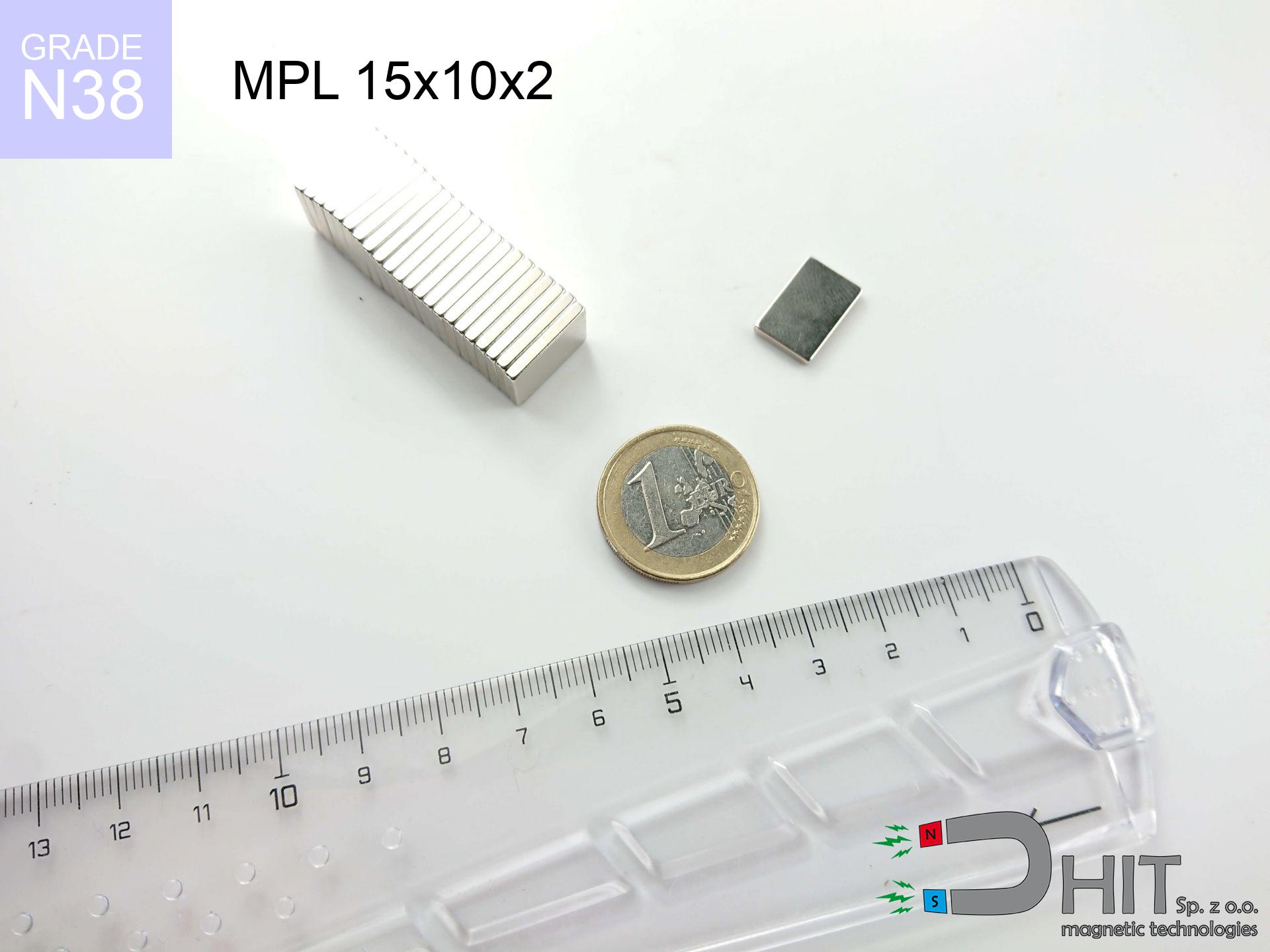

MPL 15x10x2 / N38 - lamellar magnet

lamellar magnet

Catalog no 020388

GTIN/EAN: 5906301811879

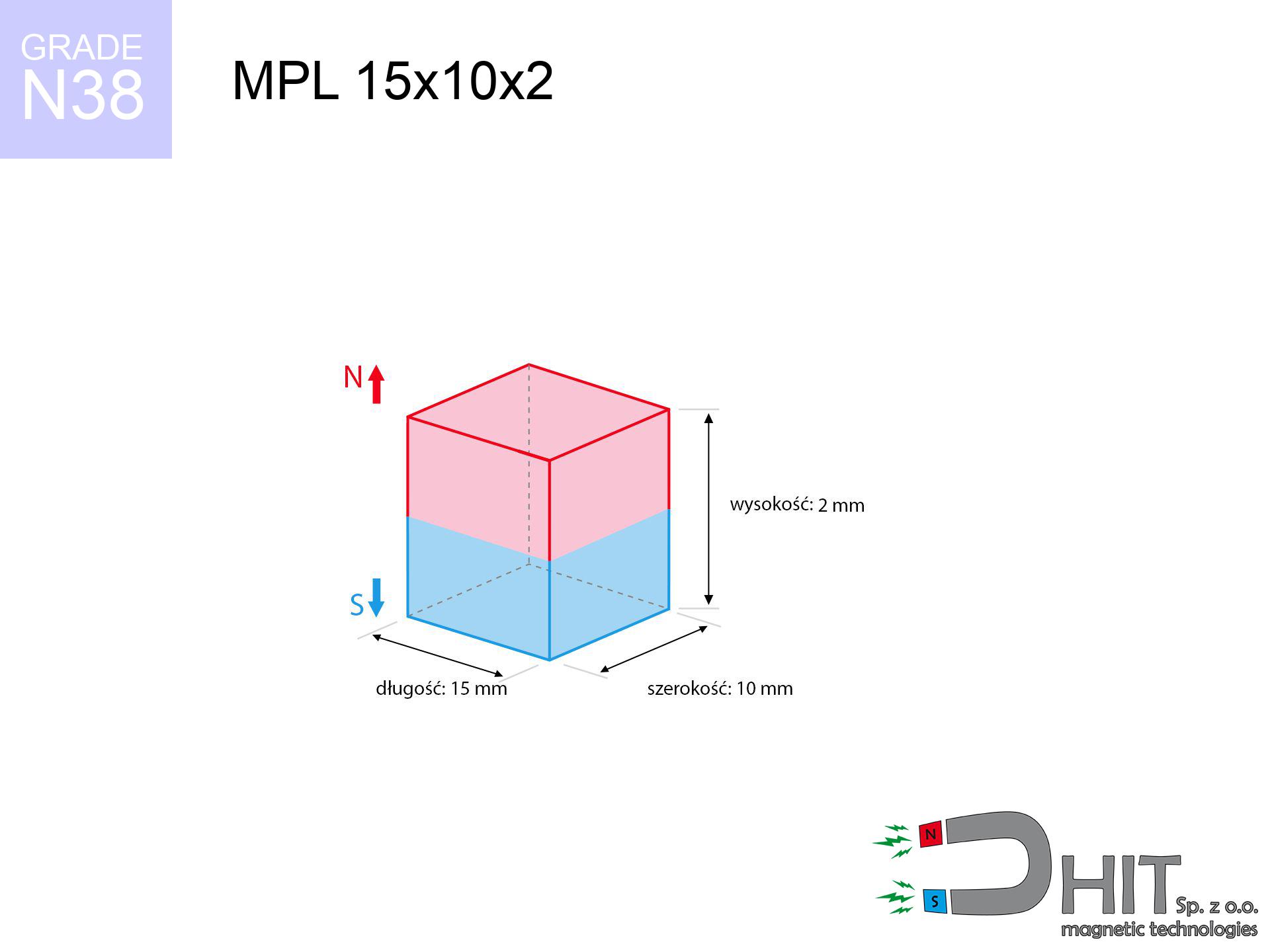

length

15 mm [±0,1 mm]

Width

10 mm [±0,1 mm]

Height

2 mm [±0,1 mm]

Weight

2.25 g

Magnetization Direction

↑ axial

Load capacity

1.57 kg / 15.45 N

Magnetic Induction

180.53 mT / 1805 Gs

Coating

[NiCuNi] Nickel

1.316 ZŁ with VAT / pcs + price for transport

1.070 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

otherwise drop us a message using

our online form

our website.

Force as well as appearance of a magnet can be tested on our

force calculator.

Order by 14:00 and we’ll ship today!

Technical details - MPL 15x10x2 / N38 - lamellar magnet

Specification / characteristics - MPL 15x10x2 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020388 |

| GTIN/EAN | 5906301811879 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 15 mm [±0,1 mm] |

| Width | 10 mm [±0,1 mm] |

| Height | 2 mm [±0,1 mm] |

| Weight | 2.25 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.57 kg / 15.45 N |

| Magnetic Induction ~ ? | 180.53 mT / 1805 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the product - data

Presented information constitute the outcome of a engineering analysis. Values rely on algorithms for the class Nd2Fe14B. Operational performance might slightly differ. Please consider these data as a reference point for designers.

Table 1: Static force (pull vs gap) - characteristics

MPL 15x10x2 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1805 Gs

180.5 mT

|

1.57 kg / 3.46 LBS

1570.0 g / 15.4 N

|

low risk |

| 1 mm |

1628 Gs

162.8 mT

|

1.28 kg / 2.82 LBS

1278.3 g / 12.5 N

|

low risk |

| 2 mm |

1394 Gs

139.4 mT

|

0.94 kg / 2.06 LBS

936.3 g / 9.2 N

|

low risk |

| 3 mm |

1152 Gs

115.2 mT

|

0.64 kg / 1.41 LBS

639.9 g / 6.3 N

|

low risk |

| 5 mm |

751 Gs

75.1 mT

|

0.27 kg / 0.60 LBS

271.5 g / 2.7 N

|

low risk |

| 10 mm |

262 Gs

26.2 mT

|

0.03 kg / 0.07 LBS

33.1 g / 0.3 N

|

low risk |

| 15 mm |

110 Gs

11.0 mT

|

0.01 kg / 0.01 LBS

5.8 g / 0.1 N

|

low risk |

| 20 mm |

54 Gs

5.4 mT

|

0.00 kg / 0.00 LBS

1.4 g / 0.0 N

|

low risk |

| 30 mm |

18 Gs

1.8 mT

|

0.00 kg / 0.00 LBS

0.2 g / 0.0 N

|

low risk |

| 50 mm |

4 Gs

0.4 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

Table 2: Vertical force (vertical surface)

MPL 15x10x2 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.31 kg / 0.69 LBS

314.0 g / 3.1 N

|

| 1 mm | Stal (~0.2) |

0.26 kg / 0.56 LBS

256.0 g / 2.5 N

|

| 2 mm | Stal (~0.2) |

0.19 kg / 0.41 LBS

188.0 g / 1.8 N

|

| 3 mm | Stal (~0.2) |

0.13 kg / 0.28 LBS

128.0 g / 1.3 N

|

| 5 mm | Stal (~0.2) |

0.05 kg / 0.12 LBS

54.0 g / 0.5 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.01 LBS

6.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MPL 15x10x2 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.47 kg / 1.04 LBS

471.0 g / 4.6 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.31 kg / 0.69 LBS

314.0 g / 3.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.16 kg / 0.35 LBS

157.0 g / 1.5 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.79 kg / 1.73 LBS

785.0 g / 7.7 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MPL 15x10x2 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.16 kg / 0.35 LBS

157.0 g / 1.5 N

|

| 1 mm |

|

0.39 kg / 0.87 LBS

392.5 g / 3.9 N

|

| 2 mm |

|

0.79 kg / 1.73 LBS

785.0 g / 7.7 N

|

| 3 mm |

|

1.18 kg / 2.60 LBS

1177.5 g / 11.6 N

|

| 5 mm |

|

1.57 kg / 3.46 LBS

1570.0 g / 15.4 N

|

| 10 mm |

|

1.57 kg / 3.46 LBS

1570.0 g / 15.4 N

|

| 11 mm |

|

1.57 kg / 3.46 LBS

1570.0 g / 15.4 N

|

| 12 mm |

|

1.57 kg / 3.46 LBS

1570.0 g / 15.4 N

|

Table 5: Thermal resistance (stability) - power drop

MPL 15x10x2 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.57 kg / 3.46 LBS

1570.0 g / 15.4 N

|

OK |

| 40 °C | -2.2% |

1.54 kg / 3.39 LBS

1535.5 g / 15.1 N

|

OK |

| 60 °C | -4.4% |

1.50 kg / 3.31 LBS

1500.9 g / 14.7 N

|

|

| 80 °C | -6.6% |

1.47 kg / 3.23 LBS

1466.4 g / 14.4 N

|

|

| 100 °C | -28.8% |

1.12 kg / 2.46 LBS

1117.8 g / 11.0 N

|

Table 6: Two magnets (repulsion) - forces in the system

MPL 15x10x2 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

3.01 kg / 6.64 LBS

3 196 Gs

|

0.45 kg / 1.00 LBS

452 g / 4.4 N

|

N/A |

| 1 mm |

2.76 kg / 6.09 LBS

3 456 Gs

|

0.41 kg / 0.91 LBS

414 g / 4.1 N

|

2.49 kg / 5.48 LBS

~0 Gs

|

| 2 mm |

2.45 kg / 5.41 LBS

3 257 Gs

|

0.37 kg / 0.81 LBS

368 g / 3.6 N

|

2.21 kg / 4.87 LBS

~0 Gs

|

| 3 mm |

2.12 kg / 4.68 LBS

3 029 Gs

|

0.32 kg / 0.70 LBS

318 g / 3.1 N

|

1.91 kg / 4.21 LBS

~0 Gs

|

| 5 mm |

1.49 kg / 3.30 LBS

2 543 Gs

|

0.22 kg / 0.49 LBS

224 g / 2.2 N

|

1.35 kg / 2.97 LBS

~0 Gs

|

| 10 mm |

0.52 kg / 1.15 LBS

1 501 Gs

|

0.08 kg / 0.17 LBS

78 g / 0.8 N

|

0.47 kg / 1.03 LBS

~0 Gs

|

| 20 mm |

0.06 kg / 0.14 LBS

524 Gs

|

0.01 kg / 0.02 LBS

10 g / 0.1 N

|

0.06 kg / 0.13 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

60 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

37 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

24 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

16 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

12 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

9 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Safety (HSE) (implants) - warnings

MPL 15x10x2 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 3.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 2.5 cm |

| Car key | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (cracking risk) - collision effects

MPL 15x10x2 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

26.99 km/h

(7.50 m/s)

|

0.06 J | |

| 30 mm |

46.15 km/h

(12.82 m/s)

|

0.18 J | |

| 50 mm |

59.57 km/h

(16.55 m/s)

|

0.31 J | |

| 100 mm |

84.24 km/h

(23.40 m/s)

|

0.62 J |

Table 9: Coating parameters (durability)

MPL 15x10x2 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MPL 15x10x2 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 194 Mx | 31.9 µWb |

| Pc Coefficient | 0.22 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 15x10x2 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.57 kg | Standard |

| Water (riverbed) |

1.80 kg

(+0.23 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Warning: On a vertical surface, the magnet holds merely a fraction of its nominal pull.

2. Steel thickness impact

*Thin metal sheet (e.g. computer case) significantly limits the holding force.

3. Temperature resistance

*For standard magnets, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.22

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more proposals

Pros and cons of neodymium magnets.

Benefits

- Their strength remains stable, and after approximately 10 years it drops only by ~1% (according to research),

- They do not lose their magnetic properties even under external field action,

- A magnet with a metallic silver surface has an effective appearance,

- Neodymium magnets achieve maximum magnetic induction on a small area, which allows for strong attraction,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Thanks to flexibility in forming and the capacity to modify to specific needs,

- Huge importance in advanced technology sectors – they find application in magnetic memories, brushless drives, precision medical tools, as well as complex engineering applications.

- Thanks to their power density, small magnets offer high operating force, in miniature format,

Cons

- At strong impacts they can crack, therefore we advise placing them in special holders. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- NdFeB magnets lose force when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of strength (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- They oxidize in a humid environment. For use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- Due to limitations in producing nuts and complex forms in magnets, we propose using a housing - magnetic mount.

- Potential hazard to health – tiny shards of magnets are risky, when accidentally swallowed, which is particularly important in the aspect of protecting the youngest. It is also worth noting that tiny parts of these magnets can complicate diagnosis medical when they are in the body.

- Due to expensive raw materials, their price exceeds standard values,

Holding force characteristics

Best holding force of the magnet in ideal parameters – what contributes to it?

- using a sheet made of low-carbon steel, acting as a circuit closing element

- whose transverse dimension reaches at least 10 mm

- with an polished touching surface

- without the slightest clearance between the magnet and steel

- for force applied at a right angle (in the magnet axis)

- in stable room temperature

What influences lifting capacity in practice

- Distance – the presence of any layer (rust, tape, gap) interrupts the magnetic circuit, which reduces capacity steeply (even by 50% at 0.5 mm).

- Pull-off angle – remember that the magnet holds strongest perpendicularly. Under shear forces, the capacity drops significantly, often to levels of 20-30% of the nominal value.

- Element thickness – to utilize 100% power, the steel must be sufficiently thick. Paper-thin metal limits the attraction force (the magnet "punches through" it).

- Metal type – not every steel reacts the same. High carbon content weaken the attraction effect.

- Surface condition – smooth surfaces guarantee perfect abutment, which increases field saturation. Uneven metal weaken the grip.

- Thermal conditions – neodymium magnets have a sensitivity to temperature. At higher temperatures they lose power, and at low temperatures they can be stronger (up to a certain limit).

Holding force was tested on the plate surface of 20 mm thickness, when the force acted perpendicularly, whereas under attempts to slide the magnet the lifting capacity is smaller. Additionally, even a slight gap between the magnet’s surface and the plate decreases the lifting capacity.

Safe handling of neodymium magnets

Phone sensors

Note: rare earth magnets produce a field that disrupts sensitive sensors. Keep a separation from your phone, device, and GPS.

Data carriers

Do not bring magnets close to a purse, laptop, or screen. The magnetism can destroy these devices and wipe information from cards.

Fire risk

Drilling and cutting of NdFeB material poses a fire hazard. Magnetic powder oxidizes rapidly with oxygen and is hard to extinguish.

Health Danger

Health Alert: Neodymium magnets can turn off heart devices and defibrillators. Do not approach if you have medical devices.

Do not give to children

Strictly keep magnets out of reach of children. Ingestion danger is high, and the consequences of magnets clamping inside the body are tragic.

Maximum temperature

Control the heat. Exposing the magnet to high heat will permanently weaken its properties and strength.

Caution required

Be careful. Neodymium magnets attract from a long distance and snap with massive power, often faster than you can react.

Material brittleness

Despite metallic appearance, neodymium is brittle and not impact-resistant. Avoid impacts, as the magnet may shatter into sharp, dangerous pieces.

Metal Allergy

It is widely known that nickel (standard magnet coating) is a potent allergen. If your skin reacts to metals, prevent touching magnets with bare hands or choose versions in plastic housing.

Serious injuries

Large magnets can break fingers in a fraction of a second. Under no circumstances place your hand between two strong magnets.

![UMP 135x40 [M10+M12] GW F600 Lina / N38 - search holder UMP 135x40 [M10+M12] GW F600 Lina / N38 - search holder](https://cdn3.dhit.pl/graphics/products/ump-135x40-m10+m12-gw-f600-+lina-sej.jpg)