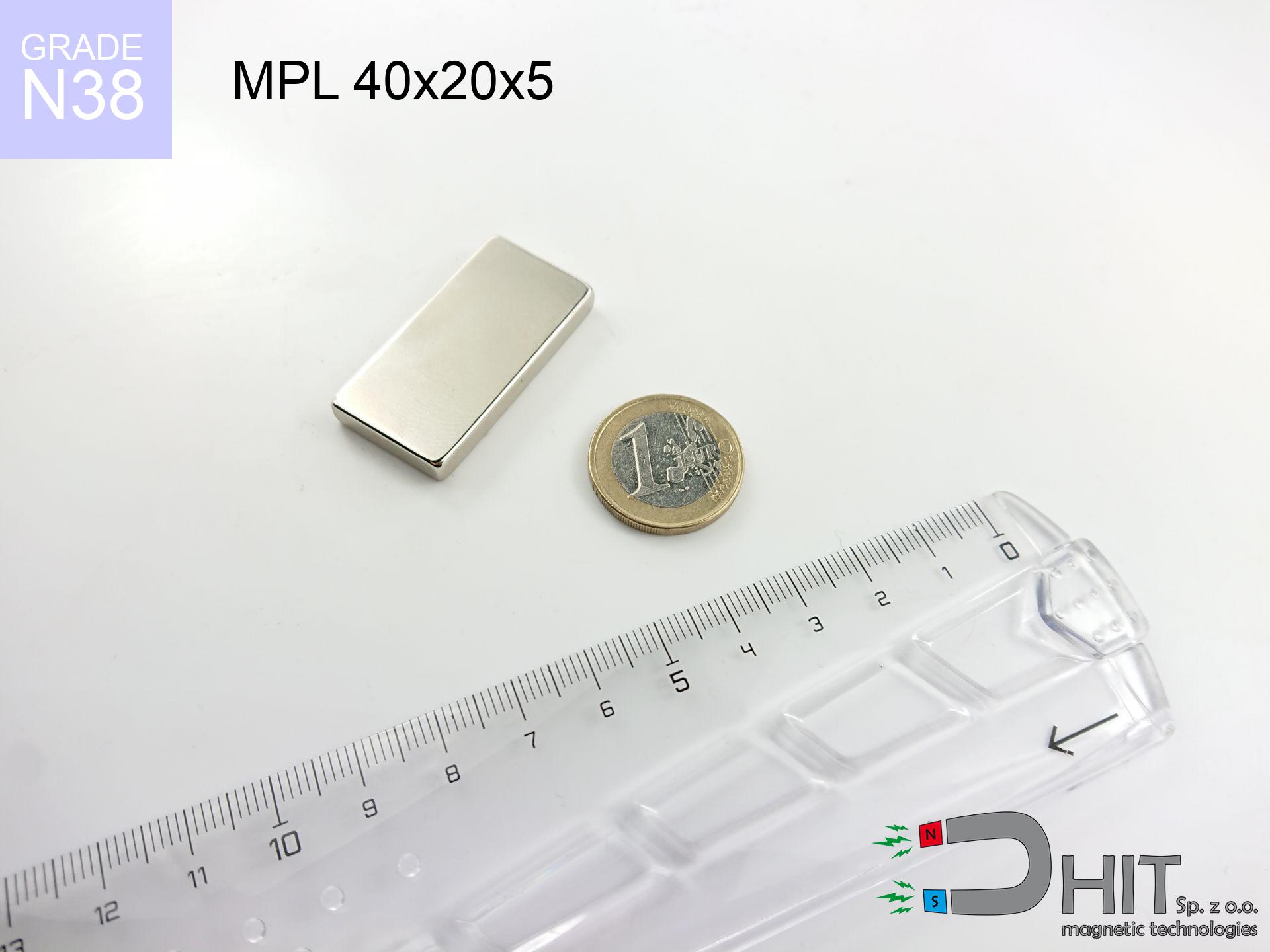

MPL 40x20x5 / N38 - lamellar magnet

lamellar magnet

Catalog no 020160

GTIN/EAN: 5906301811664

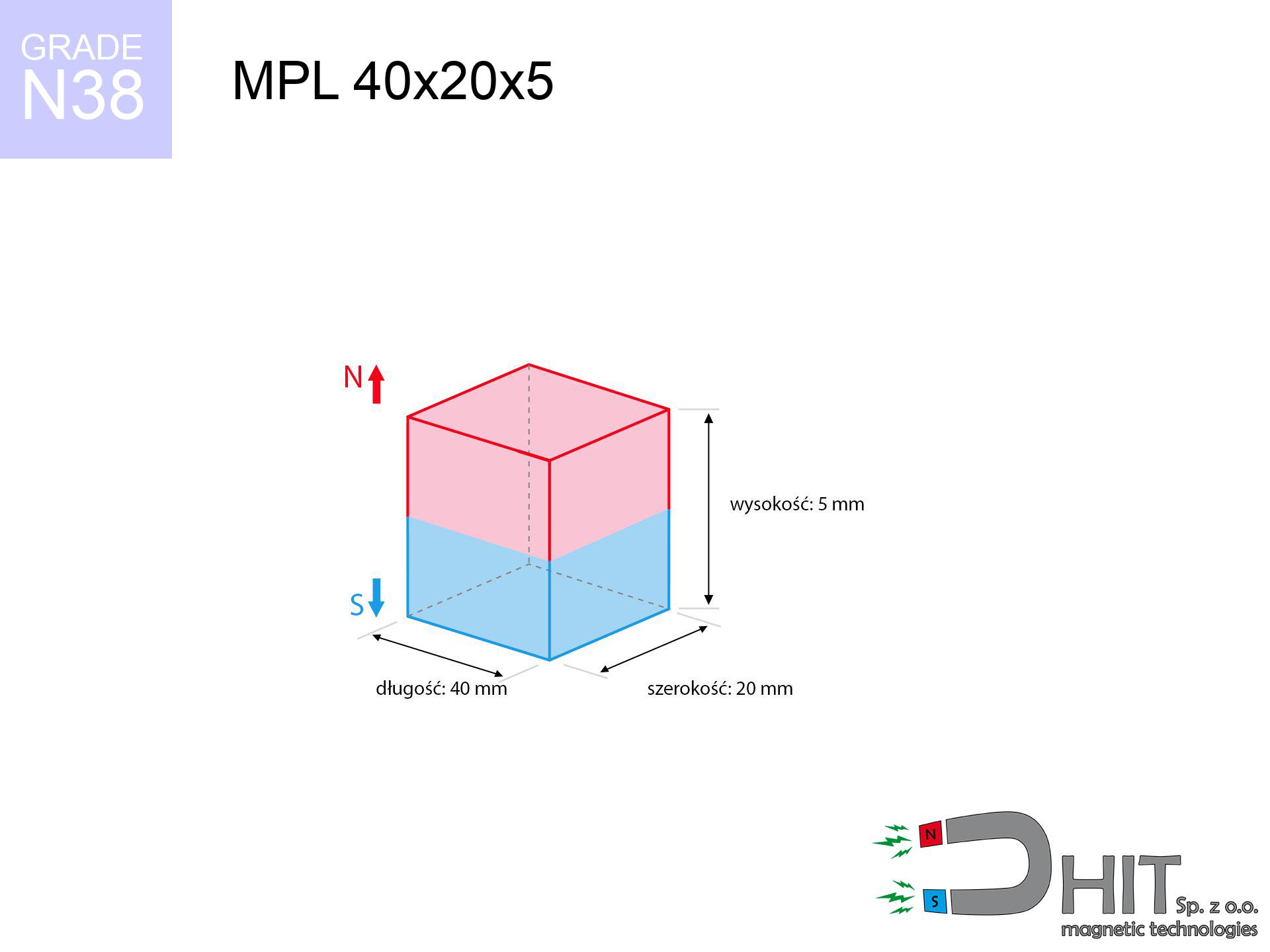

length

40 mm [±0,1 mm]

Width

20 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

30 g

Magnetization Direction

↑ axial

Load capacity

10.67 kg / 104.63 N

Magnetic Induction

205.27 mT / 2053 Gs

Coating

[NiCuNi] Nickel

12.24 ZŁ with VAT / pcs + price for transport

9.95 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

if you prefer get in touch by means of

inquiry form

the contact page.

Parameters along with structure of magnetic components can be reviewed with our

online calculation tool.

Order by 14:00 and we’ll ship today!

Technical details - MPL 40x20x5 / N38 - lamellar magnet

Specification / characteristics - MPL 40x20x5 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020160 |

| GTIN/EAN | 5906301811664 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 40 mm [±0,1 mm] |

| Width | 20 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 30 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 10.67 kg / 104.63 N |

| Magnetic Induction ~ ? | 205.27 mT / 2053 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the assembly - data

Presented values represent the result of a physical analysis. Results rely on algorithms for the material Nd2Fe14B. Operational performance might slightly deviate from the simulation results. Please consider these calculations as a preliminary roadmap during assembly planning.

Table 1: Static pull force (force vs gap) - characteristics

MPL 40x20x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2052 Gs

205.2 mT

|

10.67 kg / 23.52 lbs

10670.0 g / 104.7 N

|

critical level |

| 1 mm |

1956 Gs

195.6 mT

|

9.69 kg / 21.37 lbs

9693.2 g / 95.1 N

|

warning |

| 2 mm |

1839 Gs

183.9 mT

|

8.57 kg / 18.89 lbs

8570.5 g / 84.1 N

|

warning |

| 3 mm |

1711 Gs

171.1 mT

|

7.41 kg / 16.34 lbs

7413.1 g / 72.7 N

|

warning |

| 5 mm |

1444 Gs

144.4 mT

|

5.28 kg / 11.65 lbs

5282.9 g / 51.8 N

|

warning |

| 10 mm |

888 Gs

88.8 mT

|

2.00 kg / 4.40 lbs

1996.5 g / 19.6 N

|

low risk |

| 15 mm |

545 Gs

54.5 mT

|

0.75 kg / 1.66 lbs

752.0 g / 7.4 N

|

low risk |

| 20 mm |

346 Gs

34.6 mT

|

0.30 kg / 0.67 lbs

302.9 g / 3.0 N

|

low risk |

| 30 mm |

156 Gs

15.6 mT

|

0.06 kg / 0.14 lbs

61.9 g / 0.6 N

|

low risk |

| 50 mm |

46 Gs

4.6 mT

|

0.01 kg / 0.01 lbs

5.4 g / 0.1 N

|

low risk |

Table 2: Vertical capacity (wall)

MPL 40x20x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

2.13 kg / 4.70 lbs

2134.0 g / 20.9 N

|

| 1 mm | Stal (~0.2) |

1.94 kg / 4.27 lbs

1938.0 g / 19.0 N

|

| 2 mm | Stal (~0.2) |

1.71 kg / 3.78 lbs

1714.0 g / 16.8 N

|

| 3 mm | Stal (~0.2) |

1.48 kg / 3.27 lbs

1482.0 g / 14.5 N

|

| 5 mm | Stal (~0.2) |

1.06 kg / 2.33 lbs

1056.0 g / 10.4 N

|

| 10 mm | Stal (~0.2) |

0.40 kg / 0.88 lbs

400.0 g / 3.9 N

|

| 15 mm | Stal (~0.2) |

0.15 kg / 0.33 lbs

150.0 g / 1.5 N

|

| 20 mm | Stal (~0.2) |

0.06 kg / 0.13 lbs

60.0 g / 0.6 N

|

| 30 mm | Stal (~0.2) |

0.01 kg / 0.03 lbs

12.0 g / 0.1 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MPL 40x20x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

3.20 kg / 7.06 lbs

3201.0 g / 31.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

2.13 kg / 4.70 lbs

2134.0 g / 20.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.07 kg / 2.35 lbs

1067.0 g / 10.5 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

5.34 kg / 11.76 lbs

5335.0 g / 52.3 N

|

Table 4: Material efficiency (saturation) - power losses

MPL 40x20x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.53 kg / 1.18 lbs

533.5 g / 5.2 N

|

| 1 mm |

|

1.33 kg / 2.94 lbs

1333.8 g / 13.1 N

|

| 2 mm |

|

2.67 kg / 5.88 lbs

2667.5 g / 26.2 N

|

| 3 mm |

|

4.00 kg / 8.82 lbs

4001.2 g / 39.3 N

|

| 5 mm |

|

6.67 kg / 14.70 lbs

6668.8 g / 65.4 N

|

| 10 mm |

|

10.67 kg / 23.52 lbs

10670.0 g / 104.7 N

|

| 11 mm |

|

10.67 kg / 23.52 lbs

10670.0 g / 104.7 N

|

| 12 mm |

|

10.67 kg / 23.52 lbs

10670.0 g / 104.7 N

|

Table 5: Working in heat (stability) - power drop

MPL 40x20x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

10.67 kg / 23.52 lbs

10670.0 g / 104.7 N

|

OK |

| 40 °C | -2.2% |

10.44 kg / 23.01 lbs

10435.3 g / 102.4 N

|

OK |

| 60 °C | -4.4% |

10.20 kg / 22.49 lbs

10200.5 g / 100.1 N

|

|

| 80 °C | -6.6% |

9.97 kg / 21.97 lbs

9965.8 g / 97.8 N

|

|

| 100 °C | -28.8% |

7.60 kg / 16.75 lbs

7597.0 g / 74.5 N

|

Table 6: Magnet-Magnet interaction (repulsion) - forces in the system

MPL 40x20x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

20.78 kg / 45.80 lbs

3 495 Gs

|

3.12 kg / 6.87 lbs

3116 g / 30.6 N

|

N/A |

| 1 mm |

19.88 kg / 43.83 lbs

4 015 Gs

|

2.98 kg / 6.57 lbs

2982 g / 29.3 N

|

17.89 kg / 39.44 lbs

~0 Gs

|

| 2 mm |

18.87 kg / 41.61 lbs

3 912 Gs

|

2.83 kg / 6.24 lbs

2831 g / 27.8 N

|

16.99 kg / 37.45 lbs

~0 Gs

|

| 3 mm |

17.80 kg / 39.24 lbs

3 800 Gs

|

2.67 kg / 5.89 lbs

2670 g / 26.2 N

|

16.02 kg / 35.32 lbs

~0 Gs

|

| 5 mm |

15.56 kg / 34.30 lbs

3 552 Gs

|

2.33 kg / 5.14 lbs

2334 g / 22.9 N

|

14.00 kg / 30.87 lbs

~0 Gs

|

| 10 mm |

10.29 kg / 22.68 lbs

2 888 Gs

|

1.54 kg / 3.40 lbs

1543 g / 15.1 N

|

9.26 kg / 20.41 lbs

~0 Gs

|

| 20 mm |

3.89 kg / 8.57 lbs

1 776 Gs

|

0.58 kg / 1.29 lbs

583 g / 5.7 N

|

3.50 kg / 7.71 lbs

~0 Gs

|

| 50 mm |

0.26 kg / 0.57 lbs

456 Gs

|

0.04 kg / 0.08 lbs

39 g / 0.4 N

|

0.23 kg / 0.51 lbs

~0 Gs

|

| 60 mm |

0.12 kg / 0.27 lbs

313 Gs

|

0.02 kg / 0.04 lbs

18 g / 0.2 N

|

0.11 kg / 0.24 lbs

~0 Gs

|

| 70 mm |

0.06 kg / 0.13 lbs

221 Gs

|

0.01 kg / 0.02 lbs

9 g / 0.1 N

|

0.05 kg / 0.12 lbs

~0 Gs

|

| 80 mm |

0.03 kg / 0.07 lbs

162 Gs

|

0.00 kg / 0.01 lbs

5 g / 0.0 N

|

0.03 kg / 0.06 lbs

~0 Gs

|

| 90 mm |

0.02 kg / 0.04 lbs

121 Gs

|

0.00 kg / 0.01 lbs

3 g / 0.0 N

|

0.02 kg / 0.04 lbs

~0 Gs

|

| 100 mm |

0.01 kg / 0.02 lbs

93 Gs

|

0.00 kg / 0.00 lbs

2 g / 0.0 N

|

0.01 kg / 0.02 lbs

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MPL 40x20x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 11.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 9.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 7.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 5.5 cm |

| Car key | 50 Gs (5.0 mT) | 5.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Collisions (cracking risk) - collision effects

MPL 40x20x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

21.13 km/h

(5.87 m/s)

|

0.52 J | |

| 30 mm |

33.06 km/h

(9.18 m/s)

|

1.27 J | |

| 50 mm |

42.54 km/h

(11.82 m/s)

|

2.09 J | |

| 100 mm |

60.15 km/h

(16.71 m/s)

|

4.19 J |

Table 9: Surface protection spec

MPL 40x20x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 40x20x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 18 042 Mx | 180.4 µWb |

| Pc Coefficient | 0.23 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MPL 40x20x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 10.67 kg | Standard |

| Water (riverbed) |

12.22 kg

(+1.55 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical surface, the magnet retains merely ~20% of its perpendicular strength.

2. Steel saturation

*Thin metal sheet (e.g. computer case) significantly weakens the holding force.

3. Temperature resistance

*For N38 grade, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.23

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Strengths as well as weaknesses of neodymium magnets.

Benefits

- They retain attractive force for nearly 10 years – the drop is just ~1% (according to analyses),

- Neodymium magnets prove to be exceptionally resistant to magnetic field loss caused by magnetic disturbances,

- The use of an aesthetic layer of noble metals (nickel, gold, silver) causes the element to present itself better,

- Magnetic induction on the surface of the magnet turns out to be extremely intense,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Thanks to flexibility in designing and the capacity to customize to unusual requirements,

- Huge importance in modern industrial fields – they find application in mass storage devices, electric drive systems, advanced medical instruments, and complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer high power in tiny dimensions, which makes them useful in small systems

Weaknesses

- At very strong impacts they can break, therefore we recommend placing them in special holders. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- NdFeB magnets lose strength when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- Magnets exposed to a humid environment can corrode. Therefore during using outdoors, we suggest using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- Due to limitations in producing threads and complicated shapes in magnets, we propose using a housing - magnetic holder.

- Potential hazard to health – tiny shards of magnets pose a threat, when accidentally swallowed, which becomes key in the context of child health protection. It is also worth noting that tiny parts of these magnets are able to disrupt the diagnostic process medical after entering the body.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Holding force characteristics

Highest magnetic holding force – what contributes to it?

- with the application of a yoke made of low-carbon steel, guaranteeing maximum field concentration

- possessing a thickness of min. 10 mm to ensure full flux closure

- with an ideally smooth touching surface

- with direct contact (without coatings)

- under perpendicular application of breakaway force (90-degree angle)

- at room temperature

Practical lifting capacity: influencing factors

- Distance (between the magnet and the plate), as even a tiny distance (e.g. 0.5 mm) results in a decrease in lifting capacity by up to 50% (this also applies to paint, rust or debris).

- Direction of force – highest force is obtained only during perpendicular pulling. The resistance to sliding of the magnet along the plate is usually several times lower (approx. 1/5 of the lifting capacity).

- Base massiveness – too thin sheet does not close the flux, causing part of the power to be wasted into the air.

- Material type – ideal substrate is high-permeability steel. Hardened steels may have worse magnetic properties.

- Plate texture – ground elements ensure maximum contact, which improves force. Rough surfaces reduce efficiency.

- Thermal conditions – NdFeB sinters have a sensitivity to temperature. When it is hot they are weaker, and in frost gain strength (up to a certain limit).

Lifting capacity testing was conducted on plates with a smooth surface of suitable thickness, under perpendicular forces, whereas under parallel forces the load capacity is reduced by as much as 75%. Additionally, even a small distance between the magnet and the plate decreases the holding force.

Warnings

Combustion hazard

Combustion risk: Neodymium dust is explosive. Avoid machining magnets in home conditions as this may cause fire.

Protective goggles

Protect your eyes. Magnets can fracture upon violent connection, launching shards into the air. We recommend safety glasses.

Threat to electronics

Avoid bringing magnets near a wallet, computer, or TV. The magnetism can irreversibly ruin these devices and erase data from cards.

Phone sensors

A strong magnetic field disrupts the operation of compasses in smartphones and GPS navigation. Maintain magnets near a smartphone to avoid damaging the sensors.

Warning for allergy sufferers

Allergy Notice: The nickel-copper-nickel coating contains nickel. If redness occurs, immediately stop working with magnets and wear gloves.

Do not give to children

Only for adults. Small elements can be swallowed, causing intestinal necrosis. Keep away from kids and pets.

Pinching danger

Risk of injury: The pulling power is so great that it can cause blood blisters, crushing, and broken bones. Use thick gloves.

Implant safety

Life threat: Neodymium magnets can turn off pacemakers and defibrillators. Do not approach if you have medical devices.

Respect the power

Handle with care. Rare earth magnets attract from a distance and snap with huge force, often quicker than you can react.

Thermal limits

Keep cool. Neodymium magnets are sensitive to temperature. If you require operation above 80°C, inquire about HT versions (H, SH, UH).

![SM 32x325 [2xM8] / N42 - magnetic separator SM 32x325 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x325-2xm8-fog.jpg)