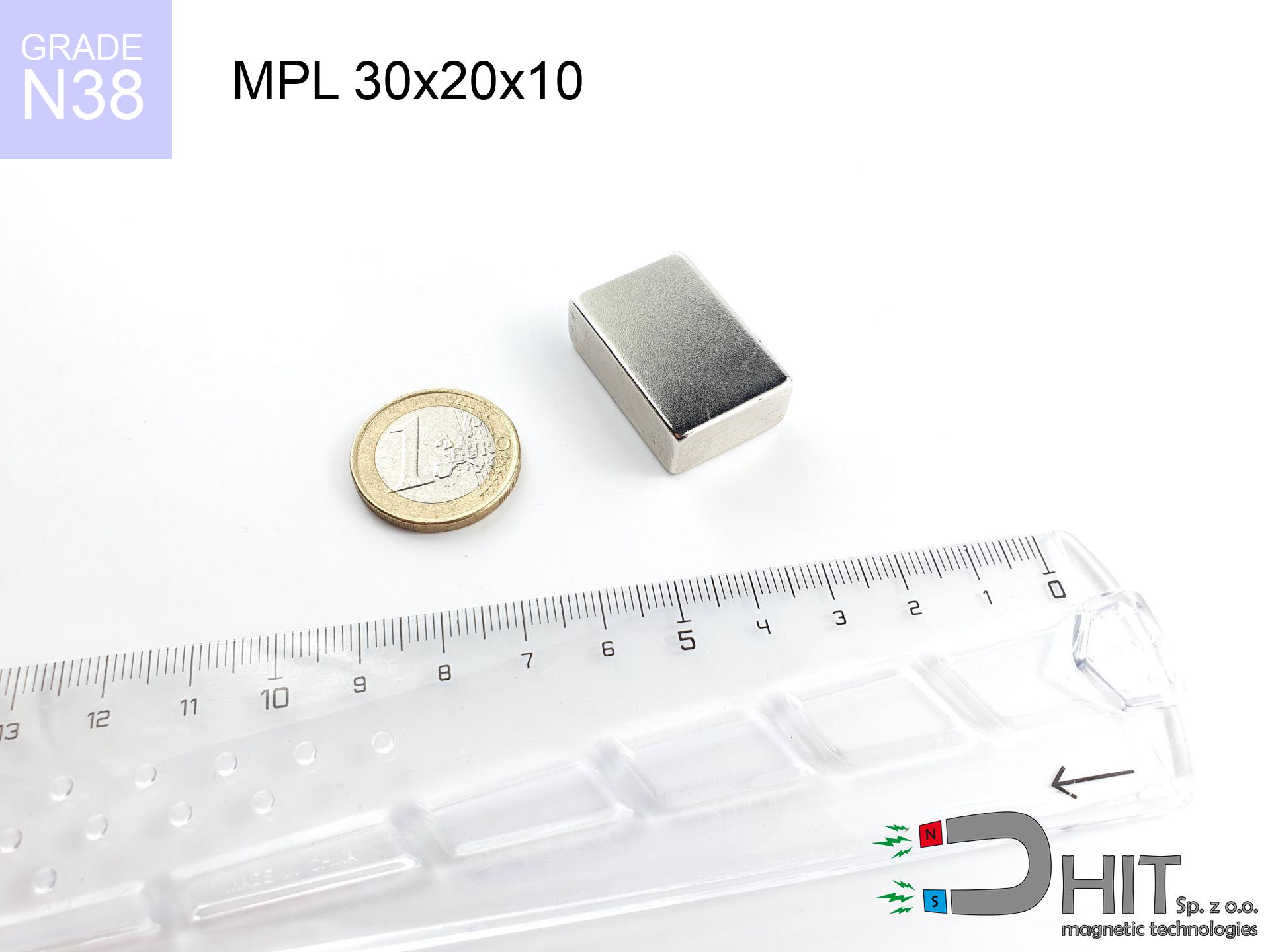

MPL 30x20x10 / N38 - lamellar magnet

lamellar magnet

Catalog no 020141

GTIN/EAN: 5906301811473

length

30 mm [±0,1 mm]

Width

20 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

45 g

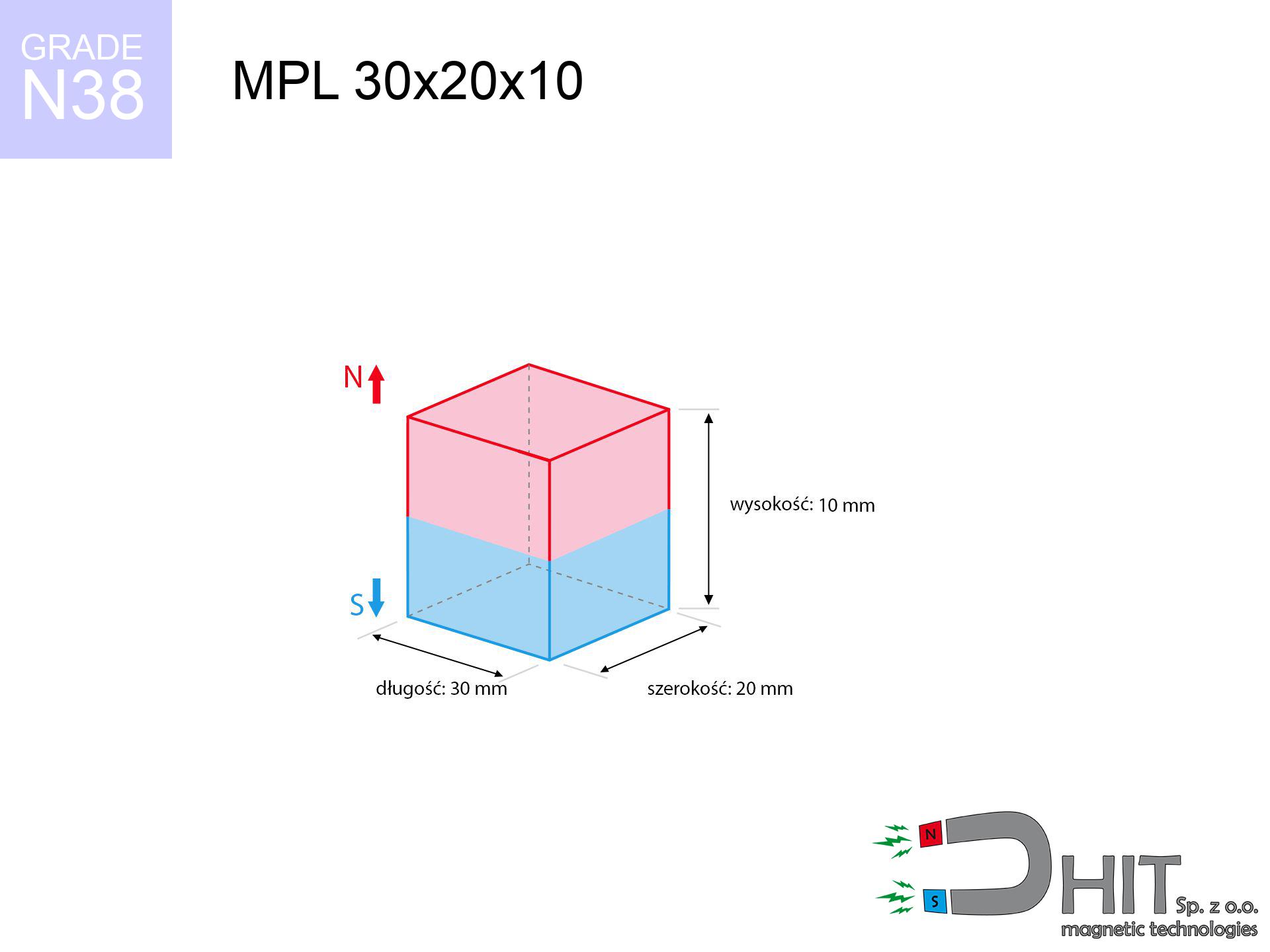

Magnetization Direction

↑ axial

Load capacity

19.53 kg / 191.55 N

Magnetic Induction

371.57 mT / 3716 Gs

Coating

[NiCuNi] Nickel

16.11 ZŁ with VAT / pcs + price for transport

13.10 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

or get in touch through

our online form

through our site.

Specifications along with form of a neodymium magnet can be checked with our

power calculator.

Order by 14:00 and we’ll ship today!

Technical data - MPL 30x20x10 / N38 - lamellar magnet

Specification / characteristics - MPL 30x20x10 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020141 |

| GTIN/EAN | 5906301811473 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 30 mm [±0,1 mm] |

| Width | 20 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 45 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 19.53 kg / 191.55 N |

| Magnetic Induction ~ ? | 371.57 mT / 3716 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the assembly - report

Presented information constitute the result of a physical calculation. Results were calculated on models for the class Nd2Fe14B. Operational performance may deviate from the simulation results. Use these calculations as a preliminary roadmap for designers.

Table 1: Static pull force (force vs distance) - characteristics

MPL 30x20x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3715 Gs

371.5 mT

|

19.53 kg / 43.06 pounds

19530.0 g / 191.6 N

|

critical level |

| 1 mm |

3464 Gs

346.4 mT

|

16.98 kg / 37.44 pounds

16983.1 g / 166.6 N

|

critical level |

| 2 mm |

3197 Gs

319.7 mT

|

14.47 kg / 31.89 pounds

14466.6 g / 141.9 N

|

critical level |

| 3 mm |

2927 Gs

292.7 mT

|

12.12 kg / 26.73 pounds

12123.3 g / 118.9 N

|

critical level |

| 5 mm |

2408 Gs

240.8 mT

|

8.21 kg / 18.10 pounds

8207.8 g / 80.5 N

|

medium risk |

| 10 mm |

1411 Gs

141.1 mT

|

2.82 kg / 6.21 pounds

2815.6 g / 27.6 N

|

medium risk |

| 15 mm |

832 Gs

83.2 mT

|

0.98 kg / 2.16 pounds

979.7 g / 9.6 N

|

weak grip |

| 20 mm |

512 Gs

51.2 mT

|

0.37 kg / 0.82 pounds

371.2 g / 3.6 N

|

weak grip |

| 30 mm |

224 Gs

22.4 mT

|

0.07 kg / 0.16 pounds

70.7 g / 0.7 N

|

weak grip |

| 50 mm |

65 Gs

6.5 mT

|

0.01 kg / 0.01 pounds

6.0 g / 0.1 N

|

weak grip |

Table 2: Slippage load (wall)

MPL 30x20x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

3.91 kg / 8.61 pounds

3906.0 g / 38.3 N

|

| 1 mm | Stal (~0.2) |

3.40 kg / 7.49 pounds

3396.0 g / 33.3 N

|

| 2 mm | Stal (~0.2) |

2.89 kg / 6.38 pounds

2894.0 g / 28.4 N

|

| 3 mm | Stal (~0.2) |

2.42 kg / 5.34 pounds

2424.0 g / 23.8 N

|

| 5 mm | Stal (~0.2) |

1.64 kg / 3.62 pounds

1642.0 g / 16.1 N

|

| 10 mm | Stal (~0.2) |

0.56 kg / 1.24 pounds

564.0 g / 5.5 N

|

| 15 mm | Stal (~0.2) |

0.20 kg / 0.43 pounds

196.0 g / 1.9 N

|

| 20 mm | Stal (~0.2) |

0.07 kg / 0.16 pounds

74.0 g / 0.7 N

|

| 30 mm | Stal (~0.2) |

0.01 kg / 0.03 pounds

14.0 g / 0.1 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MPL 30x20x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

5.86 kg / 12.92 pounds

5859.0 g / 57.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

3.91 kg / 8.61 pounds

3906.0 g / 38.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.95 kg / 4.31 pounds

1953.0 g / 19.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

9.77 kg / 21.53 pounds

9765.0 g / 95.8 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MPL 30x20x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.98 kg / 2.15 pounds

976.5 g / 9.6 N

|

| 1 mm |

|

2.44 kg / 5.38 pounds

2441.3 g / 23.9 N

|

| 2 mm |

|

4.88 kg / 10.76 pounds

4882.5 g / 47.9 N

|

| 3 mm |

|

7.32 kg / 16.15 pounds

7323.8 g / 71.8 N

|

| 5 mm |

|

12.21 kg / 26.91 pounds

12206.3 g / 119.7 N

|

| 10 mm |

|

19.53 kg / 43.06 pounds

19530.0 g / 191.6 N

|

| 11 mm |

|

19.53 kg / 43.06 pounds

19530.0 g / 191.6 N

|

| 12 mm |

|

19.53 kg / 43.06 pounds

19530.0 g / 191.6 N

|

Table 5: Working in heat (material behavior) - thermal limit

MPL 30x20x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

19.53 kg / 43.06 pounds

19530.0 g / 191.6 N

|

OK |

| 40 °C | -2.2% |

19.10 kg / 42.11 pounds

19100.3 g / 187.4 N

|

OK |

| 60 °C | -4.4% |

18.67 kg / 41.16 pounds

18670.7 g / 183.2 N

|

|

| 80 °C | -6.6% |

18.24 kg / 40.21 pounds

18241.0 g / 178.9 N

|

|

| 100 °C | -28.8% |

13.91 kg / 30.66 pounds

13905.4 g / 136.4 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MPL 30x20x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

51.05 kg / 112.54 pounds

5 124 Gs

|

7.66 kg / 16.88 pounds

7657 g / 75.1 N

|

N/A |

| 1 mm |

47.76 kg / 105.28 pounds

7 186 Gs

|

7.16 kg / 15.79 pounds

7163 g / 70.3 N

|

42.98 kg / 94.76 pounds

~0 Gs

|

| 2 mm |

44.39 kg / 97.86 pounds

6 928 Gs

|

6.66 kg / 14.68 pounds

6658 g / 65.3 N

|

39.95 kg / 88.08 pounds

~0 Gs

|

| 3 mm |

41.06 kg / 90.52 pounds

6 663 Gs

|

6.16 kg / 13.58 pounds

6159 g / 60.4 N

|

36.95 kg / 81.47 pounds

~0 Gs

|

| 5 mm |

34.68 kg / 76.45 pounds

6 124 Gs

|

5.20 kg / 11.47 pounds

5202 g / 51.0 N

|

31.21 kg / 68.81 pounds

~0 Gs

|

| 10 mm |

21.45 kg / 47.30 pounds

4 817 Gs

|

3.22 kg / 7.09 pounds

3218 g / 31.6 N

|

19.31 kg / 42.57 pounds

~0 Gs

|

| 20 mm |

7.36 kg / 16.22 pounds

2 821 Gs

|

1.10 kg / 2.43 pounds

1104 g / 10.8 N

|

6.62 kg / 14.60 pounds

~0 Gs

|

| 50 mm |

0.40 kg / 0.89 pounds

662 Gs

|

0.06 kg / 0.13 pounds

61 g / 0.6 N

|

0.36 kg / 0.80 pounds

~0 Gs

|

| 60 mm |

0.18 kg / 0.41 pounds

447 Gs

|

0.03 kg / 0.06 pounds

28 g / 0.3 N

|

0.17 kg / 0.37 pounds

~0 Gs

|

| 70 mm |

0.09 kg / 0.20 pounds

314 Gs

|

0.01 kg / 0.03 pounds

14 g / 0.1 N

|

0.08 kg / 0.18 pounds

~0 Gs

|

| 80 mm |

0.05 kg / 0.11 pounds

228 Gs

|

0.01 kg / 0.02 pounds

7 g / 0.1 N

|

0.04 kg / 0.10 pounds

~0 Gs

|

| 90 mm |

0.03 kg / 0.06 pounds

170 Gs

|

0.00 kg / 0.01 pounds

4 g / 0.0 N

|

0.02 kg / 0.05 pounds

~0 Gs

|

| 100 mm |

0.02 kg / 0.03 pounds

130 Gs

|

0.00 kg / 0.01 pounds

2 g / 0.0 N

|

0.01 kg / 0.03 pounds

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MPL 30x20x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 13.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 10.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 8.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 6.5 cm |

| Car key | 50 Gs (5.0 mT) | 6.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.0 cm |

Table 8: Impact energy (cracking risk) - warning

MPL 30x20x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.82 km/h

(6.34 m/s)

|

0.90 J | |

| 30 mm |

36.47 km/h

(10.13 m/s)

|

2.31 J | |

| 50 mm |

46.99 km/h

(13.05 m/s)

|

3.83 J | |

| 100 mm |

66.44 km/h

(18.46 m/s)

|

7.66 J |

Table 9: Anti-corrosion coating durability

MPL 30x20x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 30x20x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 22 801 Mx | 228.0 µWb |

| Pc Coefficient | 0.46 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MPL 30x20x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 19.53 kg | Standard |

| Water (riverbed) |

22.36 kg

(+2.83 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Caution: On a vertical surface, the magnet retains merely a fraction of its nominal pull.

2. Steel thickness impact

*Thin steel (e.g. computer case) significantly limits the holding force.

3. Heat tolerance

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.46

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also proposals

Advantages as well as disadvantages of Nd2Fe14B magnets.

Benefits

- They do not lose magnetism, even after nearly 10 years – the drop in strength is only ~1% (theoretically),

- They have excellent resistance to magnetic field loss as a result of opposing magnetic fields,

- The use of an refined finish of noble metals (nickel, gold, silver) causes the element to look better,

- They feature high magnetic induction at the operating surface, which improves attraction properties,

- Through (appropriate) combination of ingredients, they can achieve high thermal resistance, allowing for action at temperatures approaching 230°C and above...

- Thanks to the ability of flexible molding and adaptation to specialized needs, neodymium magnets can be modeled in a wide range of shapes and sizes, which increases their versatility,

- Fundamental importance in electronics industry – they are used in HDD drives, electric drive systems, diagnostic systems, and other advanced devices.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Weaknesses

- To avoid cracks under impact, we recommend using special steel housings. Such a solution secures the magnet and simultaneously increases its durability.

- We warn that neodymium magnets can reduce their power at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material resistant to moisture, when using outdoors

- Due to limitations in producing nuts and complex forms in magnets, we recommend using a housing - magnetic mount.

- Potential hazard to health – tiny shards of magnets pose a threat, in case of ingestion, which becomes key in the aspect of protecting the youngest. Furthermore, small elements of these products are able to be problematic in diagnostics medical in case of swallowing.

- Due to expensive raw materials, their price is higher than average,

Pull force analysis

Maximum lifting capacity of the magnet – what contributes to it?

- on a plate made of mild steel, optimally conducting the magnetic flux

- whose transverse dimension is min. 10 mm

- with a plane perfectly flat

- under conditions of ideal adhesion (metal-to-metal)

- for force acting at a right angle (in the magnet axis)

- at temperature approx. 20 degrees Celsius

Key elements affecting lifting force

- Air gap (betwixt the magnet and the metal), because even a very small distance (e.g. 0.5 mm) results in a reduction in force by up to 50% (this also applies to paint, corrosion or dirt).

- Force direction – catalog parameter refers to detachment vertically. When applying parallel force, the magnet exhibits significantly lower power (typically approx. 20-30% of nominal force).

- Steel thickness – insufficiently thick sheet causes magnetic saturation, causing part of the flux to be wasted into the air.

- Steel grade – ideal substrate is pure iron steel. Stainless steels may have worse magnetic properties.

- Plate texture – smooth surfaces guarantee perfect abutment, which increases field saturation. Uneven metal reduce efficiency.

- Temperature – temperature increase results in weakening of force. Check the thermal limit for a given model.

Holding force was tested on the plate surface of 20 mm thickness, when a perpendicular force was applied, whereas under parallel forces the load capacity is reduced by as much as fivefold. In addition, even a minimal clearance between the magnet and the plate reduces the lifting capacity.

Precautions when working with neodymium magnets

Choking Hazard

Only for adults. Tiny parts can be swallowed, leading to serious injuries. Keep out of reach of children and animals.

GPS Danger

A powerful magnetic field negatively affects the functioning of magnetometers in smartphones and GPS navigation. Maintain magnets near a device to prevent damaging the sensors.

Conscious usage

Exercise caution. Rare earth magnets attract from a distance and connect with massive power, often quicker than you can move away.

Do not overheat magnets

Watch the temperature. Heating the magnet above 80 degrees Celsius will permanently weaken its properties and strength.

Medical implants

Life threat: Strong magnets can turn off heart devices and defibrillators. Do not approach if you have medical devices.

Protect data

Intense magnetic fields can corrupt files on payment cards, HDDs, and other magnetic media. Stay away of min. 10 cm.

Bodily injuries

Mind your fingers. Two large magnets will snap together immediately with a force of several hundred kilograms, destroying everything in their path. Be careful!

Allergy Warning

Medical facts indicate that nickel (standard magnet coating) is a strong allergen. If your skin reacts to metals, avoid direct skin contact and select versions in plastic housing.

Protective goggles

NdFeB magnets are ceramic materials, which means they are fragile like glass. Collision of two magnets leads to them shattering into shards.

Do not drill into magnets

Mechanical processing of NdFeB material carries a risk of fire risk. Magnetic powder oxidizes rapidly with oxygen and is hard to extinguish.