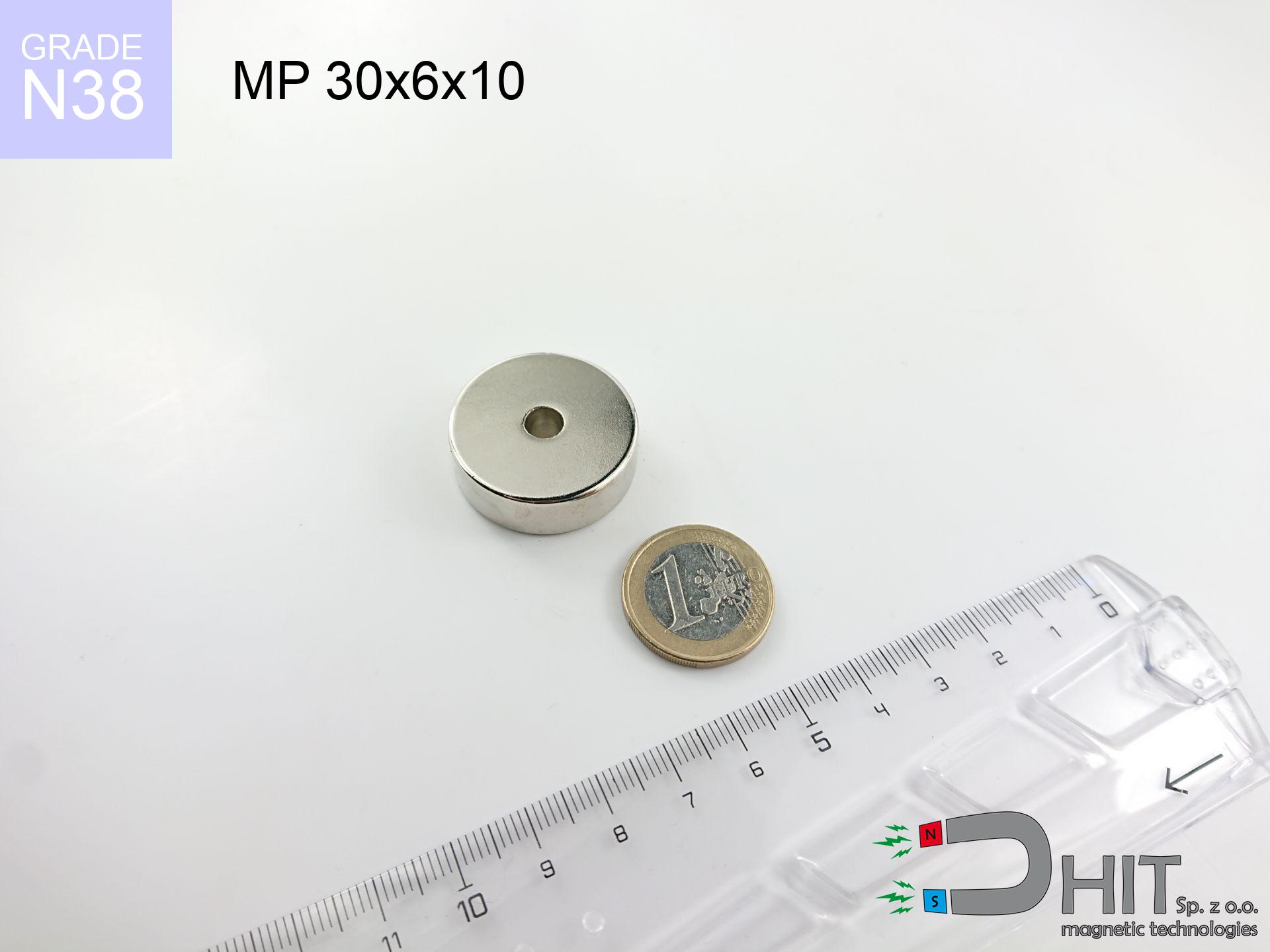

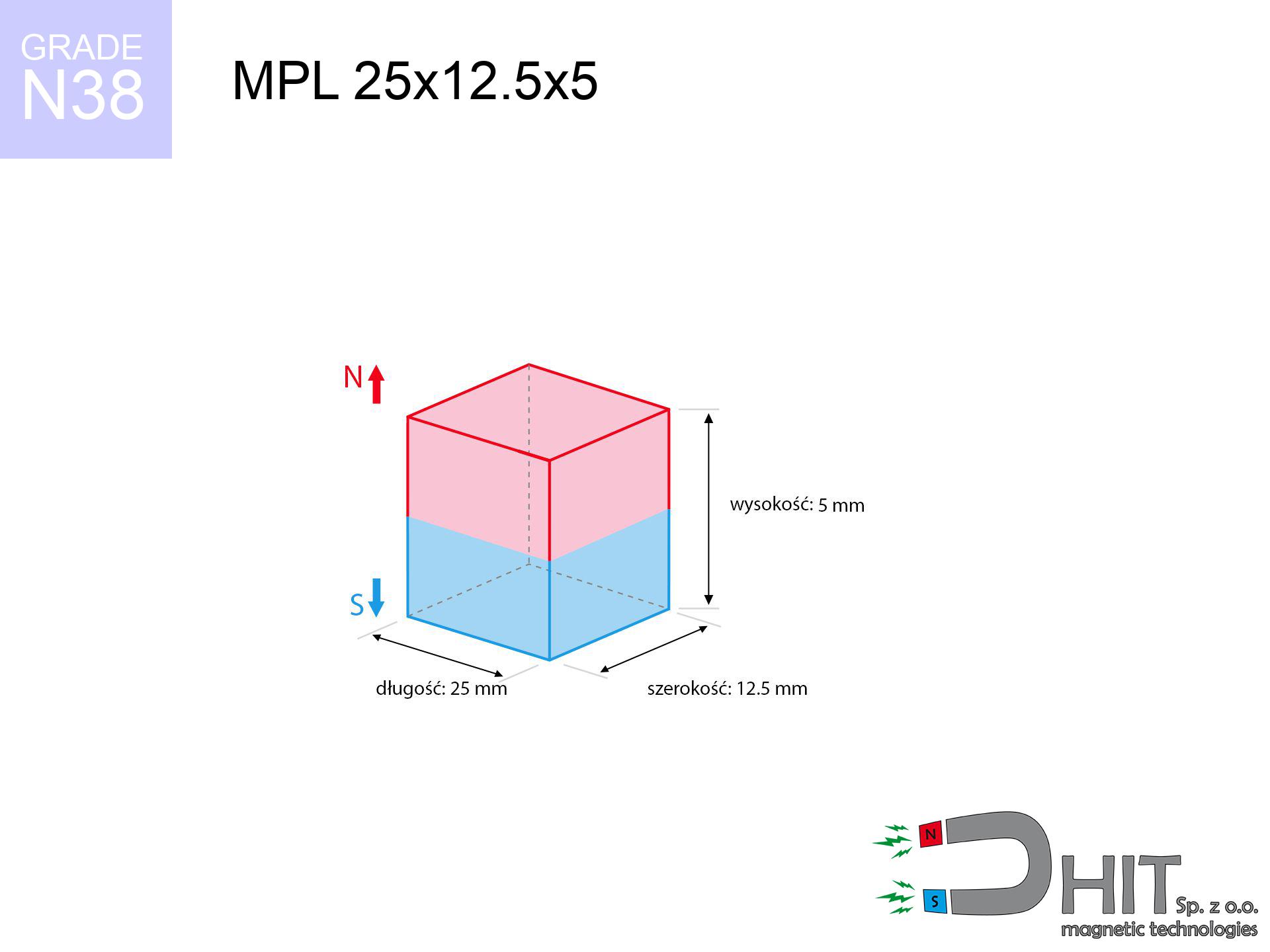

MPL 25x12.5x5 / N38 - lamellar magnet

lamellar magnet

Catalog no 020136

GTIN/EAN: 5906301811428

length

25 mm [±0,1 mm]

Width

12.5 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

11.72 g

Magnetization Direction

↑ axial

Load capacity

7.72 kg / 75.74 N

Magnetic Induction

299.70 mT / 2997 Gs

Coating

[NiCuNi] Nickel

4.92 ZŁ with VAT / pcs + price for transport

4.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

otherwise send us a note through

our online form

our website.

Force along with structure of a magnet can be reviewed using our

power calculator.

Same-day shipping for orders placed before 14:00.

Technical - MPL 25x12.5x5 / N38 - lamellar magnet

Specification / characteristics - MPL 25x12.5x5 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020136 |

| GTIN/EAN | 5906301811428 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 25 mm [±0,1 mm] |

| Width | 12.5 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 11.72 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 7.72 kg / 75.74 N |

| Magnetic Induction ~ ? | 299.70 mT / 2997 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical modeling of the assembly - report

The following data represent the result of a engineering simulation. Values are based on algorithms for the class Nd2Fe14B. Real-world conditions may deviate from the simulation results. Please consider these data as a supplementary guide during assembly planning.

Table 1: Static pull force (pull vs distance) - power drop

MPL 25x12.5x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2996 Gs

299.6 mT

|

7.72 kg / 17.02 pounds

7720.0 g / 75.7 N

|

warning |

| 1 mm |

2705 Gs

270.5 mT

|

6.29 kg / 13.87 pounds

6292.6 g / 61.7 N

|

warning |

| 2 mm |

2384 Gs

238.4 mT

|

4.89 kg / 10.77 pounds

4886.6 g / 47.9 N

|

warning |

| 3 mm |

2067 Gs

206.7 mT

|

3.67 kg / 8.10 pounds

3674.4 g / 36.0 N

|

warning |

| 5 mm |

1517 Gs

151.7 mT

|

1.98 kg / 4.36 pounds

1979.6 g / 19.4 N

|

low risk |

| 10 mm |

702 Gs

70.2 mT

|

0.42 kg / 0.93 pounds

424.1 g / 4.2 N

|

low risk |

| 15 mm |

355 Gs

35.5 mT

|

0.11 kg / 0.24 pounds

108.6 g / 1.1 N

|

low risk |

| 20 mm |

198 Gs

19.8 mT

|

0.03 kg / 0.07 pounds

33.6 g / 0.3 N

|

low risk |

| 30 mm |

76 Gs

7.6 mT

|

0.01 kg / 0.01 pounds

5.0 g / 0.0 N

|

low risk |

| 50 mm |

20 Gs

2.0 mT

|

0.00 kg / 0.00 pounds

0.3 g / 0.0 N

|

low risk |

Table 2: Slippage load (vertical surface)

MPL 25x12.5x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.54 kg / 3.40 pounds

1544.0 g / 15.1 N

|

| 1 mm | Stal (~0.2) |

1.26 kg / 2.77 pounds

1258.0 g / 12.3 N

|

| 2 mm | Stal (~0.2) |

0.98 kg / 2.16 pounds

978.0 g / 9.6 N

|

| 3 mm | Stal (~0.2) |

0.73 kg / 1.62 pounds

734.0 g / 7.2 N

|

| 5 mm | Stal (~0.2) |

0.40 kg / 0.87 pounds

396.0 g / 3.9 N

|

| 10 mm | Stal (~0.2) |

0.08 kg / 0.19 pounds

84.0 g / 0.8 N

|

| 15 mm | Stal (~0.2) |

0.02 kg / 0.05 pounds

22.0 g / 0.2 N

|

| 20 mm | Stal (~0.2) |

0.01 kg / 0.01 pounds

6.0 g / 0.1 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MPL 25x12.5x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.32 kg / 5.11 pounds

2316.0 g / 22.7 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.54 kg / 3.40 pounds

1544.0 g / 15.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.77 kg / 1.70 pounds

772.0 g / 7.6 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.86 kg / 8.51 pounds

3860.0 g / 37.9 N

|

Table 4: Steel thickness (saturation) - power losses

MPL 25x12.5x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.77 kg / 1.70 pounds

772.0 g / 7.6 N

|

| 1 mm |

|

1.93 kg / 4.25 pounds

1930.0 g / 18.9 N

|

| 2 mm |

|

3.86 kg / 8.51 pounds

3860.0 g / 37.9 N

|

| 3 mm |

|

5.79 kg / 12.76 pounds

5790.0 g / 56.8 N

|

| 5 mm |

|

7.72 kg / 17.02 pounds

7720.0 g / 75.7 N

|

| 10 mm |

|

7.72 kg / 17.02 pounds

7720.0 g / 75.7 N

|

| 11 mm |

|

7.72 kg / 17.02 pounds

7720.0 g / 75.7 N

|

| 12 mm |

|

7.72 kg / 17.02 pounds

7720.0 g / 75.7 N

|

Table 5: Thermal stability (stability) - thermal limit

MPL 25x12.5x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

7.72 kg / 17.02 pounds

7720.0 g / 75.7 N

|

OK |

| 40 °C | -2.2% |

7.55 kg / 16.65 pounds

7550.2 g / 74.1 N

|

OK |

| 60 °C | -4.4% |

7.38 kg / 16.27 pounds

7380.3 g / 72.4 N

|

|

| 80 °C | -6.6% |

7.21 kg / 15.90 pounds

7210.5 g / 70.7 N

|

|

| 100 °C | -28.8% |

5.50 kg / 12.12 pounds

5496.6 g / 53.9 N

|

Table 6: Two magnets (repulsion) - field range

MPL 25x12.5x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

17.29 kg / 38.13 pounds

4 511 Gs

|

2.59 kg / 5.72 pounds

2594 g / 25.4 N

|

N/A |

| 1 mm |

15.73 kg / 34.68 pounds

5 715 Gs

|

2.36 kg / 5.20 pounds

2360 g / 23.2 N

|

14.16 kg / 31.22 pounds

~0 Gs

|

| 2 mm |

14.10 kg / 31.08 pounds

5 410 Gs

|

2.11 kg / 4.66 pounds

2114 g / 20.7 N

|

12.69 kg / 27.97 pounds

~0 Gs

|

| 3 mm |

12.48 kg / 27.52 pounds

5 091 Gs

|

1.87 kg / 4.13 pounds

1872 g / 18.4 N

|

11.23 kg / 24.77 pounds

~0 Gs

|

| 5 mm |

9.52 kg / 20.99 pounds

4 446 Gs

|

1.43 kg / 3.15 pounds

1428 g / 14.0 N

|

8.57 kg / 18.89 pounds

~0 Gs

|

| 10 mm |

4.43 kg / 9.78 pounds

3 034 Gs

|

0.67 kg / 1.47 pounds

665 g / 6.5 N

|

3.99 kg / 8.80 pounds

~0 Gs

|

| 20 mm |

0.95 kg / 2.09 pounds

1 404 Gs

|

0.14 kg / 0.31 pounds

142 g / 1.4 N

|

0.85 kg / 1.88 pounds

~0 Gs

|

| 50 mm |

0.03 kg / 0.06 pounds

238 Gs

|

0.00 kg / 0.01 pounds

4 g / 0.0 N

|

0.02 kg / 0.05 pounds

~0 Gs

|

| 60 mm |

0.01 kg / 0.02 pounds

153 Gs

|

0.00 kg / 0.00 pounds

2 g / 0.0 N

|

0.01 kg / 0.02 pounds

~0 Gs

|

| 70 mm |

0.01 kg / 0.01 pounds

103 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.01 pounds

73 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

53 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

40 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MPL 25x12.5x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 8.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 6.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 5.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 4.0 cm |

| Car key | 50 Gs (5.0 mT) | 4.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MPL 25x12.5x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

26.76 km/h

(7.43 m/s)

|

0.32 J | |

| 30 mm |

44.85 km/h

(12.46 m/s)

|

0.91 J | |

| 50 mm |

57.88 km/h

(16.08 m/s)

|

1.51 J | |

| 100 mm |

81.85 km/h

(22.74 m/s)

|

3.03 J |

Table 9: Corrosion resistance

MPL 25x12.5x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 25x12.5x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 9 639 Mx | 96.4 µWb |

| Pc Coefficient | 0.35 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 25x12.5x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 7.72 kg | Standard |

| Water (riverbed) |

8.84 kg

(+1.12 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Note: On a vertical wall, the magnet holds merely approx. 20-30% of its perpendicular strength.

2. Steel thickness impact

*Thin metal sheet (e.g. 0.5mm PC case) severely reduces the holding force.

3. Heat tolerance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.35

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Strengths as well as weaknesses of neodymium magnets.

Pros

- They have unchanged lifting capacity, and over around 10 years their performance decreases symbolically – ~1% (according to theory),

- Neodymium magnets are extremely resistant to demagnetization caused by magnetic disturbances,

- A magnet with a smooth gold surface has better aesthetics,

- They show high magnetic induction at the operating surface, which affects their effectiveness,

- Thanks to resistance to high temperature, they are able to function (depending on the form) even at temperatures up to 230°C and higher...

- Possibility of individual machining and modifying to defined conditions,

- Key role in future technologies – they are used in computer drives, electromotive mechanisms, diagnostic systems, also modern systems.

- Thanks to concentrated force, small magnets offer high operating force, occupying minimum space,

Disadvantages

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can fracture. We advise keeping them in a strong case, which not only protects them against impacts but also increases their durability

- When exposed to high temperature, neodymium magnets experience a drop in strength. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can rust. Therefore during using outdoors, we recommend using waterproof magnets made of rubber, plastic or other material resistant to moisture

- Limited ability of producing threads in the magnet and complicated forms - preferred is casing - magnet mounting.

- Health risk related to microscopic parts of magnets can be dangerous, in case of ingestion, which becomes key in the context of child safety. Additionally, small components of these magnets are able to be problematic in diagnostics medical when they are in the body.

- Due to neodymium price, their price is higher than average,

Pull force analysis

Best holding force of the magnet in ideal parameters – what it depends on?

- with the contact of a yoke made of low-carbon steel, guaranteeing maximum field concentration

- whose thickness is min. 10 mm

- characterized by smoothness

- with direct contact (without paint)

- during pulling in a direction vertical to the plane

- at ambient temperature room level

Impact of factors on magnetic holding capacity in practice

- Gap between magnet and steel – even a fraction of a millimeter of separation (caused e.g. by varnish or dirt) significantly weakens the pulling force, often by half at just 0.5 mm.

- Force direction – catalog parameter refers to detachment vertically. When attempting to slide, the magnet exhibits much less (typically approx. 20-30% of maximum force).

- Element thickness – for full efficiency, the steel must be sufficiently thick. Thin sheet limits the lifting capacity (the magnet "punches through" it).

- Plate material – mild steel attracts best. Alloy steels reduce magnetic properties and lifting capacity.

- Surface quality – the smoother and more polished the surface, the better the adhesion and stronger the hold. Unevenness acts like micro-gaps.

- Temperature – heating the magnet causes a temporary drop of force. It is worth remembering the maximum operating temperature for a given model.

Holding force was checked on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, whereas under parallel forces the holding force is lower. Moreover, even a minimal clearance between the magnet and the plate lowers the lifting capacity.

Safe handling of NdFeB magnets

Thermal limits

Keep cool. Neodymium magnets are susceptible to heat. If you need operation above 80°C, look for special high-temperature series (H, SH, UH).

Nickel allergy

Warning for allergy sufferers: The Ni-Cu-Ni coating contains nickel. If an allergic reaction occurs, immediately stop handling magnets and wear gloves.

Medical implants

For implant holders: Powerful magnets affect electronics. Maintain at least 30 cm distance or ask another person to work with the magnets.

Mechanical processing

Dust generated during grinding of magnets is self-igniting. Avoid drilling into magnets unless you are an expert.

Protect data

Do not bring magnets near a purse, computer, or TV. The magnetism can irreversibly ruin these devices and wipe information from cards.

Crushing risk

Big blocks can break fingers instantly. Under no circumstances put your hand between two strong magnets.

Danger to the youngest

Adult use only. Tiny parts pose a choking risk, causing serious injuries. Store away from children and animals.

Magnet fragility

NdFeB magnets are sintered ceramics, which means they are prone to chipping. Impact of two magnets will cause them cracking into shards.

Precision electronics

Remember: neodymium magnets produce a field that confuses sensitive sensors. Keep a safe distance from your phone, tablet, and GPS.

Powerful field

Be careful. Neodymium magnets act from a distance and snap with massive power, often quicker than you can move away.

![SM 25x225 [2xM8] / N42 - magnetic separator SM 25x225 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x225-2xm8-tix.jpg)