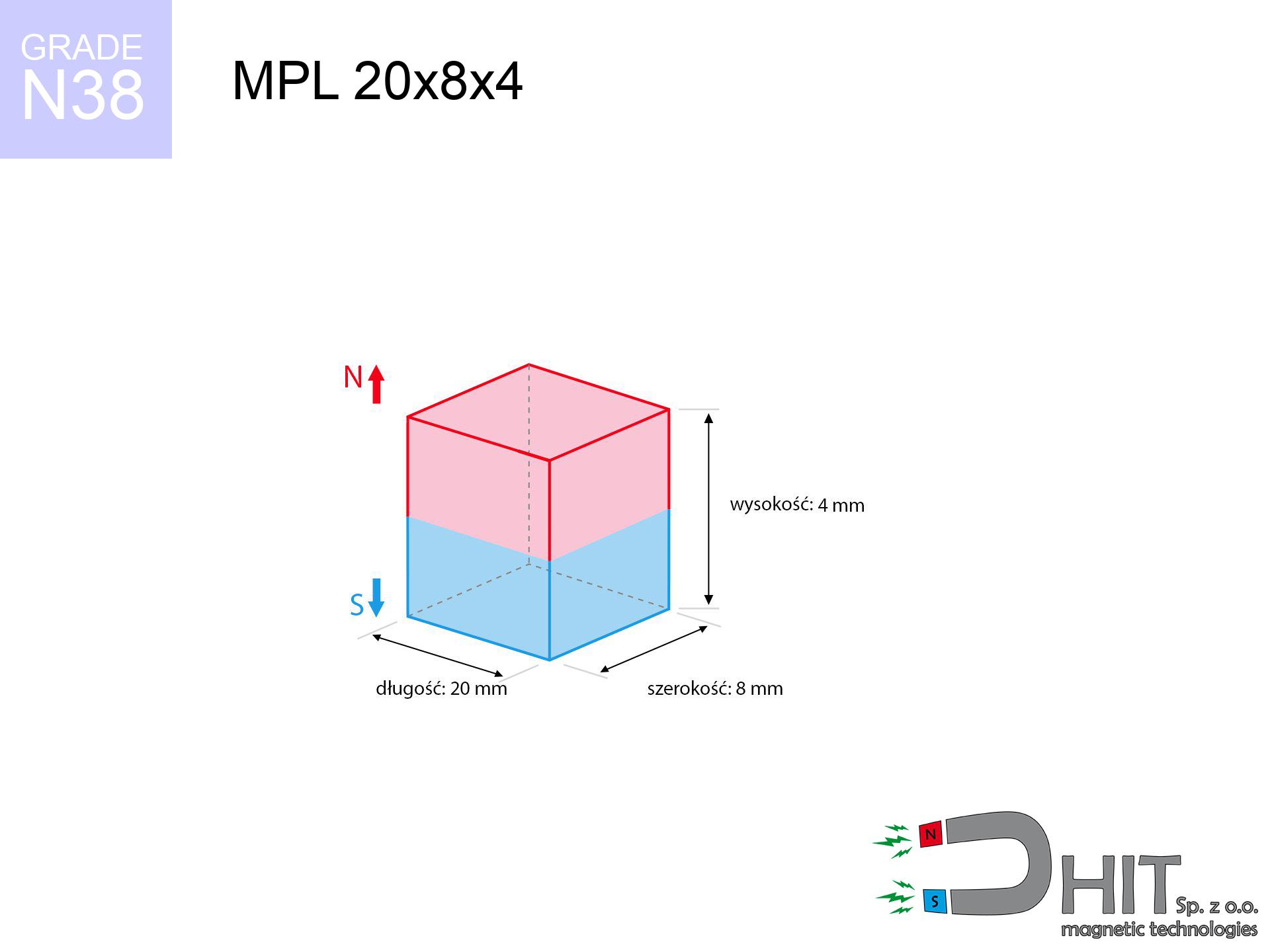

MPL 20x8x4 / N38 - lamellar magnet

lamellar magnet

Catalog no 020133

GTIN/EAN: 5906301811398

length

20 mm [±0,1 mm]

Width

8 mm [±0,1 mm]

Height

4 mm [±0,1 mm]

Weight

4.8 g

Magnetization Direction

↑ axial

Load capacity

4.79 kg / 46.98 N

Magnetic Induction

336.99 mT / 3370 Gs

Coating

[NiCuNi] Nickel

3.67 ZŁ with VAT / pcs + price for transport

2.98 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

or send us a note via

form

the contact page.

Lifting power as well as appearance of a magnet can be checked with our

force calculator.

Same-day shipping for orders placed before 14:00.

Technical parameters of the product - MPL 20x8x4 / N38 - lamellar magnet

Specification / characteristics - MPL 20x8x4 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020133 |

| GTIN/EAN | 5906301811398 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 20 mm [±0,1 mm] |

| Width | 8 mm [±0,1 mm] |

| Height | 4 mm [±0,1 mm] |

| Weight | 4.8 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 4.79 kg / 46.98 N |

| Magnetic Induction ~ ? | 336.99 mT / 3370 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the magnet - data

The following information represent the outcome of a mathematical simulation. Results are based on models for the material Nd2Fe14B. Real-world performance may differ. Use these calculations as a reference point when designing systems.

Table 1: Static force (pull vs distance) - interaction chart

MPL 20x8x4 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3368 Gs

336.8 mT

|

4.79 kg / 10.56 LBS

4790.0 g / 47.0 N

|

medium risk |

| 1 mm |

2818 Gs

281.8 mT

|

3.35 kg / 7.39 LBS

3352.3 g / 32.9 N

|

medium risk |

| 2 mm |

2266 Gs

226.6 mT

|

2.17 kg / 4.78 LBS

2167.6 g / 21.3 N

|

medium risk |

| 3 mm |

1794 Gs

179.4 mT

|

1.36 kg / 3.00 LBS

1358.6 g / 13.3 N

|

low risk |

| 5 mm |

1130 Gs

113.0 mT

|

0.54 kg / 1.19 LBS

538.9 g / 5.3 N

|

low risk |

| 10 mm |

416 Gs

41.6 mT

|

0.07 kg / 0.16 LBS

73.0 g / 0.7 N

|

low risk |

| 15 mm |

187 Gs

18.7 mT

|

0.01 kg / 0.03 LBS

14.7 g / 0.1 N

|

low risk |

| 20 mm |

97 Gs

9.7 mT

|

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

low risk |

| 30 mm |

35 Gs

3.5 mT

|

0.00 kg / 0.00 LBS

0.5 g / 0.0 N

|

low risk |

| 50 mm |

9 Gs

0.9 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

Table 2: Shear capacity (vertical surface)

MPL 20x8x4 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.96 kg / 2.11 LBS

958.0 g / 9.4 N

|

| 1 mm | Stal (~0.2) |

0.67 kg / 1.48 LBS

670.0 g / 6.6 N

|

| 2 mm | Stal (~0.2) |

0.43 kg / 0.96 LBS

434.0 g / 4.3 N

|

| 3 mm | Stal (~0.2) |

0.27 kg / 0.60 LBS

272.0 g / 2.7 N

|

| 5 mm | Stal (~0.2) |

0.11 kg / 0.24 LBS

108.0 g / 1.1 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.03 LBS

14.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MPL 20x8x4 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.44 kg / 3.17 LBS

1437.0 g / 14.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.96 kg / 2.11 LBS

958.0 g / 9.4 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.48 kg / 1.06 LBS

479.0 g / 4.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

2.40 kg / 5.28 LBS

2395.0 g / 23.5 N

|

Table 4: Material efficiency (saturation) - power losses

MPL 20x8x4 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.48 kg / 1.06 LBS

479.0 g / 4.7 N

|

| 1 mm |

|

1.20 kg / 2.64 LBS

1197.5 g / 11.7 N

|

| 2 mm |

|

2.40 kg / 5.28 LBS

2395.0 g / 23.5 N

|

| 3 mm |

|

3.59 kg / 7.92 LBS

3592.5 g / 35.2 N

|

| 5 mm |

|

4.79 kg / 10.56 LBS

4790.0 g / 47.0 N

|

| 10 mm |

|

4.79 kg / 10.56 LBS

4790.0 g / 47.0 N

|

| 11 mm |

|

4.79 kg / 10.56 LBS

4790.0 g / 47.0 N

|

| 12 mm |

|

4.79 kg / 10.56 LBS

4790.0 g / 47.0 N

|

Table 5: Working in heat (stability) - resistance threshold

MPL 20x8x4 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

4.79 kg / 10.56 LBS

4790.0 g / 47.0 N

|

OK |

| 40 °C | -2.2% |

4.68 kg / 10.33 LBS

4684.6 g / 46.0 N

|

OK |

| 60 °C | -4.4% |

4.58 kg / 10.10 LBS

4579.2 g / 44.9 N

|

|

| 80 °C | -6.6% |

4.47 kg / 9.86 LBS

4473.9 g / 43.9 N

|

|

| 100 °C | -28.8% |

3.41 kg / 7.52 LBS

3410.5 g / 33.5 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MPL 20x8x4 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

11.19 kg / 24.67 LBS

4 784 Gs

|

1.68 kg / 3.70 LBS

1678 g / 16.5 N

|

N/A |

| 1 mm |

9.49 kg / 20.93 LBS

6 205 Gs

|

1.42 kg / 3.14 LBS

1424 g / 14.0 N

|

8.54 kg / 18.84 LBS

~0 Gs

|

| 2 mm |

7.83 kg / 17.26 LBS

5 635 Gs

|

1.17 kg / 2.59 LBS

1175 g / 11.5 N

|

7.05 kg / 15.54 LBS

~0 Gs

|

| 3 mm |

6.34 kg / 13.97 LBS

5 069 Gs

|

0.95 kg / 2.10 LBS

951 g / 9.3 N

|

5.70 kg / 12.57 LBS

~0 Gs

|

| 5 mm |

4.02 kg / 8.85 LBS

4 035 Gs

|

0.60 kg / 1.33 LBS

602 g / 5.9 N

|

3.61 kg / 7.97 LBS

~0 Gs

|

| 10 mm |

1.26 kg / 2.78 LBS

2 259 Gs

|

0.19 kg / 0.42 LBS

189 g / 1.9 N

|

1.13 kg / 2.50 LBS

~0 Gs

|

| 20 mm |

0.17 kg / 0.38 LBS

832 Gs

|

0.03 kg / 0.06 LBS

26 g / 0.3 N

|

0.15 kg / 0.34 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.01 LBS

112 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

70 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

46 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

32 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

23 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

17 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Safety (HSE) (electronics) - precautionary measures

MPL 20x8x4 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 4.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.0 cm |

| Remote | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (cracking risk) - warning

MPL 20x8x4 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

32.16 km/h

(8.93 m/s)

|

0.19 J | |

| 30 mm |

55.18 km/h

(15.33 m/s)

|

0.56 J | |

| 50 mm |

71.24 km/h

(19.79 m/s)

|

0.94 J | |

| 100 mm |

100.75 km/h

(27.99 m/s)

|

1.88 J |

Table 9: Surface protection spec

MPL 20x8x4 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MPL 20x8x4 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 5 277 Mx | 52.8 µWb |

| Pc Coefficient | 0.38 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MPL 20x8x4 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 4.79 kg | Standard |

| Water (riverbed) |

5.48 kg

(+0.69 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Warning: On a vertical surface, the magnet retains just a fraction of its max power.

2. Plate thickness effect

*Thin steel (e.g. 0.5mm PC case) drastically weakens the holding force.

3. Heat tolerance

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.38

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Advantages and disadvantages of neodymium magnets.

Benefits

- Their power is maintained, and after approximately 10 years it drops only by ~1% (according to research),

- They have excellent resistance to magnetism drop when exposed to external magnetic sources,

- By covering with a reflective coating of nickel, the element gains an elegant look,

- Neodymium magnets deliver maximum magnetic induction on a small area, which increases force concentration,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and are able to act (depending on the form) even at a temperature of 230°C or more...

- Possibility of custom creating and adjusting to precise requirements,

- Significant place in innovative solutions – they are commonly used in magnetic memories, drive modules, diagnostic systems, and complex engineering applications.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Limitations

- To avoid cracks under impact, we suggest using special steel holders. Such a solution protects the magnet and simultaneously increases its durability.

- When exposed to high temperature, neodymium magnets experience a drop in power. Often, when the temperature exceeds 80°C, their power decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore while using outdoors, we recommend using waterproof magnets made of rubber, plastic or other material resistant to moisture

- Limited ability of creating threads in the magnet and complicated shapes - preferred is cover - magnet mounting.

- Health risk resulting from small fragments of magnets pose a threat, when accidentally swallowed, which is particularly important in the aspect of protecting the youngest. It is also worth noting that small elements of these magnets can complicate diagnosis medical after entering the body.

- Due to expensive raw materials, their price is higher than average,

Lifting parameters

Maximum magnetic pulling force – what contributes to it?

- on a block made of structural steel, perfectly concentrating the magnetic field

- with a thickness minimum 10 mm

- with a surface cleaned and smooth

- with direct contact (without paint)

- for force applied at a right angle (in the magnet axis)

- at standard ambient temperature

Impact of factors on magnetic holding capacity in practice

- Air gap (betwixt the magnet and the plate), since even a microscopic clearance (e.g. 0.5 mm) results in a drastic drop in force by up to 50% (this also applies to varnish, corrosion or debris).

- Force direction – catalog parameter refers to detachment vertically. When slipping, the magnet holds much less (typically approx. 20-30% of nominal force).

- Wall thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field passes through the material instead of generating force.

- Steel grade – ideal substrate is high-permeability steel. Stainless steels may attract less.

- Smoothness – full contact is obtained only on polished steel. Any scratches and bumps create air cushions, reducing force.

- Temperature influence – hot environment weakens pulling force. Too high temperature can permanently damage the magnet.

Lifting capacity was assessed with the use of a polished steel plate of optimal thickness (min. 20 mm), under vertically applied force, however under parallel forces the lifting capacity is smaller. In addition, even a small distance between the magnet’s surface and the plate reduces the load capacity.

Warnings

Precision electronics

GPS units and smartphones are extremely sensitive to magnetism. Close proximity with a strong magnet can permanently damage the internal compass in your phone.

Life threat

Life threat: Neodymium magnets can deactivate pacemakers and defibrillators. Stay away if you have electronic implants.

Electronic devices

Equipment safety: Neodymium magnets can damage data carriers and sensitive devices (heart implants, medical aids, mechanical watches).

Do not underestimate power

Be careful. Rare earth magnets attract from a long distance and connect with massive power, often faster than you can react.

Machining danger

Mechanical processing of neodymium magnets poses a fire risk. Neodymium dust reacts violently with oxygen and is hard to extinguish.

Do not give to children

Always store magnets away from children. Choking hazard is high, and the consequences of magnets clamping inside the body are life-threatening.

Nickel allergy

Certain individuals have a hypersensitivity to nickel, which is the standard coating for NdFeB magnets. Extended handling can result in dermatitis. We recommend use protective gloves.

Bone fractures

Watch your fingers. Two powerful magnets will join immediately with a force of several hundred kilograms, destroying anything in their path. Be careful!

Eye protection

Watch out for shards. Magnets can fracture upon violent connection, launching sharp fragments into the air. Wear goggles.

Heat sensitivity

Watch the temperature. Heating the magnet above 80 degrees Celsius will permanently weaken its properties and strength.

![SM 18x200 [2xM5] / N42 - magnetic separator SM 18x200 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x200-2xm5-gig.jpg)