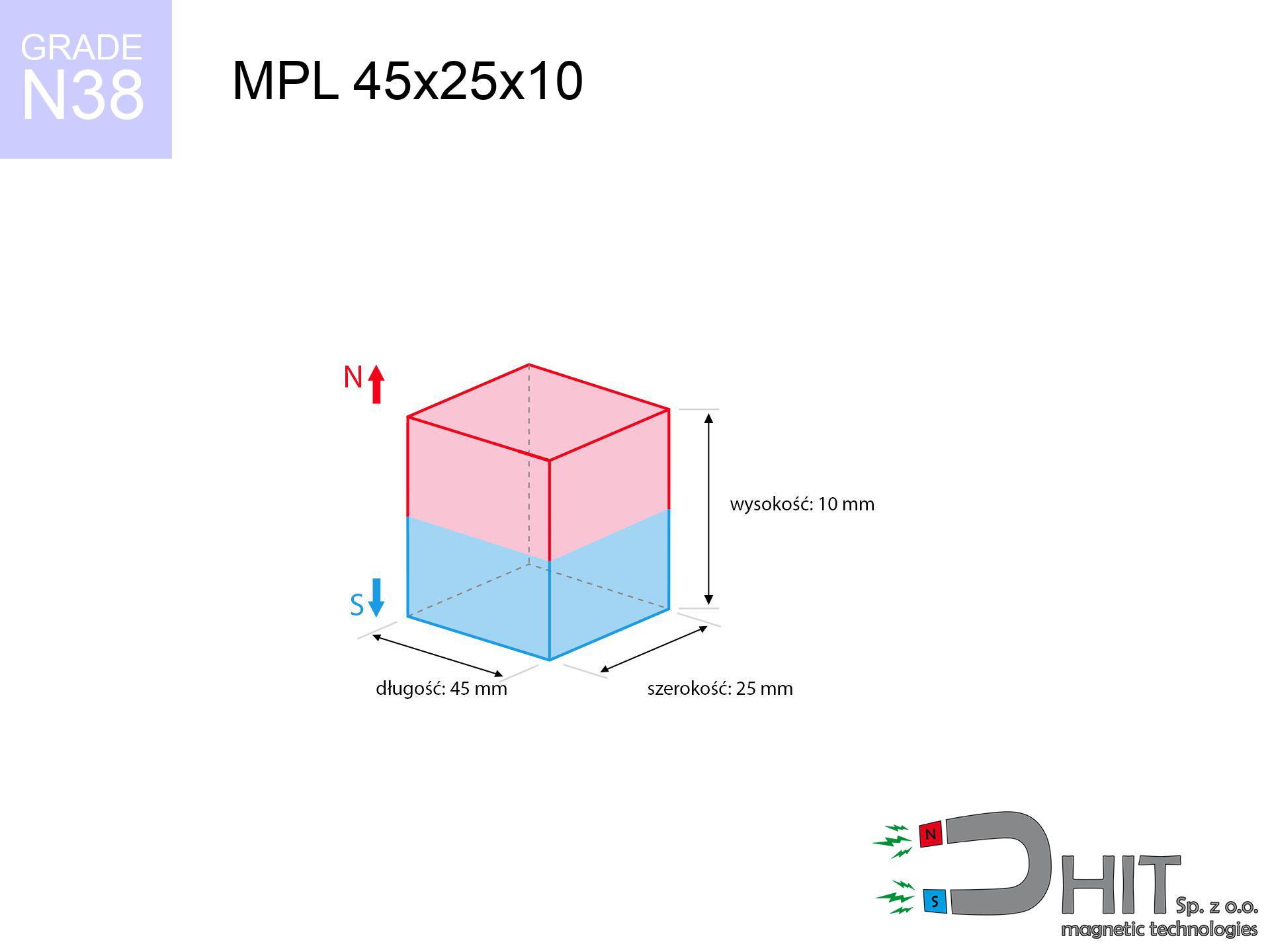

MPL 45x25x10 / N38 - lamellar magnet

lamellar magnet

Catalog no 020164

GTIN/EAN: 5906301811701

length

45 mm [±0,1 mm]

Width

25 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

84.38 g

Magnetization Direction

↑ axial

Load capacity

28.48 kg / 279.40 N

Magnetic Induction

306.29 mT / 3063 Gs

Coating

[NiCuNi] Nickel

35.01 ZŁ with VAT / pcs + price for transport

28.46 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

alternatively contact us through

inquiry form

the contact section.

Lifting power along with appearance of magnets can be checked using our

online calculation tool.

Same-day processing for orders placed before 14:00.

Technical - MPL 45x25x10 / N38 - lamellar magnet

Specification / characteristics - MPL 45x25x10 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020164 |

| GTIN/EAN | 5906301811701 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 45 mm [±0,1 mm] |

| Width | 25 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 84.38 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 28.48 kg / 279.40 N |

| Magnetic Induction ~ ? | 306.29 mT / 3063 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical modeling of the magnet - data

These information constitute the result of a engineering simulation. Results are based on models for the class Nd2Fe14B. Real-world parameters might slightly differ from theoretical values. Treat these data as a reference point during assembly planning.

Table 1: Static pull force (pull vs gap) - characteristics

MPL 45x25x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3062 Gs

306.2 mT

|

28.48 kg / 62.79 LBS

28480.0 g / 279.4 N

|

dangerous! |

| 1 mm |

2918 Gs

291.8 mT

|

25.86 kg / 57.00 LBS

25856.7 g / 253.7 N

|

dangerous! |

| 2 mm |

2760 Gs

276.0 mT

|

23.13 kg / 51.00 LBS

23133.2 g / 226.9 N

|

dangerous! |

| 3 mm |

2595 Gs

259.5 mT

|

20.45 kg / 45.08 LBS

20449.5 g / 200.6 N

|

dangerous! |

| 5 mm |

2261 Gs

226.1 mT

|

15.53 kg / 34.23 LBS

15525.8 g / 152.3 N

|

dangerous! |

| 10 mm |

1529 Gs

152.9 mT

|

7.10 kg / 15.64 LBS

7096.1 g / 69.6 N

|

medium risk |

| 15 mm |

1018 Gs

101.8 mT

|

3.15 kg / 6.94 LBS

3147.4 g / 30.9 N

|

medium risk |

| 20 mm |

688 Gs

68.8 mT

|

1.44 kg / 3.17 LBS

1439.4 g / 14.1 N

|

weak grip |

| 30 mm |

340 Gs

34.0 mT

|

0.35 kg / 0.77 LBS

350.8 g / 3.4 N

|

weak grip |

| 50 mm |

111 Gs

11.1 mT

|

0.04 kg / 0.08 LBS

37.1 g / 0.4 N

|

weak grip |

Table 2: Slippage capacity (wall)

MPL 45x25x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

5.70 kg / 12.56 LBS

5696.0 g / 55.9 N

|

| 1 mm | Stal (~0.2) |

5.17 kg / 11.40 LBS

5172.0 g / 50.7 N

|

| 2 mm | Stal (~0.2) |

4.63 kg / 10.20 LBS

4626.0 g / 45.4 N

|

| 3 mm | Stal (~0.2) |

4.09 kg / 9.02 LBS

4090.0 g / 40.1 N

|

| 5 mm | Stal (~0.2) |

3.11 kg / 6.85 LBS

3106.0 g / 30.5 N

|

| 10 mm | Stal (~0.2) |

1.42 kg / 3.13 LBS

1420.0 g / 13.9 N

|

| 15 mm | Stal (~0.2) |

0.63 kg / 1.39 LBS

630.0 g / 6.2 N

|

| 20 mm | Stal (~0.2) |

0.29 kg / 0.63 LBS

288.0 g / 2.8 N

|

| 30 mm | Stal (~0.2) |

0.07 kg / 0.15 LBS

70.0 g / 0.7 N

|

| 50 mm | Stal (~0.2) |

0.01 kg / 0.02 LBS

8.0 g / 0.1 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MPL 45x25x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

8.54 kg / 18.84 LBS

8544.0 g / 83.8 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

5.70 kg / 12.56 LBS

5696.0 g / 55.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

2.85 kg / 6.28 LBS

2848.0 g / 27.9 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

14.24 kg / 31.39 LBS

14240.0 g / 139.7 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MPL 45x25x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.42 kg / 3.14 LBS

1424.0 g / 14.0 N

|

| 1 mm |

|

3.56 kg / 7.85 LBS

3560.0 g / 34.9 N

|

| 2 mm |

|

7.12 kg / 15.70 LBS

7120.0 g / 69.8 N

|

| 3 mm |

|

10.68 kg / 23.55 LBS

10680.0 g / 104.8 N

|

| 5 mm |

|

17.80 kg / 39.24 LBS

17800.0 g / 174.6 N

|

| 10 mm |

|

28.48 kg / 62.79 LBS

28480.0 g / 279.4 N

|

| 11 mm |

|

28.48 kg / 62.79 LBS

28480.0 g / 279.4 N

|

| 12 mm |

|

28.48 kg / 62.79 LBS

28480.0 g / 279.4 N

|

Table 5: Thermal resistance (material behavior) - resistance threshold

MPL 45x25x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

28.48 kg / 62.79 LBS

28480.0 g / 279.4 N

|

OK |

| 40 °C | -2.2% |

27.85 kg / 61.41 LBS

27853.4 g / 273.2 N

|

OK |

| 60 °C | -4.4% |

27.23 kg / 60.02 LBS

27226.9 g / 267.1 N

|

|

| 80 °C | -6.6% |

26.60 kg / 58.64 LBS

26600.3 g / 260.9 N

|

|

| 100 °C | -28.8% |

20.28 kg / 44.70 LBS

20277.8 g / 198.9 N

|

Table 6: Magnet-Magnet interaction (attraction) - forces in the system

MPL 45x25x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

65.04 kg / 143.40 LBS

4 590 Gs

|

9.76 kg / 21.51 LBS

9757 g / 95.7 N

|

N/A |

| 1 mm |

62.12 kg / 136.95 LBS

5 985 Gs

|

9.32 kg / 20.54 LBS

9318 g / 91.4 N

|

55.91 kg / 123.25 LBS

~0 Gs

|

| 2 mm |

59.05 kg / 130.19 LBS

5 836 Gs

|

8.86 kg / 19.53 LBS

8858 g / 86.9 N

|

53.15 kg / 117.17 LBS

~0 Gs

|

| 3 mm |

55.95 kg / 123.34 LBS

5 680 Gs

|

8.39 kg / 18.50 LBS

8392 g / 82.3 N

|

50.35 kg / 111.01 LBS

~0 Gs

|

| 5 mm |

49.74 kg / 109.66 LBS

5 356 Gs

|

7.46 kg / 16.45 LBS

7461 g / 73.2 N

|

44.77 kg / 98.70 LBS

~0 Gs

|

| 10 mm |

35.46 kg / 78.17 LBS

4 522 Gs

|

5.32 kg / 11.73 LBS

5319 g / 52.2 N

|

31.91 kg / 70.36 LBS

~0 Gs

|

| 20 mm |

16.21 kg / 35.73 LBS

3 057 Gs

|

2.43 kg / 5.36 LBS

2431 g / 23.8 N

|

14.59 kg / 32.16 LBS

~0 Gs

|

| 50 mm |

1.58 kg / 3.48 LBS

955 Gs

|

0.24 kg / 0.52 LBS

237 g / 2.3 N

|

1.42 kg / 3.14 LBS

~0 Gs

|

| 60 mm |

0.80 kg / 1.77 LBS

680 Gs

|

0.12 kg / 0.26 LBS

120 g / 1.2 N

|

0.72 kg / 1.59 LBS

~0 Gs

|

| 70 mm |

0.43 kg / 0.94 LBS

497 Gs

|

0.06 kg / 0.14 LBS

64 g / 0.6 N

|

0.38 kg / 0.85 LBS

~0 Gs

|

| 80 mm |

0.24 kg / 0.53 LBS

372 Gs

|

0.04 kg / 0.08 LBS

36 g / 0.4 N

|

0.22 kg / 0.47 LBS

~0 Gs

|

| 90 mm |

0.14 kg / 0.31 LBS

284 Gs

|

0.02 kg / 0.05 LBS

21 g / 0.2 N

|

0.13 kg / 0.28 LBS

~0 Gs

|

| 100 mm |

0.08 kg / 0.19 LBS

221 Gs

|

0.01 kg / 0.03 LBS

13 g / 0.1 N

|

0.08 kg / 0.17 LBS

~0 Gs

|

Table 7: Hazards (electronics) - precautionary measures

MPL 45x25x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 16.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 12.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 10.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 7.5 cm |

| Car key | 50 Gs (5.0 mT) | 7.0 cm |

| Payment card | 400 Gs (40.0 mT) | 3.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.5 cm |

Table 8: Dynamics (kinetic energy) - warning

MPL 45x25x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

21.22 km/h

(5.89 m/s)

|

1.47 J | |

| 30 mm |

32.34 km/h

(8.98 m/s)

|

3.40 J | |

| 50 mm |

41.46 km/h

(11.52 m/s)

|

5.60 J | |

| 100 mm |

58.59 km/h

(16.28 m/s)

|

11.18 J |

Table 9: Corrosion resistance

MPL 45x25x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MPL 45x25x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 35 829 Mx | 358.3 µWb |

| Pc Coefficient | 0.36 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 45x25x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 28.48 kg | Standard |

| Water (riverbed) |

32.61 kg

(+4.13 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Warning: On a vertical surface, the magnet retains only a fraction of its perpendicular strength.

2. Efficiency vs thickness

*Thin steel (e.g. 0.5mm PC case) drastically reduces the holding force.

3. Heat tolerance

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.36

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Pros as well as cons of neodymium magnets.

Pros

- They virtually do not lose power, because even after ten years the decline in efficiency is only ~1% (based on calculations),

- They possess excellent resistance to weakening of magnetic properties as a result of external fields,

- The use of an elegant coating of noble metals (nickel, gold, silver) causes the element to present itself better,

- Magnetic induction on the top side of the magnet turns out to be very high,

- Through (adequate) combination of ingredients, they can achieve high thermal resistance, allowing for operation at temperatures approaching 230°C and above...

- Thanks to freedom in shaping and the capacity to customize to unusual requirements,

- Wide application in advanced technology sectors – they are used in HDD drives, motor assemblies, precision medical tools, also modern systems.

- Thanks to concentrated force, small magnets offer high operating force, with minimal size,

Disadvantages

- At very strong impacts they can crack, therefore we advise placing them in steel cases. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- Neodymium magnets lose force when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material stable to moisture, in case of application outdoors

- Due to limitations in creating threads and complex forms in magnets, we recommend using casing - magnetic mechanism.

- Health risk resulting from small fragments of magnets pose a threat, if swallowed, which is particularly important in the context of child safety. It is also worth noting that small elements of these magnets are able to be problematic in diagnostics medical after entering the body.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Holding force characteristics

Breakaway strength of the magnet in ideal conditions – what affects it?

- using a sheet made of mild steel, serving as a circuit closing element

- whose thickness reaches at least 10 mm

- characterized by smoothness

- under conditions of no distance (surface-to-surface)

- under vertical force direction (90-degree angle)

- in stable room temperature

What influences lifting capacity in practice

- Gap (betwixt the magnet and the metal), because even a microscopic clearance (e.g. 0.5 mm) can cause a decrease in lifting capacity by up to 50% (this also applies to varnish, corrosion or dirt).

- Loading method – catalog parameter refers to detachment vertically. When applying parallel force, the magnet holds much less (typically approx. 20-30% of nominal force).

- Base massiveness – insufficiently thick plate causes magnetic saturation, causing part of the flux to be escaped to the other side.

- Metal type – different alloys attracts identically. High carbon content weaken the attraction effect.

- Surface condition – ground elements ensure maximum contact, which increases force. Rough surfaces weaken the grip.

- Thermal factor – high temperature reduces pulling force. Exceeding the limit temperature can permanently damage the magnet.

Lifting capacity was assessed using a smooth steel plate of optimal thickness (min. 20 mm), under perpendicular pulling force, in contrast under parallel forces the lifting capacity is smaller. In addition, even a slight gap between the magnet’s surface and the plate reduces the load capacity.

Safety rules for work with NdFeB magnets

Magnet fragility

Despite metallic appearance, the material is delicate and not impact-resistant. Avoid impacts, as the magnet may crumble into sharp, dangerous pieces.

Warning for allergy sufferers

Allergy Notice: The nickel-copper-nickel coating consists of nickel. If an allergic reaction happens, immediately stop handling magnets and wear gloves.

Phone sensors

GPS units and smartphones are extremely sensitive to magnetism. Direct contact with a powerful NdFeB magnet can ruin the internal compass in your phone.

Danger to the youngest

Absolutely keep magnets away from children. Risk of swallowing is high, and the effects of magnets clamping inside the body are tragic.

Conscious usage

Before starting, read the rules. Sudden snapping can destroy the magnet or injure your hand. Think ahead.

Flammability

Mechanical processing of NdFeB material poses a fire risk. Neodymium dust oxidizes rapidly with oxygen and is hard to extinguish.

Do not overheat magnets

Monitor thermal conditions. Heating the magnet to high heat will ruin its magnetic structure and pulling force.

Medical implants

Patients with a pacemaker must maintain an safe separation from magnets. The magnetism can interfere with the operation of the implant.

Threat to electronics

Avoid bringing magnets near a wallet, laptop, or screen. The magnetism can destroy these devices and wipe information from cards.

Serious injuries

Mind your fingers. Two powerful magnets will snap together immediately with a force of massive weight, crushing anything in their path. Exercise extreme caution!

![SM 32x475 [2xM8] / N42 - magnetic separator SM 32x475 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x475-2xm8-jot.jpg)

![UMGZ 36x18x8 [M6] GZ / N38 - magnetic holder external thread UMGZ 36x18x8 [M6] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/um-36x18x8-m8-gz-xiv.jpg)