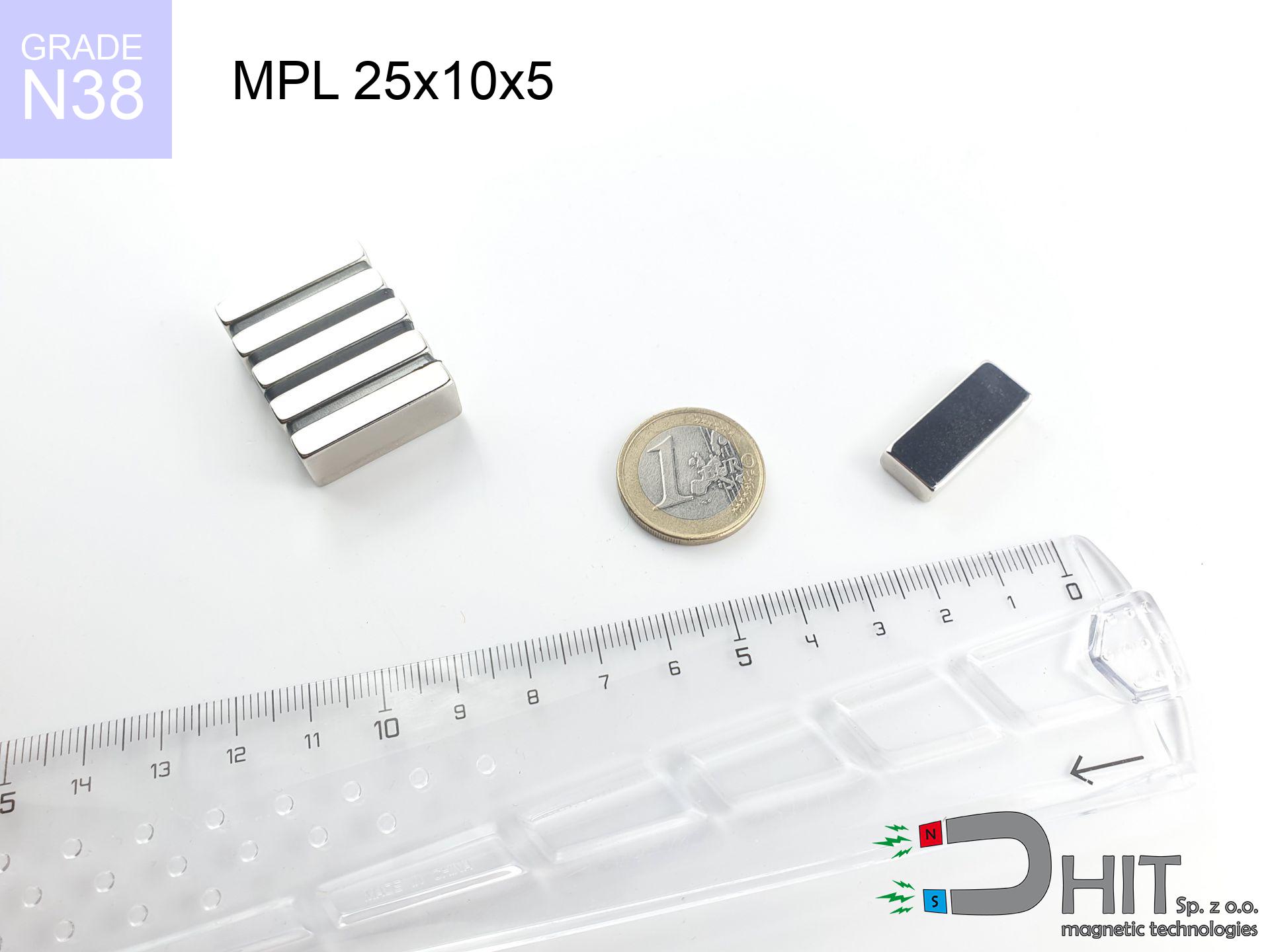

MPL 40x10x5x2[7/3.5] / N38 - lamellar magnet

lamellar magnet

Catalog no 020397

GTIN/EAN: 5906301811909

length

40 mm [±0,1 mm]

Width

10 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

15 g

Magnetization Direction

↑ axial

Load capacity

11.85 kg / 116.27 N

Magnetic Induction

321.37 mT / 3214 Gs

Coating

[NiCuNi] Nickel

9.93 ZŁ with VAT / pcs + price for transport

8.07 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

or drop us a message through

contact form

the contact page.

Force and appearance of neodymium magnets can be verified using our

power calculator.

Same-day processing for orders placed before 14:00.

Technical data - MPL 40x10x5x2[7/3.5] / N38 - lamellar magnet

Specification / characteristics - MPL 40x10x5x2[7/3.5] / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020397 |

| GTIN/EAN | 5906301811909 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 40 mm [±0,1 mm] |

| Width | 10 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 15 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 11.85 kg / 116.27 N |

| Magnetic Induction ~ ? | 321.37 mT / 3214 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the magnet - report

The following data represent the direct effect of a mathematical analysis. Results rely on algorithms for the material Nd2Fe14B. Operational parameters may deviate from the simulation results. Please consider these data as a supplementary guide for designers.

Table 1: Static force (force vs distance) - interaction chart

MPL 40x10x5x2[7/3.5] / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3212 Gs

321.2 mT

|

11.85 kg / 26.12 LBS

11850.0 g / 116.2 N

|

dangerous! |

| 1 mm |

2791 Gs

279.1 mT

|

8.95 kg / 19.73 LBS

8947.7 g / 87.8 N

|

medium risk |

| 2 mm |

2358 Gs

235.8 mT

|

6.38 kg / 14.08 LBS

6384.9 g / 62.6 N

|

medium risk |

| 3 mm |

1965 Gs

196.5 mT

|

4.43 kg / 9.77 LBS

4432.4 g / 43.5 N

|

medium risk |

| 5 mm |

1360 Gs

136.0 mT

|

2.12 kg / 4.68 LBS

2122.9 g / 20.8 N

|

medium risk |

| 10 mm |

615 Gs

61.5 mT

|

0.43 kg / 0.96 LBS

434.1 g / 4.3 N

|

safe |

| 15 mm |

329 Gs

32.9 mT

|

0.12 kg / 0.27 LBS

124.5 g / 1.2 N

|

safe |

| 20 mm |

195 Gs

19.5 mT

|

0.04 kg / 0.10 LBS

43.9 g / 0.4 N

|

safe |

| 30 mm |

83 Gs

8.3 mT

|

0.01 kg / 0.02 LBS

8.0 g / 0.1 N

|

safe |

| 50 mm |

24 Gs

2.4 mT

|

0.00 kg / 0.00 LBS

0.6 g / 0.0 N

|

safe |

Table 2: Slippage load (wall)

MPL 40x10x5x2[7/3.5] / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

2.37 kg / 5.22 LBS

2370.0 g / 23.2 N

|

| 1 mm | Stal (~0.2) |

1.79 kg / 3.95 LBS

1790.0 g / 17.6 N

|

| 2 mm | Stal (~0.2) |

1.28 kg / 2.81 LBS

1276.0 g / 12.5 N

|

| 3 mm | Stal (~0.2) |

0.89 kg / 1.95 LBS

886.0 g / 8.7 N

|

| 5 mm | Stal (~0.2) |

0.42 kg / 0.93 LBS

424.0 g / 4.2 N

|

| 10 mm | Stal (~0.2) |

0.09 kg / 0.19 LBS

86.0 g / 0.8 N

|

| 15 mm | Stal (~0.2) |

0.02 kg / 0.05 LBS

24.0 g / 0.2 N

|

| 20 mm | Stal (~0.2) |

0.01 kg / 0.02 LBS

8.0 g / 0.1 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MPL 40x10x5x2[7/3.5] / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

3.55 kg / 7.84 LBS

3555.0 g / 34.9 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

2.37 kg / 5.22 LBS

2370.0 g / 23.2 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.19 kg / 2.61 LBS

1185.0 g / 11.6 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

5.93 kg / 13.06 LBS

5925.0 g / 58.1 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MPL 40x10x5x2[7/3.5] / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.59 kg / 1.31 LBS

592.5 g / 5.8 N

|

| 1 mm |

|

1.48 kg / 3.27 LBS

1481.3 g / 14.5 N

|

| 2 mm |

|

2.96 kg / 6.53 LBS

2962.5 g / 29.1 N

|

| 3 mm |

|

4.44 kg / 9.80 LBS

4443.8 g / 43.6 N

|

| 5 mm |

|

7.41 kg / 16.33 LBS

7406.3 g / 72.7 N

|

| 10 mm |

|

11.85 kg / 26.12 LBS

11850.0 g / 116.2 N

|

| 11 mm |

|

11.85 kg / 26.12 LBS

11850.0 g / 116.2 N

|

| 12 mm |

|

11.85 kg / 26.12 LBS

11850.0 g / 116.2 N

|

Table 5: Working in heat (stability) - power drop

MPL 40x10x5x2[7/3.5] / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

11.85 kg / 26.12 LBS

11850.0 g / 116.2 N

|

OK |

| 40 °C | -2.2% |

11.59 kg / 25.55 LBS

11589.3 g / 113.7 N

|

OK |

| 60 °C | -4.4% |

11.33 kg / 24.98 LBS

11328.6 g / 111.1 N

|

|

| 80 °C | -6.6% |

11.07 kg / 24.40 LBS

11067.9 g / 108.6 N

|

|

| 100 °C | -28.8% |

8.44 kg / 18.60 LBS

8437.2 g / 82.8 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MPL 40x10x5x2[7/3.5] / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

25.44 kg / 56.10 LBS

4 569 Gs

|

3.82 kg / 8.41 LBS

3817 g / 37.4 N

|

N/A |

| 1 mm |

22.33 kg / 49.22 LBS

6 018 Gs

|

3.35 kg / 7.38 LBS

3349 g / 32.9 N

|

20.09 kg / 44.30 LBS

~0 Gs

|

| 2 mm |

19.21 kg / 42.36 LBS

5 582 Gs

|

2.88 kg / 6.35 LBS

2882 g / 28.3 N

|

17.29 kg / 38.12 LBS

~0 Gs

|

| 3 mm |

16.31 kg / 35.96 LBS

5 144 Gs

|

2.45 kg / 5.39 LBS

2447 g / 24.0 N

|

14.68 kg / 32.36 LBS

~0 Gs

|

| 5 mm |

11.45 kg / 25.23 LBS

4 309 Gs

|

1.72 kg / 3.78 LBS

1717 g / 16.8 N

|

10.30 kg / 22.71 LBS

~0 Gs

|

| 10 mm |

4.56 kg / 10.05 LBS

2 719 Gs

|

0.68 kg / 1.51 LBS

684 g / 6.7 N

|

4.10 kg / 9.04 LBS

~0 Gs

|

| 20 mm |

0.93 kg / 2.05 LBS

1 230 Gs

|

0.14 kg / 0.31 LBS

140 g / 1.4 N

|

0.84 kg / 1.85 LBS

~0 Gs

|

| 50 mm |

0.04 kg / 0.08 LBS

249 Gs

|

0.01 kg / 0.01 LBS

6 g / 0.1 N

|

0.03 kg / 0.08 LBS

~0 Gs

|

| 60 mm |

0.02 kg / 0.04 LBS

167 Gs

|

0.00 kg / 0.01 LBS

3 g / 0.0 N

|

0.02 kg / 0.03 LBS

~0 Gs

|

| 70 mm |

0.01 kg / 0.02 LBS

116 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.01 LBS

84 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.01 LBS

62 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

48 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (electronics) - warnings

MPL 40x10x5x2[7/3.5] / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 9.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 7.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 5.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 4.5 cm |

| Car key | 50 Gs (5.0 mT) | 4.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Impact energy (cracking risk) - warning

MPL 40x10x5x2[7/3.5] / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

28.99 km/h

(8.05 m/s)

|

0.49 J | |

| 30 mm |

49.12 km/h

(13.64 m/s)

|

1.40 J | |

| 50 mm |

63.39 km/h

(17.61 m/s)

|

2.33 J | |

| 100 mm |

89.64 km/h

(24.90 m/s)

|

4.65 J |

Table 9: Surface protection spec

MPL 40x10x5x2[7/3.5] / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MPL 40x10x5x2[7/3.5] / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 11 419 Mx | 114.2 µWb |

| Pc Coefficient | 0.31 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 40x10x5x2[7/3.5] / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 11.85 kg | Standard |

| Water (riverbed) |

13.57 kg

(+1.72 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical wall, the magnet retains only a fraction of its max power.

2. Steel thickness impact

*Thin steel (e.g. computer case) significantly weakens the holding force.

3. Heat tolerance

*For standard magnets, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.31

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Advantages and disadvantages of Nd2Fe14B magnets.

Strengths

- They do not lose strength, even over approximately ten years – the reduction in strength is only ~1% (according to tests),

- They feature excellent resistance to magnetism drop as a result of opposing magnetic fields,

- In other words, due to the metallic layer of nickel, the element becomes visually attractive,

- Magnetic induction on the surface of the magnet turns out to be exceptional,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Thanks to flexibility in shaping and the capacity to customize to complex applications,

- Significant place in innovative solutions – they are commonly used in HDD drives, electric drive systems, diagnostic systems, and technologically advanced constructions.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Cons

- To avoid cracks upon strong impacts, we recommend using special steel housings. Such a solution protects the magnet and simultaneously increases its durability.

- When exposed to high temperature, neodymium magnets experience a drop in force. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material stable to moisture, in case of application outdoors

- Limited possibility of making nuts in the magnet and complicated shapes - preferred is a housing - magnet mounting.

- Potential hazard to health – tiny shards of magnets can be dangerous, in case of ingestion, which is particularly important in the context of child health protection. It is also worth noting that tiny parts of these devices are able to disrupt the diagnostic process medical in case of swallowing.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Pull force analysis

Maximum magnetic pulling force – what affects it?

- on a plate made of structural steel, effectively closing the magnetic field

- with a thickness no less than 10 mm

- with a surface free of scratches

- without the slightest insulating layer between the magnet and steel

- for force acting at a right angle (pull-off, not shear)

- at ambient temperature approx. 20 degrees Celsius

Practical aspects of lifting capacity – factors

- Space between surfaces – every millimeter of separation (caused e.g. by varnish or unevenness) drastically reduces the pulling force, often by half at just 0.5 mm.

- Pull-off angle – note that the magnet holds strongest perpendicularly. Under sliding down, the capacity drops significantly, often to levels of 20-30% of the nominal value.

- Base massiveness – insufficiently thick plate does not accept the full field, causing part of the flux to be escaped into the air.

- Material type – ideal substrate is pure iron steel. Stainless steels may generate lower lifting capacity.

- Smoothness – full contact is possible only on smooth steel. Rough texture reduce the real contact area, reducing force.

- Thermal environment – heating the magnet results in weakening of induction. It is worth remembering the maximum operating temperature for a given model.

Lifting capacity was determined using a polished steel plate of suitable thickness (min. 20 mm), under perpendicular pulling force, in contrast under shearing force the holding force is lower. In addition, even a small distance between the magnet’s surface and the plate lowers the holding force.

H&S for magnets

This is not a toy

Absolutely keep magnets away from children. Ingestion danger is significant, and the consequences of magnets connecting inside the body are life-threatening.

Permanent damage

Regular neodymium magnets (N-type) lose power when the temperature exceeds 80°C. This process is irreversible.

GPS Danger

An intense magnetic field negatively affects the operation of compasses in smartphones and GPS navigation. Keep magnets near a smartphone to prevent breaking the sensors.

Metal Allergy

Nickel alert: The Ni-Cu-Ni coating consists of nickel. If skin irritation occurs, cease handling magnets and wear gloves.

Crushing risk

Risk of injury: The pulling power is so great that it can cause blood blisters, crushing, and broken bones. Use thick gloves.

Pacemakers

Medical warning: Strong magnets can deactivate heart devices and defibrillators. Stay away if you have electronic implants.

Material brittleness

Despite metallic appearance, the material is brittle and not impact-resistant. Do not hit, as the magnet may crumble into hazardous fragments.

Flammability

Combustion risk: Rare earth powder is highly flammable. Do not process magnets in home conditions as this may cause fire.

Data carriers

Device Safety: Neodymium magnets can damage payment cards and delicate electronics (heart implants, hearing aids, timepieces).

Do not underestimate power

Before starting, read the rules. Sudden snapping can destroy the magnet or injure your hand. Think ahead.

![Rectangular magnetic block MPL 40x10x5x2[7/3.5] / N38 Rectangular magnetic block MPL 40x10x5x2[7/3.5] / N38](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![MPL 40x10x5x2[7/3.5] / N38 - lamellar magnet](https://cdn3.dhit.pl/graphics/products/mpl-40x10x5x27-3.5-miw.jpg)

![UMGGW 66x8.5 [M8] GW / N38 - magnetic holder rubber internal thread UMGGW 66x8.5 [M8] GW / N38 - magnetic holder rubber internal thread](https://cdn3.dhit.pl/graphics/products/umg-66x8.5-m6-gw-wud.jpg)

![SM 32x375 [2xM8] / N52 - magnetic separator SM 32x375 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x375-2xm8-mif.jpg)