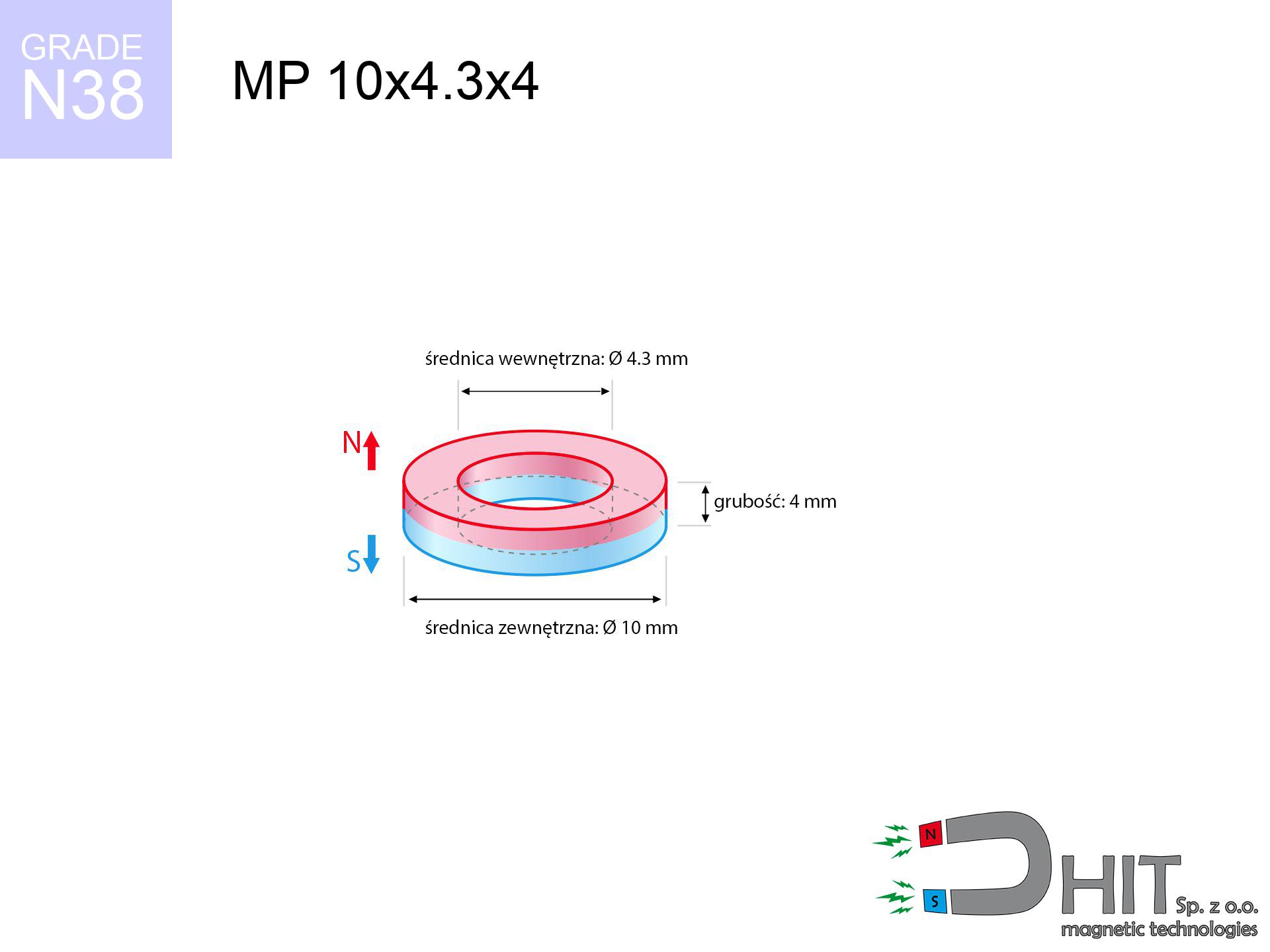

MP 10x4.3x4 / N38 - ring magnet

ring magnet

Catalog no 030178

GTIN/EAN: 5906301811954

Diameter

10 mm [±0,1 mm]

internal diameter Ø

4.3 mm [±0,1 mm]

Height

4 mm [±0,1 mm]

Weight

1.92 g

Magnetization Direction

↑ axial

Load capacity

2.28 kg / 22.35 N

Magnetic Induction

386.91 mT / 3869 Gs

Coating

[NiCuNi] Nickel

1.045 ZŁ with VAT / pcs + price for transport

0.850 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

if you prefer let us know through

inquiry form

the contact form page.

Parameters along with structure of magnetic components can be reviewed on our

online calculation tool.

Orders submitted before 14:00 will be dispatched today!

Technical data - MP 10x4.3x4 / N38 - ring magnet

Specification / characteristics - MP 10x4.3x4 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030178 |

| GTIN/EAN | 5906301811954 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 10 mm [±0,1 mm] |

| internal diameter Ø | 4.3 mm [±0,1 mm] |

| Height | 4 mm [±0,1 mm] |

| Weight | 1.92 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.28 kg / 22.35 N |

| Magnetic Induction ~ ? | 386.91 mT / 3869 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the assembly - data

Presented values represent the direct effect of a mathematical analysis. Results rely on models for the material Nd2Fe14B. Real-world performance may differ from theoretical values. Please consider these calculations as a preliminary roadmap when designing systems.

Table 1: Static force (force vs gap) - interaction chart

MP 10x4.3x4 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

6115 Gs

611.5 mT

|

2.28 kg / 5.03 lbs

2280.0 g / 22.4 N

|

medium risk |

| 1 mm |

4915 Gs

491.5 mT

|

1.47 kg / 3.25 lbs

1473.3 g / 14.5 N

|

low risk |

| 2 mm |

3833 Gs

383.3 mT

|

0.90 kg / 1.97 lbs

895.7 g / 8.8 N

|

low risk |

| 3 mm |

2949 Gs

294.9 mT

|

0.53 kg / 1.17 lbs

530.3 g / 5.2 N

|

low risk |

| 5 mm |

1761 Gs

176.1 mT

|

0.19 kg / 0.42 lbs

189.1 g / 1.9 N

|

low risk |

| 10 mm |

612 Gs

61.2 mT

|

0.02 kg / 0.05 lbs

22.8 g / 0.2 N

|

low risk |

| 15 mm |

284 Gs

28.4 mT

|

0.00 kg / 0.01 lbs

4.9 g / 0.0 N

|

low risk |

| 20 mm |

157 Gs

15.7 mT

|

0.00 kg / 0.00 lbs

1.5 g / 0.0 N

|

low risk |

| 30 mm |

64 Gs

6.4 mT

|

0.00 kg / 0.00 lbs

0.3 g / 0.0 N

|

low risk |

| 50 mm |

19 Gs

1.9 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

low risk |

Table 2: Shear force (wall)

MP 10x4.3x4 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.46 kg / 1.01 lbs

456.0 g / 4.5 N

|

| 1 mm | Stal (~0.2) |

0.29 kg / 0.65 lbs

294.0 g / 2.9 N

|

| 2 mm | Stal (~0.2) |

0.18 kg / 0.40 lbs

180.0 g / 1.8 N

|

| 3 mm | Stal (~0.2) |

0.11 kg / 0.23 lbs

106.0 g / 1.0 N

|

| 5 mm | Stal (~0.2) |

0.04 kg / 0.08 lbs

38.0 g / 0.4 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MP 10x4.3x4 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.68 kg / 1.51 lbs

684.0 g / 6.7 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.46 kg / 1.01 lbs

456.0 g / 4.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.23 kg / 0.50 lbs

228.0 g / 2.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.14 kg / 2.51 lbs

1140.0 g / 11.2 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MP 10x4.3x4 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.23 kg / 0.50 lbs

228.0 g / 2.2 N

|

| 1 mm |

|

0.57 kg / 1.26 lbs

570.0 g / 5.6 N

|

| 2 mm |

|

1.14 kg / 2.51 lbs

1140.0 g / 11.2 N

|

| 3 mm |

|

1.71 kg / 3.77 lbs

1710.0 g / 16.8 N

|

| 5 mm |

|

2.28 kg / 5.03 lbs

2280.0 g / 22.4 N

|

| 10 mm |

|

2.28 kg / 5.03 lbs

2280.0 g / 22.4 N

|

| 11 mm |

|

2.28 kg / 5.03 lbs

2280.0 g / 22.4 N

|

| 12 mm |

|

2.28 kg / 5.03 lbs

2280.0 g / 22.4 N

|

Table 5: Thermal resistance (stability) - power drop

MP 10x4.3x4 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.28 kg / 5.03 lbs

2280.0 g / 22.4 N

|

OK |

| 40 °C | -2.2% |

2.23 kg / 4.92 lbs

2229.8 g / 21.9 N

|

OK |

| 60 °C | -4.4% |

2.18 kg / 4.81 lbs

2179.7 g / 21.4 N

|

OK |

| 80 °C | -6.6% |

2.13 kg / 4.69 lbs

2129.5 g / 20.9 N

|

|

| 100 °C | -28.8% |

1.62 kg / 3.58 lbs

1623.4 g / 15.9 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MP 10x4.3x4 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

12.93 kg / 28.50 lbs

6 169 Gs

|

1.94 kg / 4.27 lbs

1939 g / 19.0 N

|

N/A |

| 1 mm |

10.50 kg / 23.16 lbs

11 025 Gs

|

1.58 kg / 3.47 lbs

1576 g / 15.5 N

|

9.45 kg / 20.84 lbs

~0 Gs

|

| 2 mm |

8.35 kg / 18.41 lbs

9 831 Gs

|

1.25 kg / 2.76 lbs

1253 g / 12.3 N

|

7.52 kg / 16.57 lbs

~0 Gs

|

| 3 mm |

6.55 kg / 14.43 lbs

8 703 Gs

|

0.98 kg / 2.17 lbs

982 g / 9.6 N

|

5.89 kg / 12.99 lbs

~0 Gs

|

| 5 mm |

3.91 kg / 8.63 lbs

6 729 Gs

|

0.59 kg / 1.29 lbs

587 g / 5.8 N

|

3.52 kg / 7.76 lbs

~0 Gs

|

| 10 mm |

1.07 kg / 2.36 lbs

3 522 Gs

|

0.16 kg / 0.35 lbs

161 g / 1.6 N

|

0.96 kg / 2.13 lbs

~0 Gs

|

| 20 mm |

0.13 kg / 0.29 lbs

1 223 Gs

|

0.02 kg / 0.04 lbs

19 g / 0.2 N

|

0.12 kg / 0.26 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.01 lbs

194 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

129 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

91 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

66 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

50 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

39 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MP 10x4.3x4 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 9.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 7.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 5.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 4.0 cm |

| Remote | 50 Gs (5.0 mT) | 3.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MP 10x4.3x4 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

34.97 km/h

(9.71 m/s)

|

0.09 J | |

| 30 mm |

60.20 km/h

(16.72 m/s)

|

0.27 J | |

| 50 mm |

77.71 km/h

(21.59 m/s)

|

0.45 J | |

| 100 mm |

109.90 km/h

(30.53 m/s)

|

0.89 J |

Table 9: Coating parameters (durability)

MP 10x4.3x4 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MP 10x4.3x4 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 4 017 Mx | 40.2 µWb |

| Pc Coefficient | 1.44 | High (Stable) |

Table 11: Submerged application

MP 10x4.3x4 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.28 kg | Standard |

| Water (riverbed) |

2.61 kg

(+0.33 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Warning: On a vertical surface, the magnet holds just ~20% of its perpendicular strength.

2. Steel thickness impact

*Thin metal sheet (e.g. 0.5mm PC case) significantly limits the holding force.

3. Thermal stability

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.44

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more proposals

Pros as well as cons of neodymium magnets.

Strengths

- They retain attractive force for around ten years – the loss is just ~1% (in theory),

- Neodymium magnets prove to be remarkably resistant to demagnetization caused by external interference,

- By using a shiny coating of gold, the element has an elegant look,

- Neodymium magnets achieve maximum magnetic induction on a small area, which allows for strong attraction,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can function (depending on the shape) even at a temperature of 230°C or more...

- Thanks to freedom in shaping and the ability to adapt to complex applications,

- Versatile presence in innovative solutions – they are utilized in hard drives, electromotive mechanisms, medical devices, as well as modern systems.

- Relatively small size with high pulling force – neodymium magnets offer high power in tiny dimensions, which allows their use in compact constructions

Weaknesses

- Brittleness is one of their disadvantages. Upon strong impact they can fracture. We advise keeping them in a strong case, which not only secures them against impacts but also raises their durability

- Neodymium magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation as well as corrosion.

- Due to limitations in creating threads and complicated shapes in magnets, we recommend using casing - magnetic holder.

- Potential hazard resulting from small fragments of magnets are risky, if swallowed, which is particularly important in the aspect of protecting the youngest. Furthermore, small elements of these magnets are able to be problematic in diagnostics medical after entering the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Holding force characteristics

Magnetic strength at its maximum – what contributes to it?

- on a base made of structural steel, perfectly concentrating the magnetic flux

- possessing a thickness of minimum 10 mm to ensure full flux closure

- with a surface free of scratches

- with total lack of distance (no coatings)

- for force applied at a right angle (in the magnet axis)

- at standard ambient temperature

Practical lifting capacity: influencing factors

- Air gap (betwixt the magnet and the metal), because even a tiny clearance (e.g. 0.5 mm) leads to a drastic drop in force by up to 50% (this also applies to varnish, corrosion or dirt).

- Force direction – remember that the magnet has greatest strength perpendicularly. Under sliding down, the capacity drops significantly, often to levels of 20-30% of the maximum value.

- Base massiveness – too thin steel causes magnetic saturation, causing part of the flux to be wasted into the air.

- Material composition – different alloys reacts the same. High carbon content worsen the interaction with the magnet.

- Surface condition – ground elements ensure maximum contact, which increases force. Rough surfaces reduce efficiency.

- Temperature – heating the magnet causes a temporary drop of induction. Check the thermal limit for a given model.

Holding force was tested on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, however under shearing force the holding force is lower. Additionally, even a slight gap between the magnet and the plate decreases the load capacity.

Warnings

Safe operation

Be careful. Rare earth magnets attract from a distance and connect with huge force, often faster than you can react.

Electronic devices

Do not bring magnets near a purse, computer, or TV. The magnetic field can destroy these devices and wipe information from cards.

Magnetic interference

An intense magnetic field interferes with the operation of magnetometers in smartphones and navigation systems. Do not bring magnets near a smartphone to prevent breaking the sensors.

Skin irritation risks

Certain individuals have a contact allergy to Ni, which is the common plating for NdFeB magnets. Prolonged contact can result in dermatitis. We suggest wear protective gloves.

Warning for heart patients

Individuals with a ICD should maintain an safe separation from magnets. The magnetic field can disrupt the functioning of the life-saving device.

Protective goggles

Despite the nickel coating, the material is brittle and not impact-resistant. Avoid impacts, as the magnet may shatter into hazardous fragments.

Swallowing risk

Only for adults. Tiny parts pose a choking risk, leading to severe trauma. Store away from children and animals.

Pinching danger

Protect your hands. Two large magnets will snap together immediately with a force of massive weight, crushing everything in their path. Exercise extreme caution!

Mechanical processing

Dust created during cutting of magnets is self-igniting. Do not drill into magnets unless you are an expert.

Thermal limits

Keep cool. Neodymium magnets are sensitive to heat. If you need operation above 80°C, ask us about HT versions (H, SH, UH).

![AM ucho małe [M8] - magnetic accessories AM ucho małe [M8] - magnetic accessories](https://cdn3.dhit.pl/graphics/products/am-ucho-małe-m8-zud.jpg)

![UMP 94x40 [3xM10] GW F550 Silver Black / N52 - search holder UMP 94x40 [3xM10] GW F550 Silver Black / N52 - search holder](https://cdn3.dhit.pl/graphics/products/ump-94x40-3xm10-gw-f550-fad.jpg)