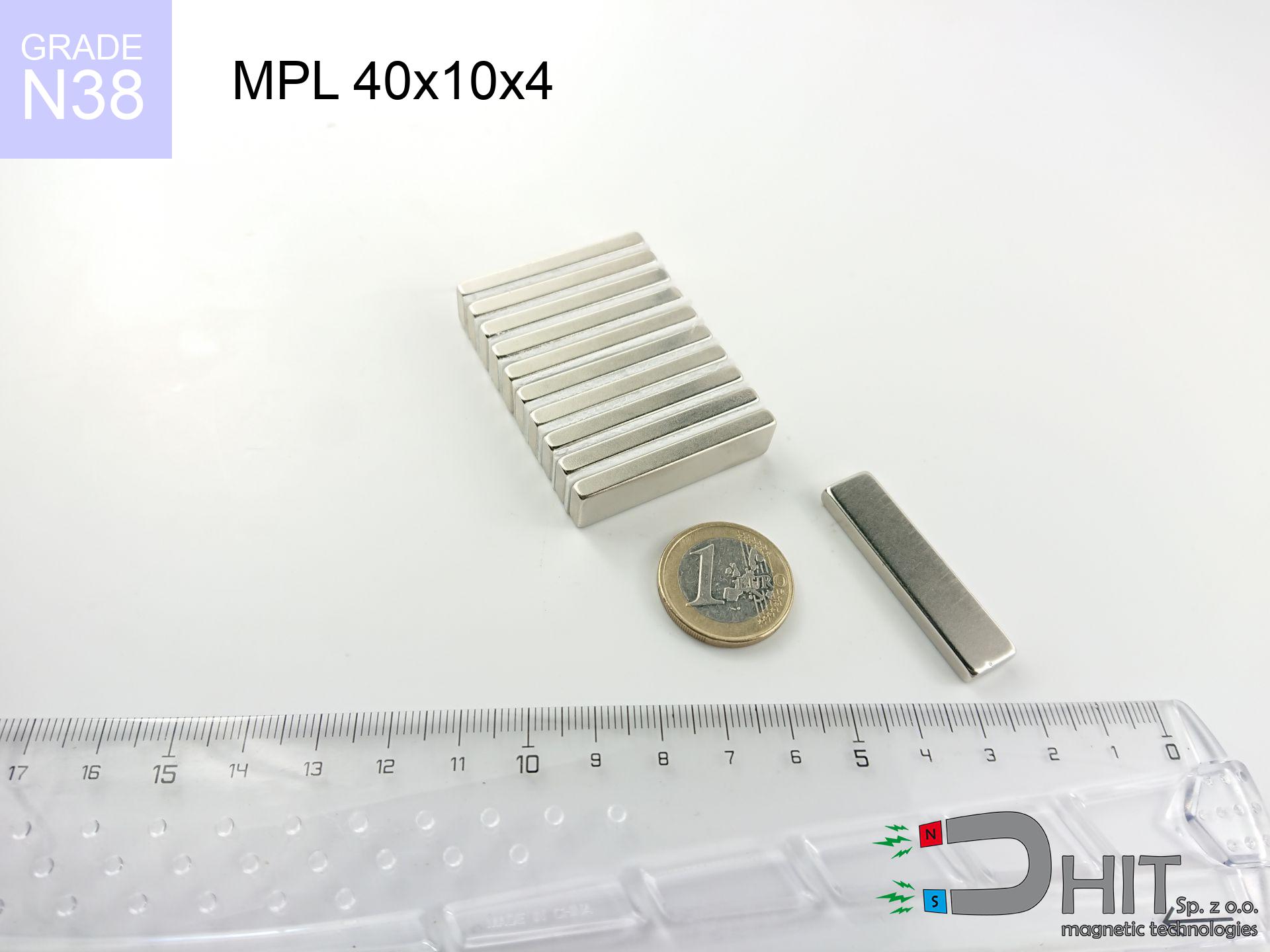

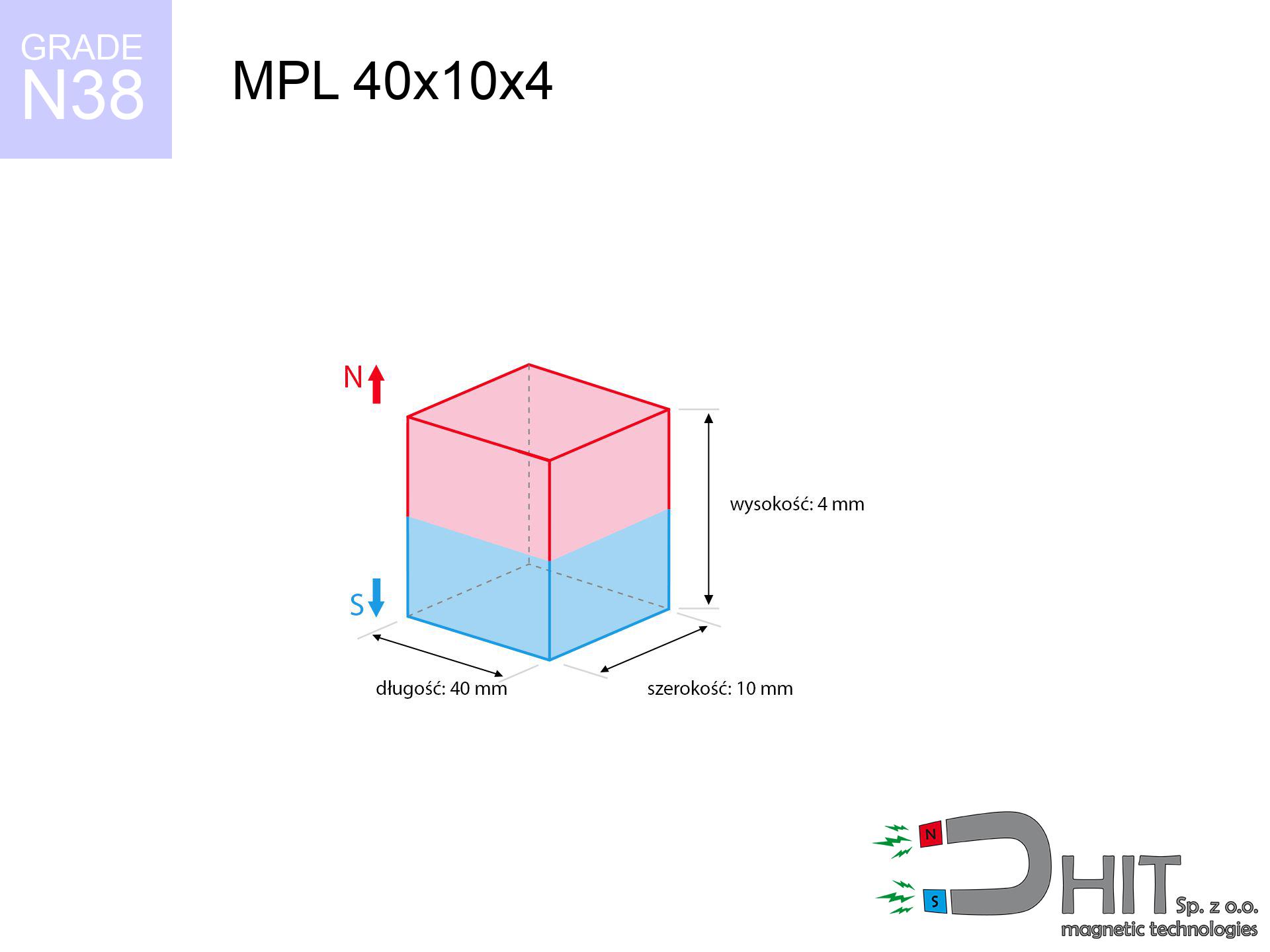

MPL 40x10x4 / N38 - lamellar magnet

lamellar magnet

Catalog no 020150

GTIN/EAN: 5906301811565

length

40 mm [±0,1 mm]

Width

10 mm [±0,1 mm]

Height

4 mm [±0,1 mm]

Weight

12 g

Magnetization Direction

↑ axial

Load capacity

9.31 kg / 91.33 N

Magnetic Induction

275.57 mT / 2756 Gs

Coating

[NiCuNi] Nickel

4.87 ZŁ with VAT / pcs + price for transport

3.96 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

otherwise contact us by means of

form

the contact page.

Weight along with form of a neodymium magnet can be verified on our

online calculation tool.

Order by 14:00 and we’ll ship today!

Technical - MPL 40x10x4 / N38 - lamellar magnet

Specification / characteristics - MPL 40x10x4 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020150 |

| GTIN/EAN | 5906301811565 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 40 mm [±0,1 mm] |

| Width | 10 mm [±0,1 mm] |

| Height | 4 mm [±0,1 mm] |

| Weight | 12 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 9.31 kg / 91.33 N |

| Magnetic Induction ~ ? | 275.57 mT / 2756 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the assembly - technical parameters

The following values represent the direct effect of a engineering analysis. Values are based on models for the material Nd2Fe14B. Operational conditions might slightly differ. Please consider these data as a preliminary roadmap during assembly planning.

Table 1: Static force (pull vs gap) - power drop

MPL 40x10x4 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2755 Gs

275.5 mT

|

9.31 kg / 20.53 lbs

9310.0 g / 91.3 N

|

strong |

| 1 mm |

2413 Gs

241.3 mT

|

7.14 kg / 15.75 lbs

7143.1 g / 70.1 N

|

strong |

| 2 mm |

2044 Gs

204.4 mT

|

5.13 kg / 11.31 lbs

5128.9 g / 50.3 N

|

strong |

| 3 mm |

1703 Gs

170.3 mT

|

3.56 kg / 7.85 lbs

3559.5 g / 34.9 N

|

strong |

| 5 mm |

1173 Gs

117.3 mT

|

1.69 kg / 3.72 lbs

1688.2 g / 16.6 N

|

safe |

| 10 mm |

522 Gs

52.2 mT

|

0.33 kg / 0.74 lbs

334.9 g / 3.3 N

|

safe |

| 15 mm |

277 Gs

27.7 mT

|

0.09 kg / 0.21 lbs

94.2 g / 0.9 N

|

safe |

| 20 mm |

163 Gs

16.3 mT

|

0.03 kg / 0.07 lbs

32.8 g / 0.3 N

|

safe |

| 30 mm |

69 Gs

6.9 mT

|

0.01 kg / 0.01 lbs

5.8 g / 0.1 N

|

safe |

| 50 mm |

19 Gs

1.9 mT

|

0.00 kg / 0.00 lbs

0.5 g / 0.0 N

|

safe |

Table 2: Shear force (wall)

MPL 40x10x4 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.86 kg / 4.11 lbs

1862.0 g / 18.3 N

|

| 1 mm | Stal (~0.2) |

1.43 kg / 3.15 lbs

1428.0 g / 14.0 N

|

| 2 mm | Stal (~0.2) |

1.03 kg / 2.26 lbs

1026.0 g / 10.1 N

|

| 3 mm | Stal (~0.2) |

0.71 kg / 1.57 lbs

712.0 g / 7.0 N

|

| 5 mm | Stal (~0.2) |

0.34 kg / 0.75 lbs

338.0 g / 3.3 N

|

| 10 mm | Stal (~0.2) |

0.07 kg / 0.15 lbs

66.0 g / 0.6 N

|

| 15 mm | Stal (~0.2) |

0.02 kg / 0.04 lbs

18.0 g / 0.2 N

|

| 20 mm | Stal (~0.2) |

0.01 kg / 0.01 lbs

6.0 g / 0.1 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MPL 40x10x4 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.79 kg / 6.16 lbs

2793.0 g / 27.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.86 kg / 4.11 lbs

1862.0 g / 18.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.93 kg / 2.05 lbs

931.0 g / 9.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

4.66 kg / 10.26 lbs

4655.0 g / 45.7 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MPL 40x10x4 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.93 kg / 2.05 lbs

931.0 g / 9.1 N

|

| 1 mm |

|

2.33 kg / 5.13 lbs

2327.5 g / 22.8 N

|

| 2 mm |

|

4.66 kg / 10.26 lbs

4655.0 g / 45.7 N

|

| 3 mm |

|

6.98 kg / 15.39 lbs

6982.5 g / 68.5 N

|

| 5 mm |

|

9.31 kg / 20.53 lbs

9310.0 g / 91.3 N

|

| 10 mm |

|

9.31 kg / 20.53 lbs

9310.0 g / 91.3 N

|

| 11 mm |

|

9.31 kg / 20.53 lbs

9310.0 g / 91.3 N

|

| 12 mm |

|

9.31 kg / 20.53 lbs

9310.0 g / 91.3 N

|

Table 5: Working in heat (material behavior) - power drop

MPL 40x10x4 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

9.31 kg / 20.53 lbs

9310.0 g / 91.3 N

|

OK |

| 40 °C | -2.2% |

9.11 kg / 20.07 lbs

9105.2 g / 89.3 N

|

OK |

| 60 °C | -4.4% |

8.90 kg / 19.62 lbs

8900.4 g / 87.3 N

|

|

| 80 °C | -6.6% |

8.70 kg / 19.17 lbs

8695.5 g / 85.3 N

|

|

| 100 °C | -28.8% |

6.63 kg / 14.61 lbs

6628.7 g / 65.0 N

|

Table 6: Two magnets (repulsion) - forces in the system

MPL 40x10x4 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

18.71 kg / 41.25 lbs

4 164 Gs

|

2.81 kg / 6.19 lbs

2807 g / 27.5 N

|

N/A |

| 1 mm |

16.57 kg / 36.53 lbs

5 185 Gs

|

2.49 kg / 5.48 lbs

2486 g / 24.4 N

|

14.91 kg / 32.88 lbs

~0 Gs

|

| 2 mm |

14.36 kg / 31.65 lbs

4 826 Gs

|

2.15 kg / 4.75 lbs

2153 g / 21.1 N

|

12.92 kg / 28.48 lbs

~0 Gs

|

| 3 mm |

12.24 kg / 26.98 lbs

4 455 Gs

|

1.84 kg / 4.05 lbs

1836 g / 18.0 N

|

11.01 kg / 24.28 lbs

~0 Gs

|

| 5 mm |

8.61 kg / 18.98 lbs

3 737 Gs

|

1.29 kg / 2.85 lbs

1291 g / 12.7 N

|

7.75 kg / 17.08 lbs

~0 Gs

|

| 10 mm |

3.39 kg / 7.48 lbs

2 346 Gs

|

0.51 kg / 1.12 lbs

509 g / 5.0 N

|

3.05 kg / 6.73 lbs

~0 Gs

|

| 20 mm |

0.67 kg / 1.48 lbs

1 045 Gs

|

0.10 kg / 0.22 lbs

101 g / 1.0 N

|

0.61 kg / 1.34 lbs

~0 Gs

|

| 50 mm |

0.03 kg / 0.06 lbs

207 Gs

|

0.00 kg / 0.01 lbs

4 g / 0.0 N

|

0.02 kg / 0.05 lbs

~0 Gs

|

| 60 mm |

0.01 kg / 0.03 lbs

138 Gs

|

0.00 kg / 0.00 lbs

2 g / 0.0 N

|

0.01 kg / 0.02 lbs

~0 Gs

|

| 70 mm |

0.01 kg / 0.01 lbs

96 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.01 lbs

69 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

51 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

39 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MPL 40x10x4 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 8.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 6.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 5.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 4.0 cm |

| Remote | 50 Gs (5.0 mT) | 3.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (cracking risk) - collision effects

MPL 40x10x4 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

28.72 km/h

(7.98 m/s)

|

0.38 J | |

| 30 mm |

48.67 km/h

(13.52 m/s)

|

1.10 J | |

| 50 mm |

62.82 km/h

(17.45 m/s)

|

1.83 J | |

| 100 mm |

88.83 km/h

(24.68 m/s)

|

3.65 J |

Table 9: Anti-corrosion coating durability

MPL 40x10x4 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 40x10x4 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 9 840 Mx | 98.4 µWb |

| Pc Coefficient | 0.26 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MPL 40x10x4 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 9.31 kg | Standard |

| Water (riverbed) |

10.66 kg

(+1.35 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Caution: On a vertical wall, the magnet holds merely approx. 20-30% of its nominal pull.

2. Efficiency vs thickness

*Thin steel (e.g. computer case) severely limits the holding force.

3. Heat tolerance

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.26

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also proposals

Pros and cons of neodymium magnets.

Advantages

- Their power is durable, and after around ten years it drops only by ~1% (according to research),

- Neodymium magnets remain exceptionally resistant to magnetic field loss caused by external magnetic fields,

- A magnet with a smooth nickel surface is more attractive,

- Magnets possess huge magnetic induction on the working surface,

- Through (appropriate) combination of ingredients, they can achieve high thermal resistance, allowing for functioning at temperatures reaching 230°C and above...

- Due to the ability of flexible molding and customization to individualized requirements, NdFeB magnets can be modeled in a broad palette of forms and dimensions, which expands the range of possible applications,

- Wide application in future technologies – they serve a role in hard drives, electric drive systems, diagnostic systems, as well as complex engineering applications.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Weaknesses

- They are fragile upon heavy impacts. To avoid cracks, it is worth securing magnets in a protective case. Such protection not only protects the magnet but also increases its resistance to damage

- Neodymium magnets lose their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- When exposed to humidity, magnets usually rust. For applications outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation and corrosion.

- Limited possibility of making threads in the magnet and complicated forms - preferred is casing - mounting mechanism.

- Potential hazard related to microscopic parts of magnets pose a threat, if swallowed, which becomes key in the context of child health protection. Furthermore, tiny parts of these products are able to be problematic in diagnostics medical in case of swallowing.

- With large orders the cost of neodymium magnets is economically unviable,

Lifting parameters

Best holding force of the magnet in ideal parameters – what affects it?

- with the use of a sheet made of low-carbon steel, guaranteeing maximum field concentration

- possessing a thickness of minimum 10 mm to avoid saturation

- with an polished contact surface

- without any air gap between the magnet and steel

- for force applied at a right angle (pull-off, not shear)

- at ambient temperature room level

Key elements affecting lifting force

- Distance – existence of any layer (rust, tape, air) acts as an insulator, which lowers power steeply (even by 50% at 0.5 mm).

- Pull-off angle – note that the magnet holds strongest perpendicularly. Under shear forces, the capacity drops drastically, often to levels of 20-30% of the nominal value.

- Element thickness – to utilize 100% power, the steel must be sufficiently thick. Paper-thin metal limits the attraction force (the magnet "punches through" it).

- Metal type – not every steel attracts identically. Alloy additives worsen the interaction with the magnet.

- Smoothness – ideal contact is obtained only on smooth steel. Rough texture create air cushions, reducing force.

- Temperature – temperature increase results in weakening of force. Check the thermal limit for a given model.

Lifting capacity testing was performed on plates with a smooth surface of optimal thickness, under perpendicular forces, in contrast under attempts to slide the magnet the load capacity is reduced by as much as 75%. In addition, even a small distance between the magnet’s surface and the plate reduces the load capacity.

Safety rules for work with neodymium magnets

Keep away from computers

Powerful magnetic fields can erase data on payment cards, HDDs, and storage devices. Maintain a gap of at least 10 cm.

Health Danger

Warning for patients: Strong magnetic fields disrupt medical devices. Maintain minimum 30 cm distance or request help to work with the magnets.

Power loss in heat

Keep cool. NdFeB magnets are susceptible to temperature. If you need resistance above 80°C, look for HT versions (H, SH, UH).

Allergic reactions

Nickel alert: The Ni-Cu-Ni coating consists of nickel. If redness happens, cease handling magnets and wear gloves.

Phone sensors

Remember: neodymium magnets generate a field that confuses sensitive sensors. Keep a safe distance from your mobile, device, and navigation systems.

Combustion hazard

Combustion risk: Rare earth powder is explosive. Do not process magnets without safety gear as this may cause fire.

Eye protection

Despite metallic appearance, neodymium is brittle and not impact-resistant. Do not hit, as the magnet may crumble into sharp, dangerous pieces.

No play value

Always store magnets away from children. Choking hazard is high, and the consequences of magnets connecting inside the body are fatal.

Respect the power

Handle with care. Neodymium magnets act from a distance and connect with huge force, often quicker than you can move away.

Pinching danger

Watch your fingers. Two large magnets will join immediately with a force of massive weight, crushing anything in their path. Exercise extreme caution!

![SM 32x425 [2xM8] / N52 - magnetic separator SM 32x425 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x425-2xm8-tas.jpg)