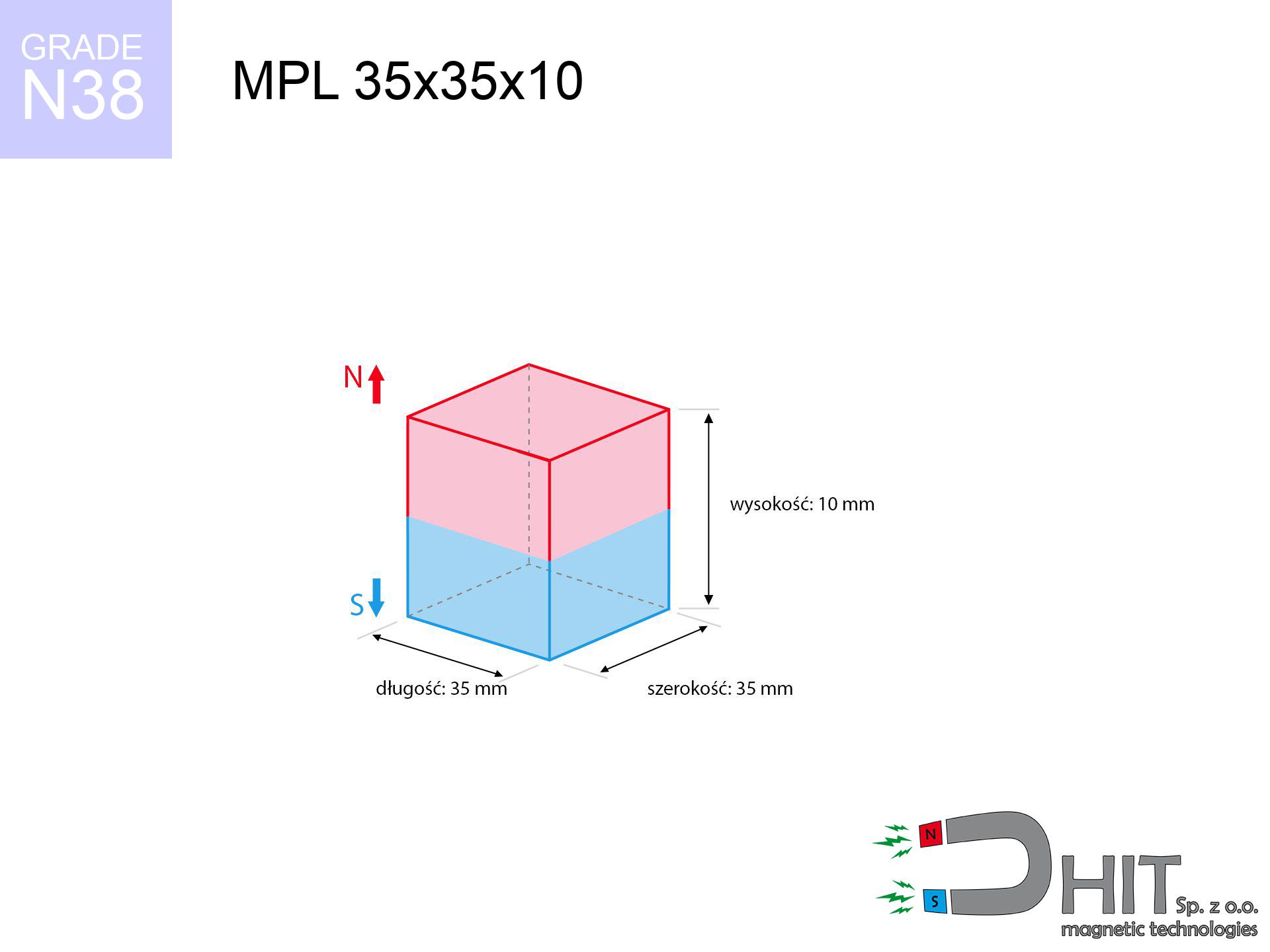

MPL 35x35x10 / N38 - lamellar magnet

lamellar magnet

Catalog no 020144

GTIN/EAN: 5906301811503

length

35 mm [±0,1 mm]

Width

35 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

91.88 g

Magnetization Direction

↑ axial

Load capacity

26.88 kg / 263.71 N

Magnetic Induction

282.90 mT / 2829 Gs

Coating

[NiCuNi] Nickel

35.10 ZŁ with VAT / pcs + price for transport

28.54 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

alternatively let us know via

contact form

through our site.

Force along with form of magnets can be verified using our

modular calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical specification - MPL 35x35x10 / N38 - lamellar magnet

Specification / characteristics - MPL 35x35x10 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020144 |

| GTIN/EAN | 5906301811503 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 35 mm [±0,1 mm] |

| Width | 35 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 91.88 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 26.88 kg / 263.71 N |

| Magnetic Induction ~ ? | 282.90 mT / 2829 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical modeling of the assembly - data

Presented values are the result of a mathematical calculation. Values are based on models for the material Nd2Fe14B. Operational conditions may deviate from the simulation results. Please consider these data as a reference point for designers.

Table 1: Static pull force (pull vs distance) - interaction chart

MPL 35x35x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2829 Gs

282.9 mT

|

26.88 kg / 59.26 LBS

26880.0 g / 263.7 N

|

critical level |

| 1 mm |

2727 Gs

272.7 mT

|

24.98 kg / 55.08 LBS

24982.7 g / 245.1 N

|

critical level |

| 2 mm |

2613 Gs

261.3 mT

|

22.94 kg / 50.57 LBS

22939.0 g / 225.0 N

|

critical level |

| 3 mm |

2491 Gs

249.1 mT

|

20.84 kg / 45.95 LBS

20841.0 g / 204.4 N

|

critical level |

| 5 mm |

2232 Gs

223.2 mT

|

16.73 kg / 36.88 LBS

16730.5 g / 164.1 N

|

critical level |

| 10 mm |

1600 Gs

160.0 mT

|

8.60 kg / 18.96 LBS

8600.7 g / 84.4 N

|

warning |

| 15 mm |

1102 Gs

110.2 mT

|

4.08 kg / 9.00 LBS

4082.9 g / 40.1 N

|

warning |

| 20 mm |

757 Gs

75.7 mT

|

1.93 kg / 4.25 LBS

1925.7 g / 18.9 N

|

low risk |

| 30 mm |

376 Gs

37.6 mT

|

0.48 kg / 1.05 LBS

475.7 g / 4.7 N

|

low risk |

| 50 mm |

122 Gs

12.2 mT

|

0.05 kg / 0.11 LBS

49.9 g / 0.5 N

|

low risk |

Table 2: Sliding hold (vertical surface)

MPL 35x35x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

5.38 kg / 11.85 LBS

5376.0 g / 52.7 N

|

| 1 mm | Stal (~0.2) |

5.00 kg / 11.01 LBS

4996.0 g / 49.0 N

|

| 2 mm | Stal (~0.2) |

4.59 kg / 10.11 LBS

4588.0 g / 45.0 N

|

| 3 mm | Stal (~0.2) |

4.17 kg / 9.19 LBS

4168.0 g / 40.9 N

|

| 5 mm | Stal (~0.2) |

3.35 kg / 7.38 LBS

3346.0 g / 32.8 N

|

| 10 mm | Stal (~0.2) |

1.72 kg / 3.79 LBS

1720.0 g / 16.9 N

|

| 15 mm | Stal (~0.2) |

0.82 kg / 1.80 LBS

816.0 g / 8.0 N

|

| 20 mm | Stal (~0.2) |

0.39 kg / 0.85 LBS

386.0 g / 3.8 N

|

| 30 mm | Stal (~0.2) |

0.10 kg / 0.21 LBS

96.0 g / 0.9 N

|

| 50 mm | Stal (~0.2) |

0.01 kg / 0.02 LBS

10.0 g / 0.1 N

|

Table 3: Wall mounting (shearing) - vertical pull

MPL 35x35x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

8.06 kg / 17.78 LBS

8064.0 g / 79.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

5.38 kg / 11.85 LBS

5376.0 g / 52.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

2.69 kg / 5.93 LBS

2688.0 g / 26.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

13.44 kg / 29.63 LBS

13440.0 g / 131.8 N

|

Table 4: Steel thickness (saturation) - power losses

MPL 35x35x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.34 kg / 2.96 LBS

1344.0 g / 13.2 N

|

| 1 mm |

|

3.36 kg / 7.41 LBS

3360.0 g / 33.0 N

|

| 2 mm |

|

6.72 kg / 14.82 LBS

6720.0 g / 65.9 N

|

| 3 mm |

|

10.08 kg / 22.22 LBS

10080.0 g / 98.9 N

|

| 5 mm |

|

16.80 kg / 37.04 LBS

16800.0 g / 164.8 N

|

| 10 mm |

|

26.88 kg / 59.26 LBS

26880.0 g / 263.7 N

|

| 11 mm |

|

26.88 kg / 59.26 LBS

26880.0 g / 263.7 N

|

| 12 mm |

|

26.88 kg / 59.26 LBS

26880.0 g / 263.7 N

|

Table 5: Thermal stability (material behavior) - thermal limit

MPL 35x35x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

26.88 kg / 59.26 LBS

26880.0 g / 263.7 N

|

OK |

| 40 °C | -2.2% |

26.29 kg / 57.96 LBS

26288.6 g / 257.9 N

|

OK |

| 60 °C | -4.4% |

25.70 kg / 56.65 LBS

25697.3 g / 252.1 N

|

|

| 80 °C | -6.6% |

25.11 kg / 55.35 LBS

25105.9 g / 246.3 N

|

|

| 100 °C | -28.8% |

19.14 kg / 42.19 LBS

19138.6 g / 187.7 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MPL 35x35x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

60.43 kg / 133.22 LBS

4 428 Gs

|

9.06 kg / 19.98 LBS

9064 g / 88.9 N

|

N/A |

| 1 mm |

58.36 kg / 128.67 LBS

5 560 Gs

|

8.75 kg / 19.30 LBS

8754 g / 85.9 N

|

52.53 kg / 115.80 LBS

~0 Gs

|

| 2 mm |

56.16 kg / 123.82 LBS

5 454 Gs

|

8.42 kg / 18.57 LBS

8424 g / 82.6 N

|

50.55 kg / 111.44 LBS

~0 Gs

|

| 3 mm |

53.89 kg / 118.81 LBS

5 343 Gs

|

8.08 kg / 17.82 LBS

8084 g / 79.3 N

|

48.50 kg / 106.93 LBS

~0 Gs

|

| 5 mm |

49.22 kg / 108.50 LBS

5 106 Gs

|

7.38 kg / 16.28 LBS

7382 g / 72.4 N

|

44.29 kg / 97.65 LBS

~0 Gs

|

| 10 mm |

37.61 kg / 82.92 LBS

4 463 Gs

|

5.64 kg / 12.44 LBS

5642 g / 55.3 N

|

33.85 kg / 74.63 LBS

~0 Gs

|

| 20 mm |

19.33 kg / 42.63 LBS

3 200 Gs

|

2.90 kg / 6.39 LBS

2900 g / 28.5 N

|

17.40 kg / 38.36 LBS

~0 Gs

|

| 50 mm |

2.10 kg / 4.64 LBS

1 056 Gs

|

0.32 kg / 0.70 LBS

316 g / 3.1 N

|

1.89 kg / 4.18 LBS

~0 Gs

|

| 60 mm |

1.07 kg / 2.36 LBS

753 Gs

|

0.16 kg / 0.35 LBS

160 g / 1.6 N

|

0.96 kg / 2.12 LBS

~0 Gs

|

| 70 mm |

0.57 kg / 1.26 LBS

550 Gs

|

0.09 kg / 0.19 LBS

86 g / 0.8 N

|

0.51 kg / 1.13 LBS

~0 Gs

|

| 80 mm |

0.32 kg / 0.70 LBS

411 Gs

|

0.05 kg / 0.11 LBS

48 g / 0.5 N

|

0.29 kg / 0.63 LBS

~0 Gs

|

| 90 mm |

0.19 kg / 0.41 LBS

313 Gs

|

0.03 kg / 0.06 LBS

28 g / 0.3 N

|

0.17 kg / 0.37 LBS

~0 Gs

|

| 100 mm |

0.11 kg / 0.25 LBS

244 Gs

|

0.02 kg / 0.04 LBS

17 g / 0.2 N

|

0.10 kg / 0.22 LBS

~0 Gs

|

Table 7: Protective zones (implants) - warnings

MPL 35x35x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 16.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 13.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 10.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 8.0 cm |

| Car key | 50 Gs (5.0 mT) | 7.5 cm |

| Payment card | 400 Gs (40.0 mT) | 3.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.5 cm |

Table 8: Dynamics (cracking risk) - collision effects

MPL 35x35x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

20.41 km/h

(5.67 m/s)

|

1.48 J | |

| 30 mm |

30.21 km/h

(8.39 m/s)

|

3.23 J | |

| 50 mm |

38.62 km/h

(10.73 m/s)

|

5.29 J | |

| 100 mm |

54.55 km/h

(15.15 m/s)

|

10.55 J |

Table 9: Anti-corrosion coating durability

MPL 35x35x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MPL 35x35x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 38 021 Mx | 380.2 µWb |

| Pc Coefficient | 0.35 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MPL 35x35x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 26.88 kg | Standard |

| Water (riverbed) |

30.78 kg

(+3.90 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Warning: On a vertical surface, the magnet retains just a fraction of its max power.

2. Steel thickness impact

*Thin metal sheet (e.g. 0.5mm PC case) drastically limits the holding force.

3. Temperature resistance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.35

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Strengths as well as weaknesses of Nd2Fe14B magnets.

Strengths

- They retain full power for around 10 years – the loss is just ~1% (based on simulations),

- They do not lose their magnetic properties even under close interference source,

- By covering with a decorative layer of nickel, the element presents an proper look,

- They feature high magnetic induction at the operating surface, which affects their effectiveness,

- Thanks to resistance to high temperature, they can operate (depending on the shape) even at temperatures up to 230°C and higher...

- Possibility of exact machining as well as optimizing to precise conditions,

- Significant place in future technologies – they serve a role in data components, electric drive systems, diagnostic systems, also other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in tiny dimensions, which enables their usage in small systems

Weaknesses

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can fracture. We recommend keeping them in a special holder, which not only protects them against impacts but also raises their durability

- Neodymium magnets decrease their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which prevent oxidation and corrosion.

- Due to limitations in producing threads and complicated shapes in magnets, we recommend using a housing - magnetic holder.

- Health risk resulting from small fragments of magnets pose a threat, when accidentally swallowed, which is particularly important in the aspect of protecting the youngest. It is also worth noting that small components of these products can disrupt the diagnostic process medical after entering the body.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Pull force analysis

Maximum lifting force for a neodymium magnet – what affects it?

- using a plate made of high-permeability steel, serving as a magnetic yoke

- possessing a thickness of at least 10 mm to avoid saturation

- with a plane free of scratches

- under conditions of no distance (metal-to-metal)

- during detachment in a direction perpendicular to the plane

- at temperature room level

Key elements affecting lifting force

- Space between surfaces – every millimeter of separation (caused e.g. by varnish or dirt) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Force direction – catalog parameter refers to pulling vertically. When slipping, the magnet holds significantly lower power (typically approx. 20-30% of nominal force).

- Plate thickness – insufficiently thick plate does not accept the full field, causing part of the flux to be escaped to the other side.

- Material type – ideal substrate is pure iron steel. Hardened steels may have worse magnetic properties.

- Surface quality – the smoother and more polished the plate, the larger the contact zone and higher the lifting capacity. Roughness creates an air distance.

- Thermal environment – heating the magnet results in weakening of force. It is worth remembering the maximum operating temperature for a given model.

Lifting capacity was assessed by applying a steel plate with a smooth surface of suitable thickness (min. 20 mm), under vertically applied force, whereas under shearing force the holding force is lower. Additionally, even a minimal clearance between the magnet and the plate reduces the lifting capacity.

Warnings

Keep away from children

Neodymium magnets are not suitable for play. Eating multiple magnets may result in them connecting inside the digestive tract, which constitutes a direct threat to life and requires urgent medical intervention.

Heat warning

Regular neodymium magnets (grade N) lose power when the temperature goes above 80°C. This process is irreversible.

Serious injuries

Pinching hazard: The attraction force is so immense that it can result in hematomas, pinching, and broken bones. Use thick gloves.

Medical implants

Warning for patients: Strong magnetic fields disrupt medical devices. Maintain at least 30 cm distance or request help to work with the magnets.

Protect data

Very strong magnetic fields can destroy records on credit cards, HDDs, and other magnetic media. Maintain a gap of min. 10 cm.

Immense force

Use magnets with awareness. Their huge power can shock even professionals. Plan your moves and do not underestimate their force.

Machining danger

Drilling and cutting of neodymium magnets poses a fire hazard. Magnetic powder reacts violently with oxygen and is difficult to extinguish.

Precision electronics

Navigation devices and mobile phones are extremely susceptible to magnetic fields. Close proximity with a strong magnet can permanently damage the sensors in your phone.

Skin irritation risks

Medical facts indicate that nickel (standard magnet coating) is a strong allergen. If your skin reacts to metals, refrain from touching magnets with bare hands and select coated magnets.

Beware of splinters

NdFeB magnets are sintered ceramics, meaning they are prone to chipping. Collision of two magnets will cause them breaking into small pieces.

![UMGZ 75x34x18 [M10] GZ / N38 - magnetic holder external thread UMGZ 75x34x18 [M10] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umgw-75x34x18-m10-gz-xid.jpg)

![SM 32x175 [2xM8] / N42 - magnetic separator SM 32x175 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x175-2xm8-tej.jpg)

![SM 32x400 [2xM8] / N42 - magnetic separator SM 32x400 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x400-2xm8-tep.jpg)