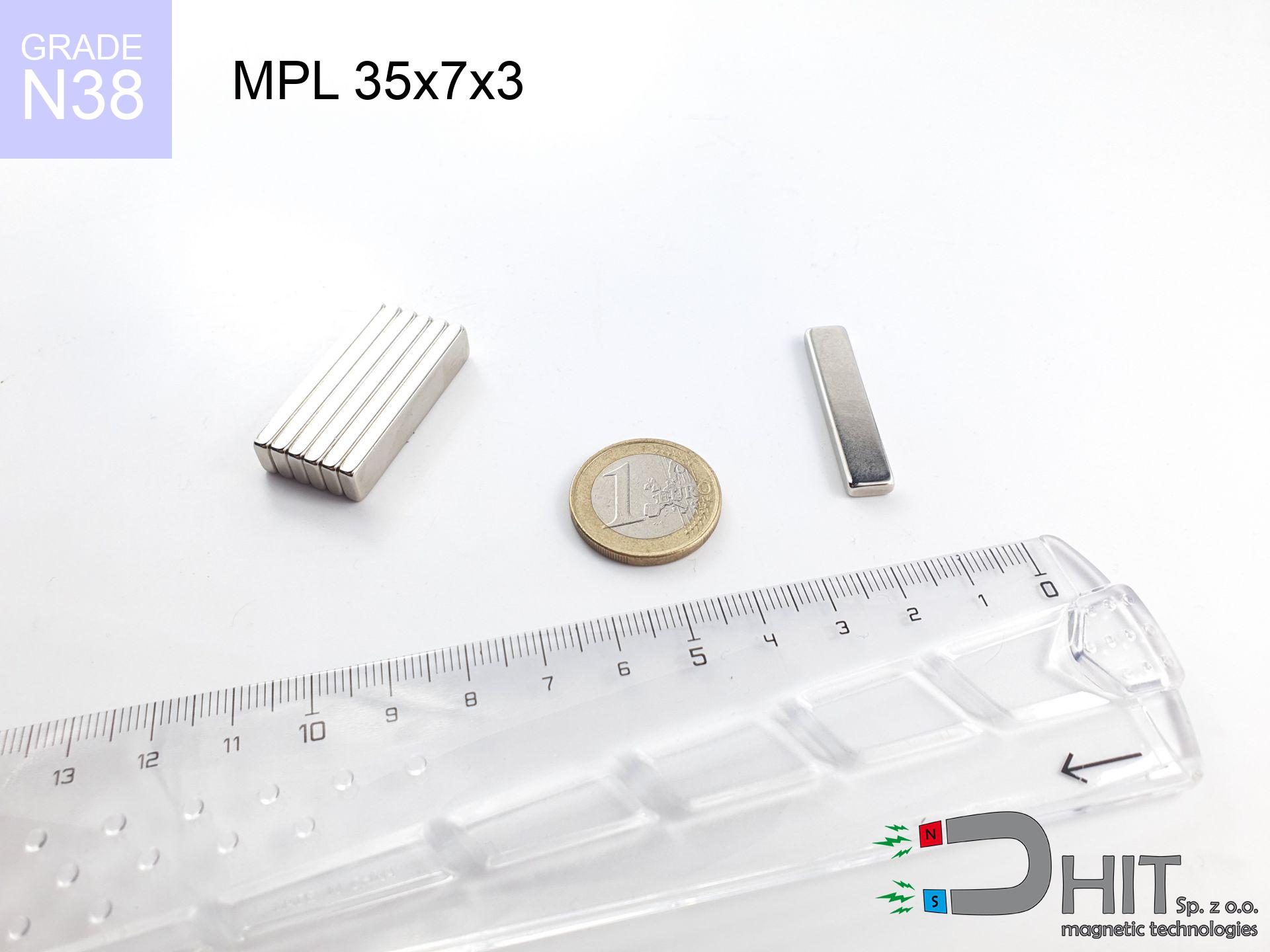

MPL 35x7x3 / N38 - lamellar magnet

lamellar magnet

Catalog no 020145

GTIN/EAN: 5906301811510

length

35 mm [±0,1 mm]

Width

7 mm [±0,1 mm]

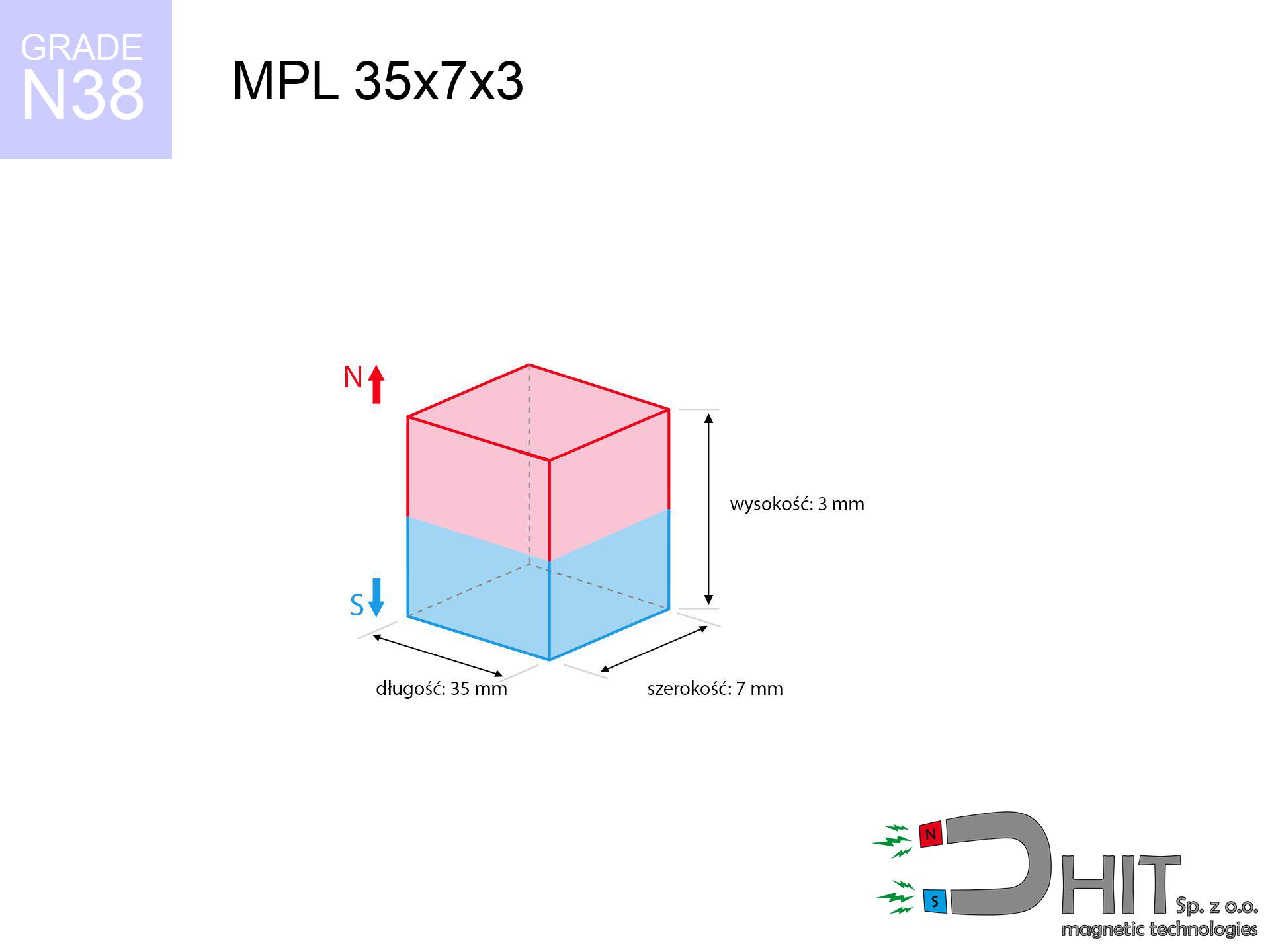

Height

3 mm [±0,1 mm]

Weight

5.51 g

Magnetization Direction

↑ axial

Load capacity

6.21 kg / 60.89 N

Magnetic Induction

285.96 mT / 2860 Gs

Coating

[NiCuNi] Nickel

2.99 ZŁ with VAT / pcs + price for transport

2.43 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

or contact us using

our online form

through our site.

Weight as well as form of magnets can be checked with our

our magnetic calculator.

Orders placed before 14:00 will be shipped the same business day.

Product card - MPL 35x7x3 / N38 - lamellar magnet

Specification / characteristics - MPL 35x7x3 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020145 |

| GTIN/EAN | 5906301811510 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 35 mm [±0,1 mm] |

| Width | 7 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 5.51 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 6.21 kg / 60.89 N |

| Magnetic Induction ~ ? | 285.96 mT / 2860 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the product - data

The following data represent the direct effect of a physical calculation. Results rely on algorithms for the material Nd2Fe14B. Real-world parameters might slightly deviate from the simulation results. Please consider these data as a reference point for designers.

Table 1: Static force (force vs distance) - power drop

MPL 35x7x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2858 Gs

285.8 mT

|

6.21 kg / 13.69 lbs

6210.0 g / 60.9 N

|

strong |

| 1 mm |

2328 Gs

232.8 mT

|

4.12 kg / 9.09 lbs

4121.1 g / 40.4 N

|

strong |

| 2 mm |

1801 Gs

180.1 mT

|

2.47 kg / 5.44 lbs

2467.6 g / 24.2 N

|

strong |

| 3 mm |

1376 Gs

137.6 mT

|

1.44 kg / 3.18 lbs

1440.7 g / 14.1 N

|

weak grip |

| 5 mm |

832 Gs

83.2 mT

|

0.53 kg / 1.16 lbs

526.9 g / 5.2 N

|

weak grip |

| 10 mm |

318 Gs

31.8 mT

|

0.08 kg / 0.17 lbs

77.1 g / 0.8 N

|

weak grip |

| 15 mm |

158 Gs

15.8 mT

|

0.02 kg / 0.04 lbs

18.9 g / 0.2 N

|

weak grip |

| 20 mm |

89 Gs

8.9 mT

|

0.01 kg / 0.01 lbs

6.0 g / 0.1 N

|

weak grip |

| 30 mm |

35 Gs

3.5 mT

|

0.00 kg / 0.00 lbs

1.0 g / 0.0 N

|

weak grip |

| 50 mm |

10 Gs

1.0 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

weak grip |

Table 2: Slippage hold (vertical surface)

MPL 35x7x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.24 kg / 2.74 lbs

1242.0 g / 12.2 N

|

| 1 mm | Stal (~0.2) |

0.82 kg / 1.82 lbs

824.0 g / 8.1 N

|

| 2 mm | Stal (~0.2) |

0.49 kg / 1.09 lbs

494.0 g / 4.8 N

|

| 3 mm | Stal (~0.2) |

0.29 kg / 0.63 lbs

288.0 g / 2.8 N

|

| 5 mm | Stal (~0.2) |

0.11 kg / 0.23 lbs

106.0 g / 1.0 N

|

| 10 mm | Stal (~0.2) |

0.02 kg / 0.04 lbs

16.0 g / 0.2 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MPL 35x7x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.86 kg / 4.11 lbs

1863.0 g / 18.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.24 kg / 2.74 lbs

1242.0 g / 12.2 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.62 kg / 1.37 lbs

621.0 g / 6.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.11 kg / 6.85 lbs

3105.0 g / 30.5 N

|

Table 4: Material efficiency (saturation) - power losses

MPL 35x7x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.62 kg / 1.37 lbs

621.0 g / 6.1 N

|

| 1 mm |

|

1.55 kg / 3.42 lbs

1552.5 g / 15.2 N

|

| 2 mm |

|

3.11 kg / 6.85 lbs

3105.0 g / 30.5 N

|

| 3 mm |

|

4.66 kg / 10.27 lbs

4657.5 g / 45.7 N

|

| 5 mm |

|

6.21 kg / 13.69 lbs

6210.0 g / 60.9 N

|

| 10 mm |

|

6.21 kg / 13.69 lbs

6210.0 g / 60.9 N

|

| 11 mm |

|

6.21 kg / 13.69 lbs

6210.0 g / 60.9 N

|

| 12 mm |

|

6.21 kg / 13.69 lbs

6210.0 g / 60.9 N

|

Table 5: Thermal resistance (stability) - power drop

MPL 35x7x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

6.21 kg / 13.69 lbs

6210.0 g / 60.9 N

|

OK |

| 40 °C | -2.2% |

6.07 kg / 13.39 lbs

6073.4 g / 59.6 N

|

OK |

| 60 °C | -4.4% |

5.94 kg / 13.09 lbs

5936.8 g / 58.2 N

|

|

| 80 °C | -6.6% |

5.80 kg / 12.79 lbs

5800.1 g / 56.9 N

|

|

| 100 °C | -28.8% |

4.42 kg / 9.75 lbs

4421.5 g / 43.4 N

|

Table 6: Two magnets (repulsion) - field range

MPL 35x7x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

12.34 kg / 27.19 lbs

4 231 Gs

|

1.85 kg / 4.08 lbs

1850 g / 18.2 N

|

N/A |

| 1 mm |

10.25 kg / 22.59 lbs

5 209 Gs

|

1.54 kg / 3.39 lbs

1537 g / 15.1 N

|

9.22 kg / 20.33 lbs

~0 Gs

|

| 2 mm |

8.19 kg / 18.05 lbs

4 656 Gs

|

1.23 kg / 2.71 lbs

1228 g / 12.0 N

|

7.37 kg / 16.24 lbs

~0 Gs

|

| 3 mm |

6.38 kg / 14.07 lbs

4 110 Gs

|

0.96 kg / 2.11 lbs

957 g / 9.4 N

|

5.74 kg / 12.66 lbs

~0 Gs

|

| 5 mm |

3.74 kg / 8.25 lbs

3 149 Gs

|

0.56 kg / 1.24 lbs

562 g / 5.5 N

|

3.37 kg / 7.43 lbs

~0 Gs

|

| 10 mm |

1.05 kg / 2.31 lbs

1 665 Gs

|

0.16 kg / 0.35 lbs

157 g / 1.5 N

|

0.94 kg / 2.08 lbs

~0 Gs

|

| 20 mm |

0.15 kg / 0.34 lbs

637 Gs

|

0.02 kg / 0.05 lbs

23 g / 0.2 N

|

0.14 kg / 0.30 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.01 lbs

109 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

71 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

48 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

34 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

25 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

19 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (electronics) - precautionary measures

MPL 35x7x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 4.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.0 cm |

| Remote | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (kinetic energy) - warning

MPL 35x7x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

34.12 km/h

(9.48 m/s)

|

0.25 J | |

| 30 mm |

58.65 km/h

(16.29 m/s)

|

0.73 J | |

| 50 mm |

75.71 km/h

(21.03 m/s)

|

1.22 J | |

| 100 mm |

107.07 km/h

(29.74 m/s)

|

2.44 J |

Table 9: Corrosion resistance

MPL 35x7x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MPL 35x7x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 5 851 Mx | 58.5 µWb |

| Pc Coefficient | 0.25 | Low (Flat) |

Table 11: Submerged application

MPL 35x7x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 6.21 kg | Standard |

| Water (riverbed) |

7.11 kg

(+0.90 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Caution: On a vertical wall, the magnet retains only approx. 20-30% of its max power.

2. Steel thickness impact

*Thin steel (e.g. computer case) significantly limits the holding force.

3. Heat tolerance

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.25

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also offers

Pros and cons of neodymium magnets.

Advantages

- They virtually do not lose power, because even after ten years the performance loss is only ~1% (in laboratory conditions),

- They do not lose their magnetic properties even under external field action,

- In other words, due to the aesthetic finish of nickel, the element is aesthetically pleasing,

- They show high magnetic induction at the operating surface, which increases their power,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Thanks to versatility in forming and the ability to adapt to individual projects,

- Wide application in advanced technology sectors – they serve a role in hard drives, drive modules, medical devices, and other advanced devices.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Cons

- At strong impacts they can crack, therefore we recommend placing them in strong housings. A metal housing provides additional protection against damage and increases the magnet's durability.

- Neodymium magnets decrease their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- Magnets exposed to a humid environment can rust. Therefore during using outdoors, we advise using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- Limited possibility of creating nuts in the magnet and complicated shapes - preferred is casing - mounting mechanism.

- Possible danger to health – tiny shards of magnets can be dangerous, when accidentally swallowed, which gains importance in the aspect of protecting the youngest. Additionally, small elements of these magnets can complicate diagnosis medical after entering the body.

- With budget limitations the cost of neodymium magnets is a challenge,

Holding force characteristics

Detachment force of the magnet in optimal conditions – what it depends on?

- using a base made of high-permeability steel, acting as a magnetic yoke

- possessing a massiveness of minimum 10 mm to avoid saturation

- characterized by smoothness

- under conditions of ideal adhesion (metal-to-metal)

- for force acting at a right angle (pull-off, not shear)

- at conditions approx. 20°C

Impact of factors on magnetic holding capacity in practice

- Air gap (betwixt the magnet and the plate), since even a microscopic distance (e.g. 0.5 mm) can cause a reduction in lifting capacity by up to 50% (this also applies to paint, rust or dirt).

- Force direction – remember that the magnet has greatest strength perpendicularly. Under shear forces, the capacity drops significantly, often to levels of 20-30% of the nominal value.

- Base massiveness – insufficiently thick sheet causes magnetic saturation, causing part of the power to be escaped into the air.

- Metal type – different alloys attracts identically. Alloy additives worsen the interaction with the magnet.

- Smoothness – full contact is obtained only on polished steel. Rough texture reduce the real contact area, reducing force.

- Temperature influence – high temperature weakens pulling force. Exceeding the limit temperature can permanently damage the magnet.

Lifting capacity was assessed using a polished steel plate of suitable thickness (min. 20 mm), under vertically applied force, in contrast under shearing force the load capacity is reduced by as much as fivefold. In addition, even a small distance between the magnet’s surface and the plate reduces the lifting capacity.

Precautions when working with NdFeB magnets

Finger safety

Big blocks can crush fingers in a fraction of a second. Never put your hand betwixt two attracting surfaces.

Implant safety

People with a ICD should keep an safe separation from magnets. The magnetism can disrupt the operation of the implant.

Allergic reactions

Nickel alert: The Ni-Cu-Ni coating contains nickel. If skin irritation happens, immediately stop working with magnets and use protective gear.

Flammability

Powder produced during cutting of magnets is flammable. Avoid drilling into magnets without proper cooling and knowledge.

Risk of cracking

Protect your eyes. Magnets can fracture upon violent connection, ejecting sharp fragments into the air. Eye protection is mandatory.

Danger to the youngest

Only for adults. Small elements can be swallowed, causing serious injuries. Keep away from kids and pets.

Do not overheat magnets

Watch the temperature. Exposing the magnet above 80 degrees Celsius will destroy its properties and strength.

Keep away from computers

Avoid bringing magnets near a purse, computer, or TV. The magnetism can permanently damage these devices and wipe information from cards.

Impact on smartphones

An intense magnetic field disrupts the operation of compasses in smartphones and GPS navigation. Maintain magnets close to a smartphone to avoid damaging the sensors.

Do not underestimate power

Use magnets consciously. Their huge power can shock even professionals. Plan your moves and respect their force.

![BM 380x180x70 [4x M8] - magnetic beam BM 380x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-380x180x70-4x-m8-wex.jpg)