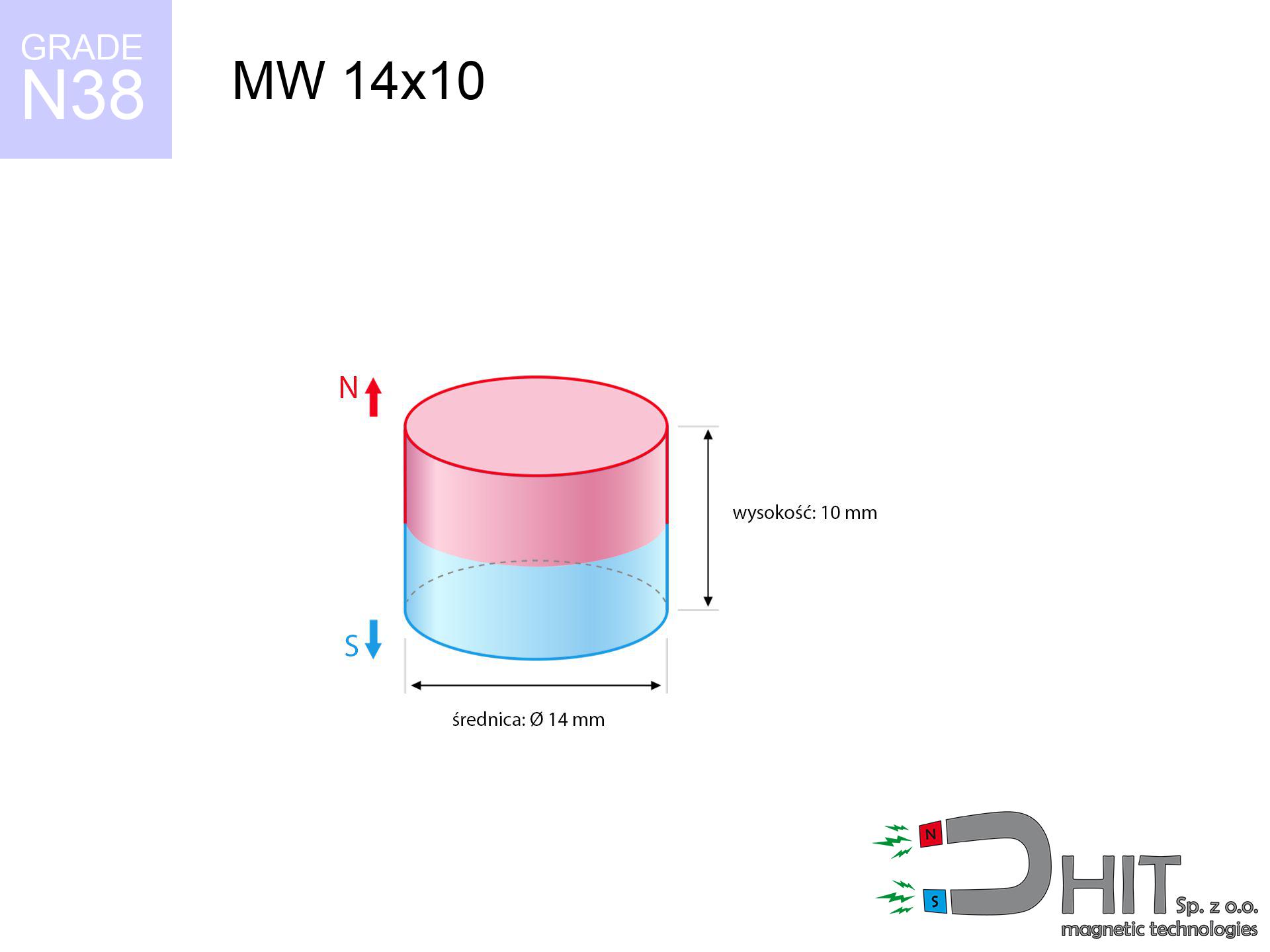

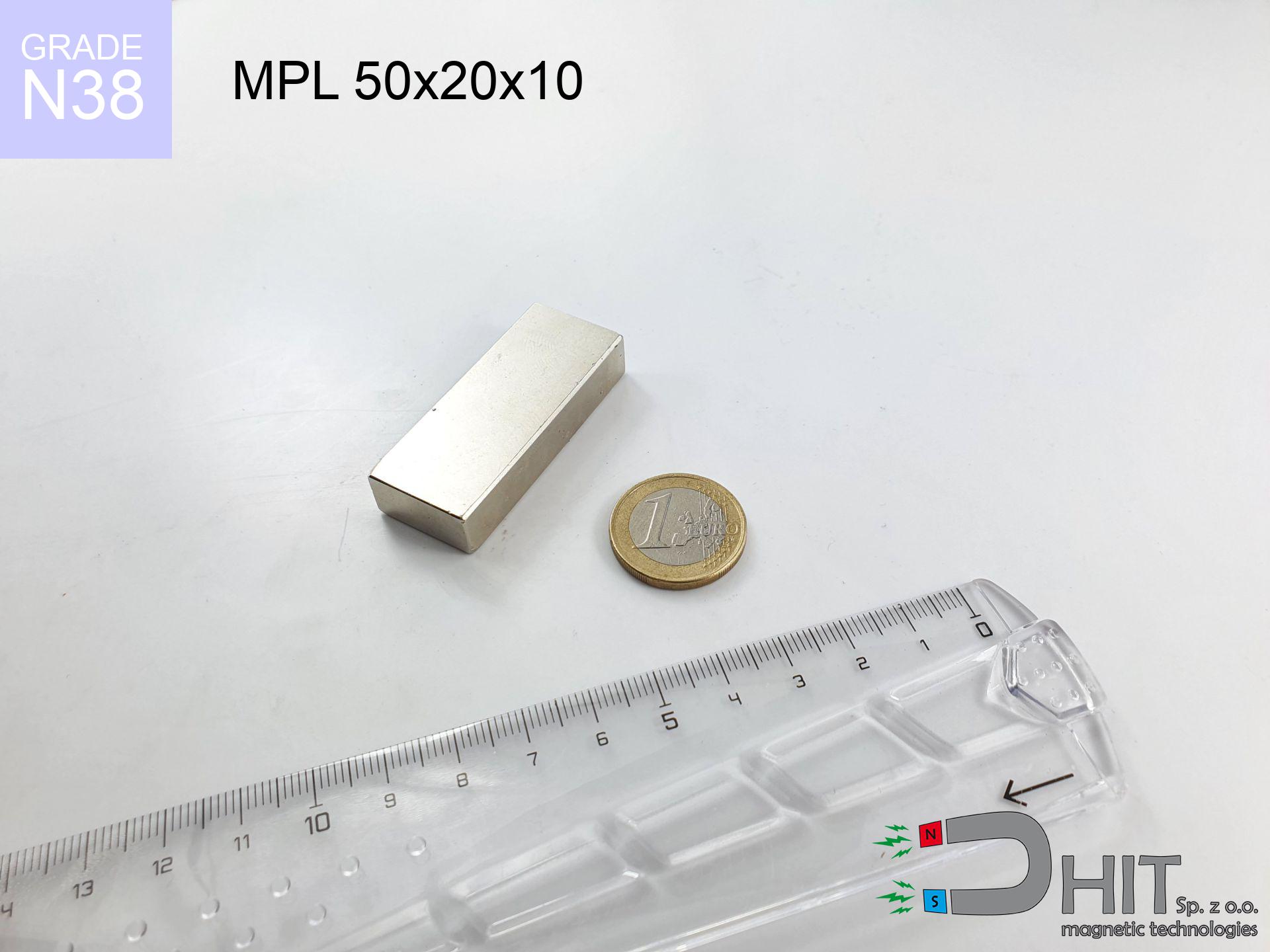

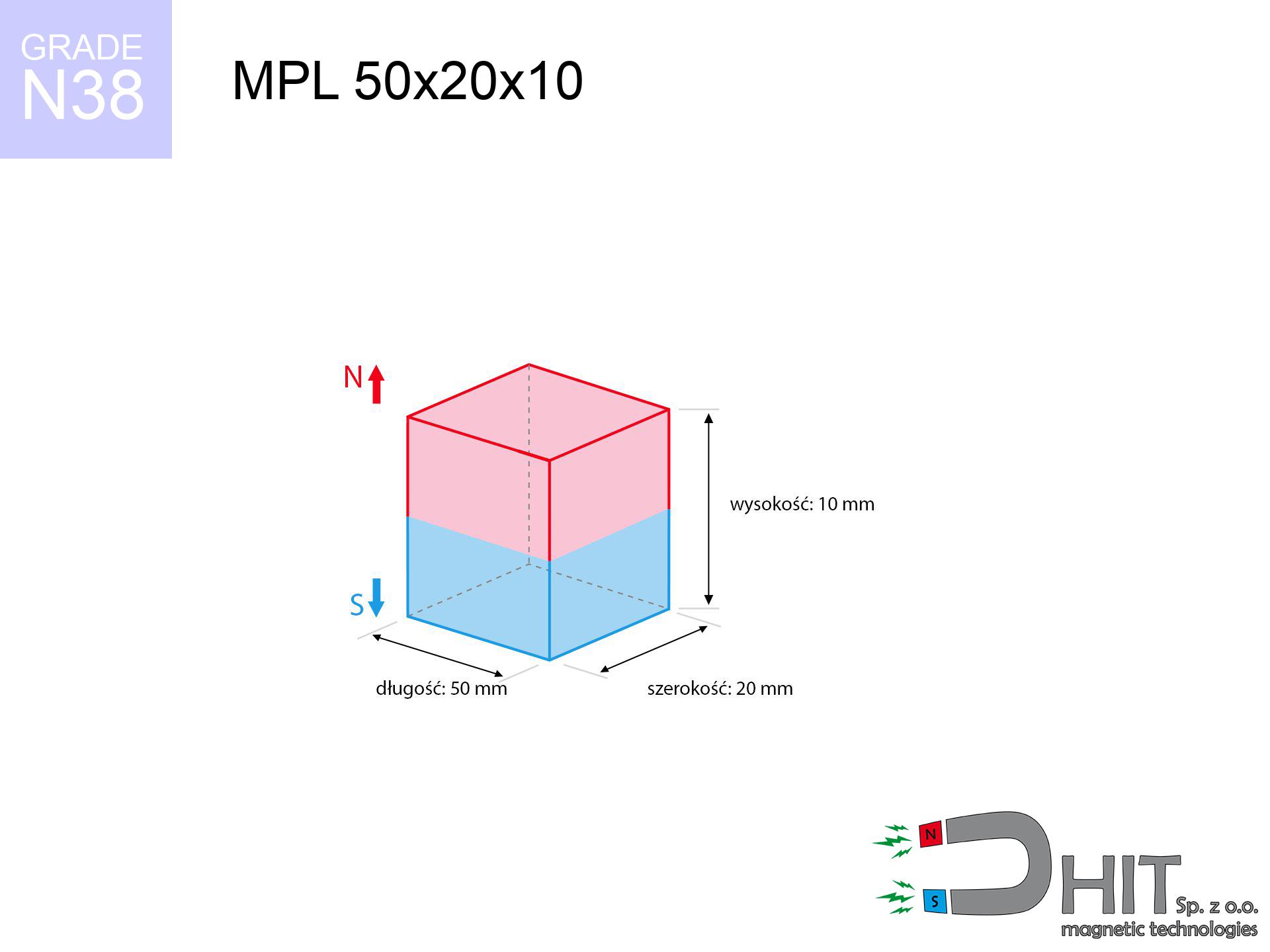

MPL 50x20x10 / N38 - lamellar magnet

lamellar magnet

Catalog no 020165

GTIN/EAN: 5906301811718

length

50 mm [±0,1 mm]

Width

20 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

75 g

Magnetization Direction

↑ axial

Load capacity

29.99 kg / 294.15 N

Magnetic Induction

337.18 mT / 3372 Gs

Coating

[NiCuNi] Nickel

43.05 ZŁ with VAT / pcs + price for transport

35.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

or let us know through

form

through our site.

Weight and form of a neodymium magnet can be analyzed using our

magnetic calculator.

Order by 14:00 and we’ll ship today!

Technical data - MPL 50x20x10 / N38 - lamellar magnet

Specification / characteristics - MPL 50x20x10 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020165 |

| GTIN/EAN | 5906301811718 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 50 mm [±0,1 mm] |

| Width | 20 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 75 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 29.99 kg / 294.15 N |

| Magnetic Induction ~ ? | 337.18 mT / 3372 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the product - data

Presented data represent the result of a mathematical simulation. Values rely on models for the material Nd2Fe14B. Operational conditions may deviate from the simulation results. Please consider these data as a reference point during assembly planning.

Table 1: Static pull force (force vs gap) - characteristics

MPL 50x20x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3371 Gs

337.1 mT

|

29.99 kg / 66.12 lbs

29990.0 g / 294.2 N

|

dangerous! |

| 1 mm |

3158 Gs

315.8 mT

|

26.32 kg / 58.03 lbs

26323.3 g / 258.2 N

|

dangerous! |

| 2 mm |

2932 Gs

293.2 mT

|

22.69 kg / 50.02 lbs

22687.6 g / 222.6 N

|

dangerous! |

| 3 mm |

2703 Gs

270.3 mT

|

19.29 kg / 42.52 lbs

19286.7 g / 189.2 N

|

dangerous! |

| 5 mm |

2266 Gs

226.6 mT

|

13.55 kg / 29.86 lbs

13546.3 g / 132.9 N

|

dangerous! |

| 10 mm |

1419 Gs

141.9 mT

|

5.31 kg / 11.71 lbs

5313.0 g / 52.1 N

|

warning |

| 15 mm |

908 Gs

90.8 mT

|

2.17 kg / 4.79 lbs

2174.5 g / 21.3 N

|

warning |

| 20 mm |

603 Gs

60.3 mT

|

0.96 kg / 2.12 lbs

961.0 g / 9.4 N

|

safe |

| 30 mm |

296 Gs

29.6 mT

|

0.23 kg / 0.51 lbs

231.0 g / 2.3 N

|

safe |

| 50 mm |

97 Gs

9.7 mT

|

0.02 kg / 0.05 lbs

24.8 g / 0.2 N

|

safe |

Table 2: Shear load (vertical surface)

MPL 50x20x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

6.00 kg / 13.22 lbs

5998.0 g / 58.8 N

|

| 1 mm | Stal (~0.2) |

5.26 kg / 11.61 lbs

5264.0 g / 51.6 N

|

| 2 mm | Stal (~0.2) |

4.54 kg / 10.00 lbs

4538.0 g / 44.5 N

|

| 3 mm | Stal (~0.2) |

3.86 kg / 8.51 lbs

3858.0 g / 37.8 N

|

| 5 mm | Stal (~0.2) |

2.71 kg / 5.97 lbs

2710.0 g / 26.6 N

|

| 10 mm | Stal (~0.2) |

1.06 kg / 2.34 lbs

1062.0 g / 10.4 N

|

| 15 mm | Stal (~0.2) |

0.43 kg / 0.96 lbs

434.0 g / 4.3 N

|

| 20 mm | Stal (~0.2) |

0.19 kg / 0.42 lbs

192.0 g / 1.9 N

|

| 30 mm | Stal (~0.2) |

0.05 kg / 0.10 lbs

46.0 g / 0.5 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MPL 50x20x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

9.00 kg / 19.83 lbs

8997.0 g / 88.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

6.00 kg / 13.22 lbs

5998.0 g / 58.8 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

3.00 kg / 6.61 lbs

2999.0 g / 29.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

15.00 kg / 33.06 lbs

14995.0 g / 147.1 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MPL 50x20x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.50 kg / 3.31 lbs

1499.5 g / 14.7 N

|

| 1 mm |

|

3.75 kg / 8.26 lbs

3748.8 g / 36.8 N

|

| 2 mm |

|

7.50 kg / 16.53 lbs

7497.5 g / 73.6 N

|

| 3 mm |

|

11.25 kg / 24.79 lbs

11246.3 g / 110.3 N

|

| 5 mm |

|

18.74 kg / 41.32 lbs

18743.8 g / 183.9 N

|

| 10 mm |

|

29.99 kg / 66.12 lbs

29990.0 g / 294.2 N

|

| 11 mm |

|

29.99 kg / 66.12 lbs

29990.0 g / 294.2 N

|

| 12 mm |

|

29.99 kg / 66.12 lbs

29990.0 g / 294.2 N

|

Table 5: Working in heat (material behavior) - thermal limit

MPL 50x20x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

29.99 kg / 66.12 lbs

29990.0 g / 294.2 N

|

OK |

| 40 °C | -2.2% |

29.33 kg / 64.66 lbs

29330.2 g / 287.7 N

|

OK |

| 60 °C | -4.4% |

28.67 kg / 63.21 lbs

28670.4 g / 281.3 N

|

|

| 80 °C | -6.6% |

28.01 kg / 61.75 lbs

28010.7 g / 274.8 N

|

|

| 100 °C | -28.8% |

21.35 kg / 47.07 lbs

21352.9 g / 209.5 N

|

Table 6: Two magnets (attraction) - field range

MPL 50x20x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

70.06 kg / 154.45 lbs

4 789 Gs

|

10.51 kg / 23.17 lbs

10509 g / 103.1 N

|

N/A |

| 1 mm |

65.83 kg / 145.13 lbs

6 535 Gs

|

9.87 kg / 21.77 lbs

9874 g / 96.9 N

|

59.25 kg / 130.61 lbs

~0 Gs

|

| 2 mm |

61.49 kg / 135.57 lbs

6 316 Gs

|

9.22 kg / 20.34 lbs

9224 g / 90.5 N

|

55.34 kg / 122.01 lbs

~0 Gs

|

| 3 mm |

57.20 kg / 126.10 lbs

6 092 Gs

|

8.58 kg / 18.92 lbs

8580 g / 84.2 N

|

51.48 kg / 113.49 lbs

~0 Gs

|

| 5 mm |

48.94 kg / 107.89 lbs

5 635 Gs

|

7.34 kg / 16.18 lbs

7341 g / 72.0 N

|

44.05 kg / 97.10 lbs

~0 Gs

|

| 10 mm |

31.64 kg / 69.76 lbs

4 531 Gs

|

4.75 kg / 10.46 lbs

4747 g / 46.6 N

|

28.48 kg / 62.79 lbs

~0 Gs

|

| 20 mm |

12.41 kg / 27.36 lbs

2 838 Gs

|

1.86 kg / 4.10 lbs

1862 g / 18.3 N

|

11.17 kg / 24.63 lbs

~0 Gs

|

| 50 mm |

1.07 kg / 2.35 lbs

832 Gs

|

0.16 kg / 0.35 lbs

160 g / 1.6 N

|

0.96 kg / 2.12 lbs

~0 Gs

|

| 60 mm |

0.54 kg / 1.19 lbs

592 Gs

|

0.08 kg / 0.18 lbs

81 g / 0.8 N

|

0.49 kg / 1.07 lbs

~0 Gs

|

| 70 mm |

0.29 kg / 0.64 lbs

433 Gs

|

0.04 kg / 0.10 lbs

43 g / 0.4 N

|

0.26 kg / 0.57 lbs

~0 Gs

|

| 80 mm |

0.16 kg / 0.36 lbs

324 Gs

|

0.02 kg / 0.05 lbs

24 g / 0.2 N

|

0.15 kg / 0.32 lbs

~0 Gs

|

| 90 mm |

0.10 kg / 0.21 lbs

248 Gs

|

0.01 kg / 0.03 lbs

14 g / 0.1 N

|

0.09 kg / 0.19 lbs

~0 Gs

|

| 100 mm |

0.06 kg / 0.13 lbs

194 Gs

|

0.01 kg / 0.02 lbs

9 g / 0.1 N

|

0.05 kg / 0.11 lbs

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MPL 50x20x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 15.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 12.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 9.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 7.5 cm |

| Remote | 50 Gs (5.0 mT) | 7.0 cm |

| Payment card | 400 Gs (40.0 mT) | 3.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.5 cm |

Table 8: Collisions (kinetic energy) - collision effects

MPL 50x20x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.29 km/h

(6.19 m/s)

|

1.44 J | |

| 30 mm |

35.10 km/h

(9.75 m/s)

|

3.56 J | |

| 50 mm |

45.12 km/h

(12.53 m/s)

|

5.89 J | |

| 100 mm |

63.77 km/h

(17.72 m/s)

|

11.77 J |

Table 9: Corrosion resistance

MPL 50x20x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MPL 50x20x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 32 980 Mx | 329.8 µWb |

| Pc Coefficient | 0.38 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 50x20x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 29.99 kg | Standard |

| Water (riverbed) |

34.34 kg

(+4.35 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Warning: On a vertical surface, the magnet holds only ~20% of its max power.

2. Plate thickness effect

*Thin steel (e.g. 0.5mm PC case) severely reduces the holding force.

3. Thermal stability

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.38

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Advantages and disadvantages of Nd2Fe14B magnets.

Benefits

- They virtually do not lose strength, because even after ten years the performance loss is only ~1% (in laboratory conditions),

- They are resistant to demagnetization induced by external field influence,

- By applying a reflective layer of nickel, the element presents an aesthetic look,

- Neodymium magnets achieve maximum magnetic induction on a contact point, which increases force concentration,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Possibility of detailed creating and optimizing to defined conditions,

- Fundamental importance in modern technologies – they find application in hard drives, brushless drives, medical devices, and industrial machines.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Limitations

- They are fragile upon too strong impacts. To avoid cracks, it is worth securing magnets in special housings. Such protection not only protects the magnet but also increases its resistance to damage

- When exposed to high temperature, neodymium magnets experience a drop in strength. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- They oxidize in a humid environment. For use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- Limited ability of producing threads in the magnet and complex forms - preferred is cover - magnet mounting.

- Potential hazard to health – tiny shards of magnets are risky, when accidentally swallowed, which is particularly important in the context of child health protection. Additionally, small elements of these magnets can be problematic in diagnostics medical after entering the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Holding force characteristics

Maximum magnetic pulling force – what affects it?

- on a base made of structural steel, perfectly concentrating the magnetic field

- whose transverse dimension reaches at least 10 mm

- with a surface free of scratches

- without any air gap between the magnet and steel

- under perpendicular force vector (90-degree angle)

- at standard ambient temperature

Determinants of lifting force in real conditions

- Distance – the presence of foreign body (rust, dirt, gap) acts as an insulator, which reduces power rapidly (even by 50% at 0.5 mm).

- Loading method – declared lifting capacity refers to pulling vertically. When applying parallel force, the magnet exhibits significantly lower power (typically approx. 20-30% of maximum force).

- Substrate thickness – to utilize 100% power, the steel must be sufficiently thick. Thin sheet restricts the attraction force (the magnet "punches through" it).

- Material composition – different alloys attracts identically. High carbon content worsen the attraction effect.

- Plate texture – ground elements guarantee perfect abutment, which improves force. Uneven metal reduce efficiency.

- Temperature influence – hot environment reduces pulling force. Exceeding the limit temperature can permanently demagnetize the magnet.

Holding force was tested on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, in contrast under shearing force the load capacity is reduced by as much as fivefold. In addition, even a small distance between the magnet and the plate lowers the load capacity.

Safety rules for work with NdFeB magnets

Magnetic media

Intense magnetic fields can corrupt files on credit cards, hard drives, and other magnetic media. Keep a distance of min. 10 cm.

Implant safety

For implant holders: Strong magnetic fields disrupt electronics. Maintain at least 30 cm distance or ask another person to work with the magnets.

Fire warning

Powder produced during cutting of magnets is self-igniting. Avoid drilling into magnets without proper cooling and knowledge.

Pinching danger

Danger of trauma: The attraction force is so great that it can cause blood blisters, crushing, and even bone fractures. Protective gloves are recommended.

Do not underestimate power

Exercise caution. Rare earth magnets attract from a long distance and snap with huge force, often quicker than you can react.

This is not a toy

Product intended for adults. Tiny parts can be swallowed, leading to severe trauma. Store away from children and animals.

Heat sensitivity

Keep cool. Neodymium magnets are susceptible to temperature. If you need operation above 80°C, ask us about special high-temperature series (H, SH, UH).

Sensitization to coating

A percentage of the population suffer from a hypersensitivity to nickel, which is the typical protective layer for neodymium magnets. Prolonged contact can result in skin redness. We recommend use protective gloves.

Protective goggles

Beware of splinters. Magnets can fracture upon violent connection, launching sharp fragments into the air. Eye protection is mandatory.

GPS Danger

GPS units and mobile phones are extremely sensitive to magnetic fields. Direct contact with a strong magnet can decalibrate the sensors in your phone.

![SM 32x200 [2xM8] / N42 - magnetic separator SM 32x200 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x200-2xm8-fub.jpg)