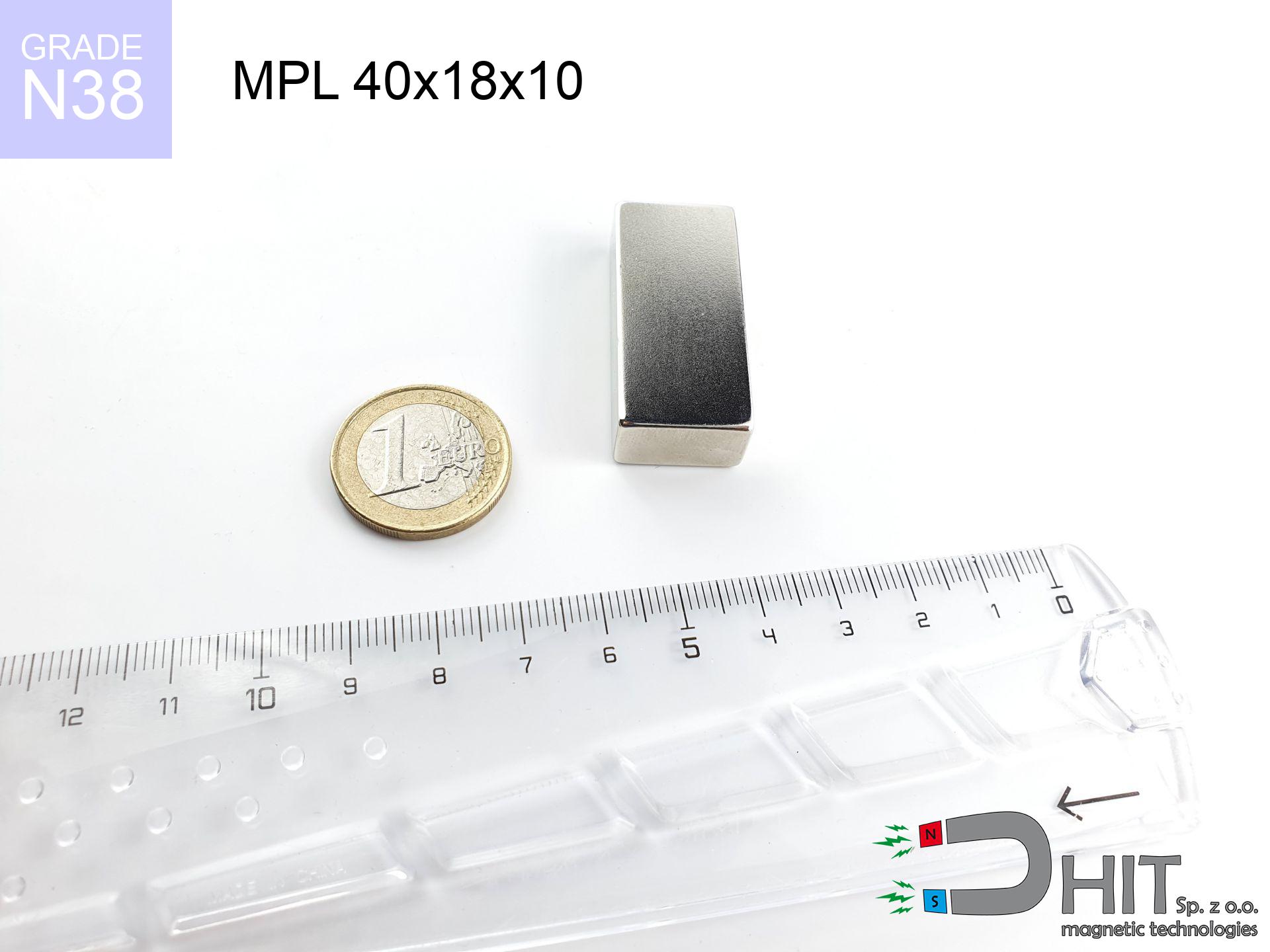

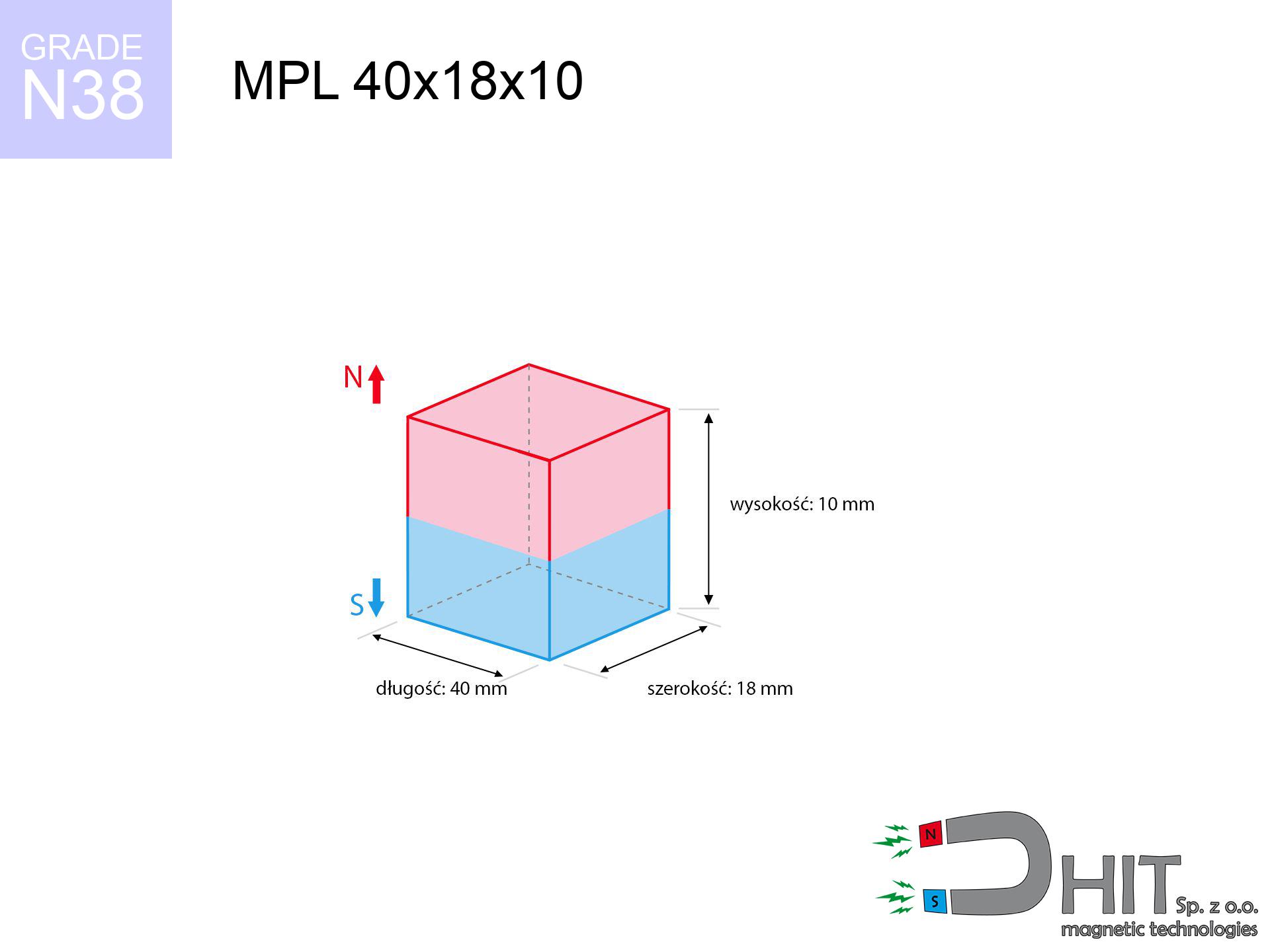

MPL 40x18x10 / N38 - lamellar magnet

lamellar magnet

Catalog no 020156

GTIN/EAN: 5906301811626

length

40 mm [±0,1 mm]

Width

18 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

54 g

Magnetization Direction

↑ axial

Load capacity

23.81 kg / 233.58 N

Magnetic Induction

366.66 mT / 3667 Gs

Coating

[NiCuNi] Nickel

30.75 ZŁ with VAT / pcs + price for transport

25.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

alternatively contact us via

inquiry form

the contact form page.

Specifications along with shape of magnetic components can be tested using our

modular calculator.

Orders submitted before 14:00 will be dispatched today!

Technical details - MPL 40x18x10 / N38 - lamellar magnet

Specification / characteristics - MPL 40x18x10 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020156 |

| GTIN/EAN | 5906301811626 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 40 mm [±0,1 mm] |

| Width | 18 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 54 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 23.81 kg / 233.58 N |

| Magnetic Induction ~ ? | 366.66 mT / 3667 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the magnet - data

These data represent the result of a engineering analysis. Results rely on models for the material Nd2Fe14B. Operational performance may deviate from the simulation results. Please consider these calculations as a supplementary guide during assembly planning.

Table 1: Static pull force (pull vs distance) - power drop

MPL 40x18x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3666 Gs

366.6 mT

|

23.81 kg / 52.49 lbs

23810.0 g / 233.6 N

|

crushing |

| 1 mm |

3399 Gs

339.9 mT

|

20.48 kg / 45.14 lbs

20476.1 g / 200.9 N

|

crushing |

| 2 mm |

3120 Gs

312.0 mT

|

17.25 kg / 38.02 lbs

17245.9 g / 169.2 N

|

crushing |

| 3 mm |

2841 Gs

284.1 mT

|

14.30 kg / 31.54 lbs

14304.1 g / 140.3 N

|

crushing |

| 5 mm |

2321 Gs

232.1 mT

|

9.55 kg / 21.05 lbs

9547.8 g / 93.7 N

|

warning |

| 10 mm |

1370 Gs

137.0 mT

|

3.32 kg / 7.33 lbs

3324.4 g / 32.6 N

|

warning |

| 15 mm |

833 Gs

83.3 mT

|

1.23 kg / 2.71 lbs

1229.0 g / 12.1 N

|

safe |

| 20 mm |

530 Gs

53.0 mT

|

0.50 kg / 1.10 lbs

498.1 g / 4.9 N

|

safe |

| 30 mm |

244 Gs

24.4 mT

|

0.11 kg / 0.23 lbs

105.3 g / 1.0 N

|

safe |

| 50 mm |

75 Gs

7.5 mT

|

0.01 kg / 0.02 lbs

9.9 g / 0.1 N

|

safe |

Table 2: Sliding force (vertical surface)

MPL 40x18x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

4.76 kg / 10.50 lbs

4762.0 g / 46.7 N

|

| 1 mm | Stal (~0.2) |

4.10 kg / 9.03 lbs

4096.0 g / 40.2 N

|

| 2 mm | Stal (~0.2) |

3.45 kg / 7.61 lbs

3450.0 g / 33.8 N

|

| 3 mm | Stal (~0.2) |

2.86 kg / 6.31 lbs

2860.0 g / 28.1 N

|

| 5 mm | Stal (~0.2) |

1.91 kg / 4.21 lbs

1910.0 g / 18.7 N

|

| 10 mm | Stal (~0.2) |

0.66 kg / 1.46 lbs

664.0 g / 6.5 N

|

| 15 mm | Stal (~0.2) |

0.25 kg / 0.54 lbs

246.0 g / 2.4 N

|

| 20 mm | Stal (~0.2) |

0.10 kg / 0.22 lbs

100.0 g / 1.0 N

|

| 30 mm | Stal (~0.2) |

0.02 kg / 0.05 lbs

22.0 g / 0.2 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MPL 40x18x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

7.14 kg / 15.75 lbs

7143.0 g / 70.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

4.76 kg / 10.50 lbs

4762.0 g / 46.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

2.38 kg / 5.25 lbs

2381.0 g / 23.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

11.91 kg / 26.25 lbs

11905.0 g / 116.8 N

|

Table 4: Material efficiency (substrate influence) - power losses

MPL 40x18x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.19 kg / 2.62 lbs

1190.5 g / 11.7 N

|

| 1 mm |

|

2.98 kg / 6.56 lbs

2976.3 g / 29.2 N

|

| 2 mm |

|

5.95 kg / 13.12 lbs

5952.5 g / 58.4 N

|

| 3 mm |

|

8.93 kg / 19.68 lbs

8928.7 g / 87.6 N

|

| 5 mm |

|

14.88 kg / 32.81 lbs

14881.3 g / 146.0 N

|

| 10 mm |

|

23.81 kg / 52.49 lbs

23810.0 g / 233.6 N

|

| 11 mm |

|

23.81 kg / 52.49 lbs

23810.0 g / 233.6 N

|

| 12 mm |

|

23.81 kg / 52.49 lbs

23810.0 g / 233.6 N

|

Table 5: Thermal resistance (material behavior) - power drop

MPL 40x18x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

23.81 kg / 52.49 lbs

23810.0 g / 233.6 N

|

OK |

| 40 °C | -2.2% |

23.29 kg / 51.34 lbs

23286.2 g / 228.4 N

|

OK |

| 60 °C | -4.4% |

22.76 kg / 50.18 lbs

22762.4 g / 223.3 N

|

|

| 80 °C | -6.6% |

22.24 kg / 49.03 lbs

22238.5 g / 218.2 N

|

|

| 100 °C | -28.8% |

16.95 kg / 37.37 lbs

16952.7 g / 166.3 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MPL 40x18x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

59.64 kg / 131.49 lbs

5 034 Gs

|

8.95 kg / 19.72 lbs

8947 g / 87.8 N

|

N/A |

| 1 mm |

55.50 kg / 122.35 lbs

7 072 Gs

|

8.32 kg / 18.35 lbs

8325 g / 81.7 N

|

49.95 kg / 110.12 lbs

~0 Gs

|

| 2 mm |

51.29 kg / 113.08 lbs

6 799 Gs

|

7.69 kg / 16.96 lbs

7694 g / 75.5 N

|

46.16 kg / 101.77 lbs

~0 Gs

|

| 3 mm |

47.18 kg / 104.01 lbs

6 520 Gs

|

7.08 kg / 15.60 lbs

7076 g / 69.4 N

|

42.46 kg / 93.61 lbs

~0 Gs

|

| 5 mm |

39.41 kg / 86.88 lbs

5 959 Gs

|

5.91 kg / 13.03 lbs

5912 g / 58.0 N

|

35.47 kg / 78.20 lbs

~0 Gs

|

| 10 mm |

23.92 kg / 52.73 lbs

4 643 Gs

|

3.59 kg / 7.91 lbs

3588 g / 35.2 N

|

21.53 kg / 47.46 lbs

~0 Gs

|

| 20 mm |

8.33 kg / 18.36 lbs

2 739 Gs

|

1.25 kg / 2.75 lbs

1249 g / 12.3 N

|

7.49 kg / 16.52 lbs

~0 Gs

|

| 50 mm |

0.55 kg / 1.22 lbs

705 Gs

|

0.08 kg / 0.18 lbs

83 g / 0.8 N

|

0.50 kg / 1.09 lbs

~0 Gs

|

| 60 mm |

0.26 kg / 0.58 lbs

487 Gs

|

0.04 kg / 0.09 lbs

40 g / 0.4 N

|

0.24 kg / 0.52 lbs

~0 Gs

|

| 70 mm |

0.13 kg / 0.30 lbs

348 Gs

|

0.02 kg / 0.04 lbs

20 g / 0.2 N

|

0.12 kg / 0.27 lbs

~0 Gs

|

| 80 mm |

0.07 kg / 0.16 lbs

256 Gs

|

0.01 kg / 0.02 lbs

11 g / 0.1 N

|

0.07 kg / 0.14 lbs

~0 Gs

|

| 90 mm |

0.04 kg / 0.09 lbs

194 Gs

|

0.01 kg / 0.01 lbs

6 g / 0.1 N

|

0.04 kg / 0.08 lbs

~0 Gs

|

| 100 mm |

0.02 kg / 0.05 lbs

149 Gs

|

0.00 kg / 0.01 lbs

4 g / 0.0 N

|

0.02 kg / 0.05 lbs

~0 Gs

|

Table 7: Safety (HSE) (electronics) - precautionary measures

MPL 40x18x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 14.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 11.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 8.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 6.5 cm |

| Car key | 50 Gs (5.0 mT) | 6.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.0 cm |

Table 8: Impact energy (cracking risk) - collision effects

MPL 40x18x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.95 km/h

(6.38 m/s)

|

1.10 J | |

| 30 mm |

36.78 km/h

(10.22 m/s)

|

2.82 J | |

| 50 mm |

47.37 km/h

(13.16 m/s)

|

4.67 J | |

| 100 mm |

66.97 km/h

(18.60 m/s)

|

9.34 J |

Table 9: Anti-corrosion coating durability

MPL 40x18x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 40x18x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 26 060 Mx | 260.6 µWb |

| Pc Coefficient | 0.43 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MPL 40x18x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 23.81 kg | Standard |

| Water (riverbed) |

27.26 kg

(+3.45 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Note: On a vertical surface, the magnet retains only a fraction of its perpendicular strength.

2. Plate thickness effect

*Thin metal sheet (e.g. computer case) drastically weakens the holding force.

3. Heat tolerance

*For standard magnets, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.43

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Strengths as well as weaknesses of rare earth magnets.

Pros

- They virtually do not lose strength, because even after 10 years the decline in efficiency is only ~1% (based on calculations),

- Neodymium magnets are distinguished by highly resistant to loss of magnetic properties caused by magnetic disturbances,

- A magnet with a metallic gold surface looks better,

- They are known for high magnetic induction at the operating surface, making them more effective,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can work (depending on the shape) even at a temperature of 230°C or more...

- Possibility of precise forming as well as modifying to defined requirements,

- Huge importance in modern technologies – they are utilized in magnetic memories, brushless drives, medical devices, also other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in compact dimensions, which allows their use in miniature devices

Disadvantages

- At strong impacts they can crack, therefore we recommend placing them in strong housings. A metal housing provides additional protection against damage and increases the magnet's durability.

- Neodymium magnets lose their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- They rust in a humid environment - during use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- Due to limitations in producing threads and complicated shapes in magnets, we recommend using cover - magnetic holder.

- Health risk to health – tiny shards of magnets pose a threat, when accidentally swallowed, which is particularly important in the context of child safety. Additionally, small components of these devices can disrupt the diagnostic process medical in case of swallowing.

- Due to complex production process, their price is higher than average,

Pull force analysis

Maximum lifting force for a neodymium magnet – what it depends on?

- using a sheet made of high-permeability steel, serving as a ideal flux conductor

- whose thickness equals approx. 10 mm

- with a surface cleaned and smooth

- with zero gap (no impurities)

- for force acting at a right angle (pull-off, not shear)

- at ambient temperature approx. 20 degrees Celsius

Lifting capacity in real conditions – factors

- Distance (between the magnet and the plate), as even a tiny distance (e.g. 0.5 mm) leads to a decrease in lifting capacity by up to 50% (this also applies to varnish, corrosion or dirt).

- Force direction – note that the magnet has greatest strength perpendicularly. Under sliding down, the holding force drops significantly, often to levels of 20-30% of the nominal value.

- Metal thickness – the thinner the sheet, the weaker the hold. Magnetic flux passes through the material instead of converting into lifting capacity.

- Plate material – low-carbon steel attracts best. Alloy admixtures reduce magnetic properties and lifting capacity.

- Surface structure – the smoother and more polished the plate, the better the adhesion and stronger the hold. Unevenness acts like micro-gaps.

- Heat – NdFeB sinters have a sensitivity to temperature. When it is hot they lose power, and in frost gain strength (up to a certain limit).

Holding force was tested on the plate surface of 20 mm thickness, when the force acted perpendicularly, in contrast under parallel forces the load capacity is reduced by as much as 75%. In addition, even a minimal clearance between the magnet and the plate lowers the load capacity.

Safety rules for work with NdFeB magnets

Bone fractures

Pinching hazard: The attraction force is so great that it can result in hematomas, crushing, and broken bones. Use thick gloves.

Dust is flammable

Machining of NdFeB material carries a risk of fire hazard. Neodymium dust oxidizes rapidly with oxygen and is hard to extinguish.

Thermal limits

Keep cool. NdFeB magnets are susceptible to temperature. If you require resistance above 80°C, inquire about special high-temperature series (H, SH, UH).

Pacemakers

Health Alert: Strong magnets can deactivate pacemakers and defibrillators. Stay away if you have medical devices.

Respect the power

Be careful. Rare earth magnets act from a long distance and connect with huge force, often faster than you can react.

Protect data

Do not bring magnets close to a purse, laptop, or screen. The magnetism can irreversibly ruin these devices and erase data from cards.

Precision electronics

GPS units and mobile phones are extremely susceptible to magnetism. Close proximity with a powerful NdFeB magnet can permanently damage the internal compass in your phone.

Risk of cracking

Protect your eyes. Magnets can fracture upon violent connection, ejecting shards into the air. Eye protection is mandatory.

Sensitization to coating

Medical facts indicate that nickel (standard magnet coating) is a strong allergen. For allergy sufferers, prevent touching magnets with bare hands and opt for coated magnets.

Danger to the youngest

Absolutely keep magnets away from children. Risk of swallowing is high, and the effects of magnets connecting inside the body are very dangerous.