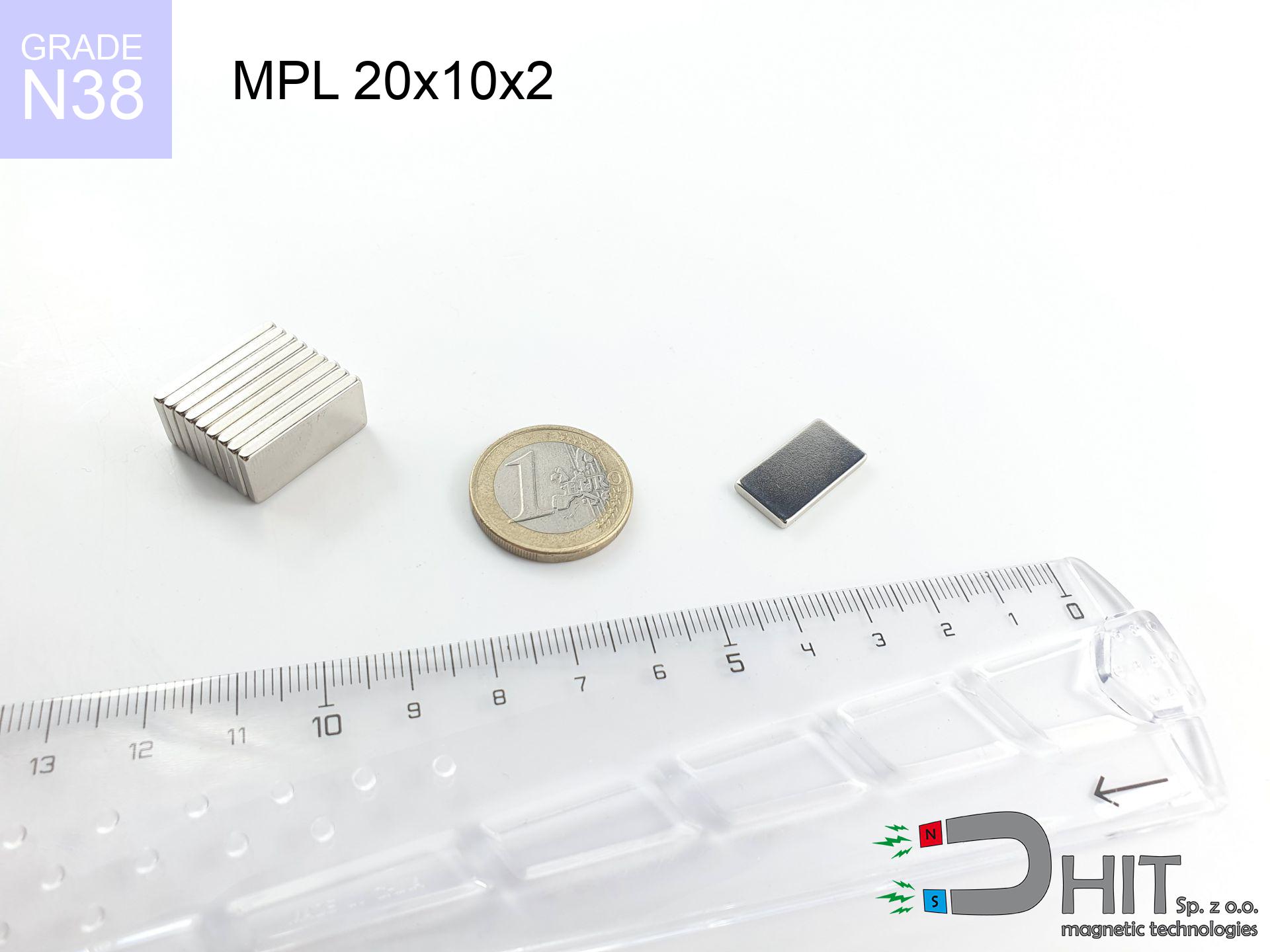

MPL 20x10x2 / N38 - lamellar magnet

lamellar magnet

Catalog no 020127

GTIN/EAN: 5906301811336

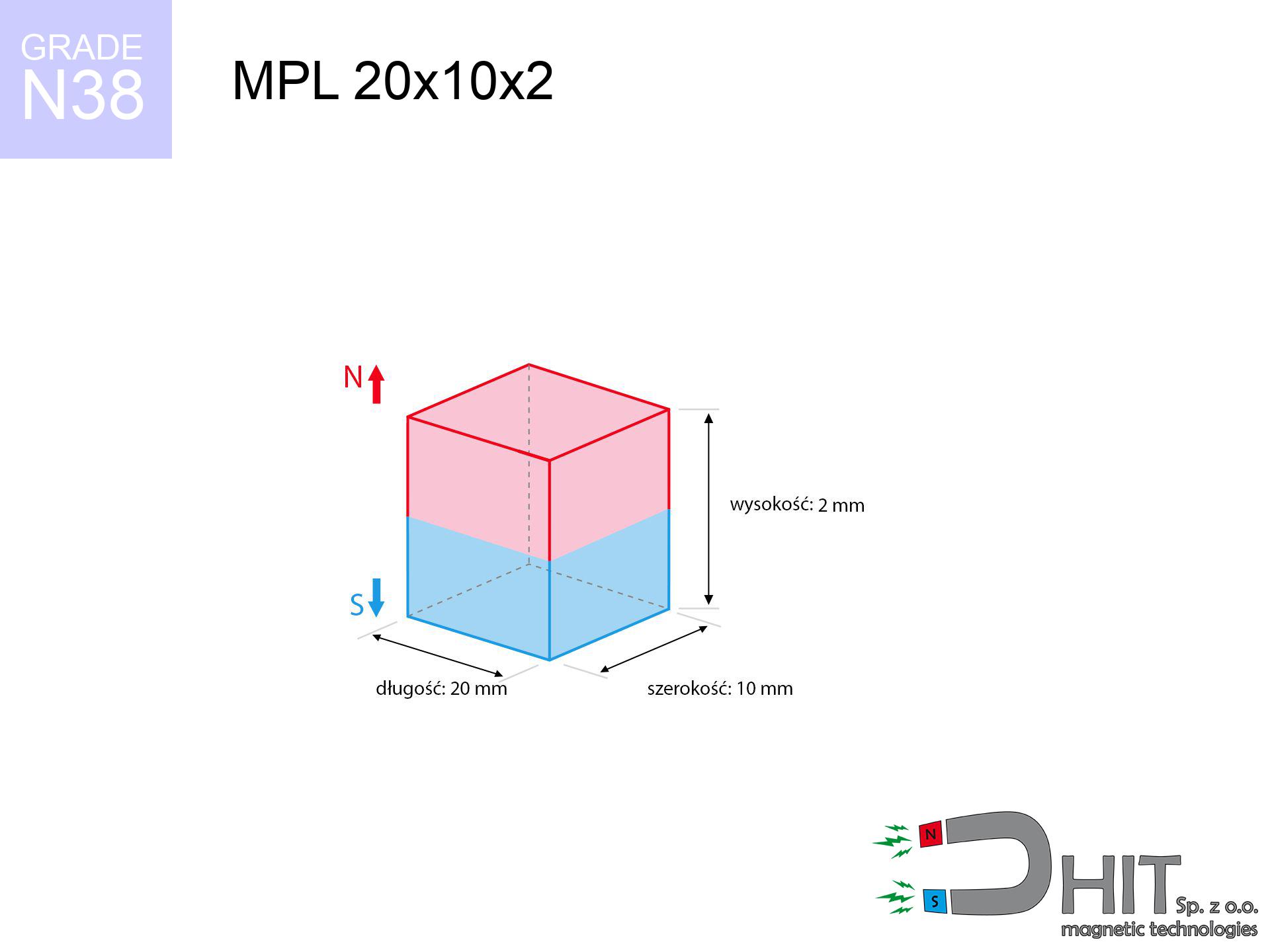

length

20 mm [±0,1 mm]

Width

10 mm [±0,1 mm]

Height

2 mm [±0,1 mm]

Weight

3 g

Magnetization Direction

↑ axial

Load capacity

1.88 kg / 18.44 N

Magnetic Induction

168.24 mT / 1682 Gs

Coating

[NiCuNi] Nickel

1.538 ZŁ with VAT / pcs + price for transport

1.250 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

if you prefer send us a note by means of

inquiry form

the contact section.

Lifting power and appearance of magnetic components can be analyzed using our

power calculator.

Order by 14:00 and we’ll ship today!

Technical details - MPL 20x10x2 / N38 - lamellar magnet

Specification / characteristics - MPL 20x10x2 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020127 |

| GTIN/EAN | 5906301811336 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 20 mm [±0,1 mm] |

| Width | 10 mm [±0,1 mm] |

| Height | 2 mm [±0,1 mm] |

| Weight | 3 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.88 kg / 18.44 N |

| Magnetic Induction ~ ? | 168.24 mT / 1682 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the assembly - technical parameters

The following values represent the result of a mathematical analysis. Values rely on models for the class Nd2Fe14B. Operational conditions might slightly differ from theoretical values. Please consider these data as a reference point when designing systems.

Table 1: Static force (pull vs gap) - interaction chart

MPL 20x10x2 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1682 Gs

168.2 mT

|

1.88 kg / 4.14 lbs

1880.0 g / 18.4 N

|

safe |

| 1 mm |

1524 Gs

152.4 mT

|

1.54 kg / 3.40 lbs

1544.3 g / 15.1 N

|

safe |

| 2 mm |

1316 Gs

131.6 mT

|

1.15 kg / 2.54 lbs

1150.1 g / 11.3 N

|

safe |

| 3 mm |

1101 Gs

110.1 mT

|

0.81 kg / 1.78 lbs

806.0 g / 7.9 N

|

safe |

| 5 mm |

744 Gs

74.4 mT

|

0.37 kg / 0.81 lbs

367.6 g / 3.6 N

|

safe |

| 10 mm |

288 Gs

28.8 mT

|

0.06 kg / 0.12 lbs

55.1 g / 0.5 N

|

safe |

| 15 mm |

129 Gs

12.9 mT

|

0.01 kg / 0.02 lbs

11.1 g / 0.1 N

|

safe |

| 20 mm |

66 Gs

6.6 mT

|

0.00 kg / 0.01 lbs

2.9 g / 0.0 N

|

safe |

| 30 mm |

23 Gs

2.3 mT

|

0.00 kg / 0.00 lbs

0.4 g / 0.0 N

|

safe |

| 50 mm |

6 Gs

0.6 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

Table 2: Slippage hold (vertical surface)

MPL 20x10x2 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.38 kg / 0.83 lbs

376.0 g / 3.7 N

|

| 1 mm | Stal (~0.2) |

0.31 kg / 0.68 lbs

308.0 g / 3.0 N

|

| 2 mm | Stal (~0.2) |

0.23 kg / 0.51 lbs

230.0 g / 2.3 N

|

| 3 mm | Stal (~0.2) |

0.16 kg / 0.36 lbs

162.0 g / 1.6 N

|

| 5 mm | Stal (~0.2) |

0.07 kg / 0.16 lbs

74.0 g / 0.7 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.03 lbs

12.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MPL 20x10x2 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.56 kg / 1.24 lbs

564.0 g / 5.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.38 kg / 0.83 lbs

376.0 g / 3.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.19 kg / 0.41 lbs

188.0 g / 1.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.94 kg / 2.07 lbs

940.0 g / 9.2 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MPL 20x10x2 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.19 kg / 0.41 lbs

188.0 g / 1.8 N

|

| 1 mm |

|

0.47 kg / 1.04 lbs

470.0 g / 4.6 N

|

| 2 mm |

|

0.94 kg / 2.07 lbs

940.0 g / 9.2 N

|

| 3 mm |

|

1.41 kg / 3.11 lbs

1410.0 g / 13.8 N

|

| 5 mm |

|

1.88 kg / 4.14 lbs

1880.0 g / 18.4 N

|

| 10 mm |

|

1.88 kg / 4.14 lbs

1880.0 g / 18.4 N

|

| 11 mm |

|

1.88 kg / 4.14 lbs

1880.0 g / 18.4 N

|

| 12 mm |

|

1.88 kg / 4.14 lbs

1880.0 g / 18.4 N

|

Table 5: Working in heat (stability) - power drop

MPL 20x10x2 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.88 kg / 4.14 lbs

1880.0 g / 18.4 N

|

OK |

| 40 °C | -2.2% |

1.84 kg / 4.05 lbs

1838.6 g / 18.0 N

|

OK |

| 60 °C | -4.4% |

1.80 kg / 3.96 lbs

1797.3 g / 17.6 N

|

|

| 80 °C | -6.6% |

1.76 kg / 3.87 lbs

1755.9 g / 17.2 N

|

|

| 100 °C | -28.8% |

1.34 kg / 2.95 lbs

1338.6 g / 13.1 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MPL 20x10x2 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

3.49 kg / 7.69 lbs

2 995 Gs

|

0.52 kg / 1.15 lbs

523 g / 5.1 N

|

N/A |

| 1 mm |

3.21 kg / 7.08 lbs

3 227 Gs

|

0.48 kg / 1.06 lbs

481 g / 4.7 N

|

2.89 kg / 6.37 lbs

~0 Gs

|

| 2 mm |

2.87 kg / 6.32 lbs

3 049 Gs

|

0.43 kg / 0.95 lbs

430 g / 4.2 N

|

2.58 kg / 5.69 lbs

~0 Gs

|

| 3 mm |

2.50 kg / 5.51 lbs

2 846 Gs

|

0.37 kg / 0.83 lbs

375 g / 3.7 N

|

2.25 kg / 4.95 lbs

~0 Gs

|

| 5 mm |

1.80 kg / 3.96 lbs

2 414 Gs

|

0.27 kg / 0.59 lbs

269 g / 2.6 N

|

1.62 kg / 3.56 lbs

~0 Gs

|

| 10 mm |

0.68 kg / 1.50 lbs

1 487 Gs

|

0.10 kg / 0.23 lbs

102 g / 1.0 N

|

0.61 kg / 1.35 lbs

~0 Gs

|

| 20 mm |

0.10 kg / 0.23 lbs

576 Gs

|

0.02 kg / 0.03 lbs

15 g / 0.2 N

|

0.09 kg / 0.20 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

76 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

47 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

31 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

21 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

15 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

11 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (electronics) - warnings

MPL 20x10x2 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 3.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 2.5 cm |

| Remote | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (cracking risk) - collision effects

MPL 20x10x2 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

25.70 km/h

(7.14 m/s)

|

0.08 J | |

| 30 mm |

43.73 km/h

(12.15 m/s)

|

0.22 J | |

| 50 mm |

56.45 km/h

(15.68 m/s)

|

0.37 J | |

| 100 mm |

79.84 km/h

(22.18 m/s)

|

0.74 J |

Table 9: Corrosion resistance

MPL 20x10x2 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 20x10x2 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 825 Mx | 38.2 µWb |

| Pc Coefficient | 0.19 | Low (Flat) |

Table 11: Submerged application

MPL 20x10x2 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.88 kg | Standard |

| Water (riverbed) |

2.15 kg

(+0.27 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Warning: On a vertical wall, the magnet retains merely ~20% of its max power.

2. Steel thickness impact

*Thin steel (e.g. computer case) severely limits the holding force.

3. Power loss vs temp

*For N38 grade, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.19

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Advantages and disadvantages of rare earth magnets.

Advantages

- They do not lose power, even over approximately ten years – the reduction in power is only ~1% (theoretically),

- They show high resistance to demagnetization induced by external magnetic fields,

- In other words, due to the shiny surface of silver, the element gains a professional look,

- Magnetic induction on the working part of the magnet turns out to be very high,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and are able to act (depending on the form) even at a temperature of 230°C or more...

- Possibility of custom shaping as well as adjusting to specific conditions,

- Wide application in modern industrial fields – they are commonly used in data components, electric motors, medical devices, and multitasking production systems.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in small dimensions, which allows their use in compact constructions

Cons

- To avoid cracks under impact, we suggest using special steel housings. Such a solution protects the magnet and simultaneously improves its durability.

- Neodymium magnets lose their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material resistant to moisture, when using outdoors

- Limited ability of creating threads in the magnet and complex shapes - recommended is a housing - mounting mechanism.

- Possible danger related to microscopic parts of magnets pose a threat, when accidentally swallowed, which becomes key in the aspect of protecting the youngest. Furthermore, small components of these devices can be problematic in diagnostics medical when they are in the body.

- With large orders the cost of neodymium magnets is a challenge,

Lifting parameters

Detachment force of the magnet in optimal conditions – what it depends on?

- using a sheet made of mild steel, acting as a ideal flux conductor

- with a cross-section minimum 10 mm

- with an ground touching surface

- with total lack of distance (without impurities)

- during pulling in a direction vertical to the mounting surface

- at room temperature

Practical aspects of lifting capacity – factors

- Gap (betwixt the magnet and the plate), as even a microscopic clearance (e.g. 0.5 mm) leads to a drastic drop in force by up to 50% (this also applies to paint, corrosion or debris).

- Force direction – catalog parameter refers to detachment vertically. When applying parallel force, the magnet holds much less (often approx. 20-30% of nominal force).

- Metal thickness – thin material does not allow full use of the magnet. Part of the magnetic field penetrates through instead of converting into lifting capacity.

- Material type – the best choice is pure iron steel. Cast iron may attract less.

- Surface quality – the more even the surface, the larger the contact zone and higher the lifting capacity. Unevenness creates an air distance.

- Thermal factor – hot environment weakens pulling force. Exceeding the limit temperature can permanently damage the magnet.

Lifting capacity testing was performed on plates with a smooth surface of suitable thickness, under a perpendicular pulling force, in contrast under attempts to slide the magnet the lifting capacity is smaller. In addition, even a minimal clearance between the magnet’s surface and the plate lowers the lifting capacity.

Precautions when working with NdFeB magnets

Allergic reactions

Studies show that nickel (the usual finish) is a common allergen. If you have an allergy, avoid direct skin contact and select versions in plastic housing.

Bodily injuries

Danger of trauma: The pulling power is so great that it can result in blood blisters, crushing, and even bone fractures. Use thick gloves.

Magnet fragility

Neodymium magnets are sintered ceramics, which means they are fragile like glass. Impact of two magnets leads to them cracking into shards.

Pacemakers

Life threat: Neodymium magnets can turn off heart devices and defibrillators. Stay away if you have medical devices.

GPS and phone interference

Be aware: rare earth magnets produce a field that disrupts sensitive sensors. Keep a safe distance from your mobile, device, and navigation systems.

Conscious usage

Use magnets with awareness. Their powerful strength can shock even experienced users. Stay alert and respect their power.

Magnetic media

Intense magnetic fields can erase data on credit cards, hard drives, and other magnetic media. Maintain a gap of min. 10 cm.

Power loss in heat

Monitor thermal conditions. Exposing the magnet above 80 degrees Celsius will permanently weaken its properties and pulling force.

Do not drill into magnets

Fire warning: Neodymium dust is highly flammable. Avoid machining magnets without safety gear as this may cause fire.

Danger to the youngest

Only for adults. Small elements can be swallowed, leading to intestinal necrosis. Keep out of reach of kids and pets.

![UMH 48x11x65 [M6] / N38 - magnetic holder with hook UMH 48x11x65 [M6] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-48x11x65-m6-wiw.jpg)

![SM 25x350 [2xM8] / N52 - magnetic separator SM 25x350 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x350-2xm8-geb.jpg)