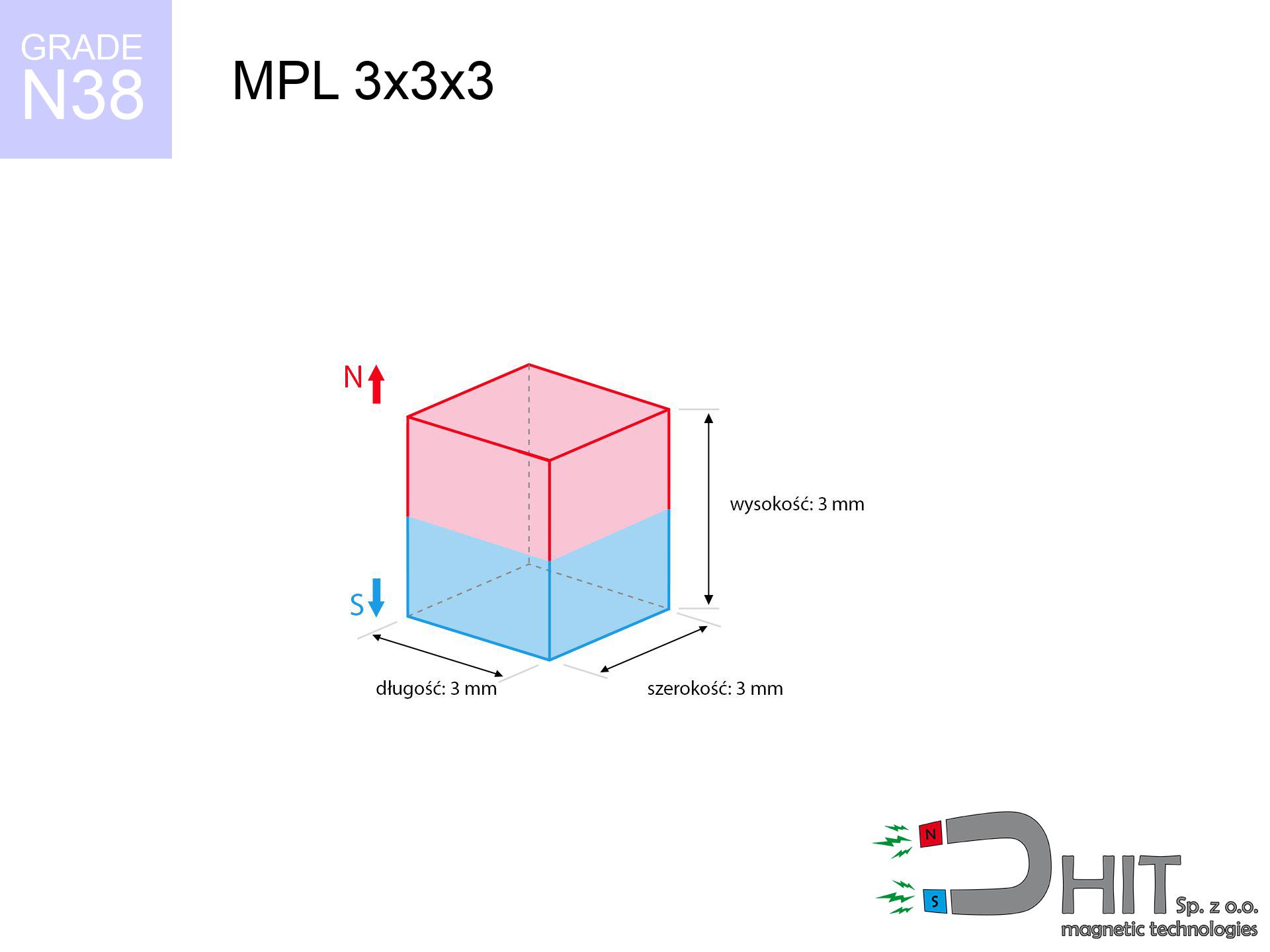

MPL 3x3x3 / N38 - lamellar magnet

lamellar magnet

Catalog no 020148

GTIN/EAN: 5906301811541

length

3 mm [±0,1 mm]

Width

3 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

0.2 g

Magnetization Direction

↑ axial

Load capacity

0.34 kg / 3.37 N

Magnetic Induction

538.48 mT / 5385 Gs

Coating

[NiCuNi] Nickel

0.1845 ZŁ with VAT / pcs + price for transport

0.1500 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

or get in touch through

inquiry form

the contact form page.

Parameters along with shape of a neodymium magnet can be verified on our

our magnetic calculator.

Order by 14:00 and we’ll ship today!

Product card - MPL 3x3x3 / N38 - lamellar magnet

Specification / characteristics - MPL 3x3x3 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020148 |

| GTIN/EAN | 5906301811541 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 3 mm [±0,1 mm] |

| Width | 3 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 0.2 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.34 kg / 3.37 N |

| Magnetic Induction ~ ? | 538.48 mT / 5385 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the product - technical parameters

Presented information are the direct effect of a mathematical analysis. Values are based on algorithms for the material Nd2Fe14B. Actual parameters might slightly differ from theoretical values. Please consider these calculations as a reference point when designing systems.

Table 1: Static force (pull vs gap) - interaction chart

MPL 3x3x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5372 Gs

537.2 mT

|

0.34 kg / 0.75 LBS

340.0 g / 3.3 N

|

safe |

| 1 mm |

2530 Gs

253.0 mT

|

0.08 kg / 0.17 LBS

75.4 g / 0.7 N

|

safe |

| 2 mm |

1127 Gs

112.7 mT

|

0.01 kg / 0.03 LBS

15.0 g / 0.1 N

|

safe |

| 3 mm |

562 Gs

56.2 mT

|

0.00 kg / 0.01 LBS

3.7 g / 0.0 N

|

safe |

| 5 mm |

192 Gs

19.2 mT

|

0.00 kg / 0.00 LBS

0.4 g / 0.0 N

|

safe |

| 10 mm |

35 Gs

3.5 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 15 mm |

12 Gs

1.2 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 20 mm |

5 Gs

0.5 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 30 mm |

2 Gs

0.2 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 50 mm |

0 Gs

0.0 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

Table 2: Sliding force (vertical surface)

MPL 3x3x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.07 kg / 0.15 LBS

68.0 g / 0.7 N

|

| 1 mm | Stal (~0.2) |

0.02 kg / 0.04 LBS

16.0 g / 0.2 N

|

| 2 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 3 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MPL 3x3x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.10 kg / 0.22 LBS

102.0 g / 1.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.07 kg / 0.15 LBS

68.0 g / 0.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.03 kg / 0.07 LBS

34.0 g / 0.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.17 kg / 0.37 LBS

170.0 g / 1.7 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MPL 3x3x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.03 kg / 0.07 LBS

34.0 g / 0.3 N

|

| 1 mm |

|

0.09 kg / 0.19 LBS

85.0 g / 0.8 N

|

| 2 mm |

|

0.17 kg / 0.37 LBS

170.0 g / 1.7 N

|

| 3 mm |

|

0.26 kg / 0.56 LBS

255.0 g / 2.5 N

|

| 5 mm |

|

0.34 kg / 0.75 LBS

340.0 g / 3.3 N

|

| 10 mm |

|

0.34 kg / 0.75 LBS

340.0 g / 3.3 N

|

| 11 mm |

|

0.34 kg / 0.75 LBS

340.0 g / 3.3 N

|

| 12 mm |

|

0.34 kg / 0.75 LBS

340.0 g / 3.3 N

|

Table 5: Working in heat (material behavior) - resistance threshold

MPL 3x3x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.34 kg / 0.75 LBS

340.0 g / 3.3 N

|

OK |

| 40 °C | -2.2% |

0.33 kg / 0.73 LBS

332.5 g / 3.3 N

|

OK |

| 60 °C | -4.4% |

0.33 kg / 0.72 LBS

325.0 g / 3.2 N

|

OK |

| 80 °C | -6.6% |

0.32 kg / 0.70 LBS

317.6 g / 3.1 N

|

|

| 100 °C | -28.8% |

0.24 kg / 0.53 LBS

242.1 g / 2.4 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MPL 3x3x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

1.60 kg / 3.53 LBS

5 931 Gs

|

0.24 kg / 0.53 LBS

240 g / 2.4 N

|

N/A |

| 1 mm |

0.80 kg / 1.77 LBS

7 610 Gs

|

0.12 kg / 0.27 LBS

120 g / 1.2 N

|

0.72 kg / 1.59 LBS

~0 Gs

|

| 2 mm |

0.36 kg / 0.78 LBS

5 061 Gs

|

0.05 kg / 0.12 LBS

53 g / 0.5 N

|

0.32 kg / 0.70 LBS

~0 Gs

|

| 3 mm |

0.15 kg / 0.34 LBS

3 343 Gs

|

0.02 kg / 0.05 LBS

23 g / 0.2 N

|

0.14 kg / 0.31 LBS

~0 Gs

|

| 5 mm |

0.03 kg / 0.08 LBS

1 568 Gs

|

0.01 kg / 0.01 LBS

5 g / 0.1 N

|

0.03 kg / 0.07 LBS

~0 Gs

|

| 10 mm |

0.00 kg / 0.00 LBS

384 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 LBS

70 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

6 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

3 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

2 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

1 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

1 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

1 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MPL 3x3x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 2.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 1.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 1.0 cm |

| Remote | 50 Gs (5.0 mT) | 1.0 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Impact energy (cracking risk) - collision effects

MPL 3x3x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

41.58 km/h

(11.55 m/s)

|

0.01 J | |

| 30 mm |

72.02 km/h

(20.01 m/s)

|

0.04 J | |

| 50 mm |

92.98 km/h

(25.83 m/s)

|

0.07 J | |

| 100 mm |

131.49 km/h

(36.53 m/s)

|

0.13 J |

Table 9: Corrosion resistance

MPL 3x3x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MPL 3x3x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 495 Mx | 5.0 µWb |

| Pc Coefficient | 0.84 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MPL 3x3x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.34 kg | Standard |

| Water (riverbed) |

0.39 kg

(+0.05 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical surface, the magnet holds just approx. 20-30% of its perpendicular strength.

2. Steel saturation

*Thin metal sheet (e.g. 0.5mm PC case) severely reduces the holding force.

3. Power loss vs temp

*For N38 grade, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.84

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also products

Advantages as well as disadvantages of neodymium magnets.

Strengths

- They retain attractive force for around ten years – the loss is just ~1% (in theory),

- They are extremely resistant to demagnetization induced by external magnetic fields,

- In other words, due to the shiny finish of gold, the element becomes visually attractive,

- Magnets exhibit huge magnetic induction on the working surface,

- Thanks to resistance to high temperature, they can operate (depending on the form) even at temperatures up to 230°C and higher...

- Thanks to flexibility in designing and the capacity to modify to specific needs,

- Huge importance in electronics industry – they are utilized in mass storage devices, electric motors, medical equipment, as well as modern systems.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in compact dimensions, which enables their usage in small systems

Disadvantages

- They are fragile upon too strong impacts. To avoid cracks, it is worth protecting magnets in special housings. Such protection not only protects the magnet but also increases its resistance to damage

- Neodymium magnets decrease their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- When exposed to humidity, magnets start to rust. For applications outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation and corrosion.

- We suggest cover - magnetic mechanism, due to difficulties in creating nuts inside the magnet and complicated shapes.

- Potential hazard resulting from small fragments of magnets are risky, if swallowed, which is particularly important in the aspect of protecting the youngest. Additionally, small elements of these devices are able to disrupt the diagnostic process medical when they are in the body.

- With mass production the cost of neodymium magnets is a challenge,

Lifting parameters

Maximum lifting force for a neodymium magnet – what affects it?

- on a base made of structural steel, perfectly concentrating the magnetic flux

- possessing a massiveness of min. 10 mm to ensure full flux closure

- characterized by lack of roughness

- without any insulating layer between the magnet and steel

- for force acting at a right angle (in the magnet axis)

- in temp. approx. 20°C

Lifting capacity in practice – influencing factors

- Gap between surfaces – even a fraction of a millimeter of separation (caused e.g. by varnish or dirt) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Force direction – declared lifting capacity refers to detachment vertically. When slipping, the magnet exhibits much less (often approx. 20-30% of nominal force).

- Metal thickness – the thinner the sheet, the weaker the hold. Magnetic flux passes through the material instead of generating force.

- Material composition – not every steel reacts the same. Alloy additives worsen the interaction with the magnet.

- Plate texture – ground elements guarantee perfect abutment, which improves force. Rough surfaces weaken the grip.

- Operating temperature – neodymium magnets have a sensitivity to temperature. At higher temperatures they are weaker, and in frost gain strength (up to a certain limit).

Holding force was tested on the plate surface of 20 mm thickness, when a perpendicular force was applied, however under shearing force the lifting capacity is smaller. Moreover, even a slight gap between the magnet’s surface and the plate lowers the holding force.

Precautions when working with neodymium magnets

Product not for children

Strictly store magnets out of reach of children. Ingestion danger is significant, and the effects of magnets clamping inside the body are tragic.

GPS and phone interference

Be aware: neodymium magnets generate a field that disrupts sensitive sensors. Keep a separation from your phone, tablet, and navigation systems.

Heat warning

Control the heat. Heating the magnet to high heat will ruin its properties and strength.

Handling rules

Before starting, check safety instructions. Uncontrolled attraction can destroy the magnet or injure your hand. Think ahead.

Metal Allergy

Medical facts indicate that the nickel plating (standard magnet coating) is a common allergen. For allergy sufferers, prevent direct skin contact or choose encased magnets.

Safe distance

Do not bring magnets close to a purse, laptop, or TV. The magnetic field can irreversibly ruin these devices and erase data from cards.

Implant safety

Health Alert: Strong magnets can deactivate heart devices and defibrillators. Stay away if you have medical devices.

Finger safety

Pinching hazard: The attraction force is so immense that it can cause blood blisters, crushing, and broken bones. Protective gloves are recommended.

Shattering risk

NdFeB magnets are sintered ceramics, which means they are prone to chipping. Collision of two magnets leads to them cracking into small pieces.

Dust is flammable

Fire hazard: Neodymium dust is highly flammable. Do not process magnets without safety gear as this risks ignition.

![UMGGW 29x8 [M4] GW / N38 - magnetic holder rubber internal thread UMGGW 29x8 [M4] GW / N38 - magnetic holder rubber internal thread](https://cdn3.dhit.pl/graphics/products/umg-29x8-m4-gw-duf.jpg)