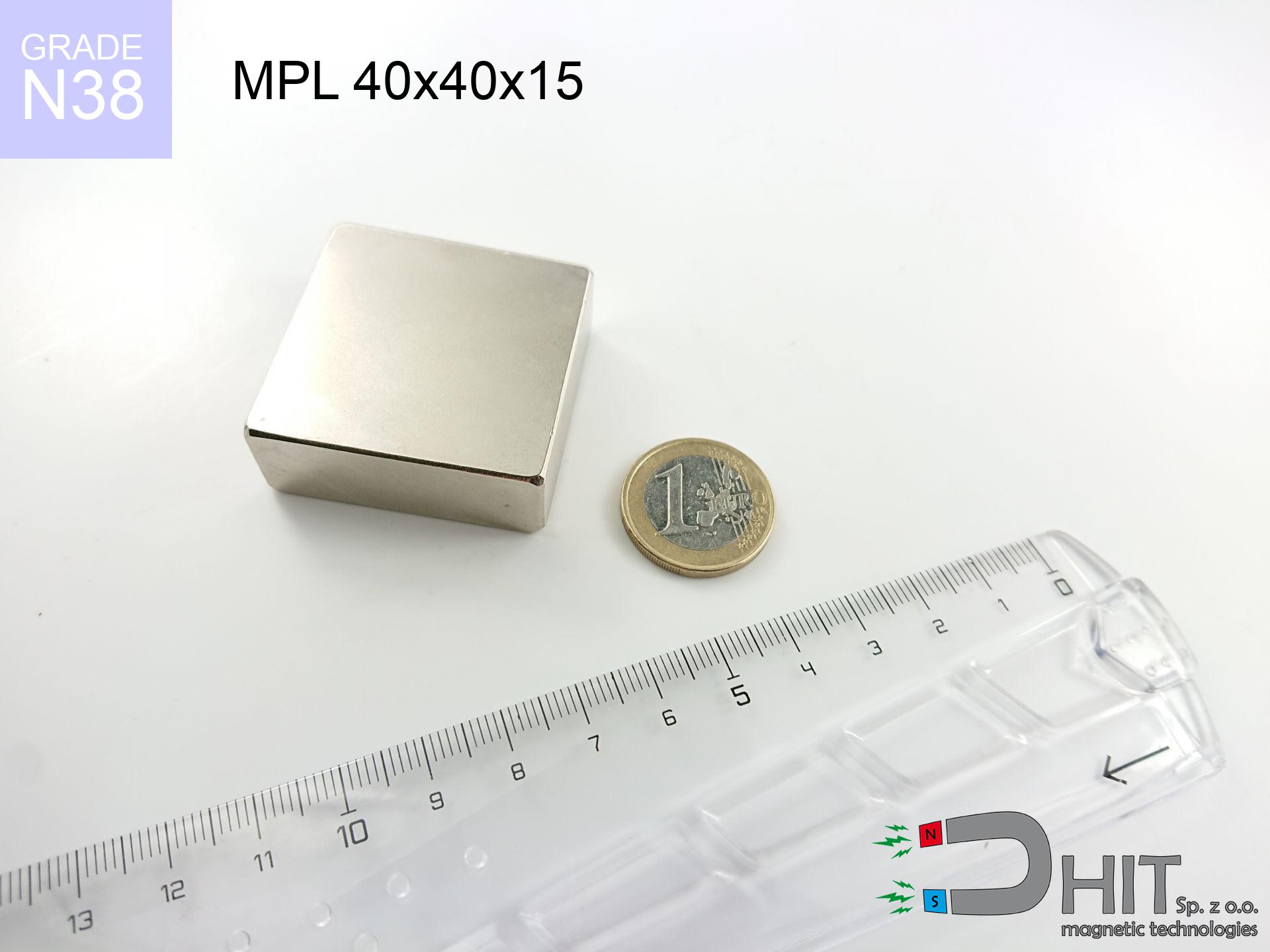

MPL 40x40x15 / N38 - lamellar magnet

lamellar magnet

Catalog no 020161

GTIN/EAN: 5906301811671

length

40 mm [±0,1 mm]

Width

40 mm [±0,1 mm]

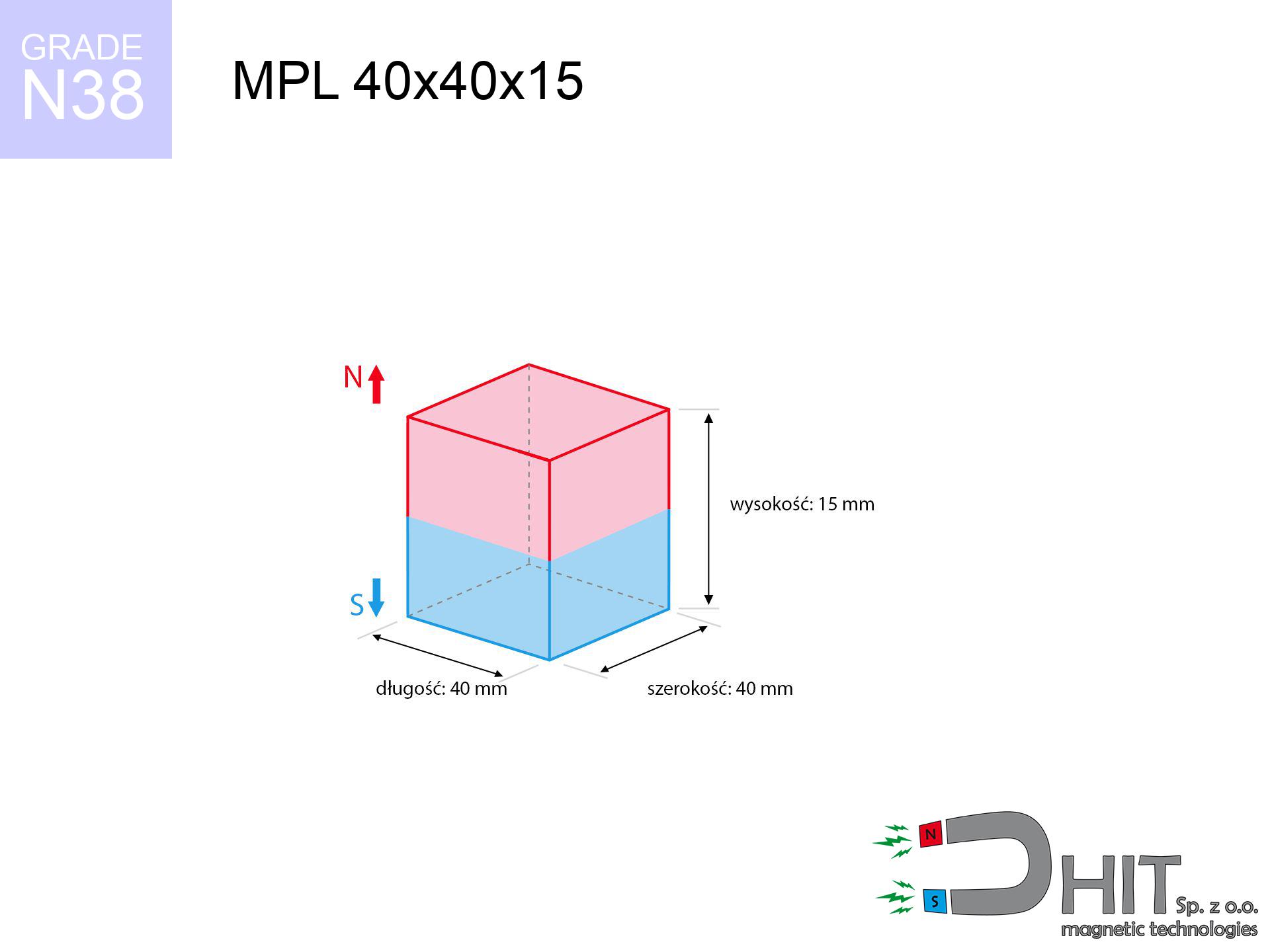

Height

15 mm [±0,1 mm]

Weight

180 g

Magnetization Direction

↑ axial

Load capacity

46.94 kg / 460.51 N

Magnetic Induction

345.80 mT / 3458 Gs

Coating

[NiCuNi] Nickel

55.37 ZŁ with VAT / pcs + price for transport

45.02 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

or contact us through

our online form

the contact page.

Lifting power as well as shape of a neodymium magnet can be tested on our

magnetic calculator.

Same-day shipping for orders placed before 14:00.

Technical data of the product - MPL 40x40x15 / N38 - lamellar magnet

Specification / characteristics - MPL 40x40x15 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020161 |

| GTIN/EAN | 5906301811671 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 40 mm [±0,1 mm] |

| Width | 40 mm [±0,1 mm] |

| Height | 15 mm [±0,1 mm] |

| Weight | 180 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 46.94 kg / 460.51 N |

| Magnetic Induction ~ ? | 345.80 mT / 3458 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical analysis of the magnet - report

These data constitute the direct effect of a engineering analysis. Values rely on algorithms for the class Nd2Fe14B. Operational parameters may differ from theoretical values. Please consider these calculations as a preliminary roadmap when designing systems.

Table 1: Static pull force (force vs distance) - power drop

MPL 40x40x15 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3458 Gs

345.8 mT

|

46.94 kg / 103.48 pounds

46940.0 g / 460.5 N

|

crushing |

| 1 mm |

3333 Gs

333.3 mT

|

43.62 kg / 96.16 pounds

43616.1 g / 427.9 N

|

crushing |

| 2 mm |

3199 Gs

319.9 mT

|

40.19 kg / 88.60 pounds

40189.1 g / 394.3 N

|

crushing |

| 3 mm |

3060 Gs

306.0 mT

|

36.77 kg / 81.06 pounds

36767.3 g / 360.7 N

|

crushing |

| 5 mm |

2773 Gs

277.3 mT

|

30.19 kg / 66.55 pounds

30187.9 g / 296.1 N

|

crushing |

| 10 mm |

2078 Gs

207.8 mT

|

16.95 kg / 37.37 pounds

16950.2 g / 166.3 N

|

crushing |

| 15 mm |

1507 Gs

150.7 mT

|

8.91 kg / 19.65 pounds

8913.7 g / 87.4 N

|

warning |

| 20 mm |

1085 Gs

108.5 mT

|

4.62 kg / 10.19 pounds

4622.3 g / 45.3 N

|

warning |

| 30 mm |

580 Gs

58.0 mT

|

1.32 kg / 2.92 pounds

1322.9 g / 13.0 N

|

safe |

| 50 mm |

204 Gs

20.4 mT

|

0.16 kg / 0.36 pounds

164.0 g / 1.6 N

|

safe |

Table 2: Sliding hold (wall)

MPL 40x40x15 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

9.39 kg / 20.70 pounds

9388.0 g / 92.1 N

|

| 1 mm | Stal (~0.2) |

8.72 kg / 19.23 pounds

8724.0 g / 85.6 N

|

| 2 mm | Stal (~0.2) |

8.04 kg / 17.72 pounds

8038.0 g / 78.9 N

|

| 3 mm | Stal (~0.2) |

7.35 kg / 16.21 pounds

7354.0 g / 72.1 N

|

| 5 mm | Stal (~0.2) |

6.04 kg / 13.31 pounds

6038.0 g / 59.2 N

|

| 10 mm | Stal (~0.2) |

3.39 kg / 7.47 pounds

3390.0 g / 33.3 N

|

| 15 mm | Stal (~0.2) |

1.78 kg / 3.93 pounds

1782.0 g / 17.5 N

|

| 20 mm | Stal (~0.2) |

0.92 kg / 2.04 pounds

924.0 g / 9.1 N

|

| 30 mm | Stal (~0.2) |

0.26 kg / 0.58 pounds

264.0 g / 2.6 N

|

| 50 mm | Stal (~0.2) |

0.03 kg / 0.07 pounds

32.0 g / 0.3 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MPL 40x40x15 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

14.08 kg / 31.05 pounds

14082.0 g / 138.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

9.39 kg / 20.70 pounds

9388.0 g / 92.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

4.69 kg / 10.35 pounds

4694.0 g / 46.0 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

23.47 kg / 51.74 pounds

23470.0 g / 230.2 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MPL 40x40x15 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

2.35 kg / 5.17 pounds

2347.0 g / 23.0 N

|

| 1 mm |

|

5.87 kg / 12.94 pounds

5867.5 g / 57.6 N

|

| 2 mm |

|

11.74 kg / 25.87 pounds

11735.0 g / 115.1 N

|

| 3 mm |

|

17.60 kg / 38.81 pounds

17602.5 g / 172.7 N

|

| 5 mm |

|

29.34 kg / 64.68 pounds

29337.5 g / 287.8 N

|

| 10 mm |

|

46.94 kg / 103.48 pounds

46940.0 g / 460.5 N

|

| 11 mm |

|

46.94 kg / 103.48 pounds

46940.0 g / 460.5 N

|

| 12 mm |

|

46.94 kg / 103.48 pounds

46940.0 g / 460.5 N

|

Table 5: Thermal stability (stability) - power drop

MPL 40x40x15 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

46.94 kg / 103.48 pounds

46940.0 g / 460.5 N

|

OK |

| 40 °C | -2.2% |

45.91 kg / 101.21 pounds

45907.3 g / 450.4 N

|

OK |

| 60 °C | -4.4% |

44.87 kg / 98.93 pounds

44874.6 g / 440.2 N

|

|

| 80 °C | -6.6% |

43.84 kg / 96.65 pounds

43842.0 g / 430.1 N

|

|

| 100 °C | -28.8% |

33.42 kg / 73.68 pounds

33421.3 g / 327.9 N

|

Table 6: Magnet-Magnet interaction (attraction) - field range

MPL 40x40x15 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

117.92 kg / 259.97 pounds

4 963 Gs

|

17.69 kg / 39.00 pounds

17688 g / 173.5 N

|

N/A |

| 1 mm |

113.82 kg / 250.94 pounds

6 794 Gs

|

17.07 kg / 37.64 pounds

17074 g / 167.5 N

|

102.44 kg / 225.84 pounds

~0 Gs

|

| 2 mm |

109.57 kg / 241.57 pounds

6 666 Gs

|

16.44 kg / 36.23 pounds

16436 g / 161.2 N

|

98.62 kg / 217.41 pounds

~0 Gs

|

| 3 mm |

105.28 kg / 232.10 pounds

6 534 Gs

|

15.79 kg / 34.81 pounds

15792 g / 154.9 N

|

94.75 kg / 208.89 pounds

~0 Gs

|

| 5 mm |

96.65 kg / 213.08 pounds

6 261 Gs

|

14.50 kg / 31.96 pounds

14498 g / 142.2 N

|

86.99 kg / 191.77 pounds

~0 Gs

|

| 10 mm |

75.84 kg / 167.19 pounds

5 546 Gs

|

11.38 kg / 25.08 pounds

11376 g / 111.6 N

|

68.25 kg / 150.47 pounds

~0 Gs

|

| 20 mm |

42.58 kg / 93.88 pounds

4 155 Gs

|

6.39 kg / 14.08 pounds

6387 g / 62.7 N

|

38.32 kg / 84.49 pounds

~0 Gs

|

| 50 mm |

6.12 kg / 13.49 pounds

1 575 Gs

|

0.92 kg / 2.02 pounds

918 g / 9.0 N

|

5.51 kg / 12.14 pounds

~0 Gs

|

| 60 mm |

3.32 kg / 7.33 pounds

1 161 Gs

|

0.50 kg / 1.10 pounds

499 g / 4.9 N

|

2.99 kg / 6.59 pounds

~0 Gs

|

| 70 mm |

1.87 kg / 4.12 pounds

871 Gs

|

0.28 kg / 0.62 pounds

281 g / 2.8 N

|

1.68 kg / 3.71 pounds

~0 Gs

|

| 80 mm |

1.09 kg / 2.41 pounds

665 Gs

|

0.16 kg / 0.36 pounds

164 g / 1.6 N

|

0.98 kg / 2.17 pounds

~0 Gs

|

| 90 mm |

0.66 kg / 1.46 pounds

517 Gs

|

0.10 kg / 0.22 pounds

99 g / 1.0 N

|

0.59 kg / 1.31 pounds

~0 Gs

|

| 100 mm |

0.41 kg / 0.91 pounds

409 Gs

|

0.06 kg / 0.14 pounds

62 g / 0.6 N

|

0.37 kg / 0.82 pounds

~0 Gs

|

Table 7: Protective zones (implants) - warnings

MPL 40x40x15 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 20.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 16.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 12.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 10.0 cm |

| Remote | 50 Gs (5.0 mT) | 9.0 cm |

| Payment card | 400 Gs (40.0 mT) | 4.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 3.0 cm |

Table 8: Dynamics (cracking risk) - warning

MPL 40x40x15 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

19.62 km/h

(5.45 m/s)

|

2.67 J | |

| 30 mm |

28.70 km/h

(7.97 m/s)

|

5.72 J | |

| 50 mm |

36.50 km/h

(10.14 m/s)

|

9.25 J | |

| 100 mm |

51.50 km/h

(14.31 m/s)

|

18.42 J |

Table 9: Coating parameters (durability)

MPL 40x40x15 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MPL 40x40x15 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 58 107 Mx | 581.1 µWb |

| Pc Coefficient | 0.43 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MPL 40x40x15 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 46.94 kg | Standard |

| Water (riverbed) |

53.75 kg

(+6.81 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Warning: On a vertical wall, the magnet retains merely a fraction of its perpendicular strength.

2. Steel thickness impact

*Thin metal sheet (e.g. computer case) drastically reduces the holding force.

3. Temperature resistance

*For N38 grade, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.43

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Pros and cons of Nd2Fe14B magnets.

Advantages

- They do not lose power, even after approximately 10 years – the drop in power is only ~1% (theoretically),

- They retain their magnetic properties even under strong external field,

- In other words, due to the shiny layer of silver, the element gains a professional look,

- Magnets exhibit excellent magnetic induction on the surface,

- Thanks to resistance to high temperature, they are able to function (depending on the shape) even at temperatures up to 230°C and higher...

- Due to the option of free shaping and adaptation to custom projects, neodymium magnets can be created in a variety of geometric configurations, which increases their versatility,

- Significant place in modern technologies – they are utilized in mass storage devices, motor assemblies, diagnostic systems, as well as modern systems.

- Thanks to concentrated force, small magnets offer high operating force, occupying minimum space,

Disadvantages

- To avoid cracks under impact, we suggest using special steel housings. Such a solution secures the magnet and simultaneously increases its durability.

- When exposed to high temperature, neodymium magnets suffer a drop in force. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which secure oxidation as well as corrosion.

- We recommend a housing - magnetic mechanism, due to difficulties in realizing threads inside the magnet and complicated forms.

- Potential hazard to health – tiny shards of magnets are risky, if swallowed, which becomes key in the aspect of protecting the youngest. It is also worth noting that tiny parts of these magnets are able to be problematic in diagnostics medical after entering the body.

- With mass production the cost of neodymium magnets is economically unviable,

Holding force characteristics

Maximum holding power of the magnet – what it depends on?

- using a base made of high-permeability steel, serving as a magnetic yoke

- possessing a thickness of minimum 10 mm to avoid saturation

- characterized by even structure

- with zero gap (without coatings)

- for force applied at a right angle (in the magnet axis)

- at standard ambient temperature

Key elements affecting lifting force

- Gap between magnet and steel – every millimeter of separation (caused e.g. by varnish or unevenness) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Loading method – catalog parameter refers to pulling vertically. When attempting to slide, the magnet exhibits much less (often approx. 20-30% of maximum force).

- Substrate thickness – to utilize 100% power, the steel must be adequately massive. Paper-thin metal restricts the lifting capacity (the magnet "punches through" it).

- Metal type – different alloys attracts identically. High carbon content weaken the interaction with the magnet.

- Plate texture – smooth surfaces ensure maximum contact, which improves force. Uneven metal reduce efficiency.

- Temperature influence – high temperature weakens pulling force. Exceeding the limit temperature can permanently demagnetize the magnet.

Holding force was measured on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, in contrast under attempts to slide the magnet the holding force is lower. In addition, even a small distance between the magnet’s surface and the plate decreases the load capacity.

Safety rules for work with NdFeB magnets

Maximum temperature

Regular neodymium magnets (grade N) lose power when the temperature goes above 80°C. The loss of strength is permanent.

GPS and phone interference

Be aware: rare earth magnets produce a field that disrupts sensitive sensors. Maintain a separation from your phone, tablet, and GPS.

Choking Hazard

Only for adults. Small elements can be swallowed, causing serious injuries. Keep away from kids and pets.

Eye protection

Neodymium magnets are sintered ceramics, meaning they are prone to chipping. Clashing of two magnets leads to them breaking into shards.

Implant safety

Medical warning: Strong magnets can deactivate pacemakers and defibrillators. Stay away if you have medical devices.

Fire warning

Dust generated during cutting of magnets is self-igniting. Do not drill into magnets unless you are an expert.

Nickel allergy

Certain individuals experience a sensitization to nickel, which is the common plating for neodymium magnets. Extended handling may cause an allergic reaction. It is best to wear protective gloves.

Crushing risk

Pinching hazard: The attraction force is so great that it can result in hematomas, pinching, and even bone fractures. Use thick gloves.

Electronic devices

Very strong magnetic fields can corrupt files on credit cards, hard drives, and storage devices. Keep a distance of min. 10 cm.

Safe operation

Be careful. Neodymium magnets act from a distance and snap with massive power, often faster than you can move away.

![SM 25x350 [2xM8] / N52 - magnetic separator SM 25x350 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x350-2xm8-geb.jpg)