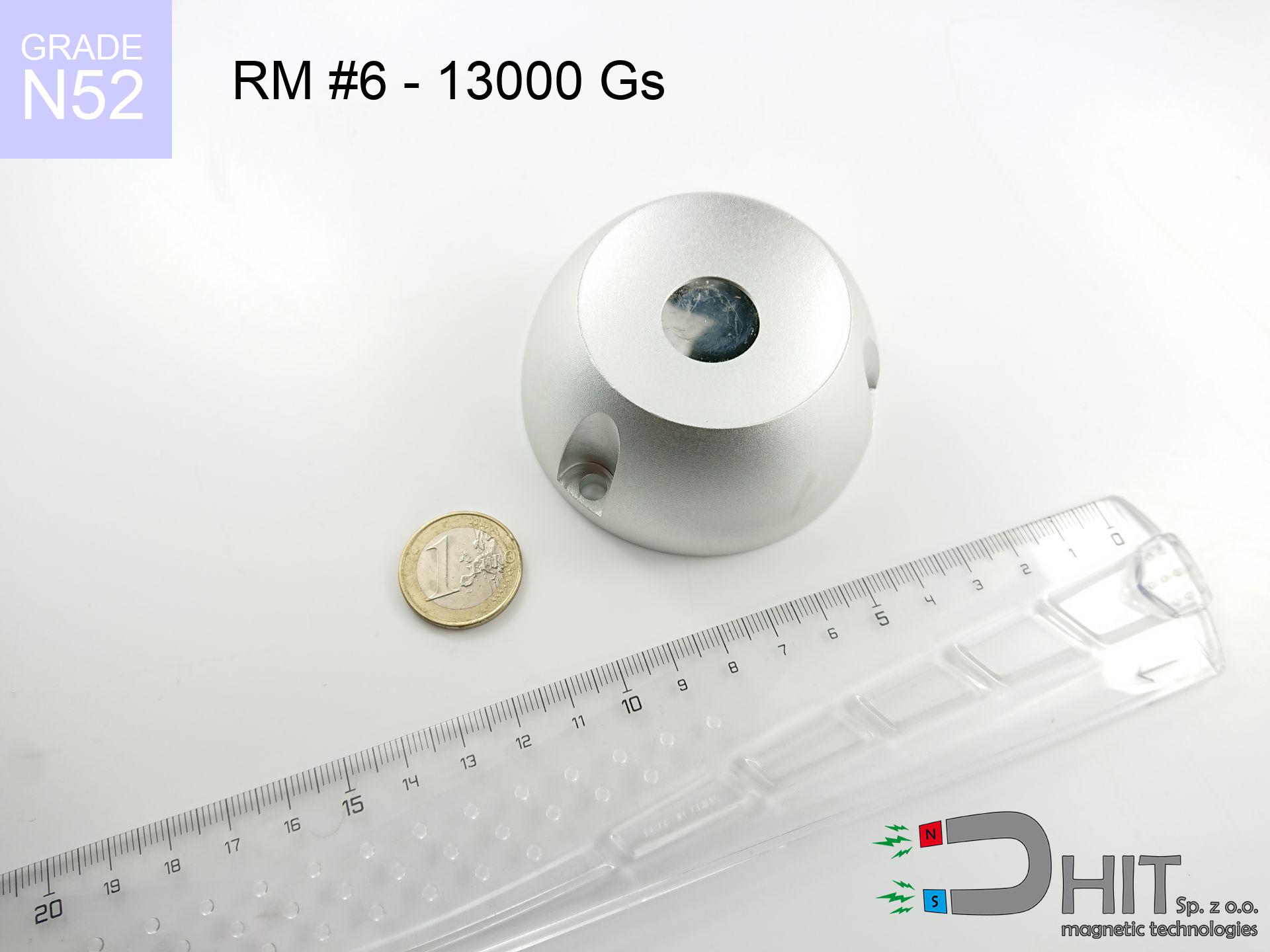

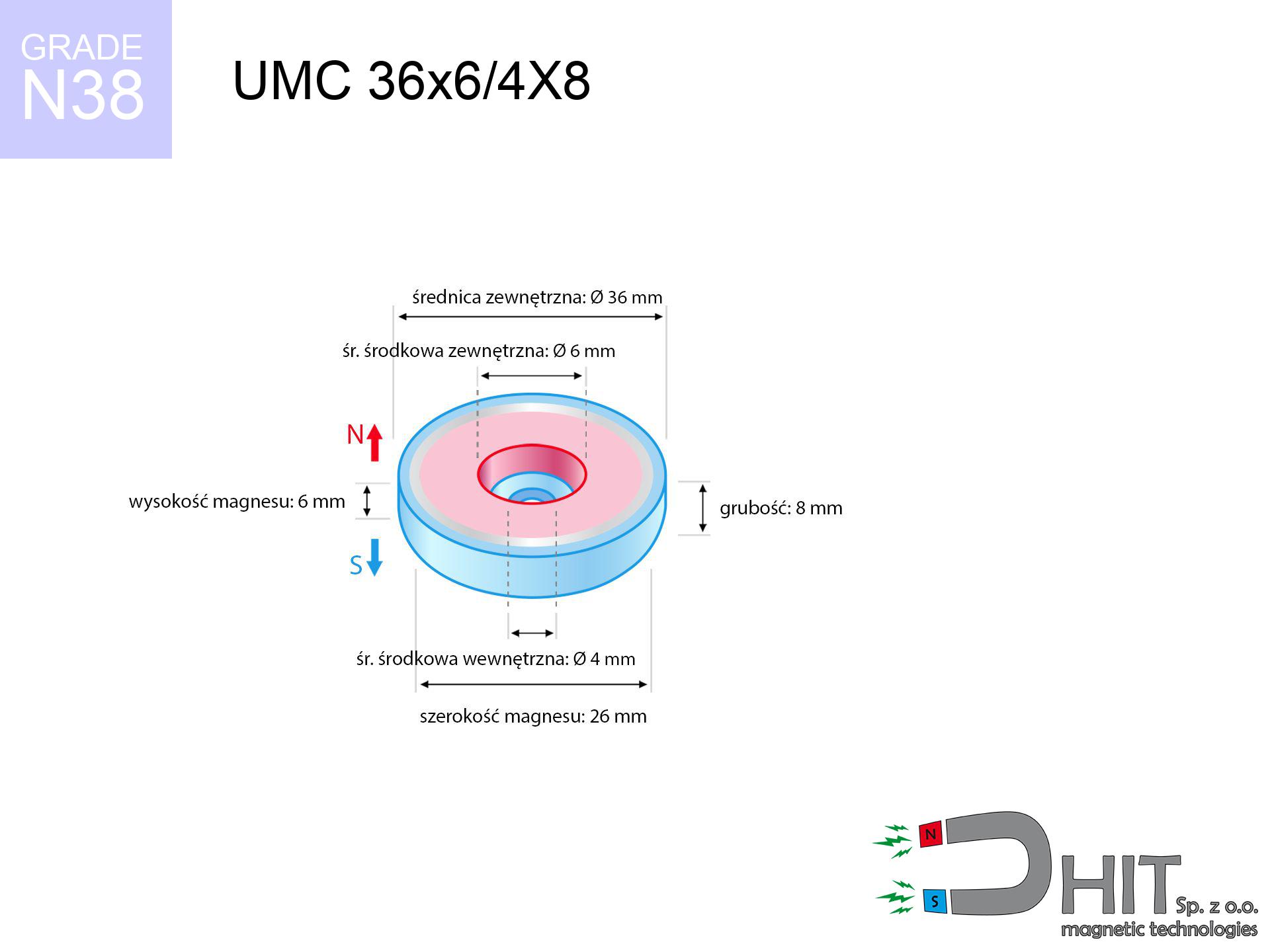

UMC 36x6/4X8 / N38 - cylindrical magnetic holder

cylindrical magnetic holder

Catalog no 320410

GTIN/EAN: 5906301814665

Diameter

36 mm [±1 mm]

internal diameter Ø

6/4 mm [±1 mm]

Height

8 mm [±1 mm]

Weight

45 g

Load capacity

29.00 kg / 284.39 N

Coating

[NiCuNi] Nickel

21.49 ZŁ with VAT / pcs + price for transport

17.47 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

otherwise drop us a message via

our online form

our website.

Parameters and shape of a magnet can be analyzed using our

modular calculator.

Same-day processing for orders placed before 14:00.

Technical data - UMC 36x6/4X8 / N38 - cylindrical magnetic holder

Specification / characteristics - UMC 36x6/4X8 / N38 - cylindrical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 320410 |

| GTIN/EAN | 5906301814665 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 36 mm [±1 mm] |

| internal diameter Ø | 6/4 mm [±1 mm] |

| Height | 8 mm [±1 mm] |

| Weight | 45 g |

| Load capacity ~ ? | 29.00 kg / 284.39 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See more proposals

Pros as well as cons of rare earth magnets.

Pros

- They virtually do not lose power, because even after 10 years the decline in efficiency is only ~1% (according to literature),

- Neodymium magnets are characterized by highly resistant to magnetic field loss caused by external magnetic fields,

- In other words, due to the aesthetic finish of gold, the element is aesthetically pleasing,

- They are known for high magnetic induction at the operating surface, which increases their power,

- Through (adequate) combination of ingredients, they can achieve high thermal strength, enabling action at temperatures approaching 230°C and above...

- Possibility of precise forming as well as modifying to complex applications,

- Fundamental importance in electronics industry – they are commonly used in data components, drive modules, advanced medical instruments, also other advanced devices.

- Thanks to concentrated force, small magnets offer high operating force, in miniature format,

Disadvantages

- To avoid cracks under impact, we recommend using special steel holders. Such a solution protects the magnet and simultaneously improves its durability.

- Neodymium magnets decrease their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- They oxidize in a humid environment. For use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- Limited possibility of making threads in the magnet and complicated forms - preferred is casing - magnet mounting.

- Health risk to health – tiny shards of magnets pose a threat, in case of ingestion, which becomes key in the aspect of protecting the youngest. It is also worth noting that small components of these products can complicate diagnosis medical after entering the body.

- Due to complex production process, their price exceeds standard values,

Lifting parameters

Highest magnetic holding force – what contributes to it?

- on a plate made of mild steel, optimally conducting the magnetic field

- with a cross-section of at least 10 mm

- with a plane free of scratches

- with total lack of distance (no paint)

- for force applied at a right angle (pull-off, not shear)

- in neutral thermal conditions

Practical lifting capacity: influencing factors

- Space between magnet and steel – even a fraction of a millimeter of distance (caused e.g. by varnish or unevenness) diminishes the magnet efficiency, often by half at just 0.5 mm.

- Angle of force application – maximum parameter is obtained only during pulling at a 90° angle. The resistance to sliding of the magnet along the plate is standardly many times smaller (approx. 1/5 of the lifting capacity).

- Base massiveness – insufficiently thick plate does not close the flux, causing part of the power to be escaped to the other side.

- Metal type – different alloys attracts identically. Alloy additives worsen the interaction with the magnet.

- Surface quality – the smoother and more polished the surface, the better the adhesion and higher the lifting capacity. Roughness acts like micro-gaps.

- Temperature influence – hot environment reduces pulling force. Too high temperature can permanently damage the magnet.

Holding force was tested on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, in contrast under parallel forces the lifting capacity is smaller. Additionally, even a slight gap between the magnet’s surface and the plate decreases the load capacity.

H&S for magnets

Immense force

Handle with care. Rare earth magnets act from a long distance and snap with massive power, often quicker than you can move away.

Swallowing risk

Neodymium magnets are not intended for children. Eating several magnets may result in them pinching intestinal walls, which poses a severe health hazard and necessitates immediate surgery.

Nickel allergy

Allergy Notice: The Ni-Cu-Ni coating contains nickel. If an allergic reaction occurs, cease working with magnets and use protective gear.

Do not drill into magnets

Machining of neodymium magnets carries a risk of fire risk. Neodymium dust reacts violently with oxygen and is difficult to extinguish.

Bone fractures

Mind your fingers. Two powerful magnets will join instantly with a force of several hundred kilograms, crushing everything in their path. Be careful!

Risk of cracking

Despite the nickel coating, neodymium is brittle and not impact-resistant. Do not hit, as the magnet may crumble into sharp, dangerous pieces.

Threat to navigation

GPS units and smartphones are extremely sensitive to magnetism. Direct contact with a strong magnet can decalibrate the sensors in your phone.

Warning for heart patients

Health Alert: Neodymium magnets can turn off heart devices and defibrillators. Stay away if you have electronic implants.

Permanent damage

Standard neodymium magnets (N-type) lose power when the temperature exceeds 80°C. This process is irreversible.

Electronic hazard

Powerful magnetic fields can destroy records on credit cards, HDDs, and storage devices. Keep a distance of min. 10 cm.

![UMGZ 16x13x5 [M4] GZ / N38 - magnetic holder external thread UMGZ 16x13x5 [M4] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/um-16x13x5-m4-gz-cor.jpg)