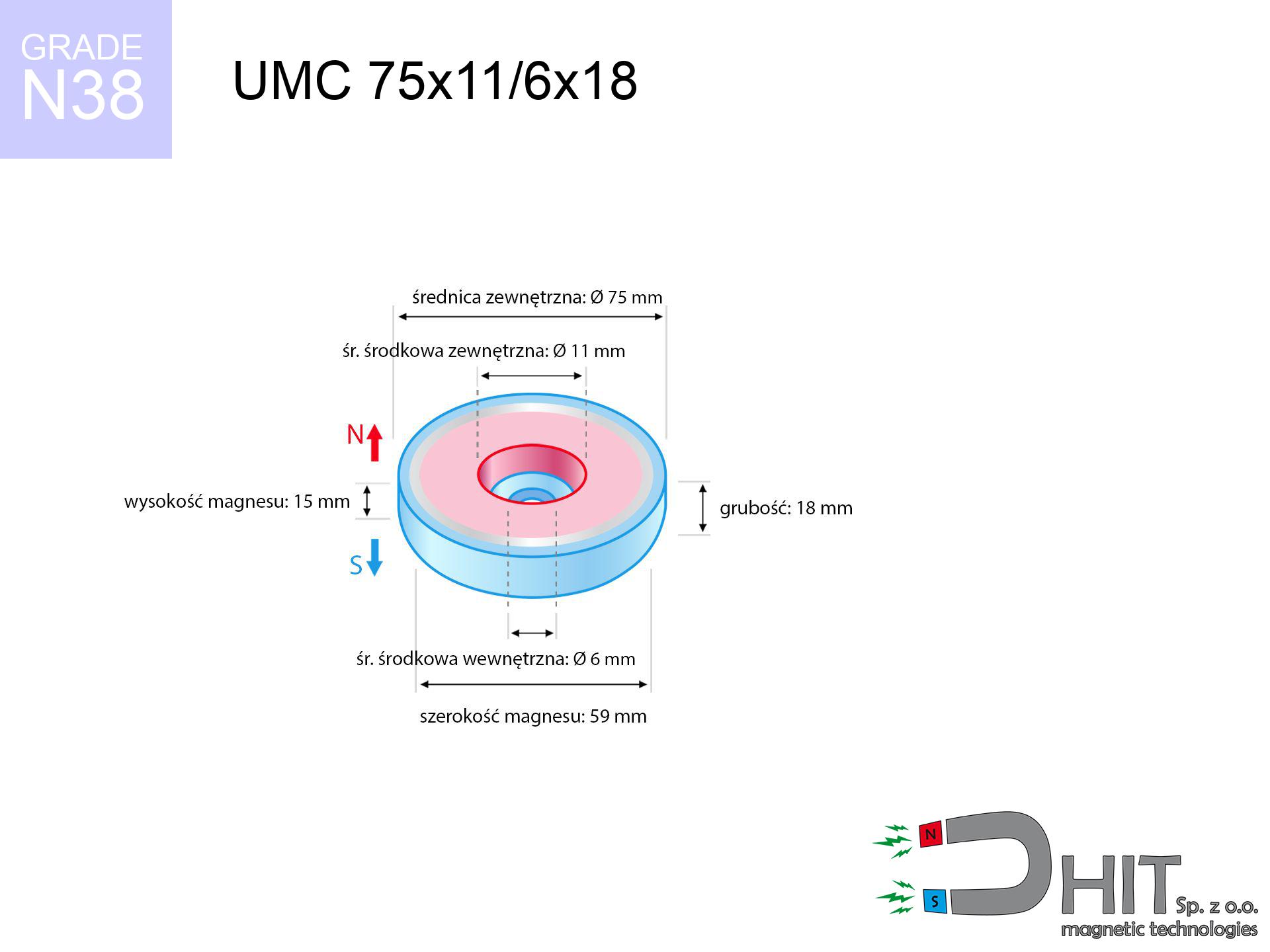

UMC 75x11/6x18 / N38 - cylindrical magnetic holder

cylindrical magnetic holder

Catalog no 320414

GTIN/EAN: 5906301814702

Diameter

75 mm [±1 mm]

internal diameter Ø

11/6 mm [±1 mm]

Height

18 mm [±1 mm]

Weight

465 g

Load capacity

155.00 kg / 1520.03 N

Coating

[NiCuNi] Nickel

169.86 ZŁ with VAT / pcs + price for transport

138.10 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

or let us know using

contact form

the contact form page.

Weight as well as appearance of magnets can be checked with our

magnetic calculator.

Same-day shipping for orders placed before 14:00.

Technical of the product - UMC 75x11/6x18 / N38 - cylindrical magnetic holder

Specification / characteristics - UMC 75x11/6x18 / N38 - cylindrical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 320414 |

| GTIN/EAN | 5906301814702 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 75 mm [±1 mm] |

| internal diameter Ø | 11/6 mm [±1 mm] |

| Height | 18 mm [±1 mm] |

| Weight | 465 g |

| Load capacity ~ ? | 155.00 kg / 1520.03 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Advantages and disadvantages of neodymium magnets.

Strengths

- They retain magnetic properties for around 10 years – the loss is just ~1% (based on simulations),

- They are extremely resistant to demagnetization induced by presence of other magnetic fields,

- Thanks to the metallic finish, the surface of Ni-Cu-Ni, gold-plated, or silver-plated gives an elegant appearance,

- The surface of neodymium magnets generates a strong magnetic field – this is one of their assets,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Possibility of detailed creating as well as modifying to specific needs,

- Versatile presence in electronics industry – they find application in magnetic memories, electromotive mechanisms, diagnostic systems, and technologically advanced constructions.

- Thanks to efficiency per cm³, small magnets offer high operating force, with minimal size,

Disadvantages

- They are fragile upon heavy impacts. To avoid cracks, it is worth protecting magnets using a steel holder. Such protection not only protects the magnet but also improves its resistance to damage

- When exposed to high temperature, neodymium magnets experience a drop in power. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore during using outdoors, we advise using waterproof magnets made of rubber, plastic or other material protecting against moisture

- Due to limitations in producing threads and complex shapes in magnets, we recommend using a housing - magnetic mechanism.

- Potential hazard to health – tiny shards of magnets are risky, if swallowed, which is particularly important in the context of child health protection. Additionally, small components of these magnets can be problematic in diagnostics medical in case of swallowing.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Holding force characteristics

Breakaway strength of the magnet in ideal conditions – what it depends on?

- on a plate made of mild steel, perfectly concentrating the magnetic field

- whose transverse dimension is min. 10 mm

- with an polished touching surface

- with direct contact (without coatings)

- under vertical force direction (90-degree angle)

- at ambient temperature room level

Lifting capacity in real conditions – factors

- Distance – existence of any layer (rust, tape, gap) interrupts the magnetic circuit, which lowers power rapidly (even by 50% at 0.5 mm).

- Load vector – highest force is reached only during perpendicular pulling. The force required to slide of the magnet along the surface is usually many times smaller (approx. 1/5 of the lifting capacity).

- Substrate thickness – for full efficiency, the steel must be adequately massive. Paper-thin metal limits the attraction force (the magnet "punches through" it).

- Material type – the best choice is high-permeability steel. Cast iron may generate lower lifting capacity.

- Plate texture – ground elements guarantee perfect abutment, which increases field saturation. Uneven metal weaken the grip.

- Temperature – heating the magnet causes a temporary drop of force. It is worth remembering the thermal limit for a given model.

Lifting capacity testing was carried out on a smooth plate of optimal thickness, under perpendicular forces, whereas under attempts to slide the magnet the load capacity is reduced by as much as 75%. In addition, even a small distance between the magnet and the plate lowers the lifting capacity.

Precautions when working with NdFeB magnets

Choking Hazard

Absolutely store magnets away from children. Choking hazard is high, and the effects of magnets clamping inside the body are tragic.

Crushing force

Pinching hazard: The attraction force is so immense that it can cause hematomas, pinching, and even bone fractures. Use thick gloves.

Protect data

Intense magnetic fields can corrupt files on credit cards, HDDs, and storage devices. Maintain a gap of at least 10 cm.

Metal Allergy

Medical facts indicate that the nickel plating (standard magnet coating) is a potent allergen. For allergy sufferers, avoid touching magnets with bare hands and select coated magnets.

Machining danger

Machining of neodymium magnets poses a fire hazard. Magnetic powder oxidizes rapidly with oxygen and is difficult to extinguish.

Protective goggles

Protect your eyes. Magnets can fracture upon uncontrolled impact, ejecting shards into the air. Eye protection is mandatory.

Compass and GPS

An intense magnetic field disrupts the functioning of magnetometers in smartphones and GPS navigation. Keep magnets close to a device to prevent damaging the sensors.

Immense force

Before starting, read the rules. Uncontrolled attraction can destroy the magnet or injure your hand. Be predictive.

Pacemakers

Warning for patients: Strong magnetic fields affect medical devices. Maintain minimum 30 cm distance or request help to handle the magnets.

Permanent damage

Standard neodymium magnets (grade N) undergo demagnetization when the temperature exceeds 80°C. The loss of strength is permanent.

![SM 32x250 [2xM8] / N52 - magnetic separator SM 32x250 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x250-2xm8-guf.jpg)

![UMH 16x5x32 [M4] / N38 - magnetic holder with hook UMH 16x5x32 [M4] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-16x5x32-m4-lak.jpg)

![UMP 94x40 [3xM10] GW F550 Silver Black / N52 - search holder UMP 94x40 [3xM10] GW F550 Silver Black / N52 - search holder](https://cdn3.dhit.pl/graphics/products/ump-94x40-3xm10-gw-f550-fad.jpg)