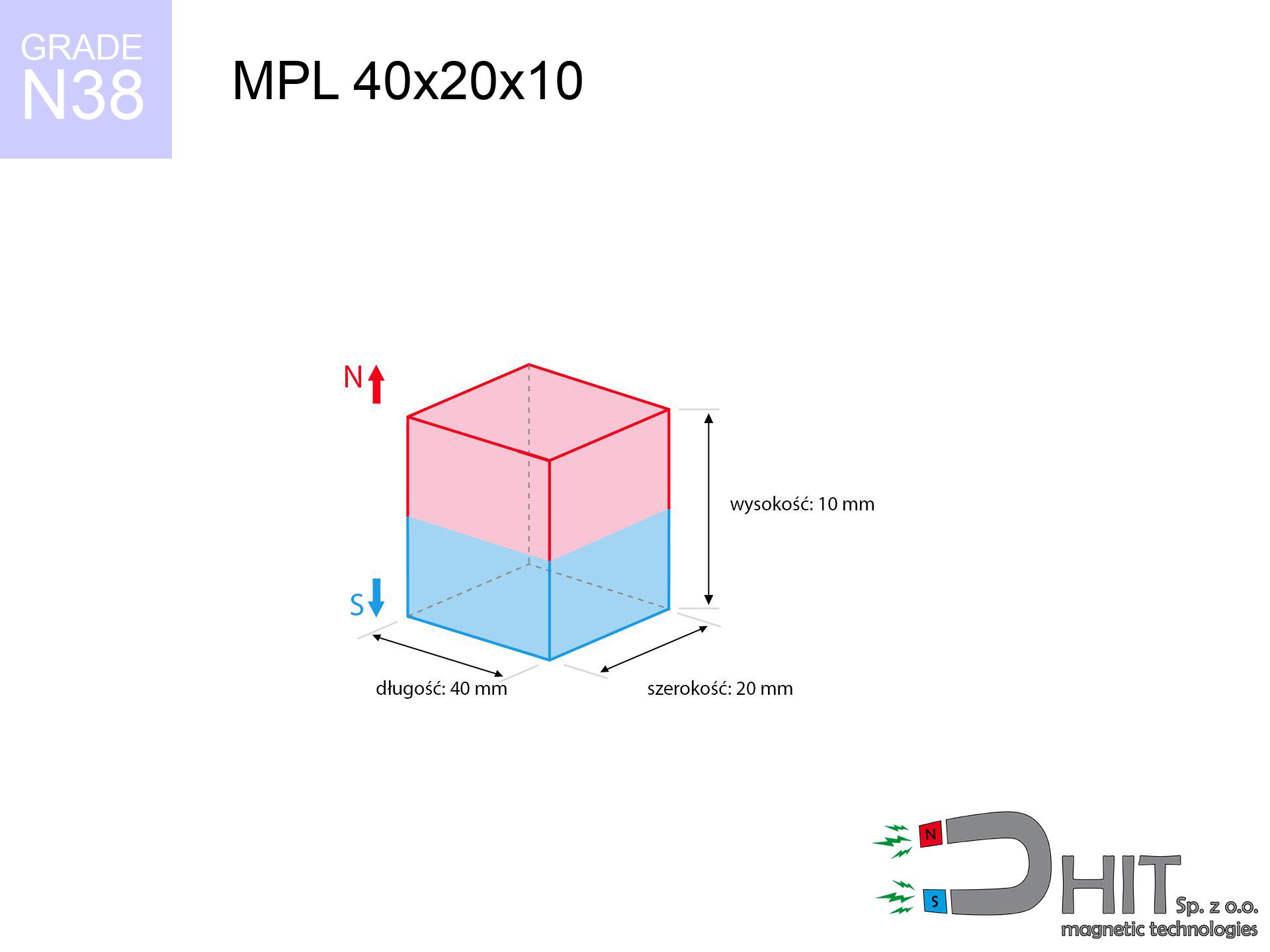

MPL 40x20x10 / N38 - lamellar magnet

lamellar magnet

Catalog no 020158

GTIN/EAN: 5906301811640

length

40 mm [±0,1 mm]

Width

20 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

60 g

Magnetization Direction

↑ axial

Load capacity

24.62 kg / 241.53 N

Magnetic Induction

349.60 mT / 3496 Gs

Coating

[NiCuNi] Nickel

31.00 ZŁ with VAT / pcs + price for transport

25.20 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

alternatively drop us a message through

inquiry form

our website.

Force and structure of neodymium magnets can be tested using our

our magnetic calculator.

Orders placed before 14:00 will be shipped the same business day.

Product card - MPL 40x20x10 / N38 - lamellar magnet

Specification / characteristics - MPL 40x20x10 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020158 |

| GTIN/EAN | 5906301811640 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 40 mm [±0,1 mm] |

| Width | 20 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 60 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 24.62 kg / 241.53 N |

| Magnetic Induction ~ ? | 349.60 mT / 3496 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the product - technical parameters

The following values constitute the outcome of a mathematical analysis. Results are based on models for the material Nd2Fe14B. Actual parameters may deviate from the simulation results. Please consider these calculations as a supplementary guide for designers.

Table 1: Static force (force vs gap) - interaction chart

MPL 40x20x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3495 Gs

349.5 mT

|

24.62 kg / 54.28 lbs

24620.0 g / 241.5 N

|

crushing |

| 1 mm |

3272 Gs

327.2 mT

|

21.58 kg / 47.57 lbs

21578.0 g / 211.7 N

|

crushing |

| 2 mm |

3035 Gs

303.5 mT

|

18.56 kg / 40.92 lbs

18559.3 g / 182.1 N

|

crushing |

| 3 mm |

2794 Gs

279.4 mT

|

15.73 kg / 34.69 lbs

15733.0 g / 154.3 N

|

crushing |

| 5 mm |

2332 Gs

233.2 mT

|

10.96 kg / 24.16 lbs

10959.2 g / 107.5 N

|

crushing |

| 10 mm |

1433 Gs

143.3 mT

|

4.14 kg / 9.12 lbs

4136.4 g / 40.6 N

|

medium risk |

| 15 mm |

891 Gs

89.1 mT

|

1.60 kg / 3.52 lbs

1598.7 g / 15.7 N

|

weak grip |

| 20 mm |

574 Gs

57.4 mT

|

0.66 kg / 1.46 lbs

664.0 g / 6.5 N

|

weak grip |

| 30 mm |

267 Gs

26.7 mT

|

0.14 kg / 0.32 lbs

143.7 g / 1.4 N

|

weak grip |

| 50 mm |

82 Gs

8.2 mT

|

0.01 kg / 0.03 lbs

13.7 g / 0.1 N

|

weak grip |

Table 2: Shear load (wall)

MPL 40x20x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

4.92 kg / 10.86 lbs

4924.0 g / 48.3 N

|

| 1 mm | Stal (~0.2) |

4.32 kg / 9.52 lbs

4316.0 g / 42.3 N

|

| 2 mm | Stal (~0.2) |

3.71 kg / 8.18 lbs

3712.0 g / 36.4 N

|

| 3 mm | Stal (~0.2) |

3.15 kg / 6.94 lbs

3146.0 g / 30.9 N

|

| 5 mm | Stal (~0.2) |

2.19 kg / 4.83 lbs

2192.0 g / 21.5 N

|

| 10 mm | Stal (~0.2) |

0.83 kg / 1.83 lbs

828.0 g / 8.1 N

|

| 15 mm | Stal (~0.2) |

0.32 kg / 0.71 lbs

320.0 g / 3.1 N

|

| 20 mm | Stal (~0.2) |

0.13 kg / 0.29 lbs

132.0 g / 1.3 N

|

| 30 mm | Stal (~0.2) |

0.03 kg / 0.06 lbs

28.0 g / 0.3 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MPL 40x20x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

7.39 kg / 16.28 lbs

7386.0 g / 72.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

4.92 kg / 10.86 lbs

4924.0 g / 48.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

2.46 kg / 5.43 lbs

2462.0 g / 24.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

12.31 kg / 27.14 lbs

12310.0 g / 120.8 N

|

Table 4: Material efficiency (saturation) - power losses

MPL 40x20x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.23 kg / 2.71 lbs

1231.0 g / 12.1 N

|

| 1 mm |

|

3.08 kg / 6.78 lbs

3077.5 g / 30.2 N

|

| 2 mm |

|

6.16 kg / 13.57 lbs

6155.0 g / 60.4 N

|

| 3 mm |

|

9.23 kg / 20.35 lbs

9232.5 g / 90.6 N

|

| 5 mm |

|

15.39 kg / 33.92 lbs

15387.5 g / 151.0 N

|

| 10 mm |

|

24.62 kg / 54.28 lbs

24620.0 g / 241.5 N

|

| 11 mm |

|

24.62 kg / 54.28 lbs

24620.0 g / 241.5 N

|

| 12 mm |

|

24.62 kg / 54.28 lbs

24620.0 g / 241.5 N

|

Table 5: Thermal resistance (material behavior) - thermal limit

MPL 40x20x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

24.62 kg / 54.28 lbs

24620.0 g / 241.5 N

|

OK |

| 40 °C | -2.2% |

24.08 kg / 53.08 lbs

24078.4 g / 236.2 N

|

OK |

| 60 °C | -4.4% |

23.54 kg / 51.89 lbs

23536.7 g / 230.9 N

|

|

| 80 °C | -6.6% |

23.00 kg / 50.70 lbs

22995.1 g / 225.6 N

|

|

| 100 °C | -28.8% |

17.53 kg / 38.65 lbs

17529.4 g / 172.0 N

|

Table 6: Two magnets (repulsion) - forces in the system

MPL 40x20x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

60.25 kg / 132.83 lbs

4 926 Gs

|

9.04 kg / 19.93 lbs

9038 g / 88.7 N

|

N/A |

| 1 mm |

56.58 kg / 124.73 lbs

6 774 Gs

|

8.49 kg / 18.71 lbs

8487 g / 83.3 N

|

50.92 kg / 112.26 lbs

~0 Gs

|

| 2 mm |

52.81 kg / 116.42 lbs

6 544 Gs

|

7.92 kg / 17.46 lbs

7921 g / 77.7 N

|

47.53 kg / 104.78 lbs

~0 Gs

|

| 3 mm |

49.07 kg / 108.19 lbs

6 309 Gs

|

7.36 kg / 16.23 lbs

7361 g / 72.2 N

|

44.17 kg / 97.37 lbs

~0 Gs

|

| 5 mm |

41.89 kg / 92.34 lbs

5 828 Gs

|

6.28 kg / 13.85 lbs

6283 g / 61.6 N

|

37.70 kg / 83.11 lbs

~0 Gs

|

| 10 mm |

26.82 kg / 59.13 lbs

4 664 Gs

|

4.02 kg / 8.87 lbs

4023 g / 39.5 N

|

24.14 kg / 53.22 lbs

~0 Gs

|

| 20 mm |

10.12 kg / 22.32 lbs

2 865 Gs

|

1.52 kg / 3.35 lbs

1518 g / 14.9 N

|

9.11 kg / 20.09 lbs

~0 Gs

|

| 50 mm |

0.73 kg / 1.61 lbs

769 Gs

|

0.11 kg / 0.24 lbs

109 g / 1.1 N

|

0.66 kg / 1.45 lbs

~0 Gs

|

| 60 mm |

0.35 kg / 0.78 lbs

534 Gs

|

0.05 kg / 0.12 lbs

53 g / 0.5 N

|

0.32 kg / 0.70 lbs

~0 Gs

|

| 70 mm |

0.18 kg / 0.40 lbs

383 Gs

|

0.03 kg / 0.06 lbs

27 g / 0.3 N

|

0.16 kg / 0.36 lbs

~0 Gs

|

| 80 mm |

0.10 kg / 0.22 lbs

282 Gs

|

0.01 kg / 0.03 lbs

15 g / 0.1 N

|

0.09 kg / 0.20 lbs

~0 Gs

|

| 90 mm |

0.06 kg / 0.12 lbs

214 Gs

|

0.01 kg / 0.02 lbs

8 g / 0.1 N

|

0.05 kg / 0.11 lbs

~0 Gs

|

| 100 mm |

0.03 kg / 0.07 lbs

165 Gs

|

0.01 kg / 0.01 lbs

5 g / 0.0 N

|

0.03 kg / 0.07 lbs

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MPL 40x20x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 14.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 11.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 9.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 7.0 cm |

| Remote | 50 Gs (5.0 mT) | 6.5 cm |

| Payment card | 400 Gs (40.0 mT) | 2.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.0 cm |

Table 8: Dynamics (kinetic energy) - warning

MPL 40x20x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.47 km/h

(6.24 m/s)

|

1.17 J | |

| 30 mm |

35.51 km/h

(9.86 m/s)

|

2.92 J | |

| 50 mm |

45.70 km/h

(12.69 m/s)

|

4.83 J | |

| 100 mm |

64.60 km/h

(17.95 m/s)

|

9.66 J |

Table 9: Surface protection spec

MPL 40x20x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MPL 40x20x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 28 125 Mx | 281.2 µWb |

| Pc Coefficient | 0.42 | Low (Flat) |

Table 11: Submerged application

MPL 40x20x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 24.62 kg | Standard |

| Water (riverbed) |

28.19 kg

(+3.57 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Note: On a vertical wall, the magnet retains merely a fraction of its perpendicular strength.

2. Steel saturation

*Thin metal sheet (e.g. 0.5mm PC case) drastically reduces the holding force.

3. Heat tolerance

*For N38 grade, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.42

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Strengths as well as weaknesses of Nd2Fe14B magnets.

Benefits

- They have unchanged lifting capacity, and over more than 10 years their attraction force decreases symbolically – ~1% (according to theory),

- Neodymium magnets are characterized by highly resistant to magnetic field loss caused by external magnetic fields,

- In other words, due to the glossy finish of nickel, the element is aesthetically pleasing,

- Magnetic induction on the surface of the magnet turns out to be extremely intense,

- Thanks to resistance to high temperature, they are capable of working (depending on the shape) even at temperatures up to 230°C and higher...

- Considering the ability of precise molding and adaptation to unique needs, neodymium magnets can be produced in a wide range of shapes and sizes, which makes them more universal,

- Universal use in advanced technology sectors – they are commonly used in computer drives, motor assemblies, diagnostic systems, as well as complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in tiny dimensions, which allows their use in small systems

Disadvantages

- To avoid cracks under impact, we recommend using special steel holders. Such a solution protects the magnet and simultaneously improves its durability.

- Neodymium magnets decrease their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- When exposed to humidity, magnets start to rust. For applications outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which prevent oxidation and corrosion.

- Due to limitations in realizing threads and complicated forms in magnets, we propose using casing - magnetic holder.

- Possible danger resulting from small fragments of magnets are risky, in case of ingestion, which is particularly important in the context of child health protection. Furthermore, small elements of these products are able to disrupt the diagnostic process medical when they are in the body.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Pull force analysis

Magnetic strength at its maximum – what it depends on?

- with the use of a yoke made of special test steel, ensuring maximum field concentration

- whose transverse dimension reaches at least 10 mm

- with a surface perfectly flat

- without the slightest air gap between the magnet and steel

- under vertical application of breakaway force (90-degree angle)

- in neutral thermal conditions

Lifting capacity in practice – influencing factors

- Clearance – existence of foreign body (paint, tape, gap) acts as an insulator, which reduces capacity rapidly (even by 50% at 0.5 mm).

- Angle of force application – highest force is obtained only during perpendicular pulling. The resistance to sliding of the magnet along the plate is usually several times smaller (approx. 1/5 of the lifting capacity).

- Plate thickness – insufficiently thick sheet does not close the flux, causing part of the flux to be escaped into the air.

- Metal type – not every steel reacts the same. High carbon content weaken the interaction with the magnet.

- Smoothness – ideal contact is possible only on smooth steel. Any scratches and bumps create air cushions, weakening the magnet.

- Thermal factor – hot environment reduces magnetic field. Exceeding the limit temperature can permanently damage the magnet.

Holding force was measured on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, in contrast under attempts to slide the magnet the lifting capacity is smaller. In addition, even a slight gap between the magnet and the plate reduces the holding force.

Warnings

Allergic reactions

It is widely known that the nickel plating (the usual finish) is a potent allergen. If you have an allergy, avoid touching magnets with bare hands or choose versions in plastic housing.

Data carriers

Device Safety: Neodymium magnets can ruin data carriers and sensitive devices (pacemakers, hearing aids, timepieces).

Choking Hazard

Absolutely keep magnets away from children. Choking hazard is significant, and the consequences of magnets connecting inside the body are very dangerous.

Heat sensitivity

Monitor thermal conditions. Heating the magnet to high heat will destroy its properties and pulling force.

Do not drill into magnets

Drilling and cutting of neodymium magnets carries a risk of fire hazard. Neodymium dust reacts violently with oxygen and is hard to extinguish.

Precision electronics

Be aware: neodymium magnets produce a field that confuses precision electronics. Keep a safe distance from your mobile, device, and navigation systems.

Magnets are brittle

NdFeB magnets are sintered ceramics, meaning they are very brittle. Collision of two magnets leads to them cracking into shards.

Safe operation

Use magnets consciously. Their huge power can surprise even professionals. Stay alert and respect their power.

Crushing risk

Big blocks can crush fingers instantly. Do not put your hand betwixt two attracting surfaces.

Medical interference

Warning for patients: Strong magnetic fields affect medical devices. Keep minimum 30 cm distance or ask another person to work with the magnets.

![SM 25x375 [2xM8] / N42 - magnetic separator SM 25x375 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x375-2xm8-feg.jpg)

![UMH 16x5x32 [M4] / N38 - magnetic holder with hook UMH 16x5x32 [M4] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-16x5x32-m4-lak.jpg)