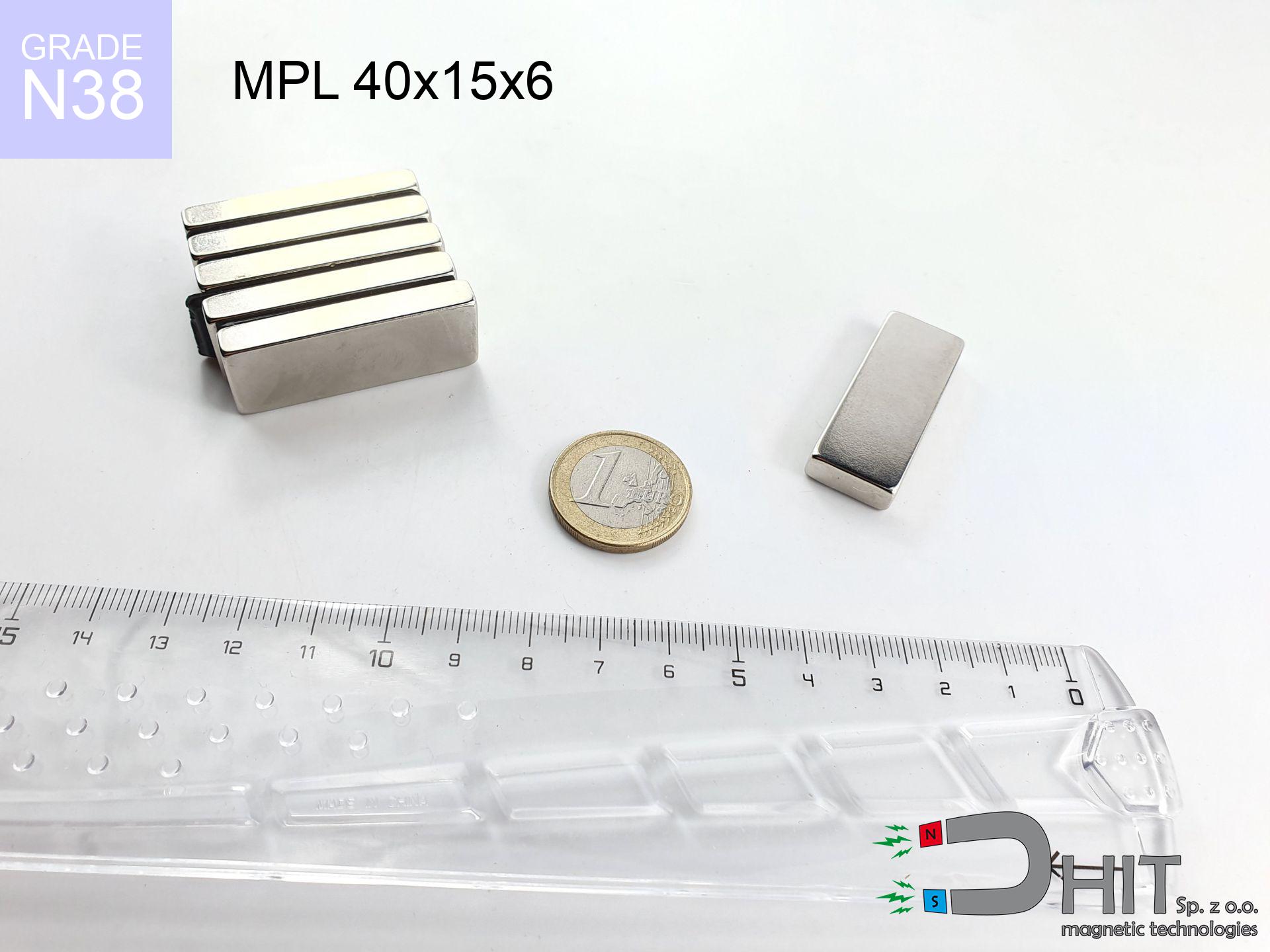

MPL 40x15x6 / N38 - lamellar magnet

lamellar magnet

Catalog no 020155

GTIN/EAN: 5906301811619

length

40 mm [±0,1 mm]

Width

15 mm [±0,1 mm]

Height

6 mm [±0,1 mm]

Weight

27 g

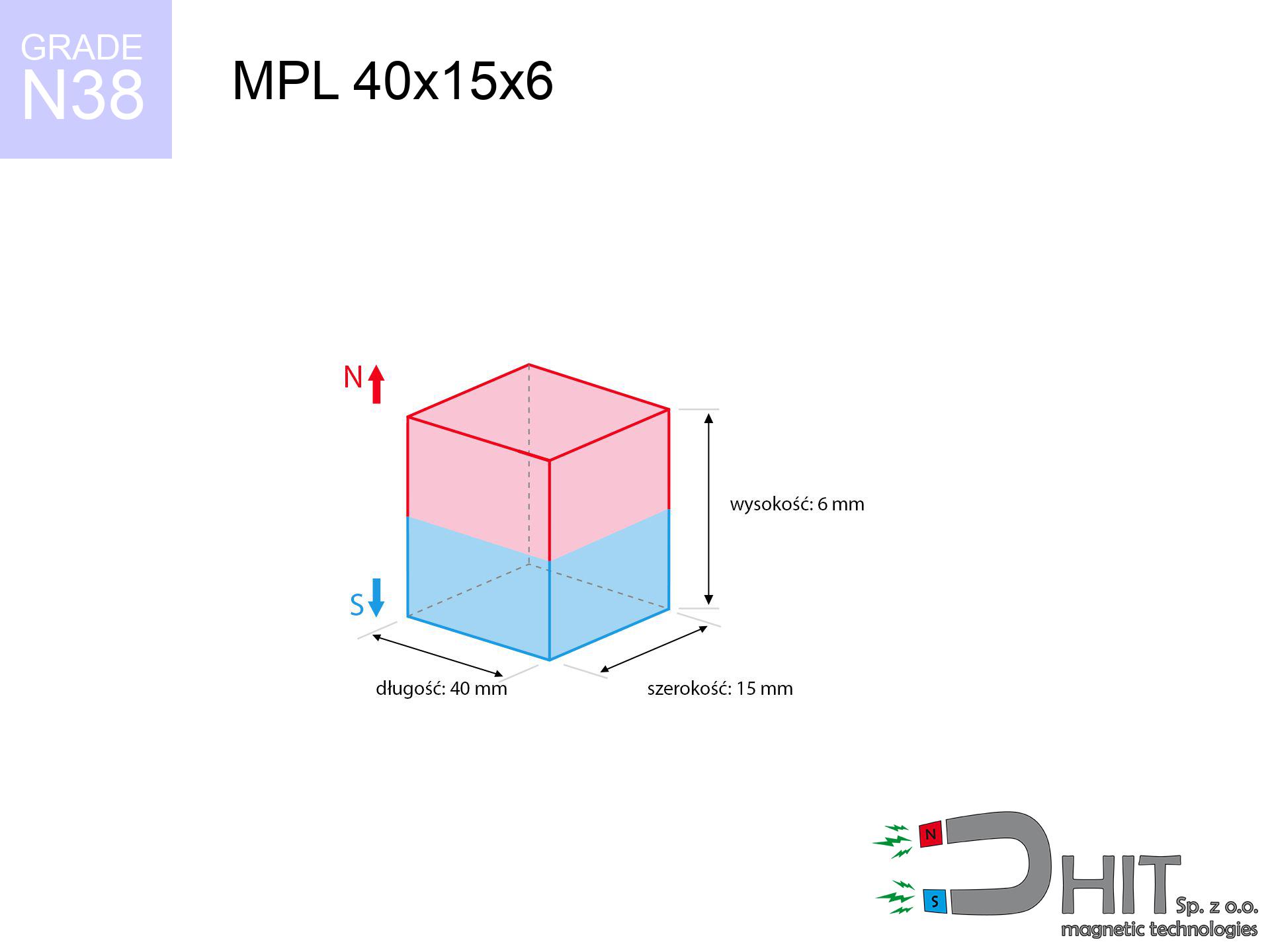

Magnetization Direction

↑ axial

Load capacity

14.21 kg / 139.45 N

Magnetic Induction

286.36 mT / 2864 Gs

Coating

[NiCuNi] Nickel

18.45 ZŁ with VAT / pcs + price for transport

15.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

alternatively get in touch via

contact form

the contact page.

Weight along with appearance of magnets can be checked with our

force calculator.

Orders submitted before 14:00 will be dispatched today!

Technical specification - MPL 40x15x6 / N38 - lamellar magnet

Specification / characteristics - MPL 40x15x6 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020155 |

| GTIN/EAN | 5906301811619 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 40 mm [±0,1 mm] |

| Width | 15 mm [±0,1 mm] |

| Height | 6 mm [±0,1 mm] |

| Weight | 27 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 14.21 kg / 139.45 N |

| Magnetic Induction ~ ? | 286.36 mT / 2864 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the product - technical parameters

These information represent the outcome of a physical analysis. Results are based on algorithms for the class Nd2Fe14B. Actual parameters may differ. Use these calculations as a reference point during assembly planning.

Table 1: Static force (pull vs gap) - interaction chart

MPL 40x15x6 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2863 Gs

286.3 mT

|

14.21 kg / 31.33 pounds

14210.0 g / 139.4 N

|

dangerous! |

| 1 mm |

2635 Gs

263.5 mT

|

12.04 kg / 26.55 pounds

12041.8 g / 118.1 N

|

dangerous! |

| 2 mm |

2385 Gs

238.5 mT

|

9.86 kg / 21.74 pounds

9859.1 g / 96.7 N

|

warning |

| 3 mm |

2132 Gs

213.2 mT

|

7.88 kg / 17.37 pounds

7880.1 g / 77.3 N

|

warning |

| 5 mm |

1670 Gs

167.0 mT

|

4.84 kg / 10.66 pounds

4837.1 g / 47.5 N

|

warning |

| 10 mm |

903 Gs

90.3 mT

|

1.41 kg / 3.11 pounds

1412.2 g / 13.9 N

|

safe |

| 15 mm |

520 Gs

52.0 mT

|

0.47 kg / 1.03 pounds

469.2 g / 4.6 N

|

safe |

| 20 mm |

320 Gs

32.0 mT

|

0.18 kg / 0.39 pounds

177.7 g / 1.7 N

|

safe |

| 30 mm |

141 Gs

14.1 mT

|

0.03 kg / 0.08 pounds

34.5 g / 0.3 N

|

safe |

| 50 mm |

41 Gs

4.1 mT

|

0.00 kg / 0.01 pounds

3.0 g / 0.0 N

|

safe |

Table 2: Sliding load (vertical surface)

MPL 40x15x6 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

2.84 kg / 6.27 pounds

2842.0 g / 27.9 N

|

| 1 mm | Stal (~0.2) |

2.41 kg / 5.31 pounds

2408.0 g / 23.6 N

|

| 2 mm | Stal (~0.2) |

1.97 kg / 4.35 pounds

1972.0 g / 19.3 N

|

| 3 mm | Stal (~0.2) |

1.58 kg / 3.47 pounds

1576.0 g / 15.5 N

|

| 5 mm | Stal (~0.2) |

0.97 kg / 2.13 pounds

968.0 g / 9.5 N

|

| 10 mm | Stal (~0.2) |

0.28 kg / 0.62 pounds

282.0 g / 2.8 N

|

| 15 mm | Stal (~0.2) |

0.09 kg / 0.21 pounds

94.0 g / 0.9 N

|

| 20 mm | Stal (~0.2) |

0.04 kg / 0.08 pounds

36.0 g / 0.4 N

|

| 30 mm | Stal (~0.2) |

0.01 kg / 0.01 pounds

6.0 g / 0.1 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MPL 40x15x6 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

4.26 kg / 9.40 pounds

4263.0 g / 41.8 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

2.84 kg / 6.27 pounds

2842.0 g / 27.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.42 kg / 3.13 pounds

1421.0 g / 13.9 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

7.11 kg / 15.66 pounds

7105.0 g / 69.7 N

|

Table 4: Material efficiency (substrate influence) - power losses

MPL 40x15x6 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.71 kg / 1.57 pounds

710.5 g / 7.0 N

|

| 1 mm |

|

1.78 kg / 3.92 pounds

1776.3 g / 17.4 N

|

| 2 mm |

|

3.55 kg / 7.83 pounds

3552.5 g / 34.9 N

|

| 3 mm |

|

5.33 kg / 11.75 pounds

5328.8 g / 52.3 N

|

| 5 mm |

|

8.88 kg / 19.58 pounds

8881.3 g / 87.1 N

|

| 10 mm |

|

14.21 kg / 31.33 pounds

14210.0 g / 139.4 N

|

| 11 mm |

|

14.21 kg / 31.33 pounds

14210.0 g / 139.4 N

|

| 12 mm |

|

14.21 kg / 31.33 pounds

14210.0 g / 139.4 N

|

Table 5: Working in heat (material behavior) - power drop

MPL 40x15x6 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

14.21 kg / 31.33 pounds

14210.0 g / 139.4 N

|

OK |

| 40 °C | -2.2% |

13.90 kg / 30.64 pounds

13897.4 g / 136.3 N

|

OK |

| 60 °C | -4.4% |

13.58 kg / 29.95 pounds

13584.8 g / 133.3 N

|

|

| 80 °C | -6.6% |

13.27 kg / 29.26 pounds

13272.1 g / 130.2 N

|

|

| 100 °C | -28.8% |

10.12 kg / 22.31 pounds

10117.5 g / 99.3 N

|

Table 6: Magnet-Magnet interaction (attraction) - forces in the system

MPL 40x15x6 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

30.32 kg / 66.84 pounds

4 334 Gs

|

4.55 kg / 10.03 pounds

4547 g / 44.6 N

|

N/A |

| 1 mm |

28.06 kg / 61.86 pounds

5 508 Gs

|

4.21 kg / 9.28 pounds

4209 g / 41.3 N

|

25.25 kg / 55.67 pounds

~0 Gs

|

| 2 mm |

25.69 kg / 56.64 pounds

5 271 Gs

|

3.85 kg / 8.50 pounds

3854 g / 37.8 N

|

23.12 kg / 50.97 pounds

~0 Gs

|

| 3 mm |

23.33 kg / 51.43 pounds

5 023 Gs

|

3.50 kg / 7.71 pounds

3499 g / 34.3 N

|

21.00 kg / 46.29 pounds

~0 Gs

|

| 5 mm |

18.85 kg / 41.56 pounds

4 515 Gs

|

2.83 kg / 6.23 pounds

2828 g / 27.7 N

|

16.97 kg / 37.40 pounds

~0 Gs

|

| 10 mm |

10.32 kg / 22.75 pounds

3 341 Gs

|

1.55 kg / 3.41 pounds

1548 g / 15.2 N

|

9.29 kg / 20.48 pounds

~0 Gs

|

| 20 mm |

3.01 kg / 6.64 pounds

1 805 Gs

|

0.45 kg / 1.00 pounds

452 g / 4.4 N

|

2.71 kg / 5.98 pounds

~0 Gs

|

| 50 mm |

0.16 kg / 0.35 pounds

416 Gs

|

0.02 kg / 0.05 pounds

24 g / 0.2 N

|

0.14 kg / 0.32 pounds

~0 Gs

|

| 60 mm |

0.07 kg / 0.16 pounds

282 Gs

|

0.01 kg / 0.02 pounds

11 g / 0.1 N

|

0.07 kg / 0.15 pounds

~0 Gs

|

| 70 mm |

0.04 kg / 0.08 pounds

199 Gs

|

0.01 kg / 0.01 pounds

5 g / 0.1 N

|

0.03 kg / 0.07 pounds

~0 Gs

|

| 80 mm |

0.02 kg / 0.04 pounds

144 Gs

|

0.00 kg / 0.01 pounds

3 g / 0.0 N

|

0.02 kg / 0.04 pounds

~0 Gs

|

| 90 mm |

0.01 kg / 0.02 pounds

108 Gs

|

0.00 kg / 0.00 pounds

2 g / 0.0 N

|

0.01 kg / 0.02 pounds

~0 Gs

|

| 100 mm |

0.01 kg / 0.01 pounds

83 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MPL 40x15x6 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 11.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 8.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 7.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 5.5 cm |

| Remote | 50 Gs (5.0 mT) | 5.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MPL 40x15x6 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

24.53 km/h

(6.81 m/s)

|

0.63 J | |

| 30 mm |

40.13 km/h

(11.15 m/s)

|

1.68 J | |

| 50 mm |

51.74 km/h

(14.37 m/s)

|

2.79 J | |

| 100 mm |

73.16 km/h

(20.32 m/s)

|

5.58 J |

Table 9: Corrosion resistance

MPL 40x15x6 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MPL 40x15x6 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 16 905 Mx | 169.0 µWb |

| Pc Coefficient | 0.31 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 40x15x6 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 14.21 kg | Standard |

| Water (riverbed) |

16.27 kg

(+2.06 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical surface, the magnet retains just ~20% of its max power.

2. Steel thickness impact

*Thin metal sheet (e.g. 0.5mm PC case) significantly limits the holding force.

3. Temperature resistance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.31

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Pros and cons of Nd2Fe14B magnets.

Advantages

- They do not lose magnetism, even after nearly ten years – the decrease in power is only ~1% (according to tests),

- They retain their magnetic properties even under close interference source,

- The use of an metallic layer of noble metals (nickel, gold, silver) causes the element to present itself better,

- They are known for high magnetic induction at the operating surface, making them more effective,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and are able to act (depending on the form) even at a temperature of 230°C or more...

- Considering the possibility of accurate forming and adaptation to custom requirements, neodymium magnets can be manufactured in a wide range of forms and dimensions, which amplifies use scope,

- Key role in high-tech industry – they are utilized in magnetic memories, electric drive systems, precision medical tools, as well as complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in compact dimensions, which enables their usage in miniature devices

Weaknesses

- To avoid cracks upon strong impacts, we recommend using special steel housings. Such a solution secures the magnet and simultaneously improves its durability.

- We warn that neodymium magnets can lose their power at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material immune to moisture, when using outdoors

- Limited ability of producing threads in the magnet and complex forms - preferred is cover - magnet mounting.

- Potential hazard to health – tiny shards of magnets pose a threat, if swallowed, which gains importance in the context of child health protection. Additionally, small elements of these magnets are able to disrupt the diagnostic process medical in case of swallowing.

- Due to expensive raw materials, their price exceeds standard values,

Pull force analysis

Breakaway strength of the magnet in ideal conditions – what affects it?

- with the application of a yoke made of low-carbon steel, ensuring maximum field concentration

- with a cross-section of at least 10 mm

- with a surface free of scratches

- with direct contact (without coatings)

- during pulling in a direction vertical to the plane

- in neutral thermal conditions

Magnet lifting force in use – key factors

- Gap (between the magnet and the metal), as even a very small distance (e.g. 0.5 mm) leads to a reduction in force by up to 50% (this also applies to paint, rust or dirt).

- Pull-off angle – note that the magnet has greatest strength perpendicularly. Under shear forces, the capacity drops drastically, often to levels of 20-30% of the nominal value.

- Steel thickness – insufficiently thick sheet does not accept the full field, causing part of the power to be escaped to the other side.

- Chemical composition of the base – low-carbon steel attracts best. Alloy steels reduce magnetic permeability and lifting capacity.

- Surface quality – the smoother and more polished the surface, the better the adhesion and stronger the hold. Roughness acts like micro-gaps.

- Temperature – heating the magnet results in weakening of induction. Check the maximum operating temperature for a given model.

Lifting capacity testing was performed on plates with a smooth surface of optimal thickness, under perpendicular forces, however under parallel forces the lifting capacity is smaller. Moreover, even a minimal clearance between the magnet’s surface and the plate decreases the load capacity.

Precautions when working with neodymium magnets

GPS and phone interference

Be aware: rare earth magnets produce a field that confuses sensitive sensors. Keep a separation from your mobile, tablet, and GPS.

Handling rules

Handle magnets consciously. Their huge power can shock even experienced users. Stay alert and respect their force.

Allergy Warning

Nickel alert: The nickel-copper-nickel coating contains nickel. If redness happens, cease working with magnets and wear gloves.

Do not overheat magnets

Watch the temperature. Heating the magnet to high heat will destroy its magnetic structure and strength.

Combustion hazard

Combustion risk: Rare earth powder is explosive. Do not process magnets in home conditions as this may cause fire.

Protect data

Equipment safety: Strong magnets can ruin data carriers and sensitive devices (heart implants, hearing aids, timepieces).

Adults only

Neodymium magnets are not toys. Eating multiple magnets may result in them attracting across intestines, which constitutes a critical condition and requires immediate surgery.

Pacemakers

People with a heart stimulator should keep an large gap from magnets. The magnetism can stop the operation of the life-saving device.

Pinching danger

Large magnets can smash fingers instantly. Under no circumstances put your hand betwixt two strong magnets.

Magnets are brittle

NdFeB magnets are ceramic materials, meaning they are fragile like glass. Impact of two magnets will cause them shattering into shards.

![SM 25x375 [2xM8] / N52 - magnetic separator SM 25x375 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x375-2xm8-soh.jpg)

![SM 32x400 [2xM8] / N42 - magnetic separator SM 32x400 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x400-2xm8-tep.jpg)