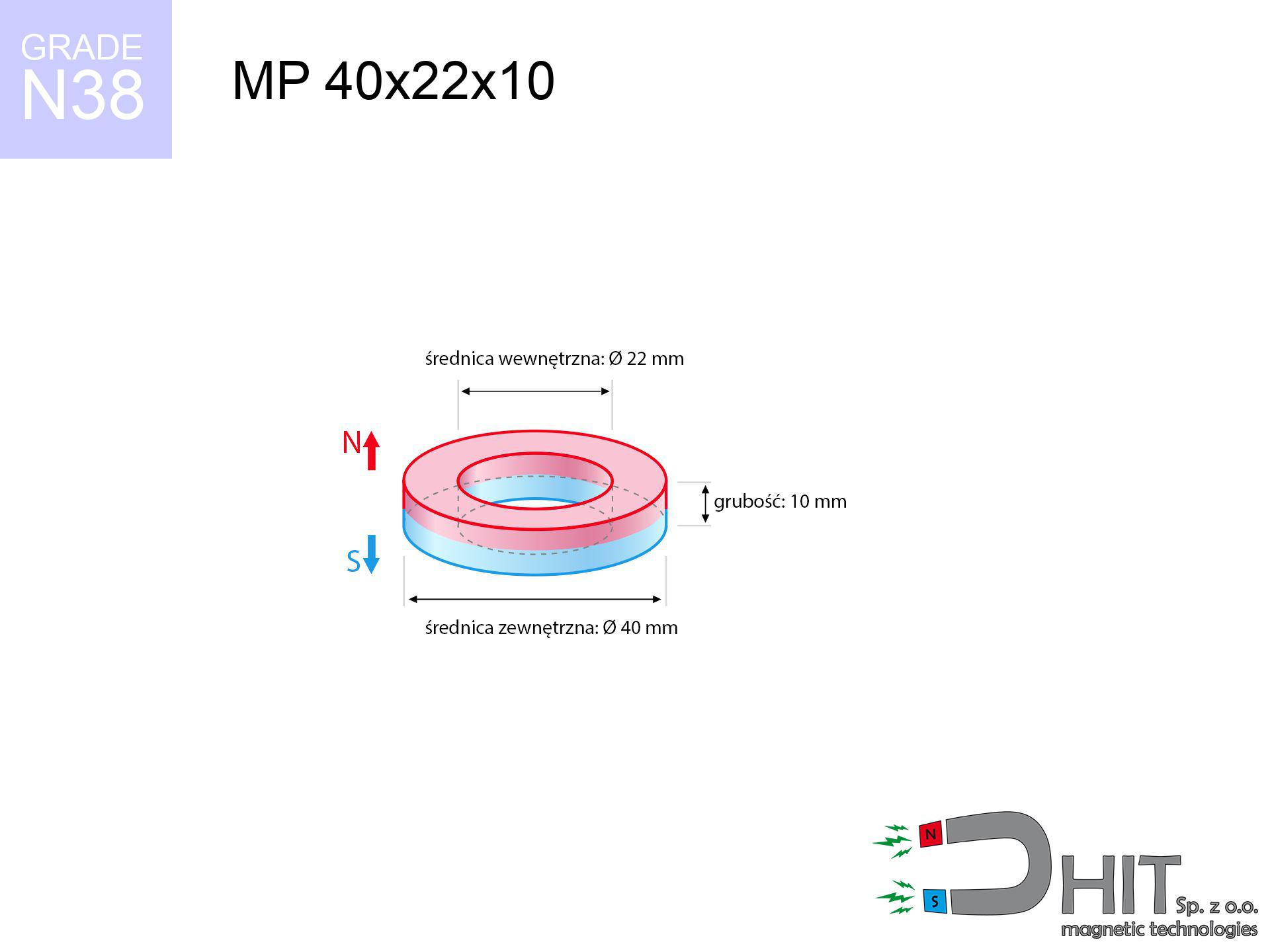

MP 40x22x10 / N38 - ring magnet

ring magnet

Catalog no 030344

GTIN/EAN: 5906301812296

Diameter

40 mm [±0,1 mm]

internal diameter Ø

22 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

65.74 g

Magnetization Direction

↑ axial

Load capacity

19.34 kg / 189.71 N

Magnetic Induction

277.22 mT / 2772 Gs

Coating

[NiCuNi] Nickel

40.59 ZŁ with VAT / pcs + price for transport

33.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

alternatively drop us a message through

contact form

through our site.

Weight along with form of neodymium magnets can be reviewed on our

power calculator.

Orders submitted before 14:00 will be dispatched today!

Technical details - MP 40x22x10 / N38 - ring magnet

Specification / characteristics - MP 40x22x10 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030344 |

| GTIN/EAN | 5906301812296 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 40 mm [±0,1 mm] |

| internal diameter Ø | 22 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 65.74 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 19.34 kg / 189.71 N |

| Magnetic Induction ~ ? | 277.22 mT / 2772 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the magnet - report

These data constitute the outcome of a mathematical calculation. Values are based on models for the material Nd2Fe14B. Actual performance might slightly differ from theoretical values. Treat these data as a preliminary roadmap during assembly planning.

Table 1: Static pull force (pull vs distance) - characteristics

MP 40x22x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5269 Gs

526.9 mT

|

19.34 kg / 42.64 lbs

19340.0 g / 189.7 N

|

crushing |

| 1 mm |

5005 Gs

500.5 mT

|

17.46 kg / 38.48 lbs

17455.9 g / 171.2 N

|

crushing |

| 2 mm |

4739 Gs

473.9 mT

|

15.65 kg / 34.50 lbs

15647.5 g / 153.5 N

|

crushing |

| 3 mm |

4475 Gs

447.5 mT

|

13.95 kg / 30.75 lbs

13950.0 g / 136.8 N

|

crushing |

| 5 mm |

3960 Gs

396.0 mT

|

10.93 kg / 24.09 lbs

10927.7 g / 107.2 N

|

crushing |

| 10 mm |

2832 Gs

283.2 mT

|

5.59 kg / 12.32 lbs

5589.2 g / 54.8 N

|

medium risk |

| 15 mm |

1990 Gs

199.0 mT

|

2.76 kg / 6.09 lbs

2760.5 g / 27.1 N

|

medium risk |

| 20 mm |

1407 Gs

140.7 mT

|

1.38 kg / 3.04 lbs

1379.2 g / 13.5 N

|

weak grip |

| 30 mm |

745 Gs

74.5 mT

|

0.39 kg / 0.85 lbs

386.2 g / 3.8 N

|

weak grip |

| 50 mm |

268 Gs

26.8 mT

|

0.05 kg / 0.11 lbs

50.1 g / 0.5 N

|

weak grip |

Table 2: Shear load (vertical surface)

MP 40x22x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

3.87 kg / 8.53 lbs

3868.0 g / 37.9 N

|

| 1 mm | Stal (~0.2) |

3.49 kg / 7.70 lbs

3492.0 g / 34.3 N

|

| 2 mm | Stal (~0.2) |

3.13 kg / 6.90 lbs

3130.0 g / 30.7 N

|

| 3 mm | Stal (~0.2) |

2.79 kg / 6.15 lbs

2790.0 g / 27.4 N

|

| 5 mm | Stal (~0.2) |

2.19 kg / 4.82 lbs

2186.0 g / 21.4 N

|

| 10 mm | Stal (~0.2) |

1.12 kg / 2.46 lbs

1118.0 g / 11.0 N

|

| 15 mm | Stal (~0.2) |

0.55 kg / 1.22 lbs

552.0 g / 5.4 N

|

| 20 mm | Stal (~0.2) |

0.28 kg / 0.61 lbs

276.0 g / 2.7 N

|

| 30 mm | Stal (~0.2) |

0.08 kg / 0.17 lbs

78.0 g / 0.8 N

|

| 50 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

10.0 g / 0.1 N

|

Table 3: Wall mounting (shearing) - vertical pull

MP 40x22x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

5.80 kg / 12.79 lbs

5802.0 g / 56.9 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

3.87 kg / 8.53 lbs

3868.0 g / 37.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.93 kg / 4.26 lbs

1934.0 g / 19.0 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

9.67 kg / 21.32 lbs

9670.0 g / 94.9 N

|

Table 4: Steel thickness (saturation) - power losses

MP 40x22x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.97 kg / 2.13 lbs

967.0 g / 9.5 N

|

| 1 mm |

|

2.42 kg / 5.33 lbs

2417.5 g / 23.7 N

|

| 2 mm |

|

4.84 kg / 10.66 lbs

4835.0 g / 47.4 N

|

| 3 mm |

|

7.25 kg / 15.99 lbs

7252.5 g / 71.1 N

|

| 5 mm |

|

12.09 kg / 26.65 lbs

12087.5 g / 118.6 N

|

| 10 mm |

|

19.34 kg / 42.64 lbs

19340.0 g / 189.7 N

|

| 11 mm |

|

19.34 kg / 42.64 lbs

19340.0 g / 189.7 N

|

| 12 mm |

|

19.34 kg / 42.64 lbs

19340.0 g / 189.7 N

|

Table 5: Thermal stability (stability) - resistance threshold

MP 40x22x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

19.34 kg / 42.64 lbs

19340.0 g / 189.7 N

|

OK |

| 40 °C | -2.2% |

18.91 kg / 41.70 lbs

18914.5 g / 185.6 N

|

OK |

| 60 °C | -4.4% |

18.49 kg / 40.76 lbs

18489.0 g / 181.4 N

|

OK |

| 80 °C | -6.6% |

18.06 kg / 39.82 lbs

18063.6 g / 177.2 N

|

|

| 100 °C | -28.8% |

13.77 kg / 30.36 lbs

13770.1 g / 135.1 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MP 40x22x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

171.37 kg / 377.80 lbs

5 920 Gs

|

25.71 kg / 56.67 lbs

25705 g / 252.2 N

|

N/A |

| 1 mm |

163.01 kg / 359.38 lbs

10 277 Gs

|

24.45 kg / 53.91 lbs

24452 g / 239.9 N

|

146.71 kg / 323.44 lbs

~0 Gs

|

| 2 mm |

154.67 kg / 341.00 lbs

10 011 Gs

|

23.20 kg / 51.15 lbs

23201 g / 227.6 N

|

139.21 kg / 306.90 lbs

~0 Gs

|

| 3 mm |

146.55 kg / 323.08 lbs

9 744 Gs

|

21.98 kg / 48.46 lbs

21982 g / 215.6 N

|

131.89 kg / 290.77 lbs

~0 Gs

|

| 5 mm |

131.00 kg / 288.81 lbs

9 213 Gs

|

19.65 kg / 43.32 lbs

19650 g / 192.8 N

|

117.90 kg / 259.92 lbs

~0 Gs

|

| 10 mm |

96.83 kg / 213.47 lbs

7 921 Gs

|

14.52 kg / 32.02 lbs

14524 g / 142.5 N

|

87.15 kg / 192.12 lbs

~0 Gs

|

| 20 mm |

49.53 kg / 109.18 lbs

5 665 Gs

|

7.43 kg / 16.38 lbs

7429 g / 72.9 N

|

44.57 kg / 98.27 lbs

~0 Gs

|

| 50 mm |

6.33 kg / 13.95 lbs

2 025 Gs

|

0.95 kg / 2.09 lbs

949 g / 9.3 N

|

5.69 kg / 12.55 lbs

~0 Gs

|

| 60 mm |

3.42 kg / 7.55 lbs

1 489 Gs

|

0.51 kg / 1.13 lbs

513 g / 5.0 N

|

3.08 kg / 6.79 lbs

~0 Gs

|

| 70 mm |

1.94 kg / 4.27 lbs

1 120 Gs

|

0.29 kg / 0.64 lbs

290 g / 2.8 N

|

1.74 kg / 3.84 lbs

~0 Gs

|

| 80 mm |

1.14 kg / 2.52 lbs

860 Gs

|

0.17 kg / 0.38 lbs

171 g / 1.7 N

|

1.03 kg / 2.27 lbs

~0 Gs

|

| 90 mm |

0.70 kg / 1.54 lbs

673 Gs

|

0.10 kg / 0.23 lbs

105 g / 1.0 N

|

0.63 kg / 1.39 lbs

~0 Gs

|

| 100 mm |

0.44 kg / 0.98 lbs

536 Gs

|

0.07 kg / 0.15 lbs

67 g / 0.7 N

|

0.40 kg / 0.88 lbs

~0 Gs

|

Table 7: Hazards (electronics) - precautionary measures

MP 40x22x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 24.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 18.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 14.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 11.0 cm |

| Remote | 50 Gs (5.0 mT) | 10.5 cm |

| Payment card | 400 Gs (40.0 mT) | 4.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 3.5 cm |

Table 8: Collisions (kinetic energy) - warning

MP 40x22x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

20.18 km/h

(5.61 m/s)

|

1.03 J | |

| 30 mm |

30.33 km/h

(8.43 m/s)

|

2.33 J | |

| 50 mm |

38.74 km/h

(10.76 m/s)

|

3.81 J | |

| 100 mm |

54.70 km/h

(15.20 m/s)

|

7.59 J |

Table 9: Surface protection spec

MP 40x22x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MP 40x22x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 54 070 Mx | 540.7 µWb |

| Pc Coefficient | 0.81 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MP 40x22x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 19.34 kg | Standard |

| Water (riverbed) |

22.14 kg

(+2.80 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Note: On a vertical surface, the magnet holds merely ~20% of its perpendicular strength.

2. Steel thickness impact

*Thin metal sheet (e.g. computer case) severely limits the holding force.

3. Heat tolerance

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.81

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Advantages as well as disadvantages of Nd2Fe14B magnets.

Pros

- They retain attractive force for nearly ten years – the loss is just ~1% (according to analyses),

- They are extremely resistant to demagnetization induced by external field influence,

- In other words, due to the shiny finish of nickel, the element becomes visually attractive,

- They feature high magnetic induction at the operating surface, which improves attraction properties,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Possibility of exact modeling as well as adapting to concrete applications,

- Wide application in future technologies – they find application in mass storage devices, electric motors, precision medical tools, also multitasking production systems.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Weaknesses

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth securing magnets using a steel holder. Such protection not only shields the magnet but also improves its resistance to damage

- When exposed to high temperature, neodymium magnets experience a drop in strength. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can rust. Therefore while using outdoors, we suggest using waterproof magnets made of rubber, plastic or other material protecting against moisture

- We recommend cover - magnetic mechanism, due to difficulties in creating threads inside the magnet and complex forms.

- Potential hazard resulting from small fragments of magnets can be dangerous, if swallowed, which gains importance in the aspect of protecting the youngest. Additionally, small elements of these devices are able to disrupt the diagnostic process medical when they are in the body.

- With budget limitations the cost of neodymium magnets can be a barrier,

Lifting parameters

Detachment force of the magnet in optimal conditions – what affects it?

- with the use of a yoke made of special test steel, guaranteeing full magnetic saturation

- with a cross-section minimum 10 mm

- with a surface free of scratches

- with direct contact (without impurities)

- during pulling in a direction perpendicular to the plane

- at room temperature

Practical lifting capacity: influencing factors

- Space between surfaces – every millimeter of separation (caused e.g. by veneer or dirt) drastically reduces the pulling force, often by half at just 0.5 mm.

- Loading method – catalog parameter refers to detachment vertically. When slipping, the magnet exhibits significantly lower power (typically approx. 20-30% of maximum force).

- Steel thickness – insufficiently thick plate does not accept the full field, causing part of the power to be lost to the other side.

- Chemical composition of the base – low-carbon steel gives the best results. Alloy steels reduce magnetic properties and holding force.

- Base smoothness – the smoother and more polished the plate, the better the adhesion and higher the lifting capacity. Unevenness acts like micro-gaps.

- Heat – neodymium magnets have a negative temperature coefficient. When it is hot they are weaker, and in frost gain strength (up to a certain limit).

Lifting capacity testing was carried out on plates with a smooth surface of suitable thickness, under perpendicular forces, in contrast under shearing force the holding force is lower. Additionally, even a slight gap between the magnet’s surface and the plate reduces the lifting capacity.

Precautions when working with neodymium magnets

Dust is flammable

Powder produced during grinding of magnets is combustible. Avoid drilling into magnets without proper cooling and knowledge.

Bone fractures

Danger of trauma: The attraction force is so immense that it can cause hematomas, crushing, and even bone fractures. Protective gloves are recommended.

Metal Allergy

Certain individuals experience a hypersensitivity to nickel, which is the typical protective layer for neodymium magnets. Frequent touching might lead to dermatitis. We recommend use protective gloves.

Safe distance

Do not bring magnets close to a wallet, computer, or TV. The magnetism can destroy these devices and wipe information from cards.

Swallowing risk

Product intended for adults. Small elements can be swallowed, causing serious injuries. Keep out of reach of children and animals.

Powerful field

Before use, read the rules. Uncontrolled attraction can destroy the magnet or injure your hand. Think ahead.

Keep away from electronics

An intense magnetic field negatively affects the operation of magnetometers in smartphones and GPS navigation. Keep magnets near a device to avoid breaking the sensors.

Magnets are brittle

Protect your eyes. Magnets can explode upon uncontrolled impact, launching sharp fragments into the air. Eye protection is mandatory.

Demagnetization risk

Watch the temperature. Heating the magnet above 80 degrees Celsius will permanently weaken its magnetic structure and strength.

Warning for heart patients

Medical warning: Neodymium magnets can turn off heart devices and defibrillators. Stay away if you have electronic implants.

![UI 40x12x7 [CA] - badge holder UI 40x12x7 [CA] - badge holder](https://cdn3.dhit.pl/graphics/products/ui40x12x7-vop.jpg)