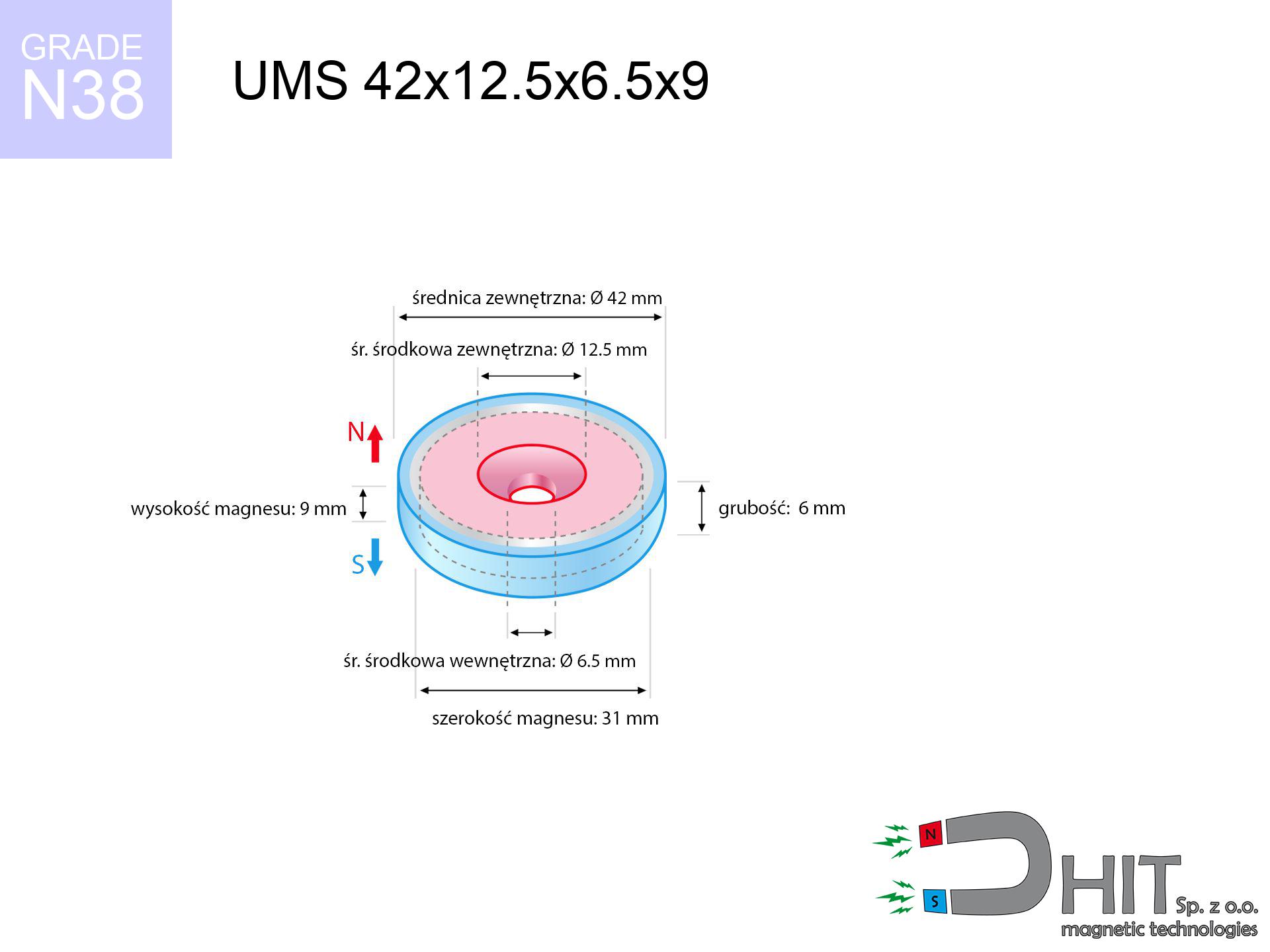

UMS 42x12.5x6.5x9 / N38 - conical magnetic holder

conical magnetic holder

Catalog no 220331

GTIN/EAN: 5906301814214

Diameter Ø

42 mm [±1 mm]

cone dimension Ø

12.5x6.5 mm [±1 mm]

Height

9 mm [±1 mm]

Weight

72 g

Magnetization Direction

↑ axial

Load capacity

37.00 kg / 362.85 N

Coating

[NiCuNi] Nickel

27.06 ZŁ with VAT / pcs + price for transport

22.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

otherwise let us know via

form

through our site.

Parameters along with form of neodymium magnets can be estimated on our

force calculator.

Same-day processing for orders placed before 14:00.

Technical of the product - UMS 42x12.5x6.5x9 / N38 - conical magnetic holder

Specification / characteristics - UMS 42x12.5x6.5x9 / N38 - conical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 220331 |

| GTIN/EAN | 5906301814214 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 42 mm [±1 mm] |

| cone dimension Ø | 12.5x6.5 mm [±1 mm] |

| Height | 9 mm [±1 mm] |

| Weight | 72 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 37.00 kg / 362.85 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more offers

Pros and cons of rare earth magnets.

Advantages

- They virtually do not lose strength, because even after ten years the performance loss is only ~1% (according to literature),

- Neodymium magnets remain exceptionally resistant to magnetic field loss caused by external field sources,

- The use of an shiny coating of noble metals (nickel, gold, silver) causes the element to be more visually attractive,

- Neodymium magnets create maximum magnetic induction on a their surface, which increases force concentration,

- Through (adequate) combination of ingredients, they can achieve high thermal resistance, allowing for functioning at temperatures approaching 230°C and above...

- Possibility of custom modeling and adjusting to concrete applications,

- Universal use in advanced technology sectors – they serve a role in mass storage devices, brushless drives, diagnostic systems, also other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in compact dimensions, which makes them useful in miniature devices

Cons

- At very strong impacts they can crack, therefore we advise placing them in strong housings. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- When exposed to high temperature, neodymium magnets experience a drop in force. Often, when the temperature exceeds 80°C, their power decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material stable to moisture, in case of application outdoors

- Limited possibility of creating nuts in the magnet and complicated shapes - preferred is a housing - magnetic holder.

- Possible danger related to microscopic parts of magnets can be dangerous, when accidentally swallowed, which is particularly important in the context of child safety. Furthermore, tiny parts of these devices can be problematic in diagnostics medical in case of swallowing.

- With budget limitations the cost of neodymium magnets can be a barrier,

Pull force analysis

Optimal lifting capacity of a neodymium magnet – what affects it?

- using a plate made of low-carbon steel, acting as a circuit closing element

- whose transverse dimension equals approx. 10 mm

- characterized by smoothness

- without any air gap between the magnet and steel

- under perpendicular application of breakaway force (90-degree angle)

- at conditions approx. 20°C

Determinants of practical lifting force of a magnet

- Gap between surfaces – even a fraction of a millimeter of separation (caused e.g. by veneer or dirt) diminishes the magnet efficiency, often by half at just 0.5 mm.

- Force direction – declared lifting capacity refers to pulling vertically. When attempting to slide, the magnet holds significantly lower power (often approx. 20-30% of maximum force).

- Metal thickness – thin material does not allow full use of the magnet. Magnetic flux passes through the material instead of generating force.

- Steel grade – ideal substrate is pure iron steel. Hardened steels may attract less.

- Surface finish – ideal contact is obtained only on smooth steel. Rough texture reduce the real contact area, weakening the magnet.

- Operating temperature – neodymium magnets have a negative temperature coefficient. At higher temperatures they are weaker, and at low temperatures gain strength (up to a certain limit).

Holding force was checked on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, however under parallel forces the lifting capacity is smaller. In addition, even a small distance between the magnet’s surface and the plate decreases the lifting capacity.

Safe handling of NdFeB magnets

Safe distance

Data protection: Strong magnets can damage payment cards and sensitive devices (heart implants, medical aids, mechanical watches).

Handling rules

Handle with care. Neodymium magnets act from a long distance and snap with massive power, often faster than you can move away.

Hand protection

Danger of trauma: The attraction force is so great that it can cause hematomas, crushing, and even bone fractures. Protective gloves are recommended.

Do not give to children

Strictly keep magnets out of reach of children. Choking hazard is high, and the consequences of magnets clamping inside the body are life-threatening.

Protective goggles

Beware of splinters. Magnets can fracture upon uncontrolled impact, ejecting sharp fragments into the air. Wear goggles.

Implant safety

Patients with a heart stimulator have to maintain an large gap from magnets. The magnetism can interfere with the functioning of the life-saving device.

Warning for allergy sufferers

Studies show that nickel (the usual finish) is a potent allergen. For allergy sufferers, refrain from direct skin contact and choose encased magnets.

Fire risk

Machining of neodymium magnets poses a fire risk. Magnetic powder oxidizes rapidly with oxygen and is hard to extinguish.

Threat to navigation

GPS units and smartphones are highly sensitive to magnetic fields. Direct contact with a powerful NdFeB magnet can ruin the internal compass in your phone.

Permanent damage

Standard neodymium magnets (grade N) lose magnetization when the temperature surpasses 80°C. This process is irreversible.