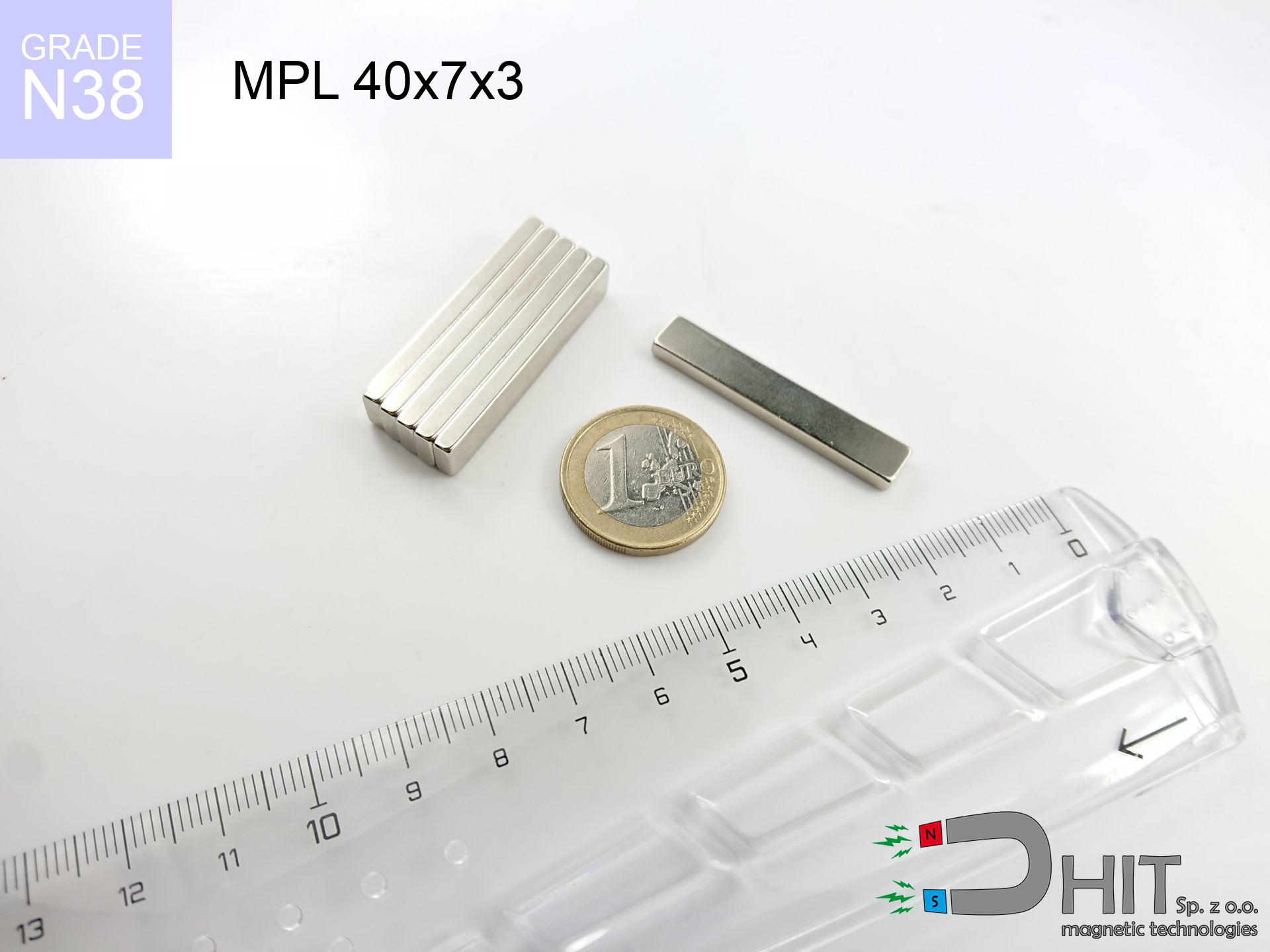

MPL 40x7x3 / N38 - lamellar magnet

lamellar magnet

Catalog no 020162

GTIN/EAN: 5906301811688

length

40 mm [±0,1 mm]

Width

7 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

6.3 g

Magnetization Direction

↑ axial

Load capacity

7.14 kg / 70.02 N

Magnetic Induction

284.46 mT / 2845 Gs

Coating

[NiCuNi] Nickel

2.79 ZŁ with VAT / pcs + price for transport

2.27 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

otherwise contact us using

inquiry form

the contact page.

Lifting power along with form of a neodymium magnet can be verified using our

online calculation tool.

Order by 14:00 and we’ll ship today!

Technical details - MPL 40x7x3 / N38 - lamellar magnet

Specification / characteristics - MPL 40x7x3 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020162 |

| GTIN/EAN | 5906301811688 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 40 mm [±0,1 mm] |

| Width | 7 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 6.3 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 7.14 kg / 70.02 N |

| Magnetic Induction ~ ? | 284.46 mT / 2845 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the magnet - data

The following data represent the direct effect of a engineering calculation. Results were calculated on algorithms for the class Nd2Fe14B. Operational performance might slightly deviate from the simulation results. Use these calculations as a reference point during assembly planning.

Table 1: Static force (force vs gap) - power drop

MPL 40x7x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2843 Gs

284.3 mT

|

7.14 kg / 15.74 LBS

7140.0 g / 70.0 N

|

warning |

| 1 mm |

2314 Gs

231.4 mT

|

4.73 kg / 10.43 LBS

4729.9 g / 46.4 N

|

warning |

| 2 mm |

1788 Gs

178.8 mT

|

2.83 kg / 6.23 LBS

2825.3 g / 27.7 N

|

warning |

| 3 mm |

1365 Gs

136.5 mT

|

1.65 kg / 3.63 LBS

1645.1 g / 16.1 N

|

safe |

| 5 mm |

824 Gs

82.4 mT

|

0.60 kg / 1.32 LBS

599.2 g / 5.9 N

|

safe |

| 10 mm |

317 Gs

31.7 mT

|

0.09 kg / 0.20 LBS

88.6 g / 0.9 N

|

safe |

| 15 mm |

160 Gs

16.0 mT

|

0.02 kg / 0.05 LBS

22.5 g / 0.2 N

|

safe |

| 20 mm |

92 Gs

9.2 mT

|

0.01 kg / 0.02 LBS

7.5 g / 0.1 N

|

safe |

| 30 mm |

38 Gs

3.8 mT

|

0.00 kg / 0.00 LBS

1.3 g / 0.0 N

|

safe |

| 50 mm |

11 Gs

1.1 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

safe |

Table 2: Sliding force (wall)

MPL 40x7x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.43 kg / 3.15 LBS

1428.0 g / 14.0 N

|

| 1 mm | Stal (~0.2) |

0.95 kg / 2.09 LBS

946.0 g / 9.3 N

|

| 2 mm | Stal (~0.2) |

0.57 kg / 1.25 LBS

566.0 g / 5.6 N

|

| 3 mm | Stal (~0.2) |

0.33 kg / 0.73 LBS

330.0 g / 3.2 N

|

| 5 mm | Stal (~0.2) |

0.12 kg / 0.26 LBS

120.0 g / 1.2 N

|

| 10 mm | Stal (~0.2) |

0.02 kg / 0.04 LBS

18.0 g / 0.2 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MPL 40x7x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.14 kg / 4.72 LBS

2142.0 g / 21.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.43 kg / 3.15 LBS

1428.0 g / 14.0 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.71 kg / 1.57 LBS

714.0 g / 7.0 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.57 kg / 7.87 LBS

3570.0 g / 35.0 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MPL 40x7x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.71 kg / 1.57 LBS

714.0 g / 7.0 N

|

| 1 mm |

|

1.79 kg / 3.94 LBS

1785.0 g / 17.5 N

|

| 2 mm |

|

3.57 kg / 7.87 LBS

3570.0 g / 35.0 N

|

| 3 mm |

|

5.35 kg / 11.81 LBS

5355.0 g / 52.5 N

|

| 5 mm |

|

7.14 kg / 15.74 LBS

7140.0 g / 70.0 N

|

| 10 mm |

|

7.14 kg / 15.74 LBS

7140.0 g / 70.0 N

|

| 11 mm |

|

7.14 kg / 15.74 LBS

7140.0 g / 70.0 N

|

| 12 mm |

|

7.14 kg / 15.74 LBS

7140.0 g / 70.0 N

|

Table 5: Thermal resistance (stability) - power drop

MPL 40x7x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

7.14 kg / 15.74 LBS

7140.0 g / 70.0 N

|

OK |

| 40 °C | -2.2% |

6.98 kg / 15.39 LBS

6982.9 g / 68.5 N

|

OK |

| 60 °C | -4.4% |

6.83 kg / 15.05 LBS

6825.8 g / 67.0 N

|

|

| 80 °C | -6.6% |

6.67 kg / 14.70 LBS

6668.8 g / 65.4 N

|

|

| 100 °C | -28.8% |

5.08 kg / 11.21 LBS

5083.7 g / 49.9 N

|

Table 6: Two magnets (repulsion) - forces in the system

MPL 40x7x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

13.95 kg / 30.75 LBS

4 204 Gs

|

2.09 kg / 4.61 LBS

2092 g / 20.5 N

|

N/A |

| 1 mm |

11.58 kg / 25.53 LBS

5 180 Gs

|

1.74 kg / 3.83 LBS

1737 g / 17.0 N

|

10.42 kg / 22.98 LBS

~0 Gs

|

| 2 mm |

9.24 kg / 20.37 LBS

4 628 Gs

|

1.39 kg / 3.06 LBS

1386 g / 13.6 N

|

8.32 kg / 18.34 LBS

~0 Gs

|

| 3 mm |

7.19 kg / 15.86 LBS

4 083 Gs

|

1.08 kg / 2.38 LBS

1079 g / 10.6 N

|

6.47 kg / 14.27 LBS

~0 Gs

|

| 5 mm |

4.21 kg / 9.28 LBS

3 124 Gs

|

0.63 kg / 1.39 LBS

632 g / 6.2 N

|

3.79 kg / 8.36 LBS

~0 Gs

|

| 10 mm |

1.17 kg / 2.58 LBS

1 647 Gs

|

0.18 kg / 0.39 LBS

176 g / 1.7 N

|

1.05 kg / 2.32 LBS

~0 Gs

|

| 20 mm |

0.17 kg / 0.38 LBS

633 Gs

|

0.03 kg / 0.06 LBS

26 g / 0.3 N

|

0.16 kg / 0.34 LBS

~0 Gs

|

| 50 mm |

0.01 kg / 0.01 LBS

115 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.01 LBS

76 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

53 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

38 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

28 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

21 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Hazards (electronics) - warnings

MPL 40x7x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 7.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 4.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.0 cm |

| Remote | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (kinetic energy) - warning

MPL 40x7x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

34.21 km/h

(9.50 m/s)

|

0.28 J | |

| 30 mm |

58.81 km/h

(16.34 m/s)

|

0.84 J | |

| 50 mm |

75.92 km/h

(21.09 m/s)

|

1.40 J | |

| 100 mm |

107.36 km/h

(29.82 m/s)

|

2.80 J |

Table 9: Anti-corrosion coating durability

MPL 40x7x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MPL 40x7x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 6 379 Mx | 63.8 µWb |

| Pc Coefficient | 0.24 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 40x7x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 7.14 kg | Standard |

| Water (riverbed) |

8.18 kg

(+1.04 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Warning: On a vertical wall, the magnet retains only approx. 20-30% of its max power.

2. Plate thickness effect

*Thin steel (e.g. 0.5mm PC case) significantly reduces the holding force.

3. Thermal stability

*For N38 grade, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.24

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Strengths and weaknesses of Nd2Fe14B magnets.

Pros

- They have constant strength, and over around ten years their performance decreases symbolically – ~1% (in testing),

- They possess excellent resistance to magnetism drop when exposed to external fields,

- Thanks to the elegant finish, the layer of Ni-Cu-Ni, gold-plated, or silver-plated gives an elegant appearance,

- They feature high magnetic induction at the operating surface, making them more effective,

- Thanks to resistance to high temperature, they are able to function (depending on the form) even at temperatures up to 230°C and higher...

- Thanks to flexibility in forming and the ability to adapt to individual projects,

- Versatile presence in innovative solutions – they serve a role in magnetic memories, motor assemblies, precision medical tools, also multitasking production systems.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Limitations

- They are fragile upon heavy impacts. To avoid cracks, it is worth securing magnets in special housings. Such protection not only protects the magnet but also increases its resistance to damage

- NdFeB magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material stable to moisture, when using outdoors

- Due to limitations in producing threads and complicated shapes in magnets, we recommend using casing - magnetic mount.

- Potential hazard resulting from small fragments of magnets pose a threat, if swallowed, which is particularly important in the context of child health protection. It is also worth noting that tiny parts of these devices can disrupt the diagnostic process medical in case of swallowing.

- Due to neodymium price, their price is relatively high,

Pull force analysis

Maximum lifting force for a neodymium magnet – what affects it?

- on a block made of mild steel, perfectly concentrating the magnetic field

- whose thickness equals approx. 10 mm

- with an ground touching surface

- without any air gap between the magnet and steel

- under axial application of breakaway force (90-degree angle)

- at room temperature

Lifting capacity in real conditions – factors

- Distance (between the magnet and the metal), as even a very small distance (e.g. 0.5 mm) leads to a decrease in lifting capacity by up to 50% (this also applies to varnish, rust or debris).

- Angle of force application – highest force is available only during perpendicular pulling. The shear force of the magnet along the surface is standardly several times lower (approx. 1/5 of the lifting capacity).

- Steel thickness – too thin sheet causes magnetic saturation, causing part of the flux to be lost into the air.

- Material composition – not every steel attracts identically. Alloy additives weaken the interaction with the magnet.

- Base smoothness – the more even the surface, the better the adhesion and higher the lifting capacity. Unevenness acts like micro-gaps.

- Operating temperature – NdFeB sinters have a sensitivity to temperature. At higher temperatures they lose power, and at low temperatures gain strength (up to a certain limit).

Lifting capacity was assessed with the use of a polished steel plate of optimal thickness (min. 20 mm), under vertically applied force, however under attempts to slide the magnet the load capacity is reduced by as much as fivefold. In addition, even a small distance between the magnet and the plate reduces the load capacity.

Precautions when working with neodymium magnets

Eye protection

Watch out for shards. Magnets can fracture upon violent connection, launching shards into the air. Wear goggles.

Power loss in heat

Regular neodymium magnets (N-type) lose magnetization when the temperature exceeds 80°C. The loss of strength is permanent.

Handling rules

Be careful. Neodymium magnets attract from a distance and connect with huge force, often quicker than you can react.

Electronic hazard

Very strong magnetic fields can corrupt files on credit cards, HDDs, and storage devices. Maintain a gap of at least 10 cm.

Flammability

Mechanical processing of NdFeB material carries a risk of fire risk. Magnetic powder reacts violently with oxygen and is hard to extinguish.

Pacemakers

Medical warning: Neodymium magnets can turn off heart devices and defibrillators. Do not approach if you have medical devices.

Metal Allergy

Certain individuals have a hypersensitivity to nickel, which is the typical protective layer for NdFeB magnets. Frequent touching might lead to an allergic reaction. We recommend use safety gloves.

Compass and GPS

A powerful magnetic field negatively affects the operation of magnetometers in phones and GPS navigation. Maintain magnets near a smartphone to prevent breaking the sensors.

Danger to the youngest

Only for adults. Tiny parts pose a choking risk, causing serious injuries. Keep out of reach of kids and pets.

Bodily injuries

Pinching hazard: The attraction force is so great that it can result in hematomas, crushing, and even bone fractures. Protective gloves are recommended.

![SM 32x250 [2xM8] / N52 - magnetic separator SM 32x250 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x250-2xm8-guf.jpg)