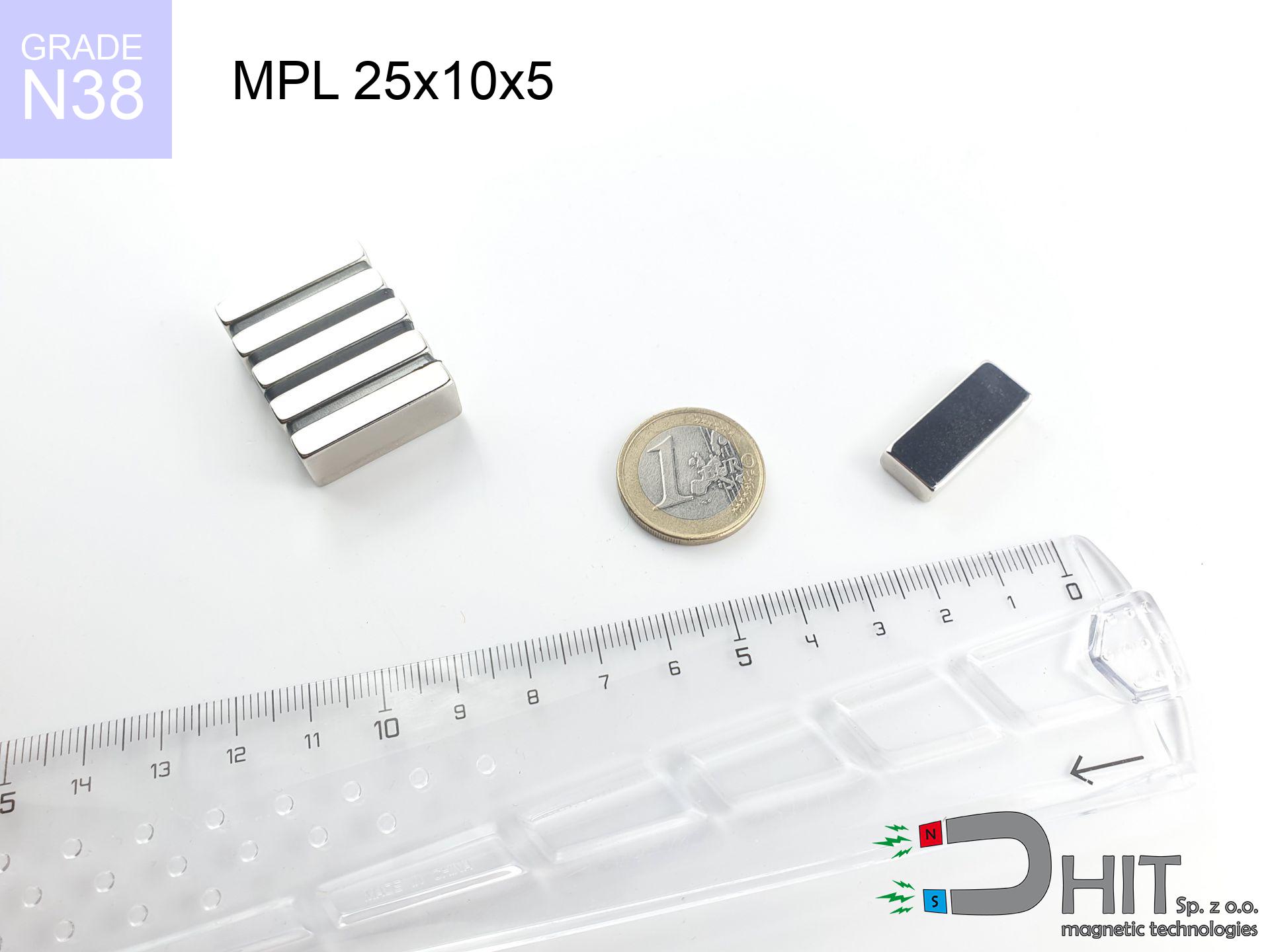

MPL 25x10x5 / N38 - lamellar magnet

lamellar magnet

Catalog no 020135

GTIN/EAN: 5906301811411

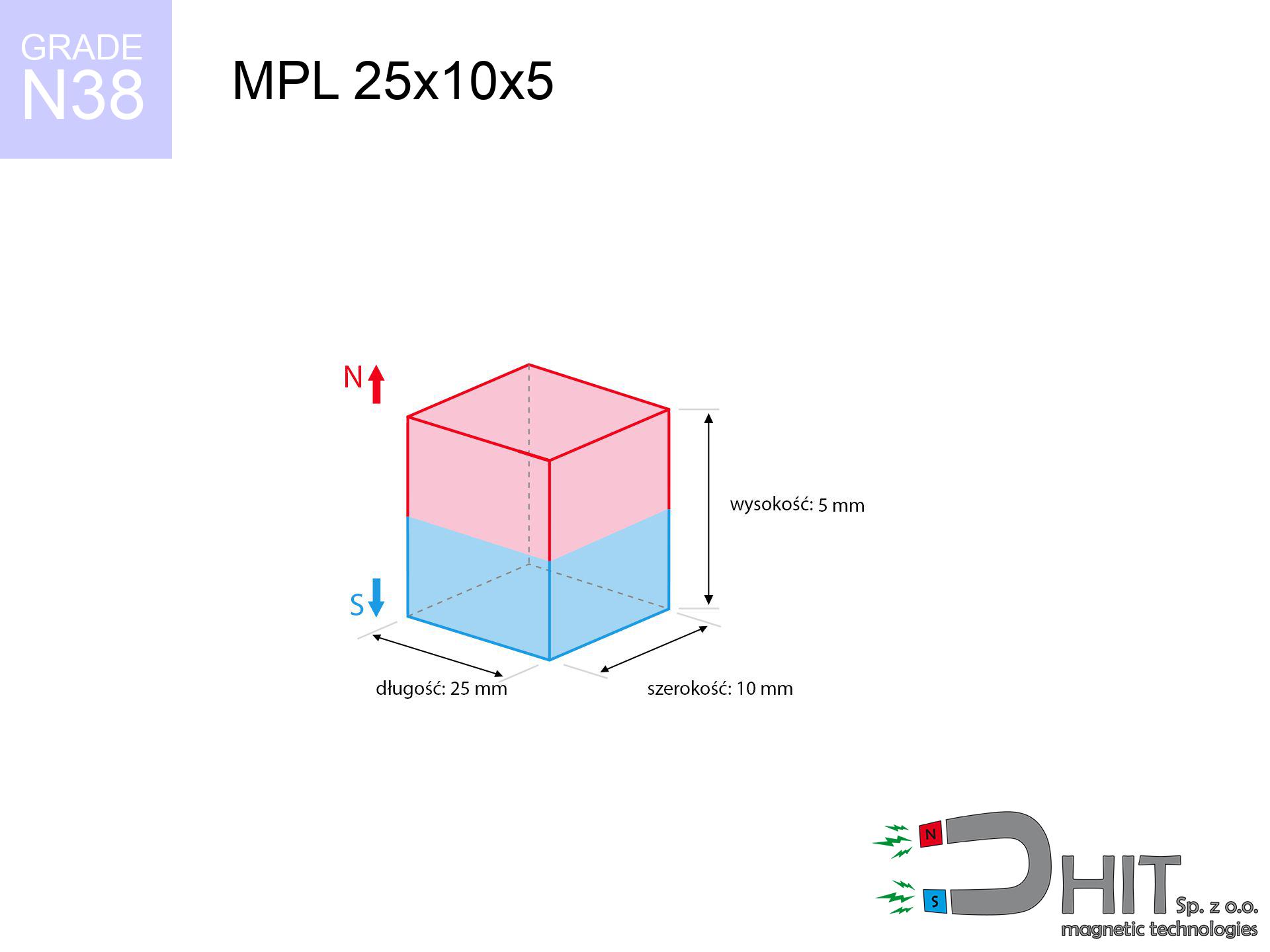

length

25 mm [±0,1 mm]

Width

10 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

9.38 g

Magnetization Direction

↑ axial

Load capacity

7.49 kg / 73.45 N

Magnetic Induction

337.05 mT / 3371 Gs

Coating

[NiCuNi] Nickel

4.66 ZŁ with VAT / pcs + price for transport

3.79 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

otherwise let us know using

request form

the contact form page.

Parameters along with appearance of magnets can be estimated using our

magnetic calculator.

Order by 14:00 and we’ll ship today!

Technical specification - MPL 25x10x5 / N38 - lamellar magnet

Specification / characteristics - MPL 25x10x5 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020135 |

| GTIN/EAN | 5906301811411 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 25 mm [±0,1 mm] |

| Width | 10 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 9.38 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 7.49 kg / 73.45 N |

| Magnetic Induction ~ ? | 337.05 mT / 3371 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the product - report

Presented information constitute the direct effect of a physical simulation. Results were calculated on models for the class Nd2Fe14B. Actual performance might slightly deviate from the simulation results. Please consider these data as a supplementary guide when designing systems.

Table 1: Static force (pull vs distance) - interaction chart

MPL 25x10x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3369 Gs

336.9 mT

|

7.49 kg / 16.51 pounds

7490.0 g / 73.5 N

|

medium risk |

| 1 mm |

2932 Gs

293.2 mT

|

5.67 kg / 12.51 pounds

5673.2 g / 55.7 N

|

medium risk |

| 2 mm |

2479 Gs

247.9 mT

|

4.06 kg / 8.94 pounds

4056.9 g / 39.8 N

|

medium risk |

| 3 mm |

2065 Gs

206.5 mT

|

2.81 kg / 6.21 pounds

2814.7 g / 27.6 N

|

medium risk |

| 5 mm |

1419 Gs

141.9 mT

|

1.33 kg / 2.93 pounds

1328.6 g / 13.0 N

|

safe |

| 10 mm |

603 Gs

60.3 mT

|

0.24 kg / 0.53 pounds

240.3 g / 2.4 N

|

safe |

| 15 mm |

296 Gs

29.6 mT

|

0.06 kg / 0.13 pounds

57.8 g / 0.6 N

|

safe |

| 20 mm |

162 Gs

16.2 mT

|

0.02 kg / 0.04 pounds

17.4 g / 0.2 N

|

safe |

| 30 mm |

62 Gs

6.2 mT

|

0.00 kg / 0.01 pounds

2.5 g / 0.0 N

|

safe |

| 50 mm |

16 Gs

1.6 mT

|

0.00 kg / 0.00 pounds

0.2 g / 0.0 N

|

safe |

Table 2: Shear hold (vertical surface)

MPL 25x10x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.50 kg / 3.30 pounds

1498.0 g / 14.7 N

|

| 1 mm | Stal (~0.2) |

1.13 kg / 2.50 pounds

1134.0 g / 11.1 N

|

| 2 mm | Stal (~0.2) |

0.81 kg / 1.79 pounds

812.0 g / 8.0 N

|

| 3 mm | Stal (~0.2) |

0.56 kg / 1.24 pounds

562.0 g / 5.5 N

|

| 5 mm | Stal (~0.2) |

0.27 kg / 0.59 pounds

266.0 g / 2.6 N

|

| 10 mm | Stal (~0.2) |

0.05 kg / 0.11 pounds

48.0 g / 0.5 N

|

| 15 mm | Stal (~0.2) |

0.01 kg / 0.03 pounds

12.0 g / 0.1 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.01 pounds

4.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MPL 25x10x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.25 kg / 4.95 pounds

2247.0 g / 22.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.50 kg / 3.30 pounds

1498.0 g / 14.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.75 kg / 1.65 pounds

749.0 g / 7.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.75 kg / 8.26 pounds

3745.0 g / 36.7 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MPL 25x10x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.75 kg / 1.65 pounds

749.0 g / 7.3 N

|

| 1 mm |

|

1.87 kg / 4.13 pounds

1872.5 g / 18.4 N

|

| 2 mm |

|

3.75 kg / 8.26 pounds

3745.0 g / 36.7 N

|

| 3 mm |

|

5.62 kg / 12.38 pounds

5617.5 g / 55.1 N

|

| 5 mm |

|

7.49 kg / 16.51 pounds

7490.0 g / 73.5 N

|

| 10 mm |

|

7.49 kg / 16.51 pounds

7490.0 g / 73.5 N

|

| 11 mm |

|

7.49 kg / 16.51 pounds

7490.0 g / 73.5 N

|

| 12 mm |

|

7.49 kg / 16.51 pounds

7490.0 g / 73.5 N

|

Table 5: Working in heat (stability) - thermal limit

MPL 25x10x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

7.49 kg / 16.51 pounds

7490.0 g / 73.5 N

|

OK |

| 40 °C | -2.2% |

7.33 kg / 16.15 pounds

7325.2 g / 71.9 N

|

OK |

| 60 °C | -4.4% |

7.16 kg / 15.79 pounds

7160.4 g / 70.2 N

|

|

| 80 °C | -6.6% |

7.00 kg / 15.42 pounds

6995.7 g / 68.6 N

|

|

| 100 °C | -28.8% |

5.33 kg / 11.76 pounds

5332.9 g / 52.3 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MPL 25x10x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

17.49 kg / 38.57 pounds

4 785 Gs

|

2.62 kg / 5.78 pounds

2624 g / 25.7 N

|

N/A |

| 1 mm |

15.37 kg / 33.89 pounds

6 316 Gs

|

2.31 kg / 5.08 pounds

2306 g / 22.6 N

|

13.84 kg / 30.50 pounds

~0 Gs

|

| 2 mm |

13.25 kg / 29.21 pounds

5 864 Gs

|

1.99 kg / 4.38 pounds

1987 g / 19.5 N

|

11.92 kg / 26.29 pounds

~0 Gs

|

| 3 mm |

11.26 kg / 24.83 pounds

5 407 Gs

|

1.69 kg / 3.72 pounds

1690 g / 16.6 N

|

10.14 kg / 22.35 pounds

~0 Gs

|

| 5 mm |

7.91 kg / 17.44 pounds

4 531 Gs

|

1.19 kg / 2.62 pounds

1187 g / 11.6 N

|

7.12 kg / 15.70 pounds

~0 Gs

|

| 10 mm |

3.10 kg / 6.84 pounds

2 838 Gs

|

0.47 kg / 1.03 pounds

465 g / 4.6 N

|

2.79 kg / 6.16 pounds

~0 Gs

|

| 20 mm |

0.56 kg / 1.24 pounds

1 207 Gs

|

0.08 kg / 0.19 pounds

84 g / 0.8 N

|

0.51 kg / 1.11 pounds

~0 Gs

|

| 50 mm |

0.01 kg / 0.03 pounds

194 Gs

|

0.00 kg / 0.00 pounds

2 g / 0.0 N

|

0.01 kg / 0.03 pounds

~0 Gs

|

| 60 mm |

0.01 kg / 0.01 pounds

124 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.01 pounds

84 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

59 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

43 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

32 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Protective zones (electronics) - warnings

MPL 25x10x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 8.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 6.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 5.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 4.0 cm |

| Remote | 50 Gs (5.0 mT) | 3.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Collisions (cracking risk) - warning

MPL 25x10x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

29.06 km/h

(8.07 m/s)

|

0.31 J | |

| 30 mm |

49.37 km/h

(13.71 m/s)

|

0.88 J | |

| 50 mm |

63.73 km/h

(17.70 m/s)

|

1.47 J | |

| 100 mm |

90.12 km/h

(25.03 m/s)

|

2.94 J |

Table 9: Coating parameters (durability)

MPL 25x10x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 25x10x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 8 245 Mx | 82.5 µWb |

| Pc Coefficient | 0.38 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MPL 25x10x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 7.49 kg | Standard |

| Water (riverbed) |

8.58 kg

(+1.09 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Warning: On a vertical surface, the magnet retains only ~20% of its max power.

2. Steel thickness impact

*Thin steel (e.g. 0.5mm PC case) severely weakens the holding force.

3. Thermal stability

*For standard magnets, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.38

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Pros and cons of neodymium magnets.

Strengths

- They retain full power for nearly 10 years – the loss is just ~1% (based on simulations),

- Magnets very well defend themselves against demagnetization caused by ambient magnetic noise,

- A magnet with a smooth nickel surface is more attractive,

- The surface of neodymium magnets generates a powerful magnetic field – this is a distinguishing feature,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Possibility of precise creating and modifying to defined applications,

- Universal use in future technologies – they are used in hard drives, electromotive mechanisms, advanced medical instruments, as well as multitasking production systems.

- Thanks to efficiency per cm³, small magnets offer high operating force, occupying minimum space,

Limitations

- At strong impacts they can crack, therefore we advise placing them in strong housings. A metal housing provides additional protection against damage and increases the magnet's durability.

- Neodymium magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- They rust in a humid environment - during use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- We recommend cover - magnetic mount, due to difficulties in creating nuts inside the magnet and complex forms.

- Health risk resulting from small fragments of magnets pose a threat, if swallowed, which gains importance in the aspect of protecting the youngest. Additionally, small elements of these devices can disrupt the diagnostic process medical after entering the body.

- With mass production the cost of neodymium magnets is economically unviable,

Holding force characteristics

Maximum lifting force for a neodymium magnet – what it depends on?

- with the application of a yoke made of low-carbon steel, guaranteeing full magnetic saturation

- possessing a massiveness of min. 10 mm to ensure full flux closure

- with a plane free of scratches

- with zero gap (no impurities)

- for force acting at a right angle (pull-off, not shear)

- at conditions approx. 20°C

Key elements affecting lifting force

- Space between surfaces – even a fraction of a millimeter of separation (caused e.g. by veneer or dirt) drastically reduces the magnet efficiency, often by half at just 0.5 mm.

- Pull-off angle – note that the magnet holds strongest perpendicularly. Under shear forces, the capacity drops drastically, often to levels of 20-30% of the nominal value.

- Steel thickness – too thin plate does not accept the full field, causing part of the flux to be escaped into the air.

- Metal type – not every steel reacts the same. High carbon content weaken the interaction with the magnet.

- Plate texture – smooth surfaces ensure maximum contact, which increases force. Uneven metal weaken the grip.

- Temperature – heating the magnet results in weakening of force. Check the maximum operating temperature for a given model.

Lifting capacity was determined by applying a polished steel plate of suitable thickness (min. 20 mm), under perpendicular detachment force, whereas under parallel forces the load capacity is reduced by as much as fivefold. Additionally, even a slight gap between the magnet’s surface and the plate decreases the lifting capacity.

Safe handling of NdFeB magnets

Thermal limits

Control the heat. Exposing the magnet to high heat will destroy its properties and strength.

Serious injuries

Pinching hazard: The attraction force is so immense that it can cause hematomas, pinching, and broken bones. Protective gloves are recommended.

Fire risk

Drilling and cutting of NdFeB material carries a risk of fire hazard. Magnetic powder reacts violently with oxygen and is hard to extinguish.

Nickel coating and allergies

Nickel alert: The nickel-copper-nickel coating consists of nickel. If an allergic reaction occurs, cease handling magnets and use protective gear.

Phone sensors

Navigation devices and mobile phones are extremely susceptible to magnetic fields. Direct contact with a strong magnet can decalibrate the internal compass in your phone.

Warning for heart patients

Life threat: Neodymium magnets can turn off heart devices and defibrillators. Stay away if you have electronic implants.

Handling rules

Before use, check safety instructions. Uncontrolled attraction can break the magnet or injure your hand. Be predictive.

Risk of cracking

Watch out for shards. Magnets can fracture upon uncontrolled impact, ejecting sharp fragments into the air. Wear goggles.

Safe distance

Do not bring magnets close to a purse, computer, or TV. The magnetism can permanently damage these devices and erase data from cards.

Product not for children

Only for adults. Small elements pose a choking risk, causing serious injuries. Store away from children and animals.

![BM 700x180x75 [8xM10] - magnetic beam BM 700x180x75 [8xM10] - magnetic beam](https://cdn3.dhit.pl/graphics/blank.jpg)

![SM 25x300 [2xM8] / N42 - magnetic separator SM 25x300 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x300-2xm8-kud.jpg)