UMGZ 75x34x18 [M10] GZ / N38 - magnetic holder external thread

magnetic holder external thread

Catalog no 190417

GTIN/EAN: 5906301813880

Diameter Ø

75 mm [±1 mm]

Height

34 mm [±1 mm]

Height

18 mm [±1 mm]

Weight

475 g

Load capacity

162.00 kg / 1588.68 N

189.42 ZŁ with VAT / pcs + price for transport

154.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

otherwise contact us via

request form

our website.

Weight along with structure of neodymium magnets can be checked with our

our magnetic calculator.

Same-day shipping for orders placed before 14:00.

Technical specification of the product - UMGZ 75x34x18 [M10] GZ / N38 - magnetic holder external thread

Specification / characteristics - UMGZ 75x34x18 [M10] GZ / N38 - magnetic holder external thread

| properties | values |

|---|---|

| Cat. no. | 190417 |

| GTIN/EAN | 5906301813880 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

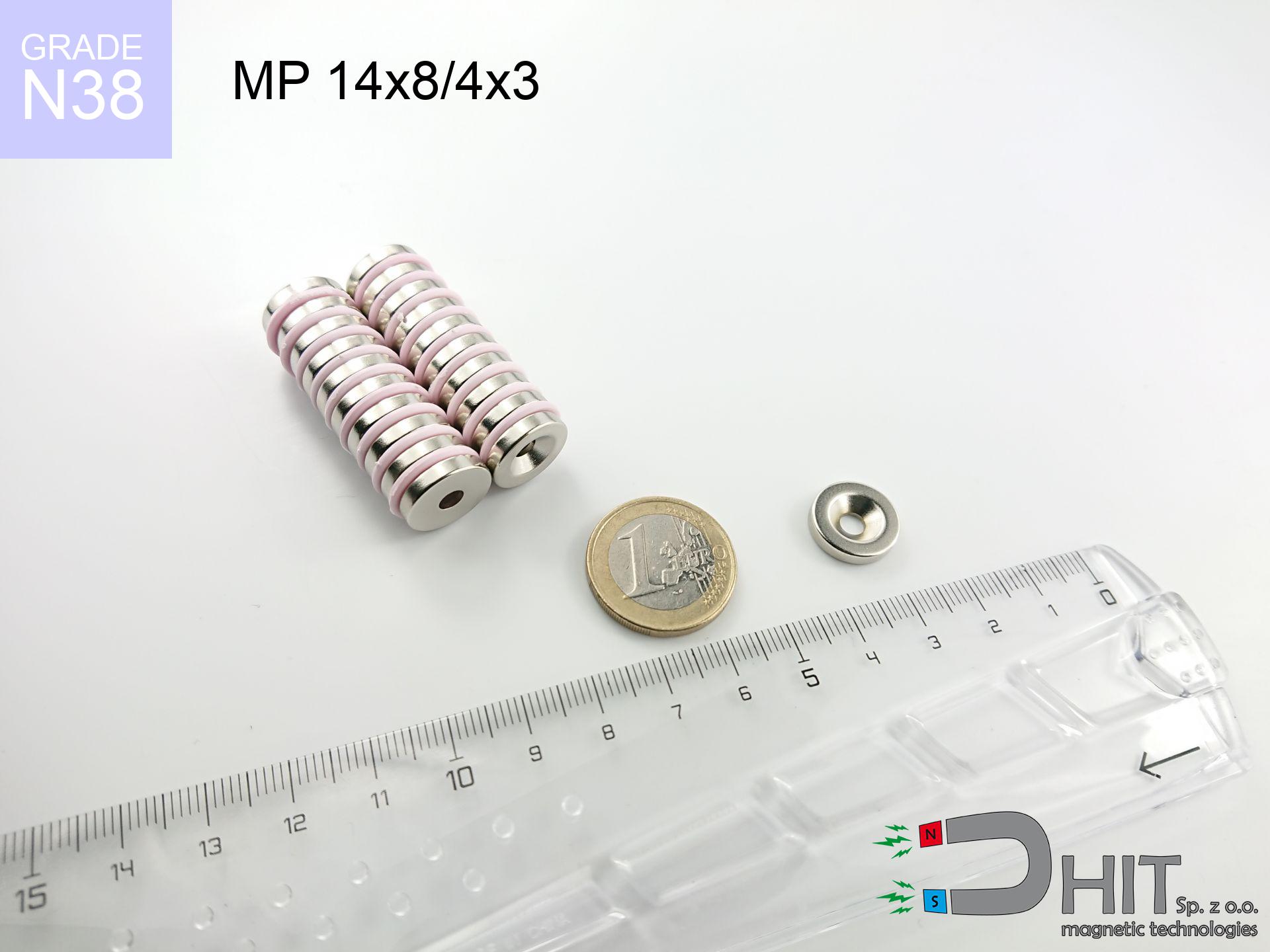

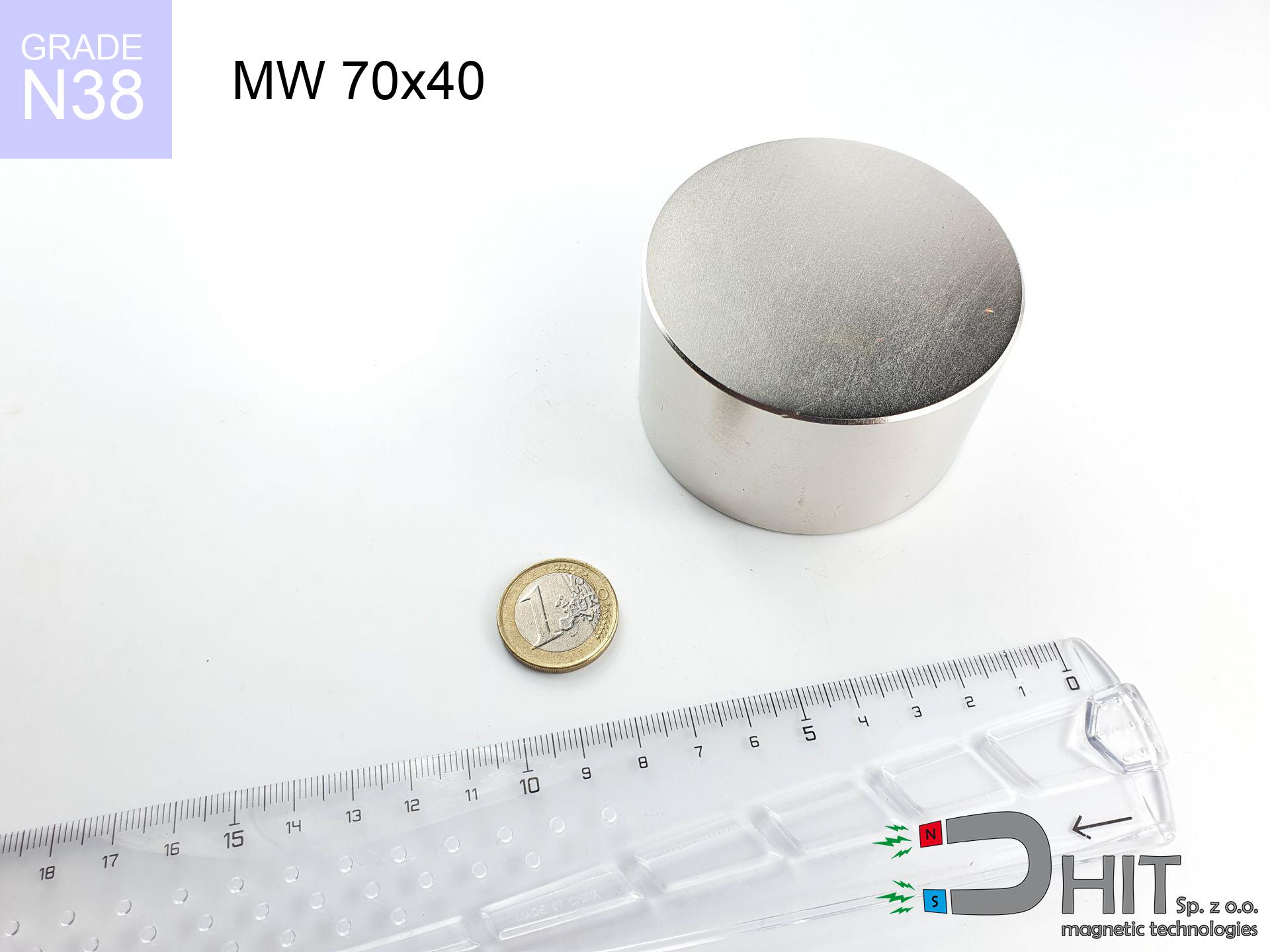

| Diameter Ø | 75 mm [±1 mm] |

| Height | 34 mm [±1 mm] |

| Height | 18 mm [±1 mm] |

| Weight | 475 g |

| Load capacity ~ ? | 162.00 kg / 1588.68 N |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Pros as well as cons of neodymium magnets.

Strengths

- They do not lose strength, even during nearly 10 years – the reduction in lifting capacity is only ~1% (theoretically),

- They maintain their magnetic properties even under close interference source,

- By using a smooth layer of silver, the element presents an elegant look,

- The surface of neodymium magnets generates a intense magnetic field – this is a key feature,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Thanks to modularity in forming and the capacity to customize to unusual requirements,

- Huge importance in innovative solutions – they are commonly used in hard drives, motor assemblies, precision medical tools, and industrial machines.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Weaknesses

- To avoid cracks under impact, we suggest using special steel holders. Such a solution secures the magnet and simultaneously improves its durability.

- We warn that neodymium magnets can reduce their power at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- Magnets exposed to a humid environment can rust. Therefore when using outdoors, we recommend using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- Due to limitations in producing nuts and complex forms in magnets, we recommend using casing - magnetic mount.

- Potential hazard resulting from small fragments of magnets pose a threat, if swallowed, which is particularly important in the context of child health protection. Furthermore, small elements of these magnets can complicate diagnosis medical after entering the body.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Pull force analysis

Optimal lifting capacity of a neodymium magnet – what contributes to it?

- on a plate made of mild steel, perfectly concentrating the magnetic flux

- possessing a massiveness of min. 10 mm to avoid saturation

- with a surface perfectly flat

- with zero gap (without impurities)

- during detachment in a direction vertical to the plane

- at room temperature

Lifting capacity in practice – influencing factors

- Gap (betwixt the magnet and the metal), since even a tiny clearance (e.g. 0.5 mm) leads to a drastic drop in lifting capacity by up to 50% (this also applies to varnish, rust or debris).

- Loading method – declared lifting capacity refers to pulling vertically. When applying parallel force, the magnet exhibits much less (typically approx. 20-30% of nominal force).

- Substrate thickness – for full efficiency, the steel must be sufficiently thick. Paper-thin metal limits the attraction force (the magnet "punches through" it).

- Material composition – not every steel attracts identically. High carbon content worsen the attraction effect.

- Base smoothness – the more even the surface, the better the adhesion and stronger the hold. Unevenness acts like micro-gaps.

- Thermal conditions – neodymium magnets have a sensitivity to temperature. When it is hot they lose power, and at low temperatures gain strength (up to a certain limit).

Lifting capacity was determined by applying a polished steel plate of suitable thickness (min. 20 mm), under vertically applied force, however under attempts to slide the magnet the load capacity is reduced by as much as 5 times. Moreover, even a minimal clearance between the magnet’s surface and the plate lowers the lifting capacity.

Precautions when working with neodymium magnets

Do not overheat magnets

Monitor thermal conditions. Heating the magnet above 80 degrees Celsius will permanently weaken its properties and strength.

Fragile material

Despite metallic appearance, neodymium is brittle and not impact-resistant. Avoid impacts, as the magnet may shatter into sharp, dangerous pieces.

GPS Danger

Note: rare earth magnets generate a field that disrupts precision electronics. Keep a separation from your mobile, device, and navigation systems.

Caution required

Handle magnets consciously. Their immense force can surprise even professionals. Stay alert and do not underestimate their force.

Keep away from children

Product intended for adults. Tiny parts can be swallowed, leading to intestinal necrosis. Keep out of reach of children and animals.

ICD Warning

Warning for patients: Powerful magnets affect medical devices. Maintain minimum 30 cm distance or request help to handle the magnets.

Combustion hazard

Dust produced during machining of magnets is self-igniting. Do not drill into magnets unless you are an expert.

Warning for allergy sufferers

Warning for allergy sufferers: The Ni-Cu-Ni coating consists of nickel. If redness happens, cease working with magnets and wear gloves.

Keep away from computers

Do not bring magnets close to a wallet, computer, or screen. The magnetic field can permanently damage these devices and wipe information from cards.

Finger safety

Mind your fingers. Two powerful magnets will snap together immediately with a force of massive weight, destroying anything in their path. Exercise extreme caution!

![Magnet with screw UMGZ 75x34x18 [M10] GZ / N38 Magnet with screw UMGZ 75x34x18 [M10] GZ / N38](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![UMGZ 75x34x18 [M10] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umgw-75x34x18-m10-gz-xid.jpg)

![UMGZ 75x34x18 [M10] GZ / N38 - magnetic holder external thread - ujęcie 2](https://cdn3.dhit.pl/graphics/products/umgw-75x34x18-m10-gz-fos.jpg)

![SM 25x175 [2xM8] / N52 - magnetic separator SM 25x175 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x175-2xm8-gif.jpg)